Documente Academic

Documente Profesional

Documente Cultură

AA-SM-002 Torsion

Încărcat de

jowarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

AA-SM-002 Torsion

Încărcat de

jowarDrepturi de autor:

Formate disponibile

Doc: AA-SM-002

Revision: A

Page: 1

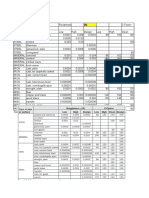

D.1.0.0 ROUND, SOLID, THICK AND THIN-WALLED SECTIONS

1. Solid round rod. Maximum torsional shear stress occurs at the outer surface r.

T = 10000 Nmm

r = 20.0 mm

J = 251327

mm

4

#NAME?

f

S

=

0.80

MPa

#NAME?

2. Thick-walled round tube. Maximum torsional shear stress occurs at the outer surface r

o

.

T = 10000 Nmm

r

o

= 20.0 mm

r

i

= 15.0 mm

J = 171806

mm

4

#NAME?

f

S

=

1.16

MPa

#NAME?

3. Thin-walled round tube. Maximum torsional shear stress occurs at the outer surface r.

T = 10000 Nmm

r = 20.0 mm

t = 5.00 mm

J = 251327

mm

4

#NAME?

f

S

=

0.80

MPa

#NAME?

r >> t

Prepared by: R. Abbott Date: April 2009 Checked by:___________________Date:__________

Standard Stress Methods

Torsion

r

r

o

r

i

r

t

Note: It is assumed that sufficient stiffness exists at the ends of the member so that a

section will maintain its geometric shape during torsion.

= 0.5 . p . r

4

= T . r / J

= 0.5 . p . (r

o

4

- r

i

4

)

= T . r

o

/ J

= 2 . p . t . r

3

= T . r / J

Doc: AA-SM-002

Revision: A

Page: 2

D.2.0.0 RECTANGULAR, SOLID AND THIN-WALLED SECTIONS

4. Solid rectangular or square bar. Maximum torsional shear stress occurs at point c .

T = 10000 Nmm

a = 50.0 mm

b = 30.0 mm

k

1

= 0.2087 #NAME?

J = 281737

mm

4

#NAME?

k

2

= 204.0 mm #NAME?

f

S

=

0.91

MPa

#NAME?

a >= b

5. Thin-walled rectangular or square bar with constant wall thickness.

T = 10000 Nmm

a = 50.0 mm

b = 30.0 mm

t = 2.00 mm

J = 95070

mm

4

#NAME?

f

S

=

1.86

MPa

#NAME?

6. Thin-walled rectangular or square bar with varying wall thickness.

T = 10000 Nmm

a = 50.0 mm

b = 30.0 mm

t

1

= 2.00 mm

t

2

= 1.50 mm

J = 85942

mm

4

f

S1

=

1.84

MPa

#NAME?

f

S2

=

2.45

MPa

#NAME?

J = 2t

1

t

2

(a - t

2

)

2

(b - t

1

)

2

/[(b - t

1

)t

1

+ (a - t

2

)t

2

]

Prepared by: R. Abbott Date: April 2009 Checked by:___________________Date:__________

Standard Stress Methods

Torsion

b

a

t

b

a

t

2

t

1

Note: It is assumed that sufficient stiffness exists at the ends of the member so that a

section will maintain its geometric shape during torsion.

b

a

c

c

= 1 / 3 - 0.21 . (b / a) . (1 - [b

4

] / [12 . a

4

])

= k

1

. a . b

3

= 3 . a + 1.8 . b

= T . k

2

/ (a

2

. b

2

)

= 2 . t . ([a - t]

2

) . ([b - t]

2

) / (a + b - 2 . t)

= T / (2 . t . [a - t] . [b - t])

= T / (2 . t

1

. [a - t

2]

. [b - t

1]

)

= T / (2 . t

2

. [a - t

2]

. [b - t

1]

)

Doc: AA-SM-002

Revision: A

Page: 3

D.3.0.0 OTHER SHAPES

7. Solid elliptical section. Maximum torsional shear stress occurs at point c .

T = 10000 Nmm

a = 50.0 mm

b = 30.0 mm

J = 3118493

mm

4

#NAME?

f

S

=

0.14

MPa

#NAME?

a >= b

8. Thin-walled elliptical tube with constant wall thickness.

T = 10000 Nmm

a = 50.0 mm

b = 30.0 mm

t = 1.50 mm

J = 514315

mm

4

#NAME?

f

S

=

0.71

MPa

#NAME?

a and b to midpoint of t

9. Solid hexagonal rod. Maximum torsional shear stress at point c , mid-point of each side.

T = 10000 Nmm

d = 50.0 mm

J = 751875

mm

4

#NAME?

f

S

=

0.43

MPa

#NAME?

10. Solid triangular rod. Maximum torsional shear stress at point c , mid-point of each side.

T = 10000 Nmm

a = 50.0 mm

J = 135316

mm

4

#NAME?

f

S

=

1.60

MPa

#NAME?

Prepared by: R. Abbott Date: April 2009 Checked by:___________________Date:__________

Standard Stress Methods

Torsion

c

c

b

a

b

a

c

d

c

a

= p . a

3

. b

3

/ (a

2

+ b

2

)

= 2 . T / (p . a . b

2

)

= 4 . p . a

2

. b

2

. t / (2 . [a

2

+ b

2

])

0.5

= T / (2 . p . a . b . t)

= 0.1203 . d

4

= T / (0.188 . d

3

)

= a

4

. 3

0.5

/ 80

= 20 . T / a

3

Doc: AA-SM-002

Revision: A

Page: 4

D.3.0.0 OTHER SHAPES (continued)

11. Circular section with one side flattened. Maximum torsional shear stress at point c .

T = 10000 Nmm

r = 20.0 mm

a = 30.0 degrees

z = 0.13 #NAME?

k

1

=

1.5708 see note

k

2

=

1.2449 see note

a =< 90

o

J = 251328

mm

4

#NAME?

f

S

=

1.00

MPa

#NAME?

Note: The coefficients k

1

and k

2

are calculated from the following equations:

Reference: Roark and Young, 6th edition, page 349, case 7

12. Circular section with opposite sides flattened. Maximum shear stress at point c .

T = 10000 Nmm

r = 20.0 mm

h = 7.3 mm

z = 0.64 #NAME?

k

3

=

0.1919 see note

k

4

=

0.2715 see note

J = 30698

mm

4

h/r > 0.2 #NAME?

f

S

=

4.60

MPa

h/r > 0.4

#NAME?

Note: The coefficients k

3

and k

4

are calculated from the following equations:

Reference: Roark and Young, 6th edition, page 350, case 9

Prepared by: R. Abbott Date: April 2009 Checked by:___________________Date:__________

Standard Stress Methods

Torsion

r

c

2a

r

c

c

h

= 1 - cos(radians[a])

= k

1

. r

4

= T / (k

2

. r

3

)

= (r - h) / r

= k

3

. r

4

= T / (k

4

. r

3

)

Doc: AA-SM-002

Revision: A

Page: 1

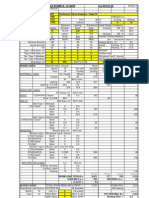

D.1.0.0 THICK-WALLED OPEN SECTIONS

References:

[1] Boeing Design Manual BDM-6400

[2] Bombardier Strength Manual

is the peak stress at point 'c' Equation 1

Equation 2

Equation 3

The terms in Equation 3 for the coefficient 'n' are:

D = diameter of the largest inscribed circle

r = fillet radius (use a positive value for r )

f = angle between segments in radians

A = cross sectional area of the segment, not the entire section

Prepared by: R. Abbott Date: April 2009 Checked by:___________________Date:__________

Standard Stress Methods

Torsion

Sections with r / t > 2.5 (ratio of the fillet radius to leg thickness) are considered thick-

walled sections.

To determine torsional constants of complex shapes, open sections are separated

into tee and/or angle segments as shown below. Torsional constant J is a sum of the

constants of constituent segments, and it is calculated from Equation 2.

In these sections the stress concentration at the fillet radius is taken into consideration.

The maximum torsional shear stress occurs at the fillet radius.

Doc: AA-SM-002

Revision: A

Page: 2

D.1.0.0 THICK-WALLED OPEN SECTIONS (continued)

1. Angle Segment

t

1

= 0.12 mm t

1

>= t

2

t

2

= 0.10 mm

b

1

= 1.10 mm

b

2

= 0.85 mm

r = 0.10 mm

f = 1.57 radians

Segment Area Equation 4

Diameter of

the Largest In- Equation 5

-scribed Circle

Coefficient Equation 6

Coefficient Equation 7

Coefficient Equation 8

Torsional Constant Equation 9

A = 0.219

mm

2

D = 0.164 mm

a = 0.111

n = 0.195 mm

K

1

= 0.00059

mm

4

K

2

= 0.00027

mm

4

J = 0.00094 mm

4

Prepared by: R. Abbott Date: April 2009 Checked by:___________________Date:__________

Standard Stress Methods

Torsion

Doc: AA-SM-002

Revision: A

Page: 3

D.1.0.0 THICK-WALLED OPEN SECTIONS (continued)

2. Tee Segment

t

1

= 0.12 mm

t

2

= 0.10 mm

b

1

= 1.10 mm

b

2

= 0.85 mm

r = 0.10 mm

f = 1.57 radians

Segment Area Equation 10

Equation 11

Coefficient for t

1

>= t

2

Equation 12

Coefficient for t

2

>= t

1

Equation 13

A = 0.221

mm

2

#NAME?

D = 0.190 mm #NAME?

a = 0.194 #NAME?

n = 0.231 mm #NAME?

K

1

= 0.00059

mm

4

#NAME?

K

2

= 0.00027

mm

4

#NAME?

J = 0.00112 mm

4

#NAME?

Prepared by: R. Abbott Date: April 2009 Checked by:___________________Date:__________

Diameter of the Largest

Inscribed Circle

Standard Stress Methods

Torsion

Doc: AA-SM-002

Revision: A

Page: 4

D.1.0.0 THICK-WALLED OPEN SECTIONS (continued)

3. Complex Section - Example

Section 1 - Angle

Section 2 - Tee

Segment 1 Segment 2 Segment 3 Segment 4

t

ype

= Angle Tee None None mm

t

1

= 0.12 0.12 0.00 0.00 mm

t

2

= 0.10 0.10 0.00 0.00 mm

b

1

= 1.10 1.10 0.00 0.00 mm

b

2

= 0.85 0.85 0.00 0.00 mm

r = 0.10 0.10 0.00 0.00 radians

f = 1.57 1.57 0.00 0.00

A = 0.219 0.221 0.00 0.00

mm

2

D = 0.164 0.190 0.00 0.00 mm

a = 0.111 0.194 0.00 0.00

n = 0.195 0.231 0.00 0.00 mm

K

1

= 0.00059 0.00059 0.00 0.00

mm

4

K

2

= 0.00027 0.00027 0.00 0.00

mm

4

J

i

=

0.00094 0.00112

0.00 0.00

mm

4

T

i

=

13.7 16.3 0.0 0.0

Nmm

T in the table above is the amount of torque on each segment, and it is a direct ratio

of the segment J to the total J .

J = 0.0021

mm

4

Torsional Constant of the Entire Section

T

o

= 30 Nmm Applied Torque

Torsional shear stresses are calculated from Equation 1:

f

SA

= 2838 MPa Shear Stress at Point A

f

SB

= 3360 MPa Shear Stress at Point B

Prepared by: R. Abbott Date: April 2009 Checked by:___________________Date:__________

Standard Stress Methods

Torsion

S-ar putea să vă placă și

- Piping Class ExampleDocument302 paginiPiping Class Examplejowar75% (4)

- Coordinate Reference SystemsDocument120 paginiCoordinate Reference SystemsBenciu Florin ValentinÎncă nu există evaluări

- Blast Fragmentation Appraisal - Means To Improve Cost-Effectiveness in MinesDocument14 paginiBlast Fragmentation Appraisal - Means To Improve Cost-Effectiveness in Minespartha das sharma100% (1)

- Static CalculationDocument4 paginiStatic CalculationAshique Muhammed T MÎncă nu există evaluări

- Sewer Pumpstation Design Calculations For AlqiDocument7 paginiSewer Pumpstation Design Calculations For AlqiTahirJabbarÎncă nu există evaluări

- Heatload Calculation - Kirloskar Ferrous - UPS RoomDocument6 paginiHeatload Calculation - Kirloskar Ferrous - UPS Roomsenthil kumarÎncă nu există evaluări

- Duct CalculationsDocument38 paginiDuct CalculationsDilnesa EjiguÎncă nu există evaluări

- Cálculo Flange ASME VIII 1 Apendice 2Document10 paginiCálculo Flange ASME VIII 1 Apendice 2jowarÎncă nu există evaluări

- Louver and Pump SizeDocument1 paginăLouver and Pump SizeShabeer HamzaÎncă nu există evaluări

- SmokeExtraction From BELIMODocument1 paginăSmokeExtraction From BELIMOswsw2011100% (1)

- De Silva Clarence W Sensors and Actuators Control Systems InstrumentationDocument346 paginiDe Silva Clarence W Sensors and Actuators Control Systems Instrumentationjhon jairoÎncă nu există evaluări

- FM-200 CalcDocument2 paginiFM-200 CalcRamiAl-fuqahaÎncă nu există evaluări

- Fire Pump Test Diesel 2012Document3 paginiFire Pump Test Diesel 2012Diego Anaya100% (1)

- Fire EquationsDocument148 paginiFire EquationsArgile-assholeÎncă nu există evaluări

- (Joseph Keddie, Alexander F. Routh) Fundamentals of Latex Film FormationDocument299 pagini(Joseph Keddie, Alexander F. Routh) Fundamentals of Latex Film FormationCarlos Alberto Cordoba50% (2)

- ASTM D7625 - 10 Standard Test Method For Laboratory Determination of AbrasiveneDocument2 paginiASTM D7625 - 10 Standard Test Method For Laboratory Determination of AbrasiveneNatoya Adams0% (1)

- Smoke & Ventilation CalculationsDocument9 paginiSmoke & Ventilation CalculationsMarcin NowelÎncă nu există evaluări

- CPD/VRF PresentationDocument23 paginiCPD/VRF PresentationthibinÎncă nu există evaluări

- Staircase PressurisationDocument7 paginiStaircase PressurisationYusuf RampÎncă nu există evaluări

- 18 Visibility Through Smoke Sup1Document4 pagini18 Visibility Through Smoke Sup1daveleyconsÎncă nu există evaluări

- AMRL Soil WorksheetsDocument88 paginiAMRL Soil WorksheetsMinh An Tran100% (1)

- Ducts Pressure Losses Board: Project: SITE: Al Madinah Duct Name: Serving: (MT) General DataDocument1 paginăDucts Pressure Losses Board: Project: SITE: Al Madinah Duct Name: Serving: (MT) General DataahmedÎncă nu există evaluări

- Window Free Area CalculationDocument3 paginiWindow Free Area CalculationNaveen KarkiÎncă nu există evaluări

- David R. Storm (Auth.) - Winery Utilities - Planning, Design and Operation-Springer US (2001) PDFDocument456 paginiDavid R. Storm (Auth.) - Winery Utilities - Planning, Design and Operation-Springer US (2001) PDFMaría Fernanda AravenaÎncă nu există evaluări

- StairCase Press-Eclipse - (Printed 29.01.2020) PDFDocument3 paginiStairCase Press-Eclipse - (Printed 29.01.2020) PDFmhmdjdgmailcomÎncă nu există evaluări

- NY1395 Smoke-Management GeidelDocument69 paginiNY1395 Smoke-Management GeidelTrong Hieu NguyenÎncă nu există evaluări

- Stair Case Pressurization Unit Software: The Amount of CFMDocument17 paginiStair Case Pressurization Unit Software: The Amount of CFMMohammed Hassan Mohiuddin KhanÎncă nu există evaluări

- Warning SphereDocument3 paginiWarning SphereantaryamisinghÎncă nu există evaluări

- Yssignal Product Brochure Catelogue 2016Document43 paginiYssignal Product Brochure Catelogue 2016邓欲国Încă nu există evaluări

- Apollo and Apollo ATI Natural Smoke VentilatorDocument2 paginiApollo and Apollo ATI Natural Smoke VentilatoradnanÎncă nu există evaluări

- 16 Duct Suspension AdsDocument46 pagini16 Duct Suspension Adssutejo tejoÎncă nu există evaluări

- Lighting Power Densities - ASHREA Load Limit PDFDocument2 paginiLighting Power Densities - ASHREA Load Limit PDFAlaa FaiqÎncă nu există evaluări

- Car Park Ventilation القواسمةDocument2 paginiCar Park Ventilation القواسمةAla ShakerÎncă nu există evaluări

- Stair Case Pressurization Calculation Class ADocument8 paginiStair Case Pressurization Calculation Class AfisplÎncă nu există evaluări

- Smoke Ventilation CalculationDocument4 paginiSmoke Ventilation CalculationJunaid MateenÎncă nu există evaluări

- Lighting Calculation 10Document1 paginăLighting Calculation 10Hansika RajapakshaÎncă nu există evaluări

- Integration - H VAC Fans and Smoke Control - Control EngineeringDocument5 paginiIntegration - H VAC Fans and Smoke Control - Control EngineeringMohamedAhmedFawzyÎncă nu există evaluări

- Air Changes Per Hour (ACH) and Time in Minutes Required For RemovalDocument1 paginăAir Changes Per Hour (ACH) and Time in Minutes Required For RemovalalbrgmailÎncă nu există evaluări

- FESCO Fire PumpsDocument24 paginiFESCO Fire PumpsZeeshan HameedÎncă nu există evaluări

- Air Changes Per HourDocument5 paginiAir Changes Per Hourاحمد الجزار2007Încă nu există evaluări

- Lighting Calculation 9Document1 paginăLighting Calculation 9Hansika RajapakshaÎncă nu există evaluări

- Sgps Id01 CalcDocument48 paginiSgps Id01 Calcsaroat moongwattanaÎncă nu există evaluări

- Smoke & Ventilation Calculations-MechDocument1 paginăSmoke & Ventilation Calculations-Mechsirovinho100% (1)

- Generator Calculation 01Document1 paginăGenerator Calculation 01Mahmoud FakhereddinÎncă nu există evaluări

- Flow Characteristics:: B. Pressure Loss (Head Loss, PressureDocument4 paginiFlow Characteristics:: B. Pressure Loss (Head Loss, PressureLily NurdianaÎncă nu există evaluări

- Seismic Calc ProcedureDocument1 paginăSeismic Calc Procedurezahoor100% (1)

- Kooltherm K18 Insulated PlasterboardDocument14 paginiKooltherm K18 Insulated PlasterboardEdwin ScallyÎncă nu există evaluări

- Lighting Calculation 2Document1 paginăLighting Calculation 2Hansika RajapakshaÎncă nu există evaluări

- VS Lab & Office - Hvac Boq 29032016Document16 paginiVS Lab & Office - Hvac Boq 29032016Ganesh RamÎncă nu există evaluări

- Al Gharafa Sports Club Irrigation Schedule RevisedDocument1 paginăAl Gharafa Sports Club Irrigation Schedule RevisedmansidevÎncă nu există evaluări

- Grease Interceptor Sizing Tool 22APR08Document3 paginiGrease Interceptor Sizing Tool 22APR08Ramil SerdanÎncă nu există evaluări

- AE7E33 Excel Template Forced Convection H T Coeff Turb Pipe Flow Si UnitsDocument3 paginiAE7E33 Excel Template Forced Convection H T Coeff Turb Pipe Flow Si UnitsjnmanivannanÎncă nu există evaluări

- Fan Noise EstimateDocument5 paginiFan Noise EstimateBen ClackÎncă nu există evaluări

- Circular Duct Attenuators: Performance Data - Open TypeDocument3 paginiCircular Duct Attenuators: Performance Data - Open TypePaul ShermanÎncă nu există evaluări

- ASHRAE SWFL Chapter - Library Archive: HistoryDocument1 paginăASHRAE SWFL Chapter - Library Archive: HistoryHarendra kumarÎncă nu există evaluări

- MAKRO MYANMAR ACMV PDF DWG PDFDocument21 paginiMAKRO MYANMAR ACMV PDF DWG PDFHnin Pwint100% (1)

- RTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20Document1 paginăRTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20alvinchuanÎncă nu există evaluări

- Lining DuctworkDocument4 paginiLining Ductworkthanh_79Încă nu există evaluări

- Boq Fans Maurer b5 b8Document6 paginiBoq Fans Maurer b5 b8georgianconstantinÎncă nu există evaluări

- ASLI 02 Supply Air Grilles Set - AIR ConditioningDocument21 paginiASLI 02 Supply Air Grilles Set - AIR ConditioningAminul Hassan50% (2)

- Return Air Square: Ceiling DiffuserDocument1 paginăReturn Air Square: Ceiling DiffuserEnak Cenir100% (1)

- A&E Construction Docs 2211Document12 paginiA&E Construction Docs 2211Winston D. RichardsÎncă nu există evaluări

- Sealant - 1st Acrylic A-700 MSDSDocument6 paginiSealant - 1st Acrylic A-700 MSDSBozow BongÎncă nu există evaluări

- Plumbing Hangers SupportsDocument27 paginiPlumbing Hangers Supportsronaldbhall1755Încă nu există evaluări

- Ventilation DesignDocument4 paginiVentilation DesignPhyu Mar Thein KyawÎncă nu există evaluări

- Kruger - Propeller FanDocument2 paginiKruger - Propeller FanKok WaiÎncă nu există evaluări

- Designing of Ground Level Water Tank 2003 FormatDocument4 paginiDesigning of Ground Level Water Tank 2003 Formatajith chandranÎncă nu există evaluări

- Mekanika Material Latihan Soal Untuk Jurusan Teknik FisikaDocument17 paginiMekanika Material Latihan Soal Untuk Jurusan Teknik FisikaEsther Kezia SimanjuntakÎncă nu există evaluări

- Princess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCDocument3 paginiPrincess Noura Bint Abdulrahman University For Women Project Joint Venture El Seif/CCCjowarÎncă nu există evaluări

- B31.3 Process Piping Code PD643 Updated October 2012Document3 paginiB31.3 Process Piping Code PD643 Updated October 2012jowarÎncă nu există evaluări

- AA-SM-004-003 Bolt Group - 3 - 3D Bolt Group Short VersionDocument4 paginiAA-SM-004-003 Bolt Group - 3 - 3D Bolt Group Short VersionjowarÎncă nu există evaluări

- Pipeline Tie-In Spoolpiece MeasurementsDocument4 paginiPipeline Tie-In Spoolpiece MeasurementsjowarÎncă nu există evaluări

- AA-SM-219 Tools - Various Mass Balances - Linear and RotationalDocument22 paginiAA-SM-219 Tools - Various Mass Balances - Linear and RotationaljowarÎncă nu există evaluări

- AA-SM-224 Tools - Intersection of Line and A CircleDocument18 paginiAA-SM-224 Tools - Intersection of Line and A CirclejowarÎncă nu există evaluări

- AA-SM-004-004 Bolt Group - 1 - 2D Bolt Group - 2 Bolts - Multiple CasesDocument3 paginiAA-SM-004-004 Bolt Group - 1 - 2D Bolt Group - 2 Bolts - Multiple CasesjowarÎncă nu există evaluări

- AA-SM-001-001 Section Properties - Seat TracksDocument2 paginiAA-SM-001-001 Section Properties - Seat TracksjowarÎncă nu există evaluări

- AA SM 008ContactStressesDocument3 paginiAA SM 008ContactStressesjowarÎncă nu există evaluări

- AA-SM-001-003 Section Properties - Node BasedDocument2 paginiAA-SM-001-003 Section Properties - Node BasedjowarÎncă nu există evaluări

- AA SM 001 002 Section Properties GeneralDocument4 paginiAA SM 001 002 Section Properties GeneraljowarÎncă nu există evaluări

- AA SM 031RambergOsgoodappliedtoCozzoneDocument1 paginăAA SM 031RambergOsgoodappliedtoCozzonejowarÎncă nu există evaluări

- AA SM 024ShearinMulti CelledsectionsduetoshearandtorsionDocument8 paginiAA SM 024ShearinMulti CelledsectionsduetoshearandtorsionjowarÎncă nu există evaluări

- AA-SM-025-002 Shape Factors of Complex ShapesDocument12 paginiAA-SM-025-002 Shape Factors of Complex ShapesjowarÎncă nu există evaluări

- AA SM 019 BendingDocument18 paginiAA SM 019 BendingjowarÎncă nu există evaluări

- Bio-Rad NGC QuestDocument24 paginiBio-Rad NGC QuestDivya DharshiniÎncă nu există evaluări

- Project of Chemistry 11thDocument9 paginiProject of Chemistry 11thNitin ChandwaniÎncă nu există evaluări

- Sma 2271: Ordinary Differential Equations: Course ContentDocument106 paginiSma 2271: Ordinary Differential Equations: Course Contentibrahim salimÎncă nu există evaluări

- Physical Chemistry Chapter 10 1 AtkinsDocument32 paginiPhysical Chemistry Chapter 10 1 AtkinswenÎncă nu există evaluări

- ZornDocument6 paginiZornMarius DiaconuÎncă nu există evaluări

- Bernoulli's Principle PDFDocument4 paginiBernoulli's Principle PDFAniruddha BoseÎncă nu există evaluări

- Section 02610 - Prime CoatDocument26 paginiSection 02610 - Prime Coatmail3shenÎncă nu există evaluări

- 01 GeoStrucAnal Cylinder Elastic PDFDocument12 pagini01 GeoStrucAnal Cylinder Elastic PDFSiddhant KaushikÎncă nu există evaluări

- Borang Kontrak Latihan Murid FORM 4 TERKINIDocument4 paginiBorang Kontrak Latihan Murid FORM 4 TERKINISafrah JamriÎncă nu există evaluări

- Research On Application of Infinite Series (1st Sem Project)Document26 paginiResearch On Application of Infinite Series (1st Sem Project)Soumyajit BhattacharyaÎncă nu există evaluări

- BHU Uet Syllabus ... PDF 2019Document3 paginiBHU Uet Syllabus ... PDF 2019Mohit RajpootÎncă nu există evaluări

- Science States of Matter JeopardyDocument34 paginiScience States of Matter Jeopardyapi-254830778Încă nu există evaluări

- Manual Ventas Teja Gravillada DecraDocument4 paginiManual Ventas Teja Gravillada Decrabproano3992Încă nu există evaluări

- Flash Point by Tag Closed Cup Tester: Standard Test Method ForDocument12 paginiFlash Point by Tag Closed Cup Tester: Standard Test Method ForAngel MonteroÎncă nu există evaluări

- Momentum, Impulse and Energy: Pre-Reading: KJF 9.1 and 9.2Document27 paginiMomentum, Impulse and Energy: Pre-Reading: KJF 9.1 and 9.2lady jazzmineÎncă nu există evaluări

- Asha - BeraDocument36 paginiAsha - BeraCarito Rivas100% (1)

- Omnisens.comDocument3 paginiOmnisens.commedesarrolloÎncă nu există evaluări

- Virtual Artificial Sensor Technique For Functional Electrical StimulationDocument11 paginiVirtual Artificial Sensor Technique For Functional Electrical StimulationCarlos Alexandre FerriÎncă nu există evaluări

- CE 343-Lab-Summer-2012 From DR Khaled GuzlanDocument62 paginiCE 343-Lab-Summer-2012 From DR Khaled GuzlanfarisÎncă nu există evaluări

- Chemistry Syllabus Mapping IITJAM NET GATE BSC MSCDocument39 paginiChemistry Syllabus Mapping IITJAM NET GATE BSC MSCAshwani KumarÎncă nu există evaluări

- DFT Calculations of Molecular Magnetic Properties of Coordination CompoundsDocument23 paginiDFT Calculations of Molecular Magnetic Properties of Coordination CompoundslitespaklaÎncă nu există evaluări

- Cassini Finds Molecular Hydrogen in The Enceladus Plume: Evidence For Hydrothermal ProcessesDocument6 paginiCassini Finds Molecular Hydrogen in The Enceladus Plume: Evidence For Hydrothermal ProcessesJulianDavidPulidoÎncă nu există evaluări

- Tutorial 1 - 2nd Law and Gas Turbine CyclesDocument2 paginiTutorial 1 - 2nd Law and Gas Turbine CyclesumarÎncă nu există evaluări