Documente Academic

Documente Profesional

Documente Cultură

Datasheet

Încărcat de

loisaomDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Datasheet

Încărcat de

loisaomDrepturi de autor:

Formate disponibile

1/9

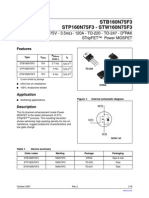

STPS20L45CF/CW/CT/CFP/CG

July 2003 - Ed: 3C

LOW DROP POWER SCHOTTKY RECTIFIER

Dual center tap Schottky rectifiers designed for

high frequency switched mode power supplies and

DC to DC converters.

These devices are intended for use in low voltage,

high frequency inverters, free-wheeling and

polarity protection applications.

DESCRIPTION

I LOW FORWARD VOLTAGE DROP MEANING

VERY SMALL CONDUCTION LOSSES

I LOW SWITCHING LOSSES ALLOWING HIGH

FREQUENCY OPERATION

I INSULATED PACKAGE: ISOWATT220AB,

TO-220FPAB

Insulating voltage = 2000VDC

Capacitance = 12pF

I AVALANCHE CAPABILITY SPECIFIED

FEATURES AND BENEFITS

Symbol Parameter Value Unit

V

RRM

Repetitive peak reverse voltage

45 V

I

F(RMS)

RMS forward current

30 A

I

F(AV)

Average forward

current

TO-220AB / D

2

PAK

TO-247

Tc = 135C

= 0.5

Per diode

Per device

10

20

A

ISOWATT220AB

TO-220FPAB

Tc = 115C

= 0.5

Per diode

Per device

10

20

A

I

FSM

Surge non repetitive forward current tp = 10 ms Sinusoidal

180 A

I

RRM

Peak repetitive reverse current tp=2 s square F=1kHz

1 A

I

RSM

Non repetitive peak reverse current tp = 100 s square

2 A

P

ARM

Repetitive peak avalanche power tp = 1s Tj = 25C

4000 W

T

stg

Storage temperature range

- 65 to + 150 C

Tj

Maximum operating junction temperature *

150 C

dV/dt

Critical rate of rise of reverse voltage

10000 V/s

ABSOLUTE RATINGS (limiting values, per diode)

I

F(AV)

2 x 10 A

V

RRM

45 V

Tj (max) 150C

V

F

(max) 0.5 V

MAJOR PRODUCTS CHARACTERISTICS

A1

K

A2

A1

K

A2

ISOWATT220AB

STPS20L45CF

TO-247

STPS20L45CW

K

A1

A2

TO-220AB

STPS20L45CT

* :

dPtot

dTj Rth j a

<

1

( )

thermal runaway condition for a diode on its own heatsink

A1

K

A2

A1

A2

K

TO-220FPAB

STPS20L45CFP

K

A1

A2

D

2

PAK

STPS20L45CG

STPS20L45CF/CW/CT/CFP/CG

2/9

Symbol Parameter Tests Conditions Min. Typ. Max. Unit

I

R

*

Reverse leakage

current

Tj = 25C V

R

= V

RRM

0.2 mA

Tj = 125C

65 130 mA

V

F

*

Forward voltage drop Tj = 25C I

F

= 10 A

0.55 V

Tj = 125C I

F

= 10 A

0.44 0.5

Tj = 25C I

F

= 20 A

0.73

Tj = 125C I

F

= 20 A

0.62 0.72

Pulse test : * tp = 380 s, < 2%

To evaluate the conduction losses use the following equation :

P = 0.28 x I

F(AV)

+ 0.022 I

F

2

(RMS)

STATIC ELECTRICAL CHARACTERISTICS (per diode)

Symbol Parameter Value Unit

R

th(j-c)

Junction to case ISOWATT220AB

TO-220FPAB

Per diode

Total

Coupling

4.5

3.5

2.5

C/W

R

th(j-c)

Junction to case TO-247

Per diode

Total

Coupling

2.2

1.20

0.3

C/W

R

th(j-c)

Junction to case TO-220AB

D

2

PAK

Per diode

Total

Coupling

2.2

1.3

0.3

C/W

THERMAL RESISTANCES

0 2 4 6 8 10 12 14

0

1

2

3

4

5

6

7

8

IF(av) (A)

PF(av)(W)

= 0.2

= 0.5

= 1

= 0.05

= 0.1

T

=tp/T tp

Fig. 1: Average forward power dissipation versus

average forward current (per diode).

0 25 50 75 100 125 150

0

1

2

3

4

5

6

7

8

9

10

11

12

IF(av)(A)

Rth(j-a)=15C/W

Rth(j-a)=Rth(j-c)

TO-220AB/TO-247

ISOWATT220AB

T

=tp/T tp

Tamb(C)

Fig. 2: Average forward current versus ambient

temperature( = 0.5, per diode).

When the diodes 1 and 2 are used simultaneously :

Tj(diode 1) = P(diode1) x R

th(j-c)

(Per diode) + P(diode 2) x R

th(c)

STPS20L45CF/CW/CT/CFP/CG

3/9

1E-3 1E-2 1E-1 1E+0

0.0

0.2

0.4

0.6

0.8

1.0

tp(s)

Zth(j-c)/Rth(j-c)

= 0.1

= 0.2

= 0.5

Single pulse

T

=tp/T tp

Fig. 6-1: Relative variation of thermal impedance

junction to case versus pulse duration (TO-220AB,

TO-247, D

2

PAK).

1E-3 1E-2 1E-1 1E+0 1E+1

0.0

0.2

0.4

0.6

0.8

1.0

tp(s)

Zth(j-c)/Rth(j-c)

T

=tp/T tp

= 0.1

= 0.2

= 0.5

Single pulse

Fig. 6-2: Relative variation of thermal impedance

junction to case versus pulse duration

(ISOWATT220AB, TO-220FPAB).

1E-3 1E-2 1E-1 1E+0

0

10

20

30

40

50

60

70

80

90

100

IM(A)

Tc=25C

Tc=100C

Tc=50C

IM

t

=0.5

t(s)

Fig. 5-2: Non repetitive surge peak forward

current versus overload duration (maximum

values, per diode, ISOWATT220AB,

TO-220FPAB).

1E-3 1E-2 1E-1 1E+0

0

20

40

60

80

100

120

140

IM(A)

Tc=25C

Tc=125C

Tc=75C

t(s)

IM

t

=0.5

Fig. 5-1: Non repetitive surge peak forward

current versus overload duration (maximum

values, per diode, TO-220AB, TO-247,

D

2

PAK).

0

0.2

0.4

0.6

0.8

1

1.2

0 25 50 75 100 125 150

T (C) j

P (t )

P (25C)

ARM p

ARM

Fig. 4: Normalized avalanche power derating

versus junction temperature.

0.001

0.01

0.1 0.01 1

0.1

10 100 1000

1

t (s) p

P (t )

P (1s)

ARM p

ARM

Fig. 3: Normalized avalanche power derating

versus pulse duration.

STPS20L45CF/CW/CT/CFP/CG

4/9

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

0.1

1.0

10.0

100.0

IFM(A)

Tj=75C

Tj=25C

Tj=125C

Typical values

Tj=150C

VFM(V)

Fig. 9: Forward voltage drop versus forward

current (maximum values) (per diode).

0 4 8 12 16 20 24 28 32 36 40

0

10

20

30

40

50

60

70

80

S(Cu) (cm)

Rth(j-a) (C/W)

Fig. 10: Thermal resistance junction to ambient

versus copper surface under tab (Epoxy printed cir-

cuit board FR4, copper thickness: 35m) (D

2

PAK).

0 5 10 15 20 25 30 35 40 45

1E-3

1E-2

1E-1

1E+0

1E+1

1E+2

2E+2

VR(V)

IR(mA)

Tj=75C

Tj=25C

Tj=125C

Tj=150C

Fig. 7: Reverse leakage current versus reverse

voltage applied (typical values, per diode).

1 2 5 10 20 50

100

1000

2000

VR(V)

C(pF)

F=1MHz

Tj=25C

Fig. 8: Junction capacitance versus reverse

voltage applied (typical values, per diode).

STPS20L40CF/CW/CT

5/9

I Cooling method : C

I Recommended torque value : 0.55 m.N

I Maximum torque value : 0.70 m.N

PACKAGE MECHANICAL DATA

ISOWATT220AB

REF.

DIMENSIONS

Millimeters Inches

Min. Max. Min. Max.

A 4.40 4.60 0.173 0.181

B 2.50 2.70 0.098 0.106

D 2.50 2.75 0.098 0.108

E 0.40 0.70 0.016 0.028

F 0.75 1.00 0.030 0.039

F1 1.15 1.70 0.045 0.067

F2 1.15 1.70 0.045 0.067

G 4.95 5.20 0.195 0.205

G1 2.40 2.70 0.094 0.106

H 10.00 10.40 0.394 0.409

L2 16.00 typ. 0.630 typ.

L3 28.60 30.60 1.125 1.205

L4 9.80 10.60 0.386 0.417

L6 15.90 16.40 0.626 0.646

L7 9.00 9.30 0.354 0.366

Diam 3.00 3.20 0.118 0.126

STPS20L45CF/CW/CT/CFP/CG

6/9

PACKAGE MECHANICAL DATA

TO-220FPAB

H

L3

L2

L4

L6

G

G1

F

F1

L5

D

E

L7

A

B

Dia

F2

REF. DIMENSIONS

Millimeters Inches

Min. Max. Min. Max.

A 4.4 4.6 0.173 0.181

B 2.5 2.7 0.098 0.106

D 2.5 2.75 0.098 0.108

E 0.45 0.70 0.018 0.027

F 0.75 1 0.030 0.039

F1 1.15 1.70 0.045 0.067

F2 1.15 1.70 0.045 0.067

G 4.95 5.20 0.195 0.205

G1 2.4 2.7 0.094 0.106

H 10 10.4 0.393 0.409

L2 16 Typ. 0.63 Typ.

L3 28.6 30.6 1.126 1.205

L4 9.8 10.6 0.386 0.417

L5 2.9 3.6 0.114 0.142

L6 15.9 16.4 0.626 0.646

L7 9.00 9.30 0.354 0.366

Dia. 3.00 3.20 0.118 0.126

I Cooling method : C

I Recommended torque value : 0.55 m.N

I Maximum torque value : 0.70 m.N

7/9

STPS20L45CF/CW/CT/CFP/CG

I Cooling method : C

I Recommended torque value : 0.55 m.N

I Maximum torque value : 0.70 m.N

PACKAGE MECHANICAL DATA

TO-220AB

A

C

D

L7

Dia

L5

L6

L9

L4

F

H2

G

G1

L2

F2

F1

E

M

REF.

DIMENSIONS

Millimeters Inches

Min. Max. Min. Max.

A 4.40 4.60 0.173 0.181

C 1.23 1.32 0.048 0.051

D 2.40 2.72 0.094 0.107

E 0.49 0.70 0.019 0.027

F 0.61 0.88 0.024 0.034

F1 1.14 1.70 0.044 0.066

F2 1.14 1.70 0.044 0.066

G 4.95 5.15 0.194 0.202

G1 2.40 2.70 0.094 0.106

H2 10 10.40 0.393 0.409

L2 16.4 typ. 0.645 typ.

L4 13 14 0.511 0.551

L5 2.65 2.95 0.104 0.116

L6 15.25 15.75 0.600 0.620

L7 6.20 6.60 0.244 0.259

L9 3.50 3.93 0.137 0.154

M 2.6 typ. 0.102 typ.

Diam. 3.75 3.85 0.147 0.151

STPS20L45CF/CW/CT/CFP/CG

8/9

PACKAGE MECHANICAL DATA

D

2

PAK

A

C2

D

R

A2

M

V2

C

A1

G

L

L3

L2

B

B2

E

*

* FLAT ZONE NO LESSTHAN 2mm

REF.

DIMENSIONS

Millimeters Inches

Min. Max. Min. Max.

A 4.40 4.60 0.173 0.181

A1 2.49 2.69 0.098 0.106

A2 0.03 0.23 0.001 0.009

B 0.70 0.93 0.027 0.037

B2 1.14 1.70 0.045 0.067

C 0.45 0.60 0.017 0.024

C2 1.23 1.36 0.048 0.054

D 8.95 9.35 0.352 0.368

E 10.00 10.40 0.393 0.409

G 4.88 5.28 0.192 0.208

L 15.00 15.85 0.590 0.624

L2 1.27 1.40 0.050 0.055

L3 1.40 1.75 0.055 0.069

M 2.40 3.20 0.094 0.126

R 0.40 typ. 0.016 typ.

V2 0 8 0 8

8.90

3.70

1.30

5.08

16.90

10.30

FOOTPRINT

9/9

STPS20L45CF/CW/CT/CFP/CG

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of

use of such information nor for any infringement of patents or other rights of third parties which may result fromits use. No license is granted by

implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject to

change without notice. This publication supersedes and replaces all information previously supplied.

STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express written

approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2003 STMicroelectronics - Printed in Italy - All rights reserved.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany

Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco - Singapore

Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

I Cooling method : C

I Recommended torque value : 0.8m.N

I Maximum torque value : 1.0m.N

PACKAGE MECHANICAL DATA

TO-247

F2

F1

V2

L4 L2

L1

L3

D

L

L5

M E

H

V

V

A

Dia.

F3

F4

G

= =

F(x3)

REF.

DIMENSIONS

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 4.85 5.15 0.191 0.203

D 2.20 2.60 0.086 0.102

E 0.40 0.80 0.015 0.031

F 1.00 1.40 0.039 0.055

F1 3.00 0.118

F2 2.00 0.078

F3 2.00 2.40 0.078 0.094

F4 3.00 3.40 0.118 0.133

G 10.90 0.429

H 15.45 15.75 0.608 0.620

L 19.85 20.15 0.781 0.793

L1 3.70 4.30 0.145 0.169

L2 18.50 0.728

L3 14.20 14.80 0.559 0.582

L4 34.60 1.362

L5 5.50 0.216

M 2.00 3.00 0.078 0.118

V 5 5

V2 60 60

Dia. 3.55 3.65 0.139 0.143

Ordering type Marking Package Weight Base qty Delivery mode

STPS20L45CF STPS20L45CF ISOWATT220AB 2.1g 50 Tube

STPS20L45CFP STPS20L45CFP TO-220FPAB 2g 50 Tube

STPS20L45CT STPS20L45CT TO-220AB 2g 50 Tube

STPS20L45CW STPS20L45CW TO-247 4.4g 30 Tube

STPS20L45CG STPS20L45CG D

2

PAK 1.48g 50 Tube

STPS20L45CG-TR STPS20L45CG D

2

PAK 1.48g 1000 Tape & Reel

I Epoxy meets UL94,V0

S-ar putea să vă placă și

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Stps2045 CT CF CGDocument7 paginiStps2045 CT CF CGCah NgaloefÎncă nu există evaluări

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1De la EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Evaluare: 4.5 din 5 stele4.5/5 (3)

- STTA1206D/DI/G: Turboswitch Ultra-Fast High Voltage DiodeDocument9 paginiSTTA1206D/DI/G: Turboswitch Ultra-Fast High Voltage DiodeMarcos AndréÎncă nu există evaluări

- Stps 20 H 100 CTDocument8 paginiStps 20 H 100 CTPablo Cruz ArchundiaÎncă nu există evaluări

- stps30l45cw 282527Document8 paginistps30l45cw 282527Zuprecqk Trance Martinez VidalÎncă nu există evaluări

- STPS3045CW PDFDocument9 paginiSTPS3045CW PDFalbertoavila77Încă nu există evaluări

- STTH40P03SDocument8 paginiSTTH40P03SAlfredo Valencia RodriguezÎncă nu există evaluări

- STPS20H100CT/CF/CG/CR/CFP: High Voltage Power Schottky RectifierDocument8 paginiSTPS20H100CT/CF/CG/CR/CFP: High Voltage Power Schottky RectifierAdeltop4everÎncă nu există evaluări

- Datasheet PDFDocument11 paginiDatasheet PDFjackass_tÎncă nu există evaluări

- Stb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetDocument16 paginiStb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetmoabdolyÎncă nu există evaluări

- 16CTQ... 16CTQ... S 16CTQ... - 1: Schottky Rectifier 16 AmpDocument9 pagini16CTQ... 16CTQ... S 16CTQ... - 1: Schottky Rectifier 16 AmpBruno NascimentoÎncă nu există evaluări

- SCRDocument10 paginiSCRHugo LopezÎncă nu există evaluări

- 4 A Triacs PDFDocument17 pagini4 A Triacs PDFcarlos16702014Încă nu există evaluări

- Go P20NM60FP PDFDocument15 paginiGo P20NM60FP PDFHenry HenriquezÎncă nu există evaluări

- Tynx10 Series: 10A SCRDocument6 paginiTynx10 Series: 10A SCRAAurelianÎncă nu există evaluări

- U1620RGDocument5 paginiU1620RGLeonardo OuverneyÎncă nu există evaluări

- BTA40 and BTA/BTB41 Series: 40A TriacDocument6 paginiBTA40 and BTA/BTB41 Series: 40A TriacAank Anggun PurnomoÎncă nu există evaluări

- Tda 7560Document10 paginiTda 7560Александр ШабановÎncă nu există evaluări

- STTH12003TV: High Frequency Secondary RectifierDocument5 paginiSTTH12003TV: High Frequency Secondary RectifierBruno NascimentoÎncă nu există evaluări

- Stp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii MosfetDocument11 paginiStp8Nc50 - Stp8Nc50Fp Stb8Nc50-1: N-Channel 500V - 0.7 - 8A To-220/To-220Fp/I2Pak Powermesh Ii Mosfetmiguel angel jaramilloÎncă nu există evaluări

- Tda7266sa PDFDocument11 paginiTda7266sa PDFerju10Încă nu există evaluări

- DMV1500SDDocument8 paginiDMV1500SDJohnÎncă nu există evaluări

- BTA41 600B Triac1Document7 paginiBTA41 600B Triac1Hùng NguyenÎncă nu există evaluări

- Bta41 600BRGDocument8 paginiBta41 600BRGjbrolsÎncă nu există evaluări

- MBR2045CT MBRB2045CT MBR2045CT-1: Schottky Rectifier 20 AmpDocument9 paginiMBR2045CT MBRB2045CT MBR2045CT-1: Schottky Rectifier 20 AmpMiloud ChouguiÎncă nu există evaluări

- Byv52 200Document7 paginiByv52 200Fady HachemÎncă nu există evaluări

- ST 232Document11 paginiST 232Negru P. PlantatieÎncă nu există evaluări

- Stx30N65M5: N-Channel 650 V, 0.130, 21 A, Mdmesh™ V Power Mosfet D Pak, I Pak, To-220Fp, To-220, To-247Document15 paginiStx30N65M5: N-Channel 650 V, 0.130, 21 A, Mdmesh™ V Power Mosfet D Pak, I Pak, To-220Fp, To-220, To-247Oscar PortelaÎncă nu există evaluări

- Data SheetDocument6 paginiData SheetCarlos Andres Cerón PugaÎncă nu există evaluări

- DVM 1500 MDocument9 paginiDVM 1500 MHanif Rathore PrinceÎncă nu există evaluări

- Mosfet p7nc70zfpDocument13 paginiMosfet p7nc70zfptheodoru2014Încă nu există evaluări

- p9nb50 PDFDocument9 paginip9nb50 PDFceftv1Încă nu există evaluări

- STTH6003CWDocument7 paginiSTTH6003CWjesusÎncă nu există evaluări

- 74HC4016Document11 pagini74HC4016jnax101Încă nu există evaluări

- mbrx0540 Schottky Barrier DiodeDocument5 paginimbrx0540 Schottky Barrier DiodeMochammad SofyanÎncă nu există evaluări

- Dsa 284557 PDFDocument6 paginiDsa 284557 PDFrrebollarÎncă nu există evaluări

- Tda 7266Document9 paginiTda 7266Miloud ChouguiÎncă nu există evaluări

- Tda 7266Document9 paginiTda 7266hawarnetÎncă nu există evaluări

- 74HC164Document12 pagini74HC164jnax101Încă nu există evaluări

- Data SheetDocument5 paginiData SheetharanahalliÎncă nu există evaluări

- TDA7269ADocument7 paginiTDA7269ACojocar FlorinÎncă nu există evaluări

- Bu808 DatasheetDocument8 paginiBu808 Datasheetvoris115Încă nu există evaluări

- BTB 24 TriacDocument10 paginiBTB 24 Triacagus2kÎncă nu există evaluări

- Fet 60NF06Document9 paginiFet 60NF06Anh Nguyễn HoàngÎncă nu există evaluări

- W15NB50Document9 paginiW15NB50G Ivan Torres RÎncă nu există evaluări

- P120NF10Document15 paginiP120NF10marpre1983Încă nu există evaluări

- Tyn410 PDFDocument4 paginiTyn410 PDFIvan Ignacio Perez IbarraÎncă nu există evaluări

- Tda 7297Document9 paginiTda 7297Pravin MevadaÎncă nu există evaluări

- MBR 20100Document7 paginiMBR 20100Rafael KoppeÎncă nu există evaluări

- Bta 24800 BDocument9 paginiBta 24800 BIulia CalinÎncă nu există evaluări

- 74HC374Document13 pagini74HC374jnax101Încă nu există evaluări

- Tda 7266Document9 paginiTda 7266huitlamenÎncă nu există evaluări

- 74HC393Document12 pagini74HC393jnax101Încă nu există evaluări

- IC-ON-LINE - CN p75nf75 71035Document16 paginiIC-ON-LINE - CN p75nf75 71035Daniel David PeñaÎncă nu există evaluări

- TDA7267ADocument7 paginiTDA7267AshareatorÎncă nu există evaluări

- 74HC27Document9 pagini74HC27jnax101Încă nu există evaluări

- 74HC74Document11 pagini74HC74jnax101Încă nu există evaluări

- 74HC4024Document11 pagini74HC4024jnax101Încă nu există evaluări

- Service Manual BA-4: Trinitron Color TVDocument74 paginiService Manual BA-4: Trinitron Color TVAlejandroVCMXÎncă nu există evaluări

- Sony HCD-RG290 RG190Document126 paginiSony HCD-RG290 RG190loisaom100% (1)

- Diagrama Sony Wega de CursoDocument4 paginiDiagrama Sony Wega de CursoWellington PrevistoÎncă nu există evaluări

- Antenna RotatorDocument2 paginiAntenna RotatorloisaomÎncă nu există evaluări

- PARTESDocument4 paginiPARTESloisaomÎncă nu există evaluări

- PARTESDocument4 paginiPARTESloisaomÎncă nu există evaluări

- TTS 80524-27 Englisch Operating Instruction+Spare Parts List PDFDocument694 paginiTTS 80524-27 Englisch Operating Instruction+Spare Parts List PDFHemraj Singh Rautela100% (3)

- 3773b - en - SM-POS - Quick Start Commissioning GuideDocument24 pagini3773b - en - SM-POS - Quick Start Commissioning GuideBruno RochaÎncă nu există evaluări

- BUC For Fire ProtectionDocument3 paginiBUC For Fire ProtectionNuwan AsankaÎncă nu există evaluări

- 2004 Element Online Reference Owner's ManualDocument233 pagini2004 Element Online Reference Owner's ManualAnton ShinelevÎncă nu există evaluări

- Instruction Manual: Microprocessor-Based Reference Adjuster RA-70Document55 paginiInstruction Manual: Microprocessor-Based Reference Adjuster RA-70luisÎncă nu există evaluări

- Dio Deluxe 2018Document50 paginiDio Deluxe 2018Seenu StonnerÎncă nu există evaluări

- DataSheet IBF DC-AC INV LV&HV PDFDocument3 paginiDataSheet IBF DC-AC INV LV&HV PDFmicrajacutÎncă nu există evaluări

- Methodstatementhq Com Testing Commissioning Report For Fire Alarm System HTMLDocument1 paginăMethodstatementhq Com Testing Commissioning Report For Fire Alarm System HTMLNESTOR YUMULÎncă nu există evaluări

- 2.display System ColoredDocument24 pagini2.display System ColoredGeetansh SharmaÎncă nu există evaluări

- Sherwood Cot InstructionsDocument12 paginiSherwood Cot Instructionsrealdaross0% (2)

- Metron Fire Pump Controls: Standard CatalogDocument102 paginiMetron Fire Pump Controls: Standard Catalogmohammad AshrafÎncă nu există evaluări

- Ix Dmci BlockdiagramDocument52 paginiIx Dmci BlockdiagramЕвгений АксёновÎncă nu există evaluări

- Power Supply System Guardian Access 3U Instruction ManualDocument54 paginiPower Supply System Guardian Access 3U Instruction ManualMohammad KilaniÎncă nu există evaluări

- Installation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterDocument78 paginiInstallation Instruction & Maintenance Service Manual: Full Automatic Blood Cell CounterevgenyÎncă nu există evaluări

- 03 CAT CB534D Vibratory System Tech InstDocument20 pagini03 CAT CB534D Vibratory System Tech InstMahmmod Al-QawasmehÎncă nu există evaluări

- Lessor Finding 41 - Engine #2 Reverser Inneer Barrel and Outer Barrel Found Oxiddation DepositDocument13 paginiLessor Finding 41 - Engine #2 Reverser Inneer Barrel and Outer Barrel Found Oxiddation DepositSurya Agung S NÎncă nu există evaluări

- Altivar Machine ATV340 - ATV340U55N4Document17 paginiAltivar Machine ATV340 - ATV340U55N4PhaniÎncă nu există evaluări

- Kubota U30-5 04-2013Document184 paginiKubota U30-5 04-2013Anderson Lira100% (1)

- Capacitor Banks For Power Factor Correction by Engr. Ralph A. Pasilan, PEEDocument51 paginiCapacitor Banks For Power Factor Correction by Engr. Ralph A. Pasilan, PEEnoel beloyÎncă nu există evaluări

- Latitude 14 5490 Laptop Setup Guide3 en UsDocument2 paginiLatitude 14 5490 Laptop Setup Guide3 en UsdrmwndrrÎncă nu există evaluări

- Solenoid ValveDocument76 paginiSolenoid ValveazlanÎncă nu există evaluări

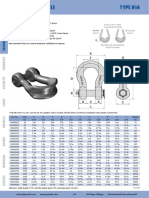

- Type H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestDocument2 paginiType H14 Wide Body Shackle: Non-Standard Sizes or Custom Products Available On RequestKonstantinos SynodinosÎncă nu există evaluări

- Lamborghini URUSPERFORMANTE AIW081 23.05.23Document18 paginiLamborghini URUSPERFORMANTE AIW081 23.05.23Rafael FreitasÎncă nu există evaluări

- ND20Document2 paginiND20Spardha GuptaÎncă nu există evaluări

- Project-Study V2.3 FinalDocument57 paginiProject-Study V2.3 FinalLopirts NiganiÎncă nu există evaluări

- Project Description: 1.1. Arduino CodeDocument6 paginiProject Description: 1.1. Arduino CodesandraÎncă nu există evaluări

- Servisni Manual Gree en Fairy 12 BGDocument92 paginiServisni Manual Gree en Fairy 12 BGVictor Marcell Oliveira MesquitaÎncă nu există evaluări

- Indian Companies Email Database List Free SampleDocument13 paginiIndian Companies Email Database List Free Sampleali khan SaifiÎncă nu există evaluări

- Parts of Mother BoardDocument17 paginiParts of Mother BoardHans De la CruzÎncă nu există evaluări

- Amazon's Top ASINs 4Q 2017 - AutomotiveDocument58 paginiAmazon's Top ASINs 4Q 2017 - AutomotiveyorchmanÎncă nu există evaluări