Documente Academic

Documente Profesional

Documente Cultură

Acoustic Calculation of Ventilation Systems

Încărcat de

Hari Babu Dharmavarapu0 evaluări0% au considerat acest document util (0 voturi)

210 vizualizări49 pagini1. The document outlines a procedure for calculating noise in ventilation systems that involves determining sound pressure level criteria, accounting for room and terminal effects, allowances for end reflections, ductwork and elbow attenuations, power level splits, and safety factors to select necessary silencer requirements.

2. It then provides an example calculation following the outlined procedure for an octave band center frequency range.

3. The document also discusses air conditioner efficiency ratings like EER and SEER, how to calculate cooling loads, convert between kW/ton and COP/EER, and determine sensible and latent heat gains that contribute to cooling loads.

Descriere originală:

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest document1. The document outlines a procedure for calculating noise in ventilation systems that involves determining sound pressure level criteria, accounting for room and terminal effects, allowances for end reflections, ductwork and elbow attenuations, power level splits, and safety factors to select necessary silencer requirements.

2. It then provides an example calculation following the outlined procedure for an octave band center frequency range.

3. The document also discusses air conditioner efficiency ratings like EER and SEER, how to calculate cooling loads, convert between kW/ton and COP/EER, and determine sensible and latent heat gains that contribute to cooling loads.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

210 vizualizări49 paginiAcoustic Calculation of Ventilation Systems

Încărcat de

Hari Babu Dharmavarapu1. The document outlines a procedure for calculating noise in ventilation systems that involves determining sound pressure level criteria, accounting for room and terminal effects, allowances for end reflections, ductwork and elbow attenuations, power level splits, and safety factors to select necessary silencer requirements.

2. It then provides an example calculation following the outlined procedure for an octave band center frequency range.

3. The document also discusses air conditioner efficiency ratings like EER and SEER, how to calculate cooling loads, convert between kW/ton and COP/EER, and determine sensible and latent heat gains that contribute to cooling loads.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 49

Acoustic Calculation of Ventilation Systems

A procedure for acoustic calculation of noise in

ventilation systems

Acoustic calculation of a ventilation system should follow a procedure similar to:

1. Sound pressure level criterion

Determine the sound pressure level criteria. This tables can be used but should be

checked against domestic rules.

In the example below Noise ating ! N"# ! is used as the criterion where the

N!values are entered in line $.

2. Room and terminal effect

The sound pressure levels ! Lp ! are converted to sound power level ! Lw ! at the

terminals. The acoustic characteristics of the room as well as the number and

location of the terminals must be considered.

a% Determine the acoustic characteristics of the room. In the example an average

sound absorption for the room is used.

b% Determine whether the receiver are in the direct or reverberant field. In the

example the listener is aprox. $.& m from the terminal.

c% 'ind the rooms absorption characteristics. In the example the absorption for

the walls( ceiling( floor( persons( curtains and their areas( is calculated to "# m

)

sabin. According

a%

and

c%

the attenuation is * d+.

d% Determine how many terminals the listener are influenced by. Note, emember

to include supply and return fans. In the example the listener are influenced by

two terminals. 'rom c% we subtract " d+.

The attenuation from the terminal to the room is & d+. The values are entered in

the example below.

3. Allowance for end reflection

In the example the duct dimension is )&# mm. Attenuation due to end reflection

is entered below.

4. Ductwork attenuation terminal to c!eckpoint

-alculate the attenuation in unlined and lined ducts. Note that the table and

diagrams list the attenuation in d+.m.

". #l$ow attenuation terminal to c!eckpoint

-alculate the attenuation in the elbows.

%. &ower'level split $ranc! to terminals

Determine the allowance for split ! branch to terminals.

(. &ower'level split main duct to $ranc! duct

Determine the allowance for split ! main duct to branch.

*. /ound power level of fan ! L

w

0nter the manufacturer1s sound power data or calculate the fan sound power.

). Safety factors

0nter safety factors ! recommended to !" d+.

1*. Silencer re+uirements

The silencer must be selected to provide the necessary attenuation. 'or this the

manufacturer1s data should be used.

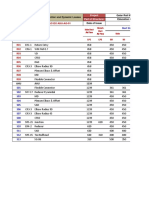

#,ample ' Acoustic Calculation of -VAC Application

2rocedure

3ctave band center fre4uency( 56

7" $)& )&# &## $### )### 8### *###

$. /ound pressure

level criterion

&9 8* 8# "8 "# ): )& )"

). oom and

terminal effect

& & & & & & & &

". Allowance for

end reflection

$) * 8 $ # # # #

8. Ductwork

attenuation(

terminal to

checkpoint

$: $: 9 & & & & &

&. 0lbow

attenuation(

terminal to

checkpoint

# # : $& )& )& $9 $&

7. 2ower!level 7 7 7 7 7 7 7 7

split( branch to

terminals

:. 2ower!level

split( main duct to

branch duct

$# $# $# $# $# $# $# $#

Totals

$#9 9$ :* :" :* :& 7: 7$

*. /ound power

level of fan ! Lw

$#) 99 9* 9* 9: 9& *7 *$

9. /afety factors " " " " " " " "

Total sound power

level of fan ! Lw

$#& $#) $#$ $#$ $## 9* *9 *8

$#. /ilencer

re4uirements

# * )# )& $9 )# $9 )#

Air Conditioner #fficiency

Air Conditioner efficiency list !ow many $tu.!r are removed for eac! watt

of power it draws.

The cooling e4uipment systems used in residential and small commercial buildings

often express cooling system efficiency in terms of the 0nergy 0fficiency atio

;00% and.or /easonal 0nergy 0fficiency atio ;/00%.

These are defined by the cooling effect in +tu ;not in tons% divided by the power

use in watts ;not in k<% for the peak day ;00%( or the seasonal average day

;/00%.

'or room air conditioners( this efficiency rating is the

#ner/y #fficiency Ratio 0##R1

'or central air conditioners( it is the

Seasonal #ner/y #fficiency Ratio 0S##R1

These ratings are posted on an #ner/y 2uide 3a$el( which shall be attached to

all new air conditioners.

/ome of the air conditioner manufacturers participate in the voluntary

#ner/yStar4 labeling program where 0nergy/tar!labeled appliances mean that

they have high 00 and /00 ratings.

#ner/y #fficiency Ratio ' ##R

oom air conditioners in general range from &(### +tu per hour to $&(### +tu per

hour. /elect room air conditioners with 00 of at least 9.# for mild climates. In a

hot climates( select air conditioners with 00 over $#.

Seasonal #ner/y #fficiency Ratio ' S##R

'or central air conditioners there is units with /00s reaching nearly $:.

#,ample

A cooling unit operating at $ k<.ton would have an 00 of $)(### +tu divided by

$### watts or $). This is mathematically e4uivalent to multiplying the -32 by

".8$". Therefore a small cooling unit operating at $ k< ;$### watts% per ton is

e4uivalent to a -32 of ".&$7( or an 00 of $).

Calculatin/ Coolin/ 3oads

Calculatin/ c!iller and coolin/ tower refri/eration in tons.

C!iller Refri/eration 5ons

A chiller refrigeration ton is defined as:

$ refrigeration ton = $)(### +tu.h = "(#)&.9 k -alories.h

Coolin/ 5ower 5ons

A cooling tower ton is defined as:

$ cooling tower ton = $&(### +tu.h = "(:*) k -alories.h

-eat 3oad and 6ater 7low

A water systems heat load in +tu.h can be calculated as:

h = 500 q dt ;$%

where

h = heat load ;+tu.h%

q = water volume flow rate ;gal.min%

dt = temperature difference ;

o

'%

#,ample ' 6ater C!iller Coolin/

<ater flows with $ gal.min and $#

o

' temperature difference. The ton of cooling

load can be calculated as:

-ooling load = &## ;$ gal.min% ;$#

o

'% . $)(###

= #.8) ton

-onverting between heat and energy units.

-onverting k<.tonn to -32 or 00.

Convertin/ k6.ton to C8& or ##R

-ow to convert $etween k6.ton C8& and ##R.

The efficiency of chillers depends on the energy consumed. Absorption chillers

are rated in fuel consumption per ton cooling. 0lectric motor driven chillers are

rated in kilowatts per ton cooling.

><.ton = $) . 00

><.ton = $) . ;-32 x ".8$)%

-32 = 00 . ".8$)

-32 = $) . ;><.ton% . ".8$)

00 = $) . ><.ton

00 = -32 x ".8$)

If a chillers efficiency is rated at $ ><.ton( the -32=".& and the 00=$)

Coolin/ 3oad in ' k6.ton

The term k<.ton is common used for large commercial and industrial air!

conditioning( heat pump and refrigeration systems.

The term is defined as the ratio of the rate of energy consumption in k< to the

rate of heat removal in tons at the rated condition. The lower the k<.ton the

more efficient the system.

kW/ton = Pc / Er ;$%

where

Pc = energy consumption ;k<%

Er = heat removed ;ton%

Coefficient of &erformance ' C8&

The -oefficient of 2erformance ! -32 ! is the basic unit less parameter used to

report the efficiency of refrigerant based systems.

The -oefficient of 2erformance ! -32 ! is the ratio between useful energy

ac4uired and energy applied and can be expressed as:

COP = Eu / Ea ;$%

where

COP = coefficient of performance

Eu = useful energy ac4uired

Ea = energy applied

-32 can be used to define both cooling efficiency or heating efficiency as for a

heat pump.

'or cooling( -32 is defined as the ratio of the rate of heat removal to the

rate of energy input to the compressor.

'or heating( -32 is defined as the ratio of rate of heat delivered to the

rate of energy input to the compressor.

-32 can be used to define the efficiency at a single standard or non!standard

rated condition or a weighted average seasonal condition. The term may or may

not include the energy consumption of auxiliary systems such as indoor or

outdoor fans( chilled water pumps( or cooling tower systems. 'or purposes of

comparison( the higher the -32 the more efficient the system.

-32 can be treated as an efficiency where -32 of ).## = )##? efficient 'or

unitary heat pumps( ratings at two standard outdoor temperatures of 8:@' and

$:@' ;*."@- and !*."@-% are typically used.

#ner/y #fficiency Ratio ' ##R

The 0nergy 0fficiency atio ! 00 ! is a term generally used to define the cooling

efficiency of unitary air!conditioning and heat pump systems.

The efficiency is determined at a single rated condition specified by the

appropriate e4uipment standard and is defined as the ratio of net cooling capacity

! or heat removed in +tu.h ! to the total input rate of electric energy applied ! in

watt hour. The units of 00 are +tu.w.h.

EER = Ec / Pa ;$%

where

EER = energy efficient ratio ;+tu.w.h%

Ec = net cooling capacity ;+tu.h%

Pa = applied energy ;w.h%

This efficiency term typically includes the energy re4uirement of auxiliary

systems such as the indoor and outdoor fans and the higher the 00 the more

efficient is the system.

Determination of Coolin/ 3oads

3atent and sensi$le !eat ..

A cooling load ;or heat gain% is the amount of heat engergy that must be removed from the house by

the 5AA- e4uipment to maintain the house at the indoor design temperature when the worst case

design temperature is being experienced outside. There are two types of cooling loads:

sensible and

latent

The sensible cooling load refers to the dry bulb temperature of the building and the latent cooling load

refers to the wet bulb temperature of the building. In the summer( humidity influence in the selection

of the 5AA- e4uipment and the latent load as well as the sensible load must be calculated.

7AC58RS 5-A5 9:73;#:C# 58 5-# S#:S9<3# C8839:2 38AD

Blass windows or doors

/unlight striking windows( skylights( or glass doors and heating the room

0xterior walls

2artitions ;that separate spaces of different temperatures%

-eilings under an attic

oofs

'loors over an open crawl space

Air infiltration through cracks in the building( doors( and windows

2eople in the building

04uipment and appliances operated in the summer

Cights

Notice that below grade walls( below grade floors( and floors on concrete slabs do not increase the

cooling load on the structure and are therefore ignored.

3ther sensible heat gains are taken care of by the 5AA- e4uipment before the air reaches the rooms

;system gains%. Two items that re4uire additional sensible cooling capacity from the 5AA- e4uipment

are:

Ductwork located in an unconditioned space

Aentilation air ;air that is mechanically introduced into the building%

7AC58RS 5-A5 9:73;#:C# 58 5-# 3A5#:5 C8839:2 38AD

Doisture is introduced into a structure through:

2eople

04uipment and appliances

Air infiltration through cracks in the building( doors( and windows

3ther latent heat gain is taken care of by the 5AA- e4uipment before the air reaches the rooms

;system gain%. The item that re4uires additional latent cooling capacity from the 5AA- e4uipment is

ventilation and infiltration air .

#+uivalent Rectan/ular and Round -VAC Duct Si=es

#+uivalent duct si=es for rectan/ular and circular duct deliverin/ air

airflows at different C7>.

C7>

0Cu$ic 7eet per

>inute1

#+uivant

Rectan/ular Duct

Si=es

09nc!es1

#+uivant

Diameter

Round Duct

Si=es

09nc!es1

$## " E 8 8

)##

" E :

8 E &

&

"##

8 E :

& E 7

7

8##

8 E 9

& E :

7 E 7

:

&## 7 E : *

:&#

& E $)

7 E $#

: E *

9

$###

: E $#

* E 9

$#

$)&#

* E $#

9 E 9

$#

$&##

* E $)

$# E $#

$)

$:&#

* E $8

9 E $)

$# E $$

$)

)###

* E $&

$# E $)

$)

)&##

$# E $8

$) E $)

$8

"### $) E $8 $8

"&## $) E $& $&

8###

$# E ))

$8 E $&

$7

8&##

$) E $9

$8 E $7

$:

&###

$# E )&

$) E )#

$:

-eat 2ain from #lectrical >otors in Continuous 8peration

-eat transferred from t!e electrical motor to t!e room for different

locations of fan and motor.

0lectrical motors in air condition system contributes to the heat loads in air

condition systems and have influence on the cooling e4uipment dimensions.

Bained heat load from electrical motor and fans in different locations can be

estimated from the table below:

0lectrical

Dotor /haft

3utput

;k<%

'ull Coad

0lectrical

Dotor

0fficiency

! -

?

Cocation of 'an and Dotor

Dotor and 'an in

the Inlet Air 'low

or in the oom

Dotor 3utside

the Air 'low or

3utside the

oom. The 'an

in the Inlet Air

'low or in the

oom

Dotor in the

oom. The 'an in

the 3utlet Air

'low.

#.#& 8# #.$" #.#& #.#*

#.#: 87 #.$& #.#: #.#*

#.$# && #.$* #.$# #.#*

#.$8 7# #.)" #.$8 #.#9

#.)# 78 #."$ #.)# #.$$

#.)* 77 #.8) #.)* #.$8

#.8# :# #.7# #.8# #.)#

#.&7 :) #.:* #.&7 #.))

#.*# :7 $.#& #.*# #.)&

$.$ *# $."* $.$ #.)*

$.7 *# ).# $.7 #.8#

).& *$ ".$ ).& #.7#

8.# *) 8.9 8.# #.9#

&.7 *8 7.: &.7 $.$

*.# *8 9.& *.# $.&

$$.) *7 $".# $$.) $.*

$7 *: $*.8 $7 ).8

)# ** )).: )# ).:

)& *9 )*.# )& ".#

") *9 "7.# ") 8.#

8# *9 8&.# 8# &.#

&# 9# &7.# &# 7.#

7" 9# :#.# 7" :.#

*# 9# *9.# *# 9.#

$## 9$ $$#.# $## $#.#

-eat 2ain from 3i/!ts

-eat /ain from li/!t contri$ute to !eat load and may !ave ma?or impact

on t!e air condition system.

The heat gained from lights in a modern office or production area may be of a

significant amount. The heat emitted to a room depends on the

preferred light level in the room

type of lights and their construction

location of the light e4uipment

3i/!t 3evel ' 9lluminance

The preferred light level in a room depends primarily on the type of activity. 'or

common office work the level may be in the range of &## ! $### lux.

ecommended Cight Cevels in ooms

:ecessary 9nstalled #lectric &ower for 3i/!ts

The electric power to the light e4uipment is at the end converted to heat emitting

to the room ;unless special arrangements is used as local cooling or air outlets

through the lighting e4uipment%. 0lectric power to achieve a recommended light

level can be expressed as:

P = b / (e r l! ;$%

where

P = installed electric power ;<.m

)

floor area%

b = recommended light level ;lux( lumen.m

)

%

e = light e4uipment efficiency

r = room lighting efficiency

l = emitted light from the source ;lumen.<%

#mitted 3i/!t 7rom Source ' l

s

The purpose of a lamp is to convert electrical power ;<atts% into light ;lumens%.

Different lamps do this with varying efficiencies and the light emitted from a

source depends on the type of source.

The typical efficiency of different lamp types can be found in the table below:

Camp Type

0mitted Cight from The

/ource

;lumen.<att%

Cifetime

;hours%

BC/ +ulbs $# ! $& $(###

Cow Aoltage

5alogen

)# )(### ! &(###

Dercury Aapor 8# ! 7# ))(###

'luorescent &# ! 9#

more than

:(###

Detal 5alide :# ! 9#

more than

$)(###

5igh 2ressure

/odium

9# ! $)& )&(###

Cow 2ressure

/odium

$)# ! )## )#(###

A typical incandescent BC/ light bulb emit approximately $# lumen.<att.

A typical fluorescent tube emit up to approximately 7# lumen.<att.

3i/!t #+uipment #fficiency '

e

The light e4uipment efficiency express how much of the light is really emitted

from the light e4uipment to the room.

A bare fluorescent tube emits $##? to the room. A shielded tube emit less !

between &#? to *#? is common.

Room 3i/!tin/ #fficiency '

r

The room lightning efficiency express how much of the light is absorbed by the

room before entering the activity area.

Cight 04uipment 0fficiency and oom Cightning 0fficiency influence each other.

-ommon values of the product e r are in the range #." ! #.7.

#,ample ' -eat 3oad from 3i/!ts

$(### lux is recommended light level in a office where detailed drawing work is

performed. The room and lightning e4uipment efficiency an be set to #.&.

Fsing standard BC/ bulbs ! the electric power for lightning can be calculated as:

P = ;$(### lumen.m

)

% . ;#.& ;$# lumen.<%%

= )## <.m

)

Fsing standard fluorescent tubes ! the electric power for lightning can be

calculated as:

P = ;$(### lumen.m

)

% . ;#.& ;7# lumen.<%%

= ""." <.m

)

Due to the high energy consumption an the maGor impact on the air conditions

system( standard BC/ bulbs is not an alternative for high illuminance

applications.

The table below shows the installed electrical effect at different light levels:

Installed effect ;<%

Illumination ! Cight Cevel ;lux%

)## 8## 7## *## $###

Incandescent BC/ bulb lamp 8# *# $)# $7# )##

'luorescent tubes 7.: $"." )# )7.: ""."

:ote@ Datasheets from manufacturers should always be consulted before detail

engineering. The numbers above will do for rough preliminary calculations.

-umidifyin/ Air ' S9 units

5!e amount of vapor ' k/ per cu$ic meter ' in !umid air

The table below can be used to estimate the amount of vapor in an air volume of

$## m

"

:

Aapor in Air

;kg per $##

m

"

airflow%

elative 5umidity ;?%

Dry

Temperature

;

o

-%

$## *& *# :& :# 7& 7# && &# 8& 8# "& "#

") "."9 ).*9 ).:) ).&& )."* ).$9 ).#8 $.9" $.: $.&" $."7 $.$9 $.#)

"$ ".)) ).:" ).&: ).8$ ).)& ).$ $.9" $.:: $.7$ $.8& $.)9 $.$" #.9:

"# ".#& ).&9 ).88 ).)9 ).$" $.9: $.*" $.7: $.&) $.": $.)) $.#: #.9$

)9 ).*9 ).8& )."$ ).$: ).#) $.** $.:" $.&9 8.8& $." $.$7 $.#$ #.*:

)* ).:" ).") ).$9 ).#& $.9$ $.:* $.78 $.& $.": $.)" $.$ #.97 #.*)

): ).&9 ).) ).#: $.98 $.*$ $.7* $.&& $.8) $.)9 $.$7 $.#" #.9$ #.:*

)7 ).8& ).#* $.97 $.*" $.:$ $.&9 $.8: $."8 $.)) $.$ #.9: #.*7 #.:"

)& )."$ $.9: $.*& $.:" $.7) $.& $."9 $.): $.$7 $.#8 #.9" #.*$ #.79

)8 ).$9 $.*7 $.:& $.78 $.&" $.8) $."$ $.) $.#9 #.9* #.*: #.:: #.77

)" ).#7 $.:7 $.7" $.&& $.8& $."8 $.)8 $.$8 $.#" #.9" #.*" #.:) #.7)

)) $.9& $.77 $.&7 $.87 $."7 $.): $.$: $.#: #.9* #.** #.:* #.7* #.&9

)$ $.*8 $.&7 $.8: $."* $.)9 $.) $.$ $.#) #.9) #.*" #.:8 #.7: #.&&

)# $.:8 $.8* $."9 $." $.)) $.$" $.#8 #.9* #.*: #.:* #.79 #.7$ #.&)

$9 $.7" $."9 $."$ $.)" $.$& $.#7 #.9* #.9 #.*) #.:8 #.7& #.&: #.89

$* $.&8 $."$ $.)8 $.$7 $.#* $ #.9" #.*& #.:: #.79 #.7) #.&8 #.87

$: $.8& $.)8 $.$7 $.#9 $.#) #.98 #.*: #.* #.:" #.7& #.&9 #.&$ #.88

$& $.)9 $.$ $.#" #.9: #.9 #.*8 #.:: #.:$ #.77 #.&* #.&) #.8& #."9

$# #.98 #.* #.:7 #.:$ #.77 #.7$ #.&: #.&) #.8: #.8" #."* #."" #.)*

# #.89 #.8$ #."9 #.": #."8 #.") #.)9 #.): #.)8 #.)) #.) #.$: #.$&

!& #."" #.)* #.)7 #.)& #.)" #.)$ #.) #.$* #.$7 #.$& #.$" #.$$ #.$

!$# #.)) #.$* #.$: #.$7 #.$& #.$8 #.$" #.$) #.$$ #.$ #.#9 #.#* #.#7

:ote@ In psychrometric charts and Dollier diagram the amount of vapor is given

in kg.kg dry air. The values from the table above can be transformed dividing by

the air density at the actual temperature.

#,ample ' -umidifyin/ Air wit! Steam

Air at )#

o

- and "#? relative humidity are humidified to )#

o

- and *#? relative

humidity.

'rom a table above air at )#

o

- and "#? relative humidity contains #.&) kg water

vapor per $## m

"

air flow. Air at )#

o

- and *#? relative humidity contains $."9

kg per $## m

"

air flow.

The amount of water vapor needed can be calculated as:

Amount of <ater Aapor = ;;$."9 kg% ! ;#.&) kg%%

= #.*: kg is the amount of water vapor necessary for an air volume of $## m

"

.

9ndoor Desi/n Conditions for 9ndustrial &roduct and

&roduction &rocesses

Recommended indoor temperature and !umidity for common industrial

product and production processes.

ecommended design conditions should provide employees with a comfortable

and healthy indoor work environment together with optimal condition for the

production process. Fnfortunately this is obvious not always possible. 3ften it

may be necessary to make special arrangements shielding the employees from

the production environment.

The table below can be used to indicate the design conditions ! temperature and

humidity ! for common production processes.

Industry 2rocess

Temperature

o

- min

Temperature

o

- max

Temperature

o

' min

Temperature

o

' max

elative

humidity

?

Abrasives Danufacturing )7 )7 :9 :9 &#

Ammunition )$ )$ :# :# 8#

+akery 'lour storage $7 )7 7$ :9 &&!7&

2roduction )" )7 :" :9 8#!:#

+illiard oom )" )8 :" :& 8#!&#

+owling -enter +owling alleys )" )8 :" :& &#! &&

+illiard rooms )" )8 :" :&

+read

'lour and

powdered

storage

)$ ): :# *# 7#

'ermentation ): ): *# *# :&

etarding of

Dough

# 8 ") 8# *&

'inal 2roof "& 89 9& $)# *&!9#

-ounter flow

-ooling

)8 )8 :& :& *#!*&

+rewing 5op storage !) # )9 ") &#!7#

Heast culture

room

*#

-andy

-hocolate 2an

supply air

$" $: && 7) &&!8&

0nrobed room ): )9 *# *& "#!)&

-hocolate

-ooling Tunnel

supply air

8 : 8# 8& *&!:#

5and Dippers $: $: 7) 7) 8&

Dolded goods

cooling

8 : 8# 8& *&!:#

-hocolate $* $* 7& 7& &#

2acking room

-hocolate

finished stock

storage

$* $* 7& 7& &#

-enters

tempering

room

)8 ): :& *# "&!"#

Darshmallow

setting room

)8 )7 :& :* 8&!8#

Brained

marshmallows

drying

8" 8" $$# $$# 8#

Bum drying &) 77 $)& $&# )&!$&

/anded Bum

drying

"* "* $## $## )&!8#

Bum finished

stock storage

$# $* &# 7& 7&

/ugar pan

supply air

)9 8$ *& $#& "#!)#

2olishing pan

supply air

)$ ): :# *# &#!8#

2an rooms )8 ): :& *# "&!"#

Nonpareil 2an

supply air

"* 89 $## $)# )#

5ard candy

cooling tunnel

air

$7 )$ 7# :# &&!8#

5ard candy

packing

)$ )8 :# :& 8#!"&

5ard candy

storage

$# )$ &# :# 8#

-aramel

rooms

)$ ): :# *# 8#

-eramics efractory 8" 77 $$# $&# &#!9#

Dolding room ): ): *# *# 7#!:#

-lay storage $7 ): 7# *# "&!7&

Decalcomania

production

)8 ): :& *# &#

Decoration

room

)8 ): :& *# &#

-ereal 2ackaging )8 ): :& *# 8&!&#

-heese -uring -heddar : $" 8& && *&!9#

/wiss $7 $7 7# 7# *#!*&

+lue 9 $# 8* &# 9&

+rick $7 $* 7# 7& 9#

Cimburger $7 $* 7# 7& 9&

-amembert $) $& &" &9 9#

-lean rooms )$ ): :# *# 8#!7#

Distilling Brain /torage $7 $7 7# 7# "&!8#

Beneral

Danufacturing

$7 )8 7# :& 8&!7#

Aging $* )) 7& :) &#!7#

'ruit /torage Apples !$ 8 "# 8# 9#

Apricots !$ # "$ ") 9#!9&

Brapefruits

;-alifornia%

$8 $7 &* 7# *&!9#

Brapefruits

;'lorida%

$# $# &# &# *&!9#

Brapes

;0astern%

!$ # "$ ") *&

Brapes

;<estern%

!$ !$ "# "$ 9#!9&

Cemons $8 $7 &* 7# *7!**

3ranges

;-alifornia%

8 : 8# 88 *&!9#

3ranges

;'lorida%

# $ ") "8 *&!9#

2eaches and

Nectarines

!$ !$ "$ "$ 9#

2lums !$ # "# ") 9#!9&

-itrus fruits " 8 "* 8# 9#!9&

'ur /torage !) 8 )* "9 )&!8#

Drying 8" 8" $#9 $#9

Bum Danufacturing )& )& :: :: ""

olling )# )# 7* 7* 7"

/tripping )) )) :) :) &"

+reaking )" )" :8 :8 8:

<rapping )" )" :8 :8 &*

5ospitals

3perating(

-ystoscopic

and fracture

rooms

)# )8 7* :7 &#

2atient rooms )8 )8 :& :& 8#!&#

Intensive care

unit

)8 )8 :& :& 8#

Administrative

and service

areas

)$ ): :# *# "#!&#

Ceather Drying )$ 89 :# $)# :&

/torage(

winter room

temperature

$# $7 &# 7# 8#!7#

Censes ;optical% 'using )8 )8 :& :& 8&

Brinding ): ): *# *# *#

Cibraries and

Duseums

Normal

reading and

viewing rooms

)$ )" :# :8 8#!&#

are

manuscript

and /torage

Aaults

)$ )) :# :) 8&

Art /torage

Areas

$* )) 7& :) &#

Datches Danufacture )) )" :) :8 &#

Drying )$ )8 :# :& 7#

/torage $7 $: 7# 7) &#!&&

Deat and fish +eef ;fresh% # $ ") "8 **!9)

+eef ;fro6en% !)" !$* !$# 9#!9&

'ish ;fresh% $ ) "" "& 9#!9&

'ish ;'ro6en% !)" !$* !$# 9#!9&

Camb and 2ork

;'resh%

# $ ") "8 *&!9#

Camb and 2ork

;'ro6en%

!)" !$* !$# 9#!9&

Dushrooms

/weating out

period

89 7# $)# $8#

/pawn added $7 )8 7# :& $##

Browing

period

9 $7 8* 7# *#

/torage # ) ") "& *#!*&

2aint

Applications

3il paint

spraying

$7 ") 7# 9# *#

Drying oil

paints

$& ") &9 9# )&!&#

+rush and

spray painting

$& ): &9 *$ )&!&#

2harmaceuticals

Danufactured

powder

storage and

packing area

)8 )8 :& :& "&

Dilling room )8 )8 :& :& "&

Tablet

compressing

and coating

)8 )8 :& :& "&

0ffervescent

tablets and

powders

)8 )8 :& :& )#

5ypodermic

tablets

)8 )8 :& :& "#

-olloids )$ )$ :# :# "#!&#

-aught drops ): ): *# *# 8#

Blandular

products

)8 )8 :7 :7 &!$#

Ampoule

manufacturing

)8 )8 :& :& "&!&#

Belatin

-apsules

)8 )8 :7 :7 "&

-apsule

storage

)8 )8 :7 :7 "&

Dicroanalysis )8 )8 :7 :7 &#

+iological

manufacturing

)8 )8 :7 :7 "&

Civer extracts )8 )8 :7 :7 "&

/erums )8 )8 :7 :7 &#

Animal rooms )8 ): :& *# &#

/mall animal

rooms

)8 )7 :& :* &#

2aper

+inding(

cutting(

drying(

folding( gluing

$& ): &9 *$ )&!&#

/torage of

paper

$& ): &9 *$ "8!8&

/torage of

books

$* )$ 78 :# "*!&#

2lastics

Danufacturing

areas

thermosetting

molding

compounds

): ): *# *# )&!"#

-ellophane

wrapping

)8 ): :& *# 8&!7&

2hotographic

Development

of film

)$ )8 :# :& 7#

Drying )8 ): :& *$ &#

2rinting )$ )$ :# :# :#

-utting )) )) :) :) 7&

2lywood

5ot pressing(

resin

") ") 9# 9# 7#!:#

-old pressing ") ") 9# 9# $&!)&

2rinting +inding )$ )$ :# :# 8&

'olding )& )& :: :: 7&

2ressing(

general

)8 )8 :& :& 7#!:*

2late making )8 ): :& *# max 8&

Cithographic

press room

)8 ): :7 *# 8"!8:

Cetterpress

and web offset

rooms

)$ ): :# *# &#

2aper storage(

letterpress

)$ ): :# *# 8"!8:

2aper storage(

multicolor

sheet feed

lithography

)8 ): :7 *# &#!&&

aw Daterial

/torage

Nuts( insect : : 8& 8& 7&!:&

Nuts( rancidity $ " "8 "* 7&!:&

0ggs !$ !$ "# "# *&!9#

-hocolate(

flats

$* $* 7& 7& &#

+utter !: !: )# )#

Dates( figs 8 : 8# 8& :&!7&

-orn /yrup 9#!$##

Ci4uid sugar )8 ): :& *# 7#!&#

ubber!dipped

goods

-ementing ): ): *# *# )&!"#

Dipping

surgical

articles

)8 ") :& 9# )&!"#

/torage prior

to

manufacture

$7 )8 7# :& 8#!&#

Caboratory(

A/TD

standard

)8 )8 :& :& &#!&&

Textile

-otton(

carding

)8 ): :& *$ &#

-otton(

spinning

$& ): &9 *$ 7#!:#

-otton(

weaving

)# )8 7* :& :#!*#

Nylon(

production

): ): *$ *$ &#!7#

ayon(

spinning

)$ )$ :# :# *&

ayon(

twisting

)$ )$ :# :# 7&

/ilk( spinning )8 ): :& *$ 7&!:#

/ilk( weaving )8 ): :& *$ 7#!:#

<ool( carding )8 ): :& *$ 7&!:#

<ool( spinning )8 ): :& *$ &&!7#

<ool( weaving )8 ): :& *$ &#!&&

Tobacco

-igar and

cigarette

making

)$ )8 :# :& &&!7&

/oftening ") ") 9# 9# *&

/temming and

strigging

)8 "# :& *7 :#

'iller tobacco

casing

conditioning

)8 )8 :& :& :&

'iller tobacco

storage and

preparation

)7 )7 :* :* :#

<rapper

tobacco

storage and

conditioning

)8

>et!ods of Air Conditionin/

Methods of cooling air

1. Spray washer

2. Surface type cooler

a) Indirect by heat exchange with water which has been cooled by a refrigerant.

b) Direct by heat exchanger in evaporator of a refrigerator system.

Methods of refrigeration

1. Compressed system

ot compressed air leaves a compressor and is li!uefied in a condenser by heat exchange

with cooling water or air. "he li!uid refrigerant then passes through an expansion valve and

the low pressure li!uid enters the evaporator. It absorbs heat from the medium to be cooled

and is vapourised. "he vapour enter the compressor and is raised to an higher pressure.

2. #bsorption system

$ow pressure refrigerant is dissolved in water in a generator and vapour at high pressure is

driven out of the solution by heat. "he vapour is li!uefied in a condenser and expanded

through an expansion valve. "he low pressure li!uid enter the evaporator and absorbs the

heat from the medium to be cooled. It vapourises and returns to the cooler.

8ptimal Stora/e Conditions for 7ruits and Ve/eta$les

8ptimal temperature and !umidity for common fruits and ve/eta$les.

2roper storage conditions ! temperature and humidity ! are needed to lengthen

storage life and maintain 4uality of harvested fruits and vegetables.

'resh fruits need low temperature and high relative humidity to reduce the

respiration and slow down the metabolic process. The table below can be used as

an indication of optimal temperature and moisture condition for common fruits

and vegetables.

Product

Optimal

Storage

Temperature

Chill

Point

Freezing

Point

Optimal

Humidity

Top Ice

Accepted

1

!ater

Sprin"le

Accepted

#

$thylene

Production

Sensiti%e

to

$thylene

&

Appro'imate

Storage (ife

Comments

o

F

o

C

o

F

o

C

o

C )

#pples %&'(& '1'( 2).% )&')* +o +o igh ,es 1'12 months Chill

sensitive

stored at

%*'(& - .2'(

C)

#pricots %1'%2 '1'& %&.1 )&')* +o +o igh ,es 1'% wee/s

#rticho/es %2'%* &'2 )&')* ,es ,es +o +o

#rticho/es0

1erusalem

%1'%2 &'2 22.& )&')* +o +o +o +o ('* months

#sparagus %2'%* %&.) )*'1&& +o ,es +o ,es 2'% wee/s

#vocados0 ripe %2'(* %'3 %4 2 2*')* +o +o igh ,es

#vocados0

unripe

(*'*& 3'1& (* 3 2*')* +o +o $ow ,es0 5ery 6eep away

from

ethylene

producing

fruits

7ananas0 green 42'3& 13'21 *4 1% 2*')* +o +o $ow ,es

7ananas0 ripe *4'4& 1%'14 *( 12 2*')* +o +o 8edium +o

7asil *2'*) 11'1* *& 1& )&')* +o ,es +o ,es

7eans0 dry (&'*& (&'*& 4'1& months

7eans0 green or

snap

(&'(* %&.3 )* 3'1& days

7eans0 sprouts %2 & )*'1&& 3') days

7eans. $ima %3'(1 & %1.& )* *'3 days

7eets %2'%* &'2 )&')* ,es ,es +o ,es

7eets0 bunched %2 & %1.% )2'1&& 1&'1( days

7eets0 topped %2 & %&.% )2'1&& ('4 months

7lac/berries %2'%% &'1 %&.* )&')* +o +o 5ery $ow +o 2'% days

7lueberries %2'%* &'2 )&')* +o +o 5ery $ow +o

7o/ Choy %2'%* &'2 )&')* +o ,es +o ,es

7roccoli %2 & %&.) )*'1&& ,es ,es +o ,es 1&'1( days

7russels

Sprouts

%2 & %&.* )&')* ,es ,es +o ,es %'* wee/s

7unched

9reens

%2 & )&')* ,es ,es +o ,es 7eets0

Chard0

9reen

Product

Optimal

Storage

Temperature

Chill

Point

Freezing

Point

Optimal

Humidity

Top Ice

Accepted

1

!ater

Sprin"le

Accepted

#

$thylene

Production

Sensiti%e

to

$thylene

&

Appro'imate

Storage (ife

Comments

o

F

o

C

o

F

o

C

o

C )

:nions0

8ustard0

;arsley0

<adish0

Spinach0

"urnip

Cabbage0

Chinese

%2 & )*'1&& +o +o +o ,es 2'% months

Cabbage0 early %2 & %&.( )2'1&& ,es ,es +o ,es %'4 wee/s

Cabbage0 late %2 & %&.( )2'1&& *'4 months

Cantaloupe %4'%2 2'% %( 1 )&')* +o +o 8edium ,es

Carrots0

bunched

%2 & )*'1&& ,es ,es +o ,es 2 wee/s =thylene

may cause

a bitter

flavor

Carrots0

immature

%2 & 2).* )2'1&& ('4 wee/s

Carrots0 mature %2 & 2).* )2'1&& 3') months

Cauliflower %2 & %&.4 )*')2 %'( wee/s

Cauliflower %2'%* &'2 )&')* +o +o +o ,es

Celery %2 & %1.1 )2'1&& ,es ,es +o ,es 2'% months

Celeriac %2 & %&.% )3')) 4'2 months

Chard %2 & )*'1&& 1&'1( days

Cherries %2'%* &'2 )&')* +o +o 5ery $ow +o

Cherries0 sour %2 & 2).& )&')* %'3 days

Cherries0 sweet %&'%1 22.2 )&')* 2'% wee/s

Chicory %2'%* &'2 )&')* ,es ,es +o +o

Chicory0 witloof %2 & )*'1&& 2'( wee/s

Chinese ;ea

;ods

%2'%* &'2 )&')* +o +o +o +o

Coconuts **'4& 1%'14 2&'2* +o +o +o +o =xtended

storage %2'

%* - .&'2 C)

Collards %2 & %&.4 )*'1&& 1&'1( days

Corn0 sweet %2 & %&.) )*')2 ,es ,es +o +o *'2 days

Cranberries %2'(2 %'4 %4 2 )&')* ,es +o +o +o

Cucumbers *&'** (& ( %1.1 )* +o +o 5ery $ow ,es 1&'1( days

Currants %1'%2 %&.2 )&')* 1'( wee/s

=ggplant (4'*( (* 3 %&.4 )&')* +o +o +o ,es 1 wee/

=lderberries %1'%2 )&')* 1'2 wee/s

=ndive %2 & %1.) )*'1&& ,es ,es +o +o 2'% wee/s

=scarole %2'%* &'2 )&')* ,es ,es +o +o

=scarole %2 & %1.) )*'1&& 2'% wee/s

-igs %2'%* &'2 )&')* +o +o $ow +o

9arlic %2 & %&.* 4*'3& +o +o +o +o 4'3 months 8ay be

stored at

**'3& - .1%'

21 C) for

Product

Optimal

Storage

Temperature

Chill

Point

Freezing

Point

Optimal

Humidity

Top Ice

Accepted

1

!ater

Sprin"le

Accepted

#

$thylene

Production

Sensiti%e

to

$thylene

&

Appro'imate

Storage (ife

Comments

o

F

o

C

o

F

o

C

o

C )

shorter

periods

9inger <oot 4&'4* 14'12 ** 1% 4*'3& +o +o +o +o

9ooseberries %1'%2 %&.& )&')* %'( wee/s

9rapefruit **'4& 1%'14 *& 1& )&')* +o +o 5ery $ow +o

9rapes %1'%2 2).3 2* +o +o 5ery $ow ,es 2'2 wee/s

9reen 7eans (&'(* ('3 %2 % )&')* +o +o +o ,es

9reen ;eas %2'%* &'2 )&')* +o +o +o ,es

9reens0 leafy %2 & )*'1&& 1&'1( days

9uavas (*'*& 3'1& (& ( )&')* +o +o 8edium ,es

erbs %2'%* &'2 )&')* +o ,es +o ,es

orseradish %&'%2 22.3 )2'1&& 1&'12 months

1icama **'4* 4*'3& 1'2 months

6ale %2 %1.1 )*'1&& 2'% wee/s

6iwi0 ripe %2'%* &'2 )&')* +o +o igh ,es

6iwi0 unripe %2'%* &'2 )&')* +e +o $ow ,es0 5ery

6ohlrabi %2 & %&.2 )2'1&& ,es ,es +o +o 2'% months

$ee/s %2 & %&.3 )*'1&& ,es ,es +o ,es 2'% months

$emons *2'** 11'1% *& 1& )&')* +o +o 5ery $ow +o

$ettuce %2 & %1.3 )2'1&& +o ,es +o ,es 2'% wee/s

$imes (2'** )'1% (* 3 )&')* +o +o 5ery $ow +o

$ychees (&'(* ('3 %4 2 )&')* +o +o 5ery $ow +o

8angos *&'** 1&'1% *& 1& 2*')* +o +o 8edium ,es

8elons0

Casaba>;ersian

*&'** 1&'1% (* 3 2*')* +o +o 5ery $ow ,es <iper

melons may

be stored at

(*'*& - .3'

1& C)

8elons0

Crenshaw

*&'** 1&'1% (* 3 2*')* +o +o $ow ,es <iper

melons may

be stored at

(*'*& - .3'

1& C)

8elons0 oney

Dew

*&'** 1&'1% (1 * 2*')* +o +o 8edium ,es <iper

melons may

be stored at

(*'*& - .3'

1& C)

8ushrooms %2 & %&.( )* +o ,es +o ,es %'( days

+apa %2'%* &'2 )&')* +o +o +o ,es

+ectarines %1'%2 %&.( )&')* +o +o igh +o 2'( wee/s

:/ra (*'*& (* 3 22.3 )&')* +o +o 5ery $ow ,es 3'1& days

:nions %2'%* &'2 4*'3* +o +o +o +o 8ay be

stored at

**'3& - .1%'

21 C) for

shorter

period

Product

Optimal

Storage

Temperature

Chill

Point

Freezing

Point

Optimal

Humidity

Top Ice

Accepted

1

!ater

Sprin"le

Accepted

#

$thylene

Production

Sensiti%e

to

$thylene

&

Appro'imate

Storage (ife

Comments

o

F

o

C

o

F

o

C

o

C )

:ranges (&'(* ('3 %2 % )&')* +o +o 5ery $ow +o

:ranges %2'%* &'2 )&')* +o +o 5ery $ow ,es

;apayas *&'** 1&'1% (* 3 2*')* +o +o 8edium ,es

;arsley %2 & %&.& )*'1&& 2'% months

;arsnips %2 & %&.( )2'1&& ,es ,es +o ,es ('4 months

;eaches %1'%2 %&.% )&')* +o +o igh ,es 2'( wee/s

;ears 2)'%1 2).2 )&')* +o +o igh ,es 2'3 months

;eas0 green %2 & %&.) )*')2 1'2 wee/s

;eas0 southern (&'(1 )* 4'2 days

;eppers0 hot

chili

%2'*& 4&'3& +o +o +o ,es 4 months

;eppers0 sweet (*'** 3'1& (2 4 %&.3 )&')* +o +o +o +o 2'% wee/s

;ersimmons %2'%* &'2 )&')* +o +o +o ,es0 5ery

;ineapples *&'** 1&'1% (* 3 2*')* +o +o 5ery $ow +o :dor may

influence

avacados

;lums %1'%2 %&.* )&')* +o +o igh ,es 2'* wee/s

;omegranates (1'*& *'1& (1 * )&')* +o +o +o +o

;otatoes (*'*& 3'1& %2 % )&')* +o +o +o ,es

;recut -ruit %2'%4 &'2 )&')* +o +o $ow +o

;recut

5egetables

%2'%4 &'2 )&')* +o +o +o ,es

;runes %1'%2 %&.* )&')* +o +o igh ,es 2'* wee/s

;ump/ins *&'** *& 1& %&.* 4*'3& +o +o +o ,es 2'% months

?uinces %1'%2 22.( )& 2'% months

?uinces %2'%* &'2 )&')* +o +o igh ,es

<adishes0 spring %2 & %&.3 )*'1&& ,es ,es +o ,es %'( wee/s

<adishes0 winter %2 )*'1&& 2'( months

<aspberries %1'%2 %&.& )&')* +o +o 5ery $ow +o 2'% days

<hubarb %2 & %&.% )*'1&& +o ,es +o +o 2'( wee/s

<utabagas %2 & %&.& )2'1&& ,es ,es +o ,es ('4 months

Salad 8ixes %2'%* &'2 )&')* +o ,es +o ,es

Salsify %2 %&.& )*')2 2'( months

Spinach %2 %1.* )*'1&& 1&'1( days

Sprouts %2'%* &'2 )&')* +o +o +o ,es

S!uashes0

summer

(1'*& (& ( %1.1 )* +o +o +o ,es 1'2 wee/s

S!uashes0

winter

*& %&.* *&'3& +o +o +o ,es 1'4 months

Strawberries %2 & %&.4 )&')* +o +o 5ery $ow +o %'3 days

Sweet ;otatoes **'4& *( 12 2).3 2*')& +o +o +o ,es ('3 months

"angerines %2'%* &'2 )&')* +o +o 5ery $ow +o

"angerines (&'(* ('3 %2 % )&')* +o +o 5ery $ow +o

Product

Optimal

Storage

Temperature

Chill

Point

Freezing

Point

Optimal

Humidity

Top Ice

Accepted

1

!ater

Sprin"le

Accepted

#

$thylene

Production

Sensiti%e

to

$thylene

&

Appro'imate

Storage (ife

Comments

o

F

o

C

o

F

o

C

o

C )

"omatoes0

mature green

**'3& %1.& )&')* +o +o $ow ,es 1'% wee/s <iping can

be delayed

by storing at

**'4& - .1%'

14 C)

"omatoes0 ripe **'3& %1.1 )&')* +o +o 8edium +o ('3 days

"urnip greens %2 %1.3 )*'1&& 1&'1( days

"urnips %2 & %&.1 )* ,es ,es +o ,es ('* months

@atercress %2 %1.( )*'1&& 2'% wee/s

@atermelon **'3& 1%'21 *& 1& 2*')* +o +o +o ,es0 5ery 6eep away

from

ethylene

producing

fruits

$%

Top icing the products may be very effective keeping the temperature low and

the product surface close to $##? humidity.

)%

/praying with water may be effective by keeping the temperature low

;evaporative cooling% and the surface $##? humid.

"%

2roducts sensitive to ethylene should not be stored together with products

producing ethylene. 0xposure to ethylene may soften the flesh( adding bitter

taste to the product or.and accelerate ripening.

&eople and -eat 2ain

Appro,imate -eat 2ain from 8ccupants in Air Conditioned Spaces ' in

$tu.!r

The table below can be used to estimate the sensible and latent heat from people.

The values can be used to calculate the heat load handled by the air condition

system.

Typical Application

/ensible 5eat

;btu.hr%

Catent 5eat

;btu.hr%

Theater!Datinee )## $"#

Theater!0vening )$& $"&

3ffices( 5otels( Apartments )$& $*&

etail I Department /tores ))# )"#

Drug /tore ))# )*#

+ank ))# )*#

estaurant )8# "$#

'actory )8# &$#

Dance 5all ):# &*#

'actory ""# 7:#

+owling Alley &$# 98#

'actory &$# 98#

Tabulated values are based on :*

o

' for dry!bulb temperature.

AdGusted total heat value for sedentary work( restaurant( includes 7# +tu.hr for food per

individual ;"# +tu.h sensible and "# +tu. latent heat%.

'or bowling figure one person per alley actually bowling( and all others as sitting ;8## +tu.h%

or standing ;&&# +tu.h%.

5eat gain from people ! watts

&erformance and #fficiency 5erminol/y

Desi/n and season related performance and efficiency terminol/y related

to !eat pumps and air condition systems.

8peratin/ >ode Desi/n Rated Conditions Seasonal Avera/e Conditions

-ooling -32

00

k<.ton

-32

I2C

/00

5eating -32

0c

0t

A'F0

-32

5/2'

Seasonal #ner/y #fficiency Ratio 0S##R1: The term /00 is used to define the

average annual cooling efficiency of an air!conditioning or heat pump system. The

term /00 is similar to the term 00 but is related to a typical ;hypothetical%

season rather than for a single rated condition. The /00 is a weighted average of

00s over a range of rated outside air conditions following a specific standard test

method. The term is generally applied to systems less than 7#(### +tu.h. The

units of /00 are +tu.<Jh. It is important to note that this efficiency term

typically includes the energy re4uirements of auxiliary systems such as the indoor

and outdoor fans. 'or purposes of comparison( the higher the /00 the more

efficient the system. Although /00s and 00s cannot be directly compared( the

/00s usually range from #.& to $.# higher than corresponding 00s.

-32

00

k<.t

9nte/rated &art'3oad Value 09&3V1: The term I2CA is used to signify the

cooling efficiency related to a typical ;hypothetical% season rather than a single

rated condition. The I2CA is calculated by determining the weighted average

efficiency at part!load capacities specified by an accepted standard. It is also

important to note that I2CAs are typically calculated using the same

condensing temperature for each part!load condition and I2CAs do not include

cycling or load.unload losses. The units of I2CA are not consistent in the literatureK

therefore( it is important to confirm which units are implied when the term I2CA is

used. A/5A0 /tandard 9#.$ ;using AI reference standards% uses the term I2CA

to report seasonal cooling efficiencies for both seasonal -32s ;unitless% and

seasonal 00s ;+tu.wJh%( depending on the e4uipment capacity categoryK and

most chillers manufacturers report seasonal efficiencies for large chillers as I2CA

using units of k<.ton. Depending on how a cooling system loads and unloads ;or

cycles%( the I2CA can be between & and &#? higher than the 00 at the standard

rated condition.

Com$ustion #fficiency 0nc or #c1: 'or fuel!fired systems( this efficiency term is

defined as the ratio of the fuel energy input minus the flue gas losses ;dry flue

gas( incomplete combustion and moisture formed by combustion of hydrogen% to

the fuel energy input. In the F./.( fuel!fired efficiencies are reported based on the

higher heating value of the fuel. 3ther countries report fuel!fired efficiencies based

on the lower heating value of the fuel. The combustion efficiency is calculated by

determining the fuel gas losses as a percent of fuel burned. L0c = $ ! flue gas

lossesM

5!ermal #fficiency 0nt or #t1: This efficiency term is generally defined as the

ratio of the heat absorbed by the water ;or the water and steam% to the heat value

of the energy consumed. The combustion efficiency of a fuel!fired system will be

higher than its thermal efficiency. /ee A/D0 2ower Test -ode 8.$ for more details

on determining the thermal efficiency of boilers and other fuel!fired systems. In

the F./.( fuel!fired efficiencies are typically reported based on the higher heating

value of the fuel. 3ther countries typically report fuel!fired efficiencies based on

the fuelNs lower heating value. The difference between a fuelNs higher heating value

and its lower heating value is the latent energy contained in the water vapor ;in

the exhaust gas% which results when hydrogen ;from the fuel% is burned. The

efficiency of a system based on a fuelNs lower heating value can be $# to $&?

higher than its efficiency based on a fuelNs higher heating value.

-eatin/ Seasonal &erformance 7actor 0-S&71: The term 5/2' is similar to

the term /00( except it is used to signify the seasonal heating efficiency of heat

pumps. The 5/2' is a weighted average efficiency over a range of outside air

conditions following a specific standard test method. The term is generally applied

to heat pump systems less than 7#(### +tu.h ;rated cooling capacity.% The units

of 5/2' are +tu.w!h. It is important to note that this efficiency term typically

includes the energy re4uirement of auxiliary systems such as the indoor and

outdoor fans. 'or purposes of comparison( the higher the 5/2' the more efficient

the system.

&ersons and >eta$olic -eat 2ain

Appro,imate meta$olic !eat /ain from occupants in air conditioned

spaces at different de/rees of activities ' in watts

The table below can be used to estimate the sensible and latent heat from people.

The values can be used to calculate the heat load handled by the air condition

system.

Degree of

Activity

Typical

Application

Average

Detabolic

rate !

male

adult ;<%

oom Dry +ulb Temperature ;

o

-%

)* ): )7 )8 )) )#

/ens. Cat. /ens. Cat. /ens. Cat. /ens. Cat. /ens. Cat. /ens. Cat.

/eated at

rest

-inema(

theatre(

school

$## &# &# && 8& 7# 8# 7: "" :) )* :9 )$

/eated(

very light

-omputer

working

$)# &# :# && 7& 7# 7# :# &# 8:* 8) *8 "7

work

3ffice

work

5otel

reception(

cashier

$"# &# *# &7 :8 7# :# :# 7# :* &) *7 88

/tanding(

walking

slowly

Caboratory

work

$"# &# *# &7 :8 7# :# :# 7# :* &) *7 88

<alking(

seated

$&# &" 9: &* 9) 78 *7 :7 :8 *8 77 9# 7#

Doderate

work

/ervant(

hair

dresser

$7# && $#& 7# $## 7* 9) *# *# 9# :# 9* 7)

Cight

bench

work

Dechanical

production

))# && $7& &) $&* :# $&# *& $"& $## $)# $$& $#&

Doderate

Dancing

2arty )&# 7) $** :# $*# :* $:) 98 $&7 $$# $8# $)& $)&

'ast

walking

Dountain

walking

"## *# ))# ** )$) 97 )#8 $$# $9# $"# $:# $8& $&&

5eavy

work

Athletics 8"# $") )9* $"* )9) $88 )*7 $&8 ):7 $:# )7# $** )8)

5eat gain from people ! btu.h

&ressure and 5emperature C!art for Ammonia :-3

A temperature 0de/ 71 and pressure 0psia psi/1 for Ammonia :-3.

TEMP. PRESSURE

@' 2/IA 2/IB

!7# &.7 18.6

!&* &.9 17.8

!&: 7.$ 17.4

!&7 7." 17.0

!&& 7.& 16.6

!&8 7.* 16.2

!&" :.# 15.7

!&) :.) 15.3

!&$ :.8 14.8

!&# :.: 14.3

!89 :.9 13.8

!8* *.) 13.3

!8: *.8 12.8

!87 *.: 12.2

!8& 9.# 11.7

!88 9.) 11.1

!8" 9.& 10.6

!8) 9.* 10.0

!8$ $#.$ 9.3

!8# $#.8 8.7

!"9 $#.: 8.1

!"* $$.# 7.4

!": $$.8 6.8

!"7 $$.: 6.1

!"& $).$ 5.4

!"8 $).8 4.7

!"" $).* 3.9

!") $".$ 3.2

!"$ $".& 2.4

!"# $".9 1.6

!)9 $8." 0.8

!)* $8.: 0.0

!): $&.$ #.8

!)7 $&.7 #.*

!)& $7.# $."

!)8 $7.8 $.:

!)" $7.9 ).)

&roperties of Refri/erant 22

Refri/erant 22 properties of saturated li+uid and saturated vapour.

TEMPERATURE

F

PRESSURE

PSIA

DENSITY,

LB/FT

LIQUID

VOLUME,

FT/LB

VAPOR

ENTHALPY,

BTU/LB

ENTROPY,

BTU/LB F

LIQUID VAPOUR LIQUID VAPOUR

-130.00 0.696 96.46 58.544 -23.150 89.864 -0.06198 0.28082

-120.00 1.080 95.53 38.833 -20.594 91.040 -0.05435 0.27430

-110.00 1.626 94.60 26.494 -18.038 92.218 -0.04694 0.26838

-100.00 2.384 93.66 18.540 -15.481 93.397 -0.03973 0.26298

-90.00 3.413 92.71 13.275 -12.921 94.572 -0.03271 0.25807

-80.00 4.778 91.75 9.7044 -10.355 95.741 -0.02587 0.25357

-70.00 6.555 90.79 7.2285 -7.783 96.901 -0.01919 0.24945

-60.00 8.830 89.81 5.4766 -5.201 98.049 -0.01266 0.24567

-50.00 11.696 88.83 4.2138 -2.608 99.182 -0.00627 0.24220

-45.00 13.383 88.33 3.7160 -1.306 99.742 -0.00312 0.24056

-41.44b 14.696 87.97 3.4048 -0.377 100.138 -0.00090 0.23944

-40.00 15.255 87.82 3.2880 0.000 100.296 0.00000 0.23899

-35.00 17.329 87.32 2.9185 1.310 100.847 0.00309 0.23748

-30.00 19.617 86.81 2.5984 2.624 101.391 0.00616 0.23602

-25.00 22.136 86.29 2.3202 3.944 101.928 0.00920 0.23462

-20.00 24.899 85.77 2.0774 5.268 102.461 0.01222 0.23327

-15.00 27.924 85.25 1.8650 6.598 102.986 0.01521 0.23197

-10.00 31.226 84.72 1.6784 7.934 103.503 0.01818 0.23071

-5.00 34.821 84.18 1.5142 9.276 104.013 0.02113 0.22949

0.00 38.726 83.64 1.3691 10.624 104.515 0.02406 0.22832

5.00 42.960 83.09 1.2406 11.979 105.009 0.02697 0.22718

10.00 47.538 82.54 1.1265 13.342 105.493 0.02987 0.22607

15.00 52.480 81.98 1.0250 14.712 105.968 0.03275 0.22500

20.00 57.803 81.41 0.9343 16.090 106.434 0.03561 0.22395

25.00 63.526 80.84 0.8532 17.476 106.891 0.03846 0.22294

30.00 69.667 80.26 0.7804 18.871 107.336 0.04129 0.22195

35.00 76.245 79.67 0.7150 20.275 107.769 0.04411 0.22098

40.00 83.280 79.07 0.6561 21.688 108.191 0.04692 0.22004

45.00 90.791 78.46 0.6029 23.111 108.600 0.04972 0.21912

50.00 98.799 77.84 0.5548 24.544 108.997 0.05251 0.21821

55.00 107.32 77.22 0.5111 25.988 109.379 0.05529 0.21732

60.00 116.38 76.58 0.4715 27.443 109.748 0.05806 0.21644

65.00 126.00 75.93 0.4355 28.909 110.103 0.06082 0.21557

Refri/erants

Some common coolin/ refri/erants and t!eir properties

efrigerant 'ormula

+oiling

temperature

;

o

-%

-ritical

temperature

;

o

-%

2roperties Applications

Ammonia N5" !"" $""

2enetrating

odor( soluble

in water.

harmless in

concentration

up to $."#?(

non

flammable(

explosive

Carge

industrial

plants

$)

Dichlorodifluoromethane

--l)') !)9.* $$)

Cittle odor(

colorless gas

or li4uid( non

flammable(

non corrosive

of ordinary

metals( stable

/mall plants

with

reciprocating

compressors.

Automotive(

Dedium

Temperature

efrigeration

$$ --l"' *.9 $9*

Non

flammable(

non corrosive

non toxic(

stable

-ommercial

plants with

centrifugal

compressors.

))

-hlorodifluoromethane

-5-l') !8#.* 97

Cittle odor(

colorless as

gas or li4uid(

non toxic(

non irritating(

non

flammable(

non

corrosive(

stable

2ackaged air!

conditioning

units where

si6e of

e4uipment

and economy

are

important. Air

-onditioning(

Cow and

Dedium

Temperature

efrigeration

!$"8a

$($($()!

tetrafluoroethane

-5)'-'"

Automotive

replacement

for !$)(

/tationary

A.-(

Dedium Temp

efrigeration

&##

--l)')

;:"(*?%

-5" -5

!""

/imilar to

$)

3ffers aprox.

)#? more

refrigeration

')

;)7.)?%

capacity than

$) for same

compressor.

&#)

--l ')

;8*(*?%

--l

')!-'"

;&$.)?%

!8&.7 9#.$

Non

flammable(

non toxic(

non

corrosive(

stable

-apacity

comparable

to )).

Relative -umidity in &roduction and &rocess #nvironments

Recommended Relative -umidity ' R- ' for production and process

environments as li$raries $reweries stora/es and more.

To avoid damage of the product( or to achieve proper process conditions( its often

important to keep the environment and indoor climate within certain limits. It

may be avoided that a low relative humidity dries up the product in the

production process( or that a high relative humidity increases the water activity

and creates mould.

The table below can be used as a guide to recommended elative 5umidity ! 5 !

for some common production and process environments.

2roduction and 2rocess

0nvironment

ecommended elative

5umidity ! 5 ;?%

/ugar /torage )#!"&?

+reweries "&!8&?

-offee 2owder "#!8#?

Dilk 2owder /torage )#!"&?

/eed /torage "&!8&?

Fnpacked Dedicine )#!"&?

Transformer <inding $&!"#?

/emiconductors "#!&#?

+ooks and 2aper

Archive

8#!&&?

2aper /torage "&!8&?

2reventing ust and

-orrosion

below &&?(

O 8#? for no rust

Cibrary &#!&&?

/pray 2aint "#!&#?

Caboratory electronics 8&!7#?

2lastic 2allets &!"#?

-omputer 2eripherals &#!7#?

ust esistance +elow 8#?

Dedical /yrups "#!8#?

-apsule /torage "#!8&?

2owder /torage "#!8&?

<ood Drying )&!"&?

0xplosives

"&!&#?

:ote@ lower 5 may

cause static electricity

and sparks ignition

Normal /torage &#!&&?

Dusical Instrument 8&!&&?

Ceather 2roduct 8#!&&?

-able <rapping $&!)&?

-hemical Caboratory "#!8&?

ead more about

elative 5umidity and 2sychrometric Terms

The 2sychrometric -hart ! The Dollier diagram

5!ermodynamic &roperties of R'22

Vapour volume ent!alpy and entropy for R'22 at different pressure and

temperatures.

TEMPERATURE

F

PRESSURE = 30 PSIA

SAT. TEMP. = -11.85F

PRESSURE = 60 PSIA

SAT. TEMP. = 21.94F

" H S " # /

-10 1.760 103.92 0.2325

30 1.943 109.92 0.2453 0.9271 108.35 0.2271

60 2.078 114.55 0.2545 1.001 113.17 0.2367

100 2.255 120.92 0.2663 1.096 119.74 0.2488

150 2.473 129.17 0.2804 1.212 128.19 0.2633

TEMPERATURE

F

PRESSURE = 75 PSIA

SAT. TEMP. = 34.06F

PRESSURE = 90 PSIA

SAT. TEMP. = 44.47F

" H S " # /

30 0.7851 107.81 0.2229

60 0.7847 112.45 0.2306 0.6401 111.69 0.2253

100 0.8639 119.13 0.2429 0.7088 118.50 0.2379

150 0.9591 127.69 0.2576 0.7906 127.18 0.2528

TEMPERATURE

F

PRESSURE = 135 PSIA

SAT. TEMP. = 69.39F

PRESSURE = 180 PSIA

SAT. TEMP. = 88.72F

" H S " # /

100 0.4492 116.50 0.2260 0.3177 114.29 0.2164

150 0.5092 125.59 0.2416 0.3678 123.90 0.2329

200 0.5655 134.79 0.2561 0.4132 133.45 0.2479

250 0.6193 144.20 0.2698 0.4558 143.10 0.2620

300 0.6713 153.84 0.2829 0.4965 152.93 0.2754

TEMPERATURE

F

PRESSURE = 200 PSIA

SAT. TEMP. = 96.17F

PRESSURE = 220 PSIA

SAT. TEMP. = 103.09F

" H S " # /

100 0.2776 113.22 0.2126

150 0.3251 123.11 0.2295 0.2900 122.30 0.2263

200 0.3674 132.83 0.2448 0.3299 132.20 0.2419

250 0.4067 142.60 0.2591 0.3666 142.09 0.2564

300 0.4441 152.52 0.2726 0.4012 152.10 0.2700

TEMPERATURE

F

PRESSURE = 240 PSIA

SAT. TEMP. = 109.57F

PRESSURE = 260 PSIA

SAT. TEMP. = 115.66F

" H S " # /

150 0.2606 121.45 0.2232 0.2356 120.58 0.2203

200 0.2985 131.56 0.2392 0.2720 130.90 0.2366

250 0.3330 141.58 0.2538 0.3046 141.06 0.2514

300 0.3654 151.69 0.2676 0.3351 151.27 0.2653

V A vapour volume0 ftB>lb h A enthalpy0 7tu>lb s A entropy0 7tu>lbCD-

;S Desi/n 8utdoor 5emperature and Relative -umidity ' 6inter

and Summer

8utdoor temperatures and relative !umidityAs in different ;S states and cities

summer and winter.

The table below can be used as an indication of the design conditions in F./ cities

summer and winter.

/tate -ity

Panuary Puly

Dry +ulb

Temperature

;

o

'%

Normal elative

5umidity ;?%

Dry +ulb

Temperature

;

o

'%

Normal elative

5umidity ;?%

::"#

am.

$:"#

pm.

::"#

pm.

::"#

am.

$:"#

pm.

::"#

pm.

Alabama

+irmingham $# *$ 7$ 77 9& *8 &7 7*

Dobile $# 9& 9# 78 :*

Ari6ona

'lagstaff !$# *" &* 9# :: "7

2hoenix )& :& 8: "9 $## &" "$ )"

Huma "# &7 ": ): $#& &$ "$ )"

Arkansas Cittle ock & *# 7: 7* $$# *& && &9

-alifornia

0ureka "# *: :: 9& 9) *#

'resno )& 9" *# 77 9# 7$ "7 )#

Cos Angeles "& 7" 87 &$ $#& *& &# &8

/acramento "# 9# *) :# 9# :7 87 )*

/an Diego "& :7 &* 7# $## *7 7* 7&

/an

'rancisco

"& *8 79 :# *& 9) :& :*

-olorado

Denver !$# &8 ": 8$ *& && ): "#

Brand

Punction

!$& :: 78 78 9& 8* ): ))

2ueblo !)# 7: 88 8* 9& :" "8 "&

-onnecticut New 5aven # :& 7& 79 9& :: 78 :8

Delaware <ilmington # :: 7) :# 9& *# &) 79

District of

-olumbia

<ashington # :" &7 78 9& :* &) 78

'lorida

Packsonville )& *9 &7 :& 9& *& &: :7

Diami "& *: &9 :& 9$ *" 78 :7

Beorgia

Atlanta $# *# 78 79 9& *" &: 7*

Augusta $# *8 &9 79 9* *" && 79

/avannah )# *" &* :) 9& *& 7$ *#

Idaho

+oise !$# *) :& :8 9& &8 "8 )"

Cewiston !& :9 :" :$ 9& 78 ": )&

Illinois

-airo # *$ 79 9* *" &:

-hicago !$# *$ :# :& 9& :* &$ &&

2eoria !$# :" :) :: 97 *$ &" &*

Indiana

'ort <ayne !$# *8 :& *$ 9& *8 &" &*

Indianapolis !$# *" :) :* 9& *8 &8 7#

Terre 5aute # *) :# :7 9& :: &# &7

Iowa

Davenport !$& 9&

/ioux -ity !)# :* 7: :) 9& *7 && &8

>ansas

Dodge -ity !$# :* &: 7$ 9& :: 8& &)

Topeka !$# :* 78 7: $## *& &8 &8

>entucky Couisville # :* 7* 79 9& :: &) &:

Couisiana

New 3rleans )# *& 7: :" 9& *8 78 :)

/hreveport )# *" 7: 77 $## *7 &7 7)

Daine 2ortland !& *$ 7& :8 9# :* &* :7

Daryland +altimore # :) 7* &7 9& :$ &) 7&

Dassachusetts +oston # :) &9 7: 9) :) && :#

Dichigan

Detroit !$# *) :$ :: 9& :8 &# &7

Brand

apids

!$# *& :* *# 9& :7 &$ &8

Dinnesota

Deluth !)& :* :8 :8 9" *: 7$ 77

Dinneapolis !)# *) :) :& 9& *) &8 &8

Dississippi Aicksburg $# *) 7& 7: 9& *: 7$ :#

Dissouri

>ansas -ity !$# :* 78 77 $## :7 8* 8:

/t. Couis # :: 7& 7* 9& :" &# &&

Dontana

+illings !)& 7: :" 7# 9# 7& 8# ""

+utte !)# :7 :# :$ 9& *) "7 ""

Nebraska North 2latte !)# *# 7) 77 *& *8 &# 87

S-ar putea să vă placă și

- Dasco 19-26Document8 paginiDasco 19-26Ahmed AzadÎncă nu există evaluări

- HVAC System in VehiclesDocument14 paginiHVAC System in Vehiclespmu2273100% (1)

- Vav BoxDocument20 paginiVav BoxCsiszer RobertÎncă nu există evaluări

- CITY HVAC Design Guide AppendicesDocument41 paginiCITY HVAC Design Guide AppendicesSimon Law100% (1)

- Diffuser Sizing GuidelinesDocument1 paginăDiffuser Sizing Guidelinessyed mustafa aliÎncă nu există evaluări

- Basics of Manual J RESNET 2014Document47 paginiBasics of Manual J RESNET 2014Juan Argueta100% (3)

- Duct Weight With InsulationDocument16 paginiDuct Weight With Insulationhasanadel88100% (1)

- AHU Operational Control Spreadsheet TrainingDocument17 paginiAHU Operational Control Spreadsheet Trainingniti860Încă nu există evaluări

- AHU Friction Loss CalculationsDocument4 paginiAHU Friction Loss CalculationsAdnan AttishÎncă nu există evaluări

- Centrifugal PumpsDocument24 paginiCentrifugal PumpsHari Babu DharmavarapuÎncă nu există evaluări

- AHU Fresh AirDocument2 paginiAHU Fresh AirSvetla Nikolova100% (1)

- Saiver AHUDocument12 paginiSaiver AHUNorsyafiqah Rozi100% (1)

- ASHRAE - HVAC-HospitalBook - Room Design PDFDocument4 paginiASHRAE - HVAC-HospitalBook - Room Design PDFalialavi2Încă nu există evaluări

- Part E - 2 - (HVAC) Engineering DesignDocument69 paginiPart E - 2 - (HVAC) Engineering Designkeya2020Încă nu există evaluări

- Dedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity ControlDocument39 paginiDedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity Controlhtanh100% (1)

- AHU Design GuideDocument37 paginiAHU Design Guidesachin100% (1)

- Preventive Maintenance of FDAS and Sprinkler SystemDocument6 paginiPreventive Maintenance of FDAS and Sprinkler SystemchocostarfishÎncă nu există evaluări

- 4 ACMV SystemsDocument293 pagini4 ACMV SystemsMorgan HengÎncă nu există evaluări

- Installation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreDocument25 paginiInstallation of Hvac System and Standby Generator Set For DFPC Naia T3 - Landside StoreScherraine Khrys CastillonÎncă nu există evaluări

- Fcu PipingDocument20 paginiFcu PipingRamadan RashadÎncă nu există evaluări

- تقرير تدريب صيفي لواء الدين مظفرDocument23 paginiتقرير تدريب صيفي لواء الدين مظفرlalaÎncă nu există evaluări

- TS-02 Ventilation Fans - Toilet & BasementDocument11 paginiTS-02 Ventilation Fans - Toilet & BasementPraveen KumarÎncă nu există evaluări

- AHU Design BasicsDocument29 paginiAHU Design BasicsHari Babu Dharmavarapu100% (2)

- VAV Terminal UnitsDocument15 paginiVAV Terminal Unitsckyee88Încă nu există evaluări

- Sample Problems ExergyDocument5 paginiSample Problems ExergySamer Al-MimarÎncă nu există evaluări

- CA - Commissioning - Guide - New - California - CostDocument84 paginiCA - Commissioning - Guide - New - California - Costlong minn2Încă nu există evaluări

- Design and Fabrication of Solar Powered Ice BoxDocument5 paginiDesign and Fabrication of Solar Powered Ice BoxesatjournalsÎncă nu există evaluări

- Heat Recovery From Industrial Compressed Air SystemsDocument4 paginiHeat Recovery From Industrial Compressed Air SystemsmawooaÎncă nu există evaluări

- Mullti-Story Building Water Supply Pumping: Roof TanksDocument7 paginiMullti-Story Building Water Supply Pumping: Roof TanksAjay Raju.bÎncă nu există evaluări

- Ventilation Design Sample For Locker Rooms and HACCPDocument10 paginiVentilation Design Sample For Locker Rooms and HACCPerickquinto100% (1)

- Staircase Pressurization System TestingDocument5 paginiStaircase Pressurization System TestingJavedÎncă nu există evaluări

- Im j1 Personnel Cooling Load Estimation 2014Document40 paginiIm j1 Personnel Cooling Load Estimation 2014Melvin SanchezÎncă nu există evaluări

- CP13 - 1999 MV and AC in BuildingDocument56 paginiCP13 - 1999 MV and AC in Buildingbozow bozowlÎncă nu există evaluări

- HVAC Design For Healthcare Facilities: Course No: M06-011 Credit: 6 PDHDocument60 paginiHVAC Design For Healthcare Facilities: Course No: M06-011 Credit: 6 PDHNelson VargasÎncă nu există evaluări

- Wkze AhuDocument18 paginiWkze AhuShahrukh AnsariÎncă nu există evaluări

- Introductory Sessions For The AC Design Guide, 2003 EditionDocument50 paginiIntroductory Sessions For The AC Design Guide, 2003 Editionener3333Încă nu există evaluări

- Lec 14 Mass TransferDocument36 paginiLec 14 Mass TransferWaseem abbas100% (1)

- VRF & DX Split Type ACU Testing MethodologyDocument1 paginăVRF & DX Split Type ACU Testing MethodologydamianÎncă nu există evaluări

- Catalogo ChillerDocument8 paginiCatalogo ChillerJoan Sebastian DazaÎncă nu există evaluări

- ASHRAE Journal - How To Design & Control Waterside Economizers-TaylorDocument7 paginiASHRAE Journal - How To Design & Control Waterside Economizers-TaylorsajuhereÎncă nu există evaluări

- VAV System Air BalancingDocument3 paginiVAV System Air BalancingShoukat Ali ShaikhÎncă nu există evaluări

- Technical Overview On AHUDocument12 paginiTechnical Overview On AHUJahidul IslamÎncă nu există evaluări

- Domestic - MTD SilentDocument6 paginiDomestic - MTD SilentVan Vinh NguyenÎncă nu există evaluări

- System Design Manual-DPCVDocument29 paginiSystem Design Manual-DPCVrama_easÎncă nu există evaluări

- 5-Corrective Maintenance FahuDocument2 pagini5-Corrective Maintenance FahuUmair LiaqatÎncă nu există evaluări

- Plantroom ExhaustDocument2 paginiPlantroom ExhaustDota NgÎncă nu există evaluări

- Air Handler Check ListDocument3 paginiAir Handler Check Listmnt6176100% (1)

- Kitchen Exhaust/Fresh Air Fan Sequence: To BMS For MonitoringDocument2 paginiKitchen Exhaust/Fresh Air Fan Sequence: To BMS For MonitoringShiyam SathiyajithÎncă nu există evaluări

- Dynair Ecology UnitDocument12 paginiDynair Ecology Unitrid100% (1)

- SKM Chiller Pre-Commissioning Check List Rev 20.06.2022Document2 paginiSKM Chiller Pre-Commissioning Check List Rev 20.06.2022Riju Scaria/EMD/QTRÎncă nu există evaluări

- Air Conditioning System: Section 15 / 1Document12 paginiAir Conditioning System: Section 15 / 1Ahmed Yousri AhmedÎncă nu există evaluări

- Hygienic Air Handling Unit Technical SpecificationsDocument7 paginiHygienic Air Handling Unit Technical SpecificationsMuhammad IlyasÎncă nu există evaluări

- Variable Frequency DrivesDocument6 paginiVariable Frequency DrivesMohammed Sayeeduddin100% (1)

- Moisture Load CalculationDocument2 paginiMoisture Load CalculationNguyễn Anh TuấnÎncă nu există evaluări

- Pharmaceutical Facility DesignDocument27 paginiPharmaceutical Facility Designmdalt9180Încă nu există evaluări

- Materaial For Question 3. - Cooling Load CLTD Example Ashrae PDFDocument5 paginiMateraial For Question 3. - Cooling Load CLTD Example Ashrae PDFkumarÎncă nu există evaluări

- Hvac Condensate Calculator: Difference in Specific Humidity gr/ft3Document4 paginiHvac Condensate Calculator: Difference in Specific Humidity gr/ft3Pradeep SukumaranÎncă nu există evaluări

- BTU Meter Installation GuideDocument1 paginăBTU Meter Installation GuidePraveen SagayarajÎncă nu există evaluări

- CO2 Sensor RoomDocument8 paginiCO2 Sensor RoomTrần Khắc ĐộÎncă nu există evaluări

- TSI PANDA 341 User ManualDocument38 paginiTSI PANDA 341 User ManualHernan RomeroÎncă nu există evaluări

- Table 7.1 Design Parameters: ANSI/ASHRAE/ASHE Standard 170 - 2008Document6 paginiTable 7.1 Design Parameters: ANSI/ASHRAE/ASHE Standard 170 - 2008mkkÎncă nu există evaluări

- Cooling Tower Makeup Water EstimationDocument3 paginiCooling Tower Makeup Water EstimationMuhammad NaeemÎncă nu există evaluări

- EF303 - Climate Systems - AHU SystemDocument175 paginiEF303 - Climate Systems - AHU SystemAizat Faliq100% (2)

- Comparision - VCD, NRD, FDDocument8 paginiComparision - VCD, NRD, FDMAZHAR ALIÎncă nu există evaluări

- Tsi Panda 341 User ManualDocument37 paginiTsi Panda 341 User Manuala k bÎncă nu există evaluări

- DX Split ChecklistDocument2 paginiDX Split ChecklistdesignselvaÎncă nu există evaluări

- Systemair DataCentre Cooling Solutions - v2 - Web PDFDocument15 paginiSystemair DataCentre Cooling Solutions - v2 - Web PDFkhamsone pengmanivongÎncă nu există evaluări

- Selecting Air Conditioners For EnclosureDocument7 paginiSelecting Air Conditioners For EnclosureErdinc KlimaÎncă nu există evaluări

- The Chiller Efficiency Depends On The Energy ConsumedDocument2 paginiThe Chiller Efficiency Depends On The Energy ConsumednkoviÎncă nu există evaluări

- HVAC Tips For Green BuildingsDocument201 paginiHVAC Tips For Green BuildingsCastoroil7Încă nu există evaluări

- Project - Review ThermoelectricDocument30 paginiProject - Review ThermoelectricAbhishek KumarÎncă nu există evaluări

- CLB20804 Mass Transfer 1 Assignment: DistillationDocument17 paginiCLB20804 Mass Transfer 1 Assignment: DistillationSiti Hajar MohamedÎncă nu există evaluări

- Kvpy SA StreamDocument4 paginiKvpy SA Streamaum vatsÎncă nu există evaluări

- ChE 313 Topic 1 EquilibriumDocument60 paginiChE 313 Topic 1 EquilibriumMikhoy RiveralÎncă nu există evaluări

- Topic 7. Equilibrium HL PP Pack, MarkschemeDocument17 paginiTopic 7. Equilibrium HL PP Pack, MarkschemeAylin KasaÎncă nu există evaluări

- Analysis of A Refrigeration Cycle With Coolprop PDFDocument6 paginiAnalysis of A Refrigeration Cycle With Coolprop PDFewan_73Încă nu există evaluări

- Epa Cert ColemanDocument40 paginiEpa Cert ColemanvldmrrrÎncă nu există evaluări

- K050 DMDocument1 paginăK050 DMvitor4santos_6Încă nu există evaluări

- Marley Perfomance Cooling Tower CTII-01ADocument4 paginiMarley Perfomance Cooling Tower CTII-01ApiolinwallsÎncă nu există evaluări

- Chapter 5 BME NotesDocument16 paginiChapter 5 BME Notesgamingendless003Încă nu există evaluări

- Me Ther - Act 5 Group2Document14 paginiMe Ther - Act 5 Group2ILAGAN ANNE FRANCINEÎncă nu există evaluări

- Thermocouple CompensatorDocument7 paginiThermocouple CompensatorArnab MondalÎncă nu există evaluări

- Hwi Schedule 2 Plus Rated Castables - gr520Document2 paginiHwi Schedule 2 Plus Rated Castables - gr520มิตร อันมา100% (1)

- ETA 00 32Km2.Ctl Bloc de NotasDocument2 paginiETA 00 32Km2.Ctl Bloc de NotasAníbal López PeñaÎncă nu există evaluări

- Bs 3 Unit 2 AC For Small BLGDocument26 paginiBs 3 Unit 2 AC For Small BLGRitika RituÎncă nu există evaluări

- Determination of Refrigerator COPDocument16 paginiDetermination of Refrigerator COPJermaineLambosoÎncă nu există evaluări

- TheoryDocument3 paginiTheoryAhmad SyamilÎncă nu există evaluări

- Condensers Control and Reclaim VOCsDocument3 paginiCondensers Control and Reclaim VOCsgpcshfÎncă nu există evaluări

- Boiler Safety BanglaDocument48 paginiBoiler Safety BanglaMazharul IslamÎncă nu există evaluări

- HEAT LOAD FORM (Computerized Computation) : Kasai, Ian G. S200Document4 paginiHEAT LOAD FORM (Computerized Computation) : Kasai, Ian G. S200Ian KasaiÎncă nu există evaluări

- Ch09 Diagrama de FasesDocument13 paginiCh09 Diagrama de FasesFERNANDO JOSE NOVAESÎncă nu există evaluări

- Phenomenological Theory of Phase Transition: Presented by Niratyaya DasDocument17 paginiPhenomenological Theory of Phase Transition: Presented by Niratyaya DasAndrews MelwinÎncă nu există evaluări

- Design and Parametric Investigation of An Ejector - R717 - AlexisDocument14 paginiDesign and Parametric Investigation of An Ejector - R717 - AlexisAdrianUnteaÎncă nu există evaluări

- CIPRIANI A5 Saldobrasati SCDocument4 paginiCIPRIANI A5 Saldobrasati SCSebastian MirandaÎncă nu există evaluări