Documente Academic

Documente Profesional

Documente Cultură

F-16 Landing Gear Simulation For Structural and Reliability Analyses

Încărcat de

mukeshdtTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

F-16 Landing Gear Simulation For Structural and Reliability Analyses

Încărcat de

mukeshdtDrepturi de autor:

Formate disponibile

1

F16 Landing Gear Simulation for Structural and Reliability Analyses

H.W. Ng*, G.K. Neo, X. W. Xie and W.X. Chu

Nanyang Technological University

School of Mechanical and Aerospace Engineering

50, Nanyang Avenue

Singapore 639798

*Corresponding author email: mhwng@ntu.edu.sg

Abstract

The minor deformations on an aircraft landing gear and the associated wheel well doors

structures due to wear and tear over time, and various loadings on them has been studied

to determine their effects on landing gear operation reliability. The aircraft landing gear

system uses micro-switches to feedback the exact position of the parts and they operate

with close tolerances. Minor deformations on the landing gear and its associated wheel

doors structures may cause small misalignment between the moving parts due to various

aerodynamic loadings. These deflections are large enough to affect the micro-switches in

flight but not easily detectable on ground during troubleshooting.

The structural components of the landing gears consists of: shock struts, drag and side

stays, actuator mechanisms, various linkages and pivot pins, up or down locks and

position sensors for cockpit indications. The wheel well and doors also have a large

number of parts such as alignment pins, hinges, locking mechanisms at points of

attachment and position sensors. These parts experiences cyclic and sometimes extreme

loads during service. Over time, due to in service wear and distortions, the functional

tolerances of critical pins, bushings and actuators degrade to affect the operability of the

landing gear mechanisms before scheduled overhaul are due.

Finite Element Method (FEM) and Hydraulic Simulation software together have the

capability to analyse localized detailed stresses and simulate possible small combined

relative movements of the various mechanisms due to wear and in service loadings of

landing gear components. This presentation describes the application of modeling and

analyses for in-service conditions to predict localized high stress areas or wear hot

spots and distortion modes of the landing gear and its associated wheel well doors

components.

A highly detailed CAD model of the structures of the F-16 port side main landing gear,

wheel well and doors have been constructed. The applicable loads besides the various

aerodynamic loads include air load, inertia loading due to mechanism acceleration and

deceleration and gyroscopic loads and induced by landing gear extension and retraction.

The loading cases also including vertical reaction landing loads and brake loads are

considered.

2

1. Introduction

The landing gear system is one of the aircraft most critical systems allowing it to taxi,

take off and land. A failure of the landing gear may result in aircraft on ground (AOG),

loss of mission and/or aircraft and endangerment of flight crew. All of the

aforementioned will also result in loss of operational capability. The F16 landing gear

configuration has a multitude of joints to enable it to be retracted into the fuselage wheel

well. The large number of joints necessitated more maintenance compared to other types

of landing gear. According to the past defect trends, common defects found include those

due to tolerance such as rigging problems, wear and tear in joints and tire worn to limit

and excessive stress causing shearing of bolt. Of this, a portion of the defects are related

to the main landing gear system looseness in pins and bushings of joints. It is therefore

essential to investigate the causes of the defects in the joints to improve the availability of

the aircraft and solve some of its reliability issues. Although the F16 landing gear is the

focus of the article, it is to an extent for illustrative purpose only, other aircraft are

equally amenable to the analysis methodology described.

2. Analysis Methodology

The main objectives of the methodology are:

2.1. Analyse the global stresses on a large model and extract local loads at bearings

for the load cases:

(i) aerodynamic drag due to relative air speed during take off and landing.

(ii) inertia force due to retraction or extending mass of gear through 90

o

within

a time of 6 seconds.

(iii) gyroscopic force, caused by rotating wheel swiveled through 90

o

to lie flat

in the wheel well. Although a prebrake is often applied to stop wheel

turning after takeoff, it takes a few seconds to be activated.

(iv) vertical reaction force, a landing load factor Nz of 3 was used.

(v) side reaction force caused by taxiing around a curve.

(vi) spin up force due to inertia when wheel spin up upon landing.

The operational cycles of the landing gear consists of the following phases:

Phase 1: Landing approach

Phase 2: Touchdown

Phase 3: Taxiing roll

Phase 4: Taxiing turn

Phase 5: Take-off

Each phase is a combination of the load cases selected from above. One of the most

severe phase encountered is during landing touch down which involves cases (i), (v)

and (vii). A landing gear system is designed comprehensively to withstand these

loads (refs. 1 and 2) and have adequate structural capacity for all combinations of

loads.

3

2.2. Analyse the inertia forces due to actuator actions during retraction and extension

for the local contact stress analysis at the connections at the ends of the actuator.

This is a more precise analysis including interaction with the hydraulic system.

2.3. Analyse the local stresses due to contact between the bushes and internal pins.

2.4. Determine the deformation of the main landing gear components under various

loadings.

2.5. Determine the possible wear characteristics on the critical areas under various

loadings.

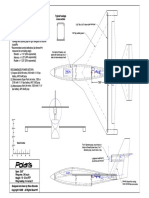

3. Landing Gear Description

The landing gear system of the F-16 is fuselage-mounted, tricycle-type and retractable.

The fuselage attachment is simply through three hard points, two main points carry in-

line hinging allowing the landing gear to swing outward i.e. sideways from the side of the

fuselage. The third point located forward carry the drag stay connection. The wheel path

swing forward and is swiveled to horizontally fit flat inside the fuselage. (An animation

is shown in the presentation). Figure 1 (ref. 3) illustrates the main components of the

main landing gear.

A hydraulic system provide hydraulic power for normal operation of the landing gear,

which include extension and retraction, landing gear door opening and closing, braking,

and nose wheel steering. The main landing gear and door subsystem has standard

landing gear structures on both sides of the fuselage. The main gear doors cover the

wheel wells during flight and are hydraulically opened and closed.

Figure 1: Main landing gear components (ref 3).

4

The tension strut assembly consists of the tension strut, the axle fitting, wheel positioning

collar and link. The drag brace assembly is a folding stay with internal locking

mechanism at the folding joint. It consists of an upper drag brace, a lower drag brace, and

a downlock mechanism. It connects to the tension strut wheel positioning collar at the

lower end. The upper drag brace connects to the aircraft structure in the forward part of

the wheel well. It houses the downlock actuator and the toggle assembly.

4. Finite Element Analyses

Finite element analysis is divided into two phases; namely a global phase and local phase.

The global phase analyses the entire landing gear subjected to the above mentioned

loading cases (i) to (v). The purpose of the global phase is to extract forces at the joints

to be later applied to the more finely meshed local component level i.e. the local phase.

Also, the global phase allows for the visualization of the motion during the extraction and

retraction. In this presentation, the wheel well structure and the attached doors are not

considered. They will be carried out in future to determine the in-flight deflections when

they are subjected to air and dynamic loads.

4.1. Motion Model of Landing Gear

The main structural components of the main landing gear and wheel well are drawn using

Pro-Engineer Wildfire 2.0 Software (ref.4). The main structural components include

main landing gear wheel well, main landing gear wheel well door, tension strut, shock

strut, upper and lower drag brace, axle, toggle, centrelink, wheel, link, collar, and

bushing. A detailed CAD drawing of the main landing gear, and wheel well and door

are as shown in figure 2 and 3. The file is imported in Visual Nastran which performed

the motion simulation and finite element analysis. The motion file is shown in the

presentation. Figures 4 to 5 shows various positions during the motion of the landing

gear and wheel well. For the motion model to work well, as is clearly shown in the

animation, all the linkages and tolerance have been accurately set.

Figure 2: CAD solid model of detached landing gear wheel well door.

5

Figure 3: Solid models for the wheel well and extended main landing gear .

Figure 4. Motion model showing the landing gear fully retracted into wheel well, note

the wheel swivel.

6

MLG in fully extended state Retraction of MLG

MLG is fully retracted state Closing of Wheel well door

MLG fully retracted and wheel well door fully closed

Figure 5. Stopped motion screen shots at different points in the retraction cycle.

4.2. Global Stress Analysis of Complete Landing Gear

The final mesh of the FE model is shown in figure 6. A relatively crude mesh is applied

to the solid model in order to reduce computational times. Furthermore, the purpose of

the global model is not to obtained accurate stresses but to derive the joint forces. It is

noted that despite this the stresses along the struts and stays are relatively accurate. The

joint forces are later extracted to be input into refined local component models which will

be elaborated in the next section to obtain the local contact stresses. For this phase of the

analysis, the landing gear is separately analysed by removing from the wheel well and the

three attachment hard points were rigidly fixed. Also all the joints are made rigid by

connecting pin to bush surfaces. Also, the landing gear is frozen into the fully extended

down and locked position.

7

Figure 6: Mesh of the main landing gear

4.3. Local Contact Stress Model

The contact stresses in pins and bushings are dependent on the joint geometry and

local forces applied. The local models are finite element models created for all joints

which consisted of the bush and pin rolling contact parts (ref 5). These were aimed at

obtaining the high contact stresses during load transfer between the landing gear

structures during various phases of operation. It is intended in this presentation to

describe one such joint at the connection between the gear actuator and the tension

strut. In creating this model, contact elements were used to model the contact

between the pin and bush. By imposing symmetry condition, the joint is reduced to a

half two dimensional model shown in figure 7, using finely meshed 2D solid

elements. The maximum force was applied to the lower collar of the bush assembly

while the pin was restrained by spring elements representing the stiffness of the pin

under 3 point loading. The contact elements connect the lower semicircular surfaces

of the bush and pin. Preliminary results are presented in section 6 because this work

is currently in progress.

8

Figure 7: The half two dimensional model of the bush to collar joint between gear

actuator and tension strut pin. Note: the structure undeformed shape is shown in

white.

5. Hydraulic flow modeling

Hydraulic flow modeling is employed to investigate the behaviour of the hydraulic

system in terms of pressure and flow rate when subjected to loads due to landing gear

extension and retraction (ref. 6). The analysis determine the load applied at the joints

during extension and retraction of the landing gear by hydraulic actuator. The actuation

force is dependent on the inertia of the combined structure and wheel assembly and the

hydraulic flow response. To determine these forces, the dynamic performance of the

landing gear hydraulics system during extension and retraction operations was examined

under various conditions using FLOWMASTER (ref. 7). The aircraft landing gear

extension and retraction may be simplified as a constant load on the hydraulic system.

However in order for the model to be applicable to actual landing gear extension and

retraction, the resultant load required is non-linear because of the changing position and

acceleration of the gear. It is the available pressure and flow rate delivered by the

hydraulic pump that will determine the acceleration and speed of extension or retraction

of the landing gear. On the other hand, the inertia of the landing gear resists the

acceleration imposed by the hydraulic actuator, which presented it as a dynamic load.

Thus, the inertia of the system interacts dynamically with the hydraulic system, resulting

in force balance giving rise to the final acceleration of the gear. Hence, simple kinematic

analysis cannot be used to determine the loads carried by the landing gear and wheel

doors during extension and retraction operations.

Figure 8 shows the hydraulic system model representing the complete system controlling

the actuation and locking of the gear and wheel well doors during extended and retracted

9

phase for the main gear. In the presentation, the important item is the landing gear

actuator (circled in figure 8). The completeness of the system is necessary if it is to

assess the capability of the system to cope with all the demands of the system.

Figure 8: Flowmaster model representing the hydraulic components including

actuators for the landing gear, wheel well door, uplock and downlock.

The Flowmaster simulation use the Visual Basic logic script to simulate the sequence

of movement of the Door Uplock, Door Actuator, Door Downlock, Landing Gear

Uplock, Landing Gear Actuator and Landing Gear Downlock, throughout both the

extension and retraction of the landing gear.

10

5.1. Analytical model for the LG actuator load

An analytical model shown in Figure 9 is required to derive the actuator force F

T

exerted by the hydraulic actuator in order to rotate the landing gear from a fully

extended position to a retracted position. The analysis of the applied force to

overcome gravity load and the inertia load ( i.e. the resistance by the mass M to

accelerate under applied force) gives the following equations.

Figure 9: Analytical model to derive the landing gear actuator load under applied

displacement, velocity and acceleration.

=

96 . 0

1

cos

2

1 AC

L

(1)

( )( )( )

( )( )

sin 96 . 0

2 L L

&

&

(2)

( )( )

( )( )( )

( )( )

+ =

sin 48 . 0

cos 48 . 0

&

& & & & &

L L L (3)

( )

=

AC

L

sin

8 . 0 sin (4)

I G T

F F F + = (5)

Finally, ( )

( )( )( )

sin . 12 sin

cos

& &

BC

T

L m

mg F (6)

A B

F

Y

F

F

X

90

mgx

mgy

mg

90

11

From the equations obtained above, it can be seen that with input values of L , L

&

andL

& &

,

all the unknown values in the F

T

equation can now be defined when substituted into

the ,

&

,

& &

and sin equations. To obtain the values of L , L

&

and L

& &

gauges (see figure

10 for the concept of gauges) are connected to the hydraulic cylinder inside the

Flowmaster network to measure the displacement, velocity and acceleration. A visual

basic script controller embedded the above equations to give the required actuator load.

The Flowmaster solver iterates at each time step until convergence i.e. force balance is

achieved in which the actuator output force equal to the script calculated value.

Figure 10: Concept of defining a load on an actuator by means of a controller (rectangle)

and gauges (circles). The controller contains Visual Basic Script that processes the data

from gauges to calculate the applied load on the actuator.

6. Results and Discussion

Two different finite element models have been created, the first being a global model

consisting of all the major structural components and the second the local model for

contact stress evaluation in specific joints. Although it is linear elastic problem, the

global model problem is prohibitively expensive in computational time despite

simplifications such as rigid joints. The non-linear gap element local model can be run

quickly and yielded quick results.

6.1. Results of the Global Stress Analysis

The contour plots of von-mises equivalent stress are shown in figures 11 and 12 for the

load case of vertical reaction during touchdown. The mesh refinement on the main

structure yielded adequate stress results. However, due to the rigid assumption on the

rotating joints, the stresses near to the pins and bushes are unreliable, so more detailed

analysis was carried out using gap elements (see local analysis results in next section).

12

Figure 11: Overall top and isometric view of von-mises equivalent stress for landing gear

during touchdown.

Figure 12: Von-mises stress contours on the wheel axle (left) and lower tension strut

(right) during touchdown.

6.2. Results of the Local Stress Analysis

Figure 13 shows the von-mises equivalent stress at the maximum load applied to the

actuator. The resulting contact stresses covers the area immediately below the pin. The

peak stress is considerably below the allowable stress for yielding indicating that the

13

structure can still support further increase in load. However high loads can cause

deformation and progressive enlargement of the clearance gap between the pin and bush

in other joints, leading to looseness or play in the joint. A more suitable measure of

ability to sustain further load is through strain limits or through deformation based

measure.

Figure 13: Von-mises equivalent stress at bushpin region.

6.3. Results of Hydraulic Analysis

The actuator loading calculated by the Flowmaster simulation with the use of controller

script is shown in figure 13. In-flight conditions such as aerodynamic drag on the landing

gear during extension/retraction have not been included. This and other scenarios may be

evaluated in future.

0 5 10 15 20 25 30 35 40

Time <s>

0

10000

20000

30000

40000

50000

60000

E

x

t

e

r

n

a

l

P

i

s

t

o

n

L

o

a

d

<

N

>

Figure 13: Plot of landing gear actuator load against time during extension (at 4 seconds)

and retraction (at 30 seconds) phases.

14

7. Conclusions

From the various loads and cases analysed, it can be seen that the bushing, pins, tension

strut and axle are components which experience higher stresses. The contact stress

between the pins and bushings are areas that experienced the highest von mises stresses

which currently under investigation. High contact stress is most likely to cause wear and

tear, result in minor deformation of the parts and thus further work are required to

develop a wear quantification model. FEM together with hydraulic simulation software

have been applied successfully to determine critical areas of the landing gear mechanism

in troubleshooting and identification of wear and distortion modes, as well as

understanding of the effects of the various loadings.

8. Acknowledgements

We are grateful to the Air Logistics Division, Republic of Singapore Air Force for the

opportunity to work on this project. We would like to thank their staff members

especially; Ed Pang (former Head) Cpt. Phillip Ong and Ms. Foo Wei Ling for their

assistance and arrangement for site visits.

9. References

1. Conway, H. G., Landing Gear Design, Chapman & Hall, London, 1958.

2. Currey, N. S., Aircraft Landing Gear Design: Principles and Practices, AIAA

Education Series, Washington, 1988.

3. F-16 Aircraft information (Courtesy of AeB, ALD RSAF).

4. Neo G.K. F16 Main Landing Gear Modelling and Simulation. School of

Mechanical and Aerospace Engineering, Nanyang Technological University.

Singapore.

5. Chu W.X. Finite Element Analysis of Contact Stress in Aircraft Landing Gear

Bush to Pin Bearings. School of Mechanical and Aerospace Engineering,

Nanyang Technological University. Singapore.

6. Xin X.W. Simulation of Behaviour of Aircraft Landing Gear Hydraulic System.

School of Mechanical and Aerospace Engineering, Nanyang Technological

University. Singapore.

7. Flowmaster User Manual (www.flowmaster.com).

S-ar putea să vă placă și

- Methods of Radar Cross-section AnalysisDe la EverandMethods of Radar Cross-section AnalysisJ.W. Jr. CrispinÎncă nu există evaluări

- Land GearDocument18 paginiLand Geardatav44Încă nu există evaluări

- Integrated Landing Gear System PDFDocument14 paginiIntegrated Landing Gear System PDFMario Di PisaÎncă nu există evaluări

- Design and Analysis of Modified Oleo Strut Shock Absorber System in Aircraft Landing GearDocument4 paginiDesign and Analysis of Modified Oleo Strut Shock Absorber System in Aircraft Landing GearMisbah PatelÎncă nu există evaluări

- crj-1000 FSB PDFDocument152 paginicrj-1000 FSB PDFSEBASTIAN SALAMANCA SERRAÎncă nu există evaluări

- General Dynamics F-16 Fighting Falcon-Tech SheetDocument19 paginiGeneral Dynamics F-16 Fighting Falcon-Tech Sheetrock67% (3)

- Aces II EjectionSeat RestorationDocument2 paginiAces II EjectionSeat RestorationEastWest IndustriesÎncă nu există evaluări

- Ejection SeatDocument5 paginiEjection SeatBlake Sheppard WingmanÎncă nu există evaluări

- $MP 015 25Document12 pagini$MP 015 25Mohammad Sli100% (1)

- Afi11 2f 16v3 - 944fwsup1Document21 paginiAfi11 2f 16v3 - 944fwsup1yoyoÎncă nu există evaluări

- Fim CRJ-200Document6 paginiFim CRJ-200David Camilo Limachi QuispeÎncă nu există evaluări

- F-16d BLK 50 AlbaceteDocument40 paginiF-16d BLK 50 AlbacetedimÎncă nu există evaluări

- Duracell Ultra SLA General Purpose Product Sheet ID3713Document2 paginiDuracell Ultra SLA General Purpose Product Sheet ID3713Caja FuegoÎncă nu există evaluări

- Overview of The Full Scale Durability Tests On F-35 Lightning II ProgramDocument21 paginiOverview of The Full Scale Durability Tests On F-35 Lightning II ProgrampuhumightÎncă nu există evaluări

- Service News Vol 30 No 2 2005 PDFDocument14 paginiService News Vol 30 No 2 2005 PDFangelo marraÎncă nu există evaluări

- To BMS1F 16CM 1Document207 paginiTo BMS1F 16CM 1Michael EvansÎncă nu există evaluări

- FS2004 - The Aircraft - CFG FileDocument5 paginiFS2004 - The Aircraft - CFG FiletumbÎncă nu există evaluări

- Matlab Based Software For Aircraft Structural Analysis and DesignDocument11 paginiMatlab Based Software For Aircraft Structural Analysis and DesignsaadÎncă nu există evaluări

- Analysis of Different Designed Landing Gears For A Light AircraftDocument4 paginiAnalysis of Different Designed Landing Gears For A Light AircraftarulmuruguÎncă nu există evaluări

- Esna CatalogDocument12 paginiEsna Catalogbalaji_jayadeva9546Încă nu există evaluări

- Aircraft Flight Control System ModellingDocument10 paginiAircraft Flight Control System ModellingMahmoudÎncă nu există evaluări

- Testing of The V-22 Flight Control SystemDocument16 paginiTesting of The V-22 Flight Control SystemliuhkÎncă nu există evaluări

- Fighters Performance EvaluationDocument35 paginiFighters Performance Evaluationavenger001Încă nu există evaluări

- Landing Gear Articolo Stress - 2 PDFDocument9 paginiLanding Gear Articolo Stress - 2 PDFAB1984Încă nu există evaluări

- ADS 33E RotorcraftDocument103 paginiADS 33E RotorcraftEmmanuelÎncă nu există evaluări

- Datasheet F404 FamilyDocument2 paginiDatasheet F404 FamilyhÎncă nu există evaluări

- Optimization: of Joined-Wing AircraftDocument10 paginiOptimization: of Joined-Wing AircraftSagar KulkarniÎncă nu există evaluări

- A Perspective On The Requirements and Design For Advanced Cruise MissilesDocument7 paginiA Perspective On The Requirements and Design For Advanced Cruise Missilesgrindormh53100% (1)

- Aircraft Conceptual Design - DraftDocument25 paginiAircraft Conceptual Design - DraftFrank Rubio CÎncă nu există evaluări

- Design and Analysis of Wing Fuselage AttachmentDocument6 paginiDesign and Analysis of Wing Fuselage AttachmentAbrahamJPulickalÎncă nu există evaluări

- Energy-Maneuverability MethodsDocument5 paginiEnergy-Maneuverability Methodsaleemsalman55Încă nu există evaluări

- A479056 PDFDocument37 paginiA479056 PDFkisariÎncă nu există evaluări

- Design and Analysis of The Main Assembly Jig For A Multirole Civilian Aircraft's Main DoorDocument6 paginiDesign and Analysis of The Main Assembly Jig For A Multirole Civilian Aircraft's Main DoorPrasanta Kumar SamalÎncă nu există evaluări

- Mil C 9084CDocument20 paginiMil C 9084CNick AlanenÎncă nu există evaluări

- Control Techniques of Tilt Rotor Unmanned Aerial Vehicle Systems A ReviewDocument18 paginiControl Techniques of Tilt Rotor Unmanned Aerial Vehicle Systems A Reviewchen4567Încă nu există evaluări

- Preliminary Design and Structural Analysis of Nose Landing Gear Oleo-Pneumatic Shock Absorber For Cessna 172S AircraftDocument56 paginiPreliminary Design and Structural Analysis of Nose Landing Gear Oleo-Pneumatic Shock Absorber For Cessna 172S AircraftTewelde WorkuÎncă nu există evaluări

- Design of Bomber Aircraft: Department of Aeronautical Engineering Gojan School of Business and TechnologyDocument51 paginiDesign of Bomber Aircraft: Department of Aeronautical Engineering Gojan School of Business and TechnologyThilak KumarÎncă nu există evaluări

- Accessory DrivesDocument2 paginiAccessory Drivesbassumudhol100% (1)

- Mettler Bernard 2000 1Document25 paginiMettler Bernard 2000 1sanjesh100% (1)

- 1107 02 MainDocument36 pagini1107 02 MainbganongÎncă nu există evaluări

- PC6 StolDocument14 paginiPC6 StolHtain WinÎncă nu există evaluări

- Flight Test #2 ReportDocument38 paginiFlight Test #2 ReportBsharrellÎncă nu există evaluări

- Section3 Flight TestDocument30 paginiSection3 Flight TestOmri AmayaÎncă nu există evaluări

- Polaris Assembly Drawing (Nontiled) PDFDocument1 paginăPolaris Assembly Drawing (Nontiled) PDFSavu DanielÎncă nu există evaluări

- Autopilot HistoryDocument20 paginiAutopilot HistoryKamesh PrasadÎncă nu există evaluări

- Dassault Falcon 000dx Ex StructureDocument30 paginiDassault Falcon 000dx Ex StructureAB1984Încă nu există evaluări

- Hondajet BrochureDocument17 paginiHondajet BrochureranoÎncă nu există evaluări

- Performance Envelopes For Preliminary Sizing of Aircraft StructuresDocument257 paginiPerformance Envelopes For Preliminary Sizing of Aircraft StructuresRaghunandan BSÎncă nu există evaluări

- Swept WingsDocument4 paginiSwept WingsAmal JoyÎncă nu există evaluări

- Thank You.: Texstars, Inc. TEL: 972.647.1366 FAX: 972.641.2800Document24 paginiThank You.: Texstars, Inc. TEL: 972.647.1366 FAX: 972.641.2800Balwinder GherhaÎncă nu există evaluări

- SONEX Do SNX-W07-02 Squaring and Skinning The Wings InstructionDocument2 paginiSONEX Do SNX-W07-02 Squaring and Skinning The Wings InstructionNZHHÎncă nu există evaluări

- Landing Gear Design and DevelopmentDocument12 paginiLanding Gear Design and DevelopmentC V CHANDRASHEKARAÎncă nu există evaluări

- Avions Marcel Dassault: Maintenance ManualDocument4 paginiAvions Marcel Dassault: Maintenance ManualSergio VázquezÎncă nu există evaluări

- Aerodynamic Design Schemes of The Inlet Guide VaneDocument9 paginiAerodynamic Design Schemes of The Inlet Guide VanedbÎncă nu există evaluări

- Weapons ChecklistDocument8 paginiWeapons ChecklistAlejandro VelezÎncă nu există evaluări

- Compass Module Application Note PDFDocument8 paginiCompass Module Application Note PDFrokbraihan2Încă nu există evaluări

- Multhopp Method NASADocument81 paginiMulthopp Method NASAGabriel PiresÎncă nu există evaluări

- 30 - Hansen 110607 MACC BriefingDocument25 pagini30 - Hansen 110607 MACC BriefingMuhammad FayyadhÎncă nu există evaluări

- A Review On Bird Strike Capability On Service-Age Aircraft CanopyDocument14 paginiA Review On Bird Strike Capability On Service-Age Aircraft Canopytomzee1Încă nu există evaluări

- Speed Palmistry: by Pt. V.R SharmaDocument32 paginiSpeed Palmistry: by Pt. V.R Sharmasiev29Încă nu există evaluări

- Stress Course For Liasion EngineersDocument240 paginiStress Course For Liasion EngineersiorquizaÎncă nu există evaluări

- A Matlab Program To Study Gust Loading On A Simple Aircraft ModelDocument83 paginiA Matlab Program To Study Gust Loading On A Simple Aircraft Modelmohammadrezamadadi100% (5)

- Javascript Cheat SheetDocument1 paginăJavascript Cheat Sheetdanielle leigh100% (4)

- Corrosion and PreventionDocument2 paginiCorrosion and PreventionmukeshdtÎncă nu există evaluări

- Catia V5 R16 - Assembly DesignDocument551 paginiCatia V5 R16 - Assembly DesignHarsh100% (33)

- HHHHDocument1 paginăHHHHmukeshdtÎncă nu există evaluări

- TtpodDocument1 paginăTtpodmukeshdtÎncă nu există evaluări

- Simulating Drop Tests in Solidworks Software: White PaperDocument7 paginiSimulating Drop Tests in Solidworks Software: White Paperakhilesh120Încă nu există evaluări

- Topic 4: Classification, Properties and Applications of S.G. and C.G.Iron S.G.IRONDocument11 paginiTopic 4: Classification, Properties and Applications of S.G. and C.G.Iron S.G.IRONsandeep kumarÎncă nu există evaluări

- Course Syllabus - SIT CollegeDocument82 paginiCourse Syllabus - SIT CollegenagasundaramÎncă nu există evaluări

- SpringerwiennewyorkDocument579 paginiSpringerwiennewyorkNhân NguyễnÎncă nu există evaluări

- Vibration Isolation - Mounting SystemsDocument67 paginiVibration Isolation - Mounting Systemsnaveenmg201100% (1)

- Load-Bearing Glass StructuresDocument16 paginiLoad-Bearing Glass StructuresSocheata channÎncă nu există evaluări

- Fatigue of MetalsDocument54 paginiFatigue of MetalsMuhammad UreedÎncă nu există evaluări

- 1.1.1 Reinforced Concrete: ReinforcementDocument18 pagini1.1.1 Reinforced Concrete: ReinforcementiffahÎncă nu există evaluări

- Water Hammer FormingDocument7 paginiWater Hammer FormingHariÎncă nu există evaluări

- BSC FYP Thesis, by GL - Abu Bakar MalikDocument73 paginiBSC FYP Thesis, by GL - Abu Bakar Malikshahid aliÎncă nu există evaluări

- Structural Maintenance DocksideDocument35 paginiStructural Maintenance DocksidefjalzinaÎncă nu există evaluări

- 5.04 Sai Singh KhongrymmaiDocument27 pagini5.04 Sai Singh Khongrymmaij krishnanÎncă nu există evaluări

- Rankawat - Nonlinear Seismic Evaluation of Confined Masonry Structures Using Equivalent Truss ModelDocument18 paginiRankawat - Nonlinear Seismic Evaluation of Confined Masonry Structures Using Equivalent Truss ModelSergio Alonso SunleyÎncă nu există evaluări

- Bolt Clamping ForceDocument4 paginiBolt Clamping ForceGary YuenÎncă nu există evaluări

- Structural MasonryDocument309 paginiStructural MasonryFanis88% (8)

- In 738 Alloy Strain CharacteristicsDocument7 paginiIn 738 Alloy Strain CharacteristicsJJÎncă nu există evaluări

- Cispm MSDocument8 paginiCispm MSDacianMÎncă nu există evaluări

- Knuckle Joints DesignDocument10 paginiKnuckle Joints DesignKvrd Prasad100% (1)

- Etabs 2013Document26 paginiEtabs 2013laurentiu_paciogluÎncă nu există evaluări

- 1 s2.0 S0921509304006136 MainDocument5 pagini1 s2.0 S0921509304006136 MainVenkatesh PandianÎncă nu există evaluări

- Design Optimization of IC Engine Rocker-Arm Using Taguchi Based Design of ExperimentsDocument5 paginiDesign Optimization of IC Engine Rocker-Arm Using Taguchi Based Design of ExperimentsWylieÎncă nu există evaluări

- David Roylance - Mechanics of MaterialsDocument357 paginiDavid Roylance - Mechanics of MaterialsHezi HilikÎncă nu există evaluări

- Experimental Evaluation of Bamboo Reinforced Concrete Slab PanelsDocument9 paginiExperimental Evaluation of Bamboo Reinforced Concrete Slab PanelsAlemayehu Darge100% (1)

- Report For Suspension Design - Group - 12Document47 paginiReport For Suspension Design - Group - 12member2 mtriÎncă nu există evaluări

- CENG 5503: Design of Steel & Timber StructuresDocument37 paginiCENG 5503: Design of Steel & Timber StructuresBern Moses DuachÎncă nu există evaluări

- Enhancement of ECCS Design RecomendationDocument252 paginiEnhancement of ECCS Design Recomendationnoambar1Încă nu există evaluări

- Fracture Mechanic ACIDocument71 paginiFracture Mechanic ACIHarun AlrasyidÎncă nu există evaluări

- Foundation Design For A High Bay Warehouse With A Steel Fibre Reinforced Concrete SlabDocument13 paginiFoundation Design For A High Bay Warehouse With A Steel Fibre Reinforced Concrete SlabEstetika chinta PertiwiÎncă nu există evaluări

- CIGRE Vol1Document141 paginiCIGRE Vol1reinscÎncă nu există evaluări

- ASTM D4014 - Elastomeric BearingDocument7 paginiASTM D4014 - Elastomeric BearingLai DieuÎncă nu există evaluări