Documente Academic

Documente Profesional

Documente Cultură

Powder Metallurgy PDF

Încărcat de

Jubin SuranaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Powder Metallurgy PDF

Încărcat de

Jubin SuranaDrepturi de autor:

Formate disponibile

1

Processing of Powder

Metals

2

Classification of Metal Fabrication

Techniques

3

A fabrication technique involves the

compaction of powdered metal, followed

by a heat treatment to produce a more

dense piece.

Powder metallurgy is especially suitable

for metals

having low ductilities

having high melting temperatures

Powder Metallurgy (P/M)

4

Operations of PP

1. Powder production

(metals, alloys,

metalloids)

2. Blending and

mixing of powders

3. Compaction

4. Sintering

5. Finishing

operations

Powder

production

Compaction

Sintering

5

Process Steps

6

Why PP?

The capability to produce parts to near

net shapes

Properties of components can vary in a

wide range (eg. porosity, electric

conductivity, strength, etc.)

The economics of the overall operation

Alloys with special properties

7

PRECISE CONTROL : properties of end products can

be suited to the demands of applications

CUSTOM-MADE COMPOSITION : widely different

characteristics can be compacted

PHYSICAL PROPERTIES : properties can be altered

easily by this method(e.g. density,porosity)

NEAR NETT SHAPING BECOMES NETT SHAPING :

eliminating the further processes (e.g. machining)

REPRODUCIBILITY : the dies are the most repetitively

accurate

Advantages of powder

metallurgy

8

Materials for PP

Metal powders (Fe, Cu, Ni, Ti, Co, W,

Mo, stb.)

Alloys (HSS, bronze, stainless steels,

etc.)

Non-metallic powders (graphite, metal

carbides, oxides, etc.)

9

Production of metal powders

Mechanical comminution

(pulverization)

Crushing, milling

Atomization (melting and breaking by

gas, air, water jet)

Reduction of metal oxides using gases

Carbonyls (iron-, nickel carbonyl)

reacting with CO

Electrolitic deposition

10

Example: atomization

Melting

Atomization

Filling

11

Shape and size of powders

Shape and size of powders depend on

the metod of production

Particle size range: 0,0011 mm

Shapes (one-, two, three dimensional):

spherical

elongated

irregular

porous

12

Powder Sources

13

Blending metal powders

Screening by screens of various mesh

sizes

Mixing by size and by material to

uniform distribution of components

Lubrication

Objective:

Favourable composition

Better properties

Lower friction at compaction

14

Consolidation

Consolidation = to impart shape or form

Net shape methods

Pressing, die compaction (hot or cold)

Metal injection molding (MIM)

Cold isostatic pressing (CIP)

Bulk shape methods

Hot isostatic pressing (HIP)

Cold isostatic pressing (CIP)

Roll

Extrude

Spray form

15

Compaction

Blended powders are pressed into

shapes in dies

The pressed powder is known as green

compact (rigid, low strength)

Tooling:

Single acting punch

Floating container

Two counteracting punches

16

Compaction Net Shape

17

Compaction

example: floating container

Density distribution is better than that of

using single acting punch

Filling Compaction Eject part

Powder

Punch

Die

Counter punch

Green compact

18

Compaction Net Shape

19

Consolidation MIM

Metal injection molding

20

Consolidation Bulk forming

21

Isostatic pressing

Green compacts are subjected to

hydrostatic pressure in order to

achieve more uniform compaction

Two variants:

Cold isostatic pressing (CIP)

Hot isostatic pressing (HIP)

The metal powder is placed in a flexible

container (rubber or sheet metal), then

pressurised by hydrostatic fluid or gas

22

The effect of compaction on the

green compact (1)

Size-density, pressure-density functions:

- Optimal size distribution of powder

increases density (amount of fine

particles)

- The higher the compaction pressure,

the higher will be the density

=> high density increases the

strength and elastic modulus

23

The effect of compaction on the

green compact (2)

Pressure

Density

Density of

base metal

Density

of green

compact

Properties of green c.

Density

Strength

Conduc-

tivity

Elongation

24

Sintering (principle)

Metallurgical bonding of powder particles

Solid state diffusion

Liquid phase

Thermal activated event

Atomic transport

Particle rearrangement

Particle growth

Results

Densification, yield useful physical

properties (UTS, YS, ductility, and fatigue

strength)

25

Sintering (process)

Compressed powder is

heated in controlled

atmosphere

Variables:

temperature,

atmosphere and time

Result:

increasing strength

and thoughness,

lowering porosity.

26

Sintering process parameters

Time

Density

Strength

Ductility

Fully

sintered

Particles

bonded,

pore size

reduced

Necks

formed

Green

com-

pact

27

Sintering (microstructure)

28

Sintering (infiltration)

29

Sintering:

process variables

Temperature:

Metallic powders: T=0,70,9 T

melt

Sintering time: 0,58 hours

Atmosphere:

vacuum, inert or reducing gas

Processes: diffusion, microstructural

changes, solid-state bonding of

particles, pore size reduction

30

Sintering temperature and time

480 2350 Tungsten

120 2050 Molybdenium

3060 11001290 Stainless steel

845 10001150 Iron

1045 760900 Copper, brass

Time

(min)

Temperature

(

o

C)

MATERIAL

31

Finishing operations

Coining and sizing: improve

dimensional accuracy, strength and

surface finish

Cold forging, upsetting: modify shape,

increase strength

Impregnating with fluid: bearings and

bushes

Infiltration: molten metal infiltrates the

pores

32

Application: High Speed Steels (1)

Hot Isostatic Pressing

a.) b.)

Carbide distribution of

HSS

a.) powder metallurgy

b.) conventional

Melting

Isostatic

compression

33

Application: High Speed Steels (2)

Process:

Welding

Hot isostatic

compaction

Rolling

Forging

Product:

Bars, forged

parts

34

Application: cutting tools

W- and Ti-carbide

plates for high-

speed cutting

35

Example (1)

36

Example (2)

37

Example (3)

38

Example: gears

By cutting

Forging

Turning

Milling of teeth

Material yield: 31%

By powder metallurgy

Sintered part

Finishing operation

Material yield : 86%

39

Applications

Competitive with casting, forging,

machining

Excellent material yield

Limitations in shapes

No sharp changes in contour, no sharp

radius

Avoid thin sections, high length-to-

diameter ratios, reentry corners

40

Example: connecting rod

Manufacturing methods:

Forging (low alloyed steel)

Casting (spheroidal graphite cast iron)

Powder metallurgy (low alloyed iron

powder)

Comparison:

Material cost

Manufacturing cost

Mechanical properties

41

Connecting rod: powder

metallurgy

Atomized iron powder

Blending: graphite + lubricant

Compaction: volume ratio 2,5:1;

density ratio 80%

Sintering: 1120

o

C; 30 min; reducing

atmosphere, porosity 35%

First manufacturers:

Porsche 928 (V8 engine) 1976

Toyota Camry (4 cyl. 1,9 l engine) 1981

42

Comparison:

3 production methods

Good

5

Medium

3

Good

5

Strength

Good

5

Medium

3

Week

1

Cost of secondary

operations

Week

1

Good

5

Medium

3

Cost of primary

process

Medium

3

Good

5

Good

5

Material cost

Powder

process

Casting Forging

43

Summary

Production steps of powder products:

powder production, blending,

compacting, sintering, finishing

Advantages:

favourable structure, near net shape,

materials of unique properties

Wide range of applications

S-ar putea să vă placă și

- Welding For Design EngineersDocument518 paginiWelding For Design EngineersHumberto Magno FukeÎncă nu există evaluări

- CH 7-Methods of CastingDocument44 paginiCH 7-Methods of CastingGosaye DesalegnÎncă nu există evaluări

- Astm A514 1977Document6 paginiAstm A514 1977Elumalai Srinivasan100% (1)

- Powder MetallurgyDocument24 paginiPowder MetallurgyMilan PanchalÎncă nu există evaluări

- QC of SuppositoriesDocument36 paginiQC of Suppositoriesroma imtiazÎncă nu există evaluări

- Powder MetallurgyDocument33 paginiPowder MetallurgyMohanakumara K CÎncă nu există evaluări

- Equipment Design and Drawing: Project ReportDocument40 paginiEquipment Design and Drawing: Project Reportsurajagtap01Încă nu există evaluări

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDe la EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonÎncă nu există evaluări

- The Essentials of Material Science and Technology for EngineersDe la EverandThe Essentials of Material Science and Technology for EngineersEvaluare: 5 din 5 stele5/5 (1)

- Powder MetallurgyDocument79 paginiPowder MetallurgyTrevor Menezes100% (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDe la EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonEvaluare: 4 din 5 stele4/5 (1)

- Feedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationDe la EverandFeedstock Technology for Reactive Metal Injection Molding: Process, Design, and ApplicationÎncă nu există evaluări

- Evaluation and Analysis of Soil Stabilization With Some Non Conventional Additives IJERTV9IS070265Document8 paginiEvaluation and Analysis of Soil Stabilization With Some Non Conventional Additives IJERTV9IS070265slv buildersÎncă nu există evaluări

- VRM Gas FlowDocument16 paginiVRM Gas FlowIrfan AhmedÎncă nu există evaluări

- AME - M1 Ktunotes - inDocument71 paginiAME - M1 Ktunotes - inMadhav P SachithÎncă nu există evaluări

- Powder MetallurgyDocument9 paginiPowder MetallurgyYashvir SinghÎncă nu există evaluări

- MT Test Procedure According To AsmeDocument22 paginiMT Test Procedure According To AsmemohamedÎncă nu există evaluări

- Types of Chemical ReactionsDocument35 paginiTypes of Chemical ReactionsJemina R. B. EspedillonÎncă nu există evaluări

- Powder Metallurgy Full Notes SwathiDocument101 paginiPowder Metallurgy Full Notes SwathiSwathiÎncă nu există evaluări

- Processing of Powder Metals, Ceramics, Glass & SuperconductorsDocument27 paginiProcessing of Powder Metals, Ceramics, Glass & SuperconductorsMahesh CnÎncă nu există evaluări

- Powder MetallurgyDocument44 paginiPowder MetallurgyjrvinodÎncă nu există evaluări

- Powder MetallurgyDocument64 paginiPowder Metallurgybitish commectÎncă nu există evaluări

- Powder MetallurgyDocument21 paginiPowder MetallurgyHamed MeghÎncă nu există evaluări

- Particulate Processing of Metals and CeramicsDocument98 paginiParticulate Processing of Metals and CeramicsDamy Manesi0% (2)

- Powder MetallurgyDocument79 paginiPowder MetallurgyhavalÎncă nu există evaluări

- Powder Metallurgy - ReportDocument47 paginiPowder Metallurgy - ReportG. Dancer GhÎncă nu există evaluări

- Powder Composite Related To Powder Metallurgy: Ordinance Factory Institute of LearningDocument72 paginiPowder Composite Related To Powder Metallurgy: Ordinance Factory Institute of LearningriyamondalÎncă nu există evaluări

- Twenty OneDocument39 paginiTwenty OneMurugan KvÎncă nu există evaluări

- Powder MetallurgyDocument7 paginiPowder Metallurgykawsar_002100% (2)

- Foundry 1Document17 paginiFoundry 1Raghav MohtaÎncă nu există evaluări

- Powder Metallurgy: Ms C MawareDocument41 paginiPowder Metallurgy: Ms C Mawarechris mushunjeÎncă nu există evaluări

- Powder MetallurgyDocument43 paginiPowder MetallurgythirumalaikumaranÎncă nu există evaluări

- Powder 1Document84 paginiPowder 1Nyanda MadiliÎncă nu există evaluări

- MME 3518-Powder Metallurgy-1-2Document80 paginiMME 3518-Powder Metallurgy-1-2Mohammed GhisheerÎncă nu există evaluări

- Chapter 9Document59 paginiChapter 9amonmeizÎncă nu există evaluări

- Powder Metallurgy ProjectDocument54 paginiPowder Metallurgy ProjectDhruv Raj33% (3)

- Powder Matullargy MSDocument36 paginiPowder Matullargy MSvinay12016070Încă nu există evaluări

- Powder Metallurgy PDFDocument85 paginiPowder Metallurgy PDFharsurajÎncă nu există evaluări

- 8 Metal Powder ProcessingDocument25 pagini8 Metal Powder ProcessingLahiru JananjayaÎncă nu există evaluări

- Powder Metallurgy (PM) : Usual PM Production SequenceDocument21 paginiPowder Metallurgy (PM) : Usual PM Production SequencerohanÎncă nu există evaluări

- Materials Processing MM-303 Intro-Metals - Aug 2022Document24 paginiMaterials Processing MM-303 Intro-Metals - Aug 2022CHENCHALA SAI SHARANÎncă nu există evaluări

- Powder MetallurgyDocument27 paginiPowder Metallurgy20BME011 HARSHIT GUPTAÎncă nu există evaluări

- Casting FormingDocument40 paginiCasting FormingA PRATYUSHÎncă nu există evaluări

- Powder Metallurgy ProcessDocument27 paginiPowder Metallurgy ProcessKunal PatidarÎncă nu există evaluări

- Manufacturing TechnologyDocument46 paginiManufacturing TechnologyMuthu BaskaranÎncă nu există evaluări

- Powder MetallurgyDocument6 paginiPowder MetallurgyjayadevakodiÎncă nu există evaluări

- Al-Mno System Powder Production Analysis of Powder 1. Sieve Analysis 2. Tg-Dta AnalysisDocument15 paginiAl-Mno System Powder Production Analysis of Powder 1. Sieve Analysis 2. Tg-Dta Analysisraghavendrajoshi87Încă nu există evaluări

- ميحرلا نمحرلا الله مسب Manufacturing Techniques 0703314: Powder MetallurgyDocument33 paginiميحرلا نمحرلا الله مسب Manufacturing Techniques 0703314: Powder MetallurgyAbdullahÎncă nu există evaluări

- Unit V Powder Metallurgy and Plastic MoldingDocument48 paginiUnit V Powder Metallurgy and Plastic MoldingGayatri KanwadeÎncă nu există evaluări

- Powder MetallurgyDocument11 paginiPowder MetallurgyChandan PathakÎncă nu există evaluări

- Unit - 1 Metal Casting Processes-NVRDocument287 paginiUnit - 1 Metal Casting Processes-NVRPrashon GÎncă nu există evaluări

- Powder Metallurgy, Processing of Ceramics and CermetsDocument59 paginiPowder Metallurgy, Processing of Ceramics and CermetsDiego Fernando Arana RojasÎncă nu există evaluări

- Mechanical Engineering Manufacturing-Process Powder-Metallurgy NotesDocument14 paginiMechanical Engineering Manufacturing-Process Powder-Metallurgy NotesSiddheswar BiswalÎncă nu există evaluări

- Powder MetallurgyDocument24 paginiPowder MetallurgyAyan BhardwajÎncă nu există evaluări

- Powder MetallurgyDocument83 paginiPowder Metallurgyrahul72Încă nu există evaluări

- Powder MetallurgyDocument15 paginiPowder Metallurgypankajsinghbaghel100% (2)

- MECH202 - 2015-16 FALL - L04 - Powder MetallurgyDocument46 paginiMECH202 - 2015-16 FALL - L04 - Powder MetallurgyDanish IftikharÎncă nu există evaluări

- Powder MetallurgyDocument24 paginiPowder MetallurgyمحمودالوصيفÎncă nu există evaluări

- Unit Iv Powder MetallurgyDocument39 paginiUnit Iv Powder MetallurgyNyanda MadiliÎncă nu există evaluări

- 1b1 Nonarc Process ContinuedDocument41 pagini1b1 Nonarc Process Continuedsushil sandhuÎncă nu există evaluări

- Assignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Document12 paginiAssignment: Submitted To: Miss Sobia Anwar Submitted By: Uzair Khan (2018-CH-01)Uzair KhanÎncă nu există evaluări

- Particle SizeDocument38 paginiParticle SizeChandan KumarÎncă nu există evaluări

- Powder Metallurgy Advantages and LimitationsDocument6 paginiPowder Metallurgy Advantages and LimitationsHafiezul HassanÎncă nu există evaluări

- Powder Metallurgy PDFDocument9 paginiPowder Metallurgy PDFetamil87Încă nu există evaluări

- Me Law ReportDocument19 paginiMe Law ReportChristian Angelo AndoyÎncă nu există evaluări

- Thixoforming: Semi-solid Metal ProcessingDe la EverandThixoforming: Semi-solid Metal ProcessingGerhard HirtÎncă nu există evaluări

- Hanwha Total PP HJ700Document2 paginiHanwha Total PP HJ700Nguyễn Hồng NamÎncă nu există evaluări

- Uji Fitokimia Ekstrak Etanol Daun Kemangi (Ocimum Basilicum L)Document6 paginiUji Fitokimia Ekstrak Etanol Daun Kemangi (Ocimum Basilicum L)Kezia VristianÎncă nu există evaluări

- The Student Work Experience Programme (SWEP) For 2019/2020 SessionDocument31 paginiThe Student Work Experience Programme (SWEP) For 2019/2020 SessionModesola Shoroye100% (1)

- MCQs All With KeysDocument47 paginiMCQs All With KeysSana UllahÎncă nu există evaluări

- 15 BergstromDocument40 pagini15 BergstromAdolfo Gálvez VillacortaÎncă nu există evaluări

- MSDS Accelerator MBT 2-Mercaptobenzothiazole KemaiDocument7 paginiMSDS Accelerator MBT 2-Mercaptobenzothiazole KemaicarlosÎncă nu există evaluări

- 2 Color in FoodDocument44 pagini2 Color in FoodAbdul RahmanÎncă nu există evaluări

- MC Cabe Graphical Model-Based Distillation Column DesignDocument21 paginiMC Cabe Graphical Model-Based Distillation Column DesignReguloÎncă nu există evaluări

- Fracture Toughness and FatigueDocument10 paginiFracture Toughness and FatigueiamjemahÎncă nu există evaluări

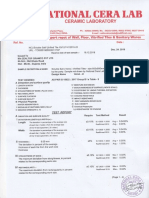

- 12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Document3 pagini12 - National Cera Lab Test Report - 600x1200 MM - 24.12.2019Shaikh MohammedHanifSultanÎncă nu există evaluări

- Model M05 Non-Metallic Design Level 2: Service & Operating ManualDocument33 paginiModel M05 Non-Metallic Design Level 2: Service & Operating ManualTrungGVÎncă nu există evaluări

- WTC2005 63324 PDFDocument2 paginiWTC2005 63324 PDFMarcelo VeronezÎncă nu există evaluări

- 坦客人哦Document9 pagini坦客人哦Ajay SinghÎncă nu există evaluări

- The Phases of MatterDocument6 paginiThe Phases of MatterbettynogpoÎncă nu există evaluări

- Boiler Water Treatment: Product InformationDocument1 paginăBoiler Water Treatment: Product InformationJunaid Jamil100% (1)

- IJSRDV6I60154Document6 paginiIJSRDV6I60154Vu Mai BaÎncă nu există evaluări

- Sodium ThiosulfateDocument8 paginiSodium ThiosulfateJakeÎncă nu există evaluări

- RTV (Chinese National Standard)Document16 paginiRTV (Chinese National Standard)Prem AnandÎncă nu există evaluări

- USP-43-NF - Zinc Acetate Oral SolutionDocument2 paginiUSP-43-NF - Zinc Acetate Oral SolutionsyÎncă nu există evaluări

- Dow Corning Corporation Material Safety Data SheetDocument7 paginiDow Corning Corporation Material Safety Data SheetSalvador NegreteÎncă nu există evaluări

- G-protein-Coupled ReceptorsDocument24 paginiG-protein-Coupled ReceptorsNaimi Amalia hatimahÎncă nu există evaluări

- Material Safety Data Sheet - NITRIC ACID PDFDocument9 paginiMaterial Safety Data Sheet - NITRIC ACID PDFJunaid AhmadÎncă nu există evaluări

- Fernandes 2019Document8 paginiFernandes 2019Jagan KbÎncă nu există evaluări