Documente Academic

Documente Profesional

Documente Cultură

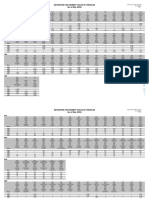

FMC Trim Model Seats Purchasing Version Control: Date Initiator Updates Made

Încărcat de

Jennifer MartinTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FMC Trim Model Seats Purchasing Version Control: Date Initiator Updates Made

Încărcat de

Jennifer MartinDrepturi de autor:

Formate disponibile

FMC Trim Model

Seats Purchasing

Version Control

Version Date Initiator Updates made

(initial version by JT)

05.25.07 J Trupiano General aesthetic changes for workbook, addition of drop down lists, addition of

Embroidery option in sew times, change stops from 11" to 7" per stop, addition of

ED&T worksheet with set rate of $55/hour. Change from 100% utilization to 85%

utilization.

V.2 06.05.07 J Trupiano Formula error in model corrected for IB freight to capture all incoming materials less

leather (as stated in the model instructions).

V.2a 06.20.07 J Trupiano Added protected cells for Ford model values.

V.2b 06.28.07 J Trupiano Statement added to instructions regarding use of 85% material utilization only as

placeholder and that actual utilizations will be used once those are determined.

V.2c 08.22.07 J Trupiano Statement added to instructions to clarify method to determine material utilization.

Added version control worksheet.

V.2d 09.27.11 M Falk Added Vinyl as a Ford Directed Material, General Maintenance items, Adjusted

mark-up values, sew minutes, compliled list of standard purchased components.

V.2e 01.09.12 M Falk Added tables & drop down lists. Ammended Directed Materials Page. Deleted 85%

utilization. Updated Markups.

V.2f 02.28.12 M Falk Reformatted entire ACM. Renamed ACM2.0.

V.2g 07.31.12 M Falk Appearance revision to ACM2.0. Addition of autofill cells, selective components on

summary tab, modified tables & updated Directed Materials tab.

V.2h 03.12.13 M Falk Updated Vinyl Section on component tabs. Added part number field to summary

page & component tabs. Updated vinyl section on Directed Materials tab.

Page 1 of 27

FMC Trim Model

Seats Purchasing

Version Control

sent to all trim suppliers with P473 market

testand to Cost Ops

06..28.07 - sent to all trim suppliers with

P473 market test.and Cost Opsand Ford PD

Trim Eng.

Page 2 of 27

SUPPLIER GENERAL INSTRUCTIONS

I. Complete one workbook for each available trim style in the program assumptions provided to you by Ford, unless otherwise specified.

II. Within each workbook, complete the component cost model forms (pink worksheet tabs) for every trim cover within the vehicle set for a given trim style.

III. Input data in cells as indicated by the instructions on the cost model.

IV. Please do not delete, add, or rename tabs in the workbook.

V. On the 'Summary Tab' only, Input the PROGRAM, MODEL YEAR, and TRIM STYLE.

VI. Enter the COMPONENT NAME, PART NUMBER, and MANUFACTURING REGION on each of the component tabs .

VI. Do not embed any objects, formulas, tables, or referenced worksheets into the workbook. Workbooks submitted with embedded items will not be accpeted.

VIII. Return the completed cost model workbooks to the Ford Purchasing representative. Please save the files to include 'PROGRAM NAME & TRIM STYLE'.

Example: P415 Cloth XLT or P473 Leather Lariat

FSB Front Seat Back

FSC Front Seat Cushion

HR Headrest

FRT Front

RR Rear

RSB Rear Seat Back

RSC Rear Seat Cushion

AR or A/R Armrest

CVR Cover

LY Linear Yards

SY Square Yards

SF Square Foot

LI Linear Inch

EA Each

R1 Row 1

R2 Row 2

R3 Row 3

Directed Materials & Prices

All dircted materials and corresponding prices will be input by Ford Purchasing on the 'Directed Materials & Prices ' Tab

Please selected the required material on each Componet Tab, the corresponding information will automatically be populated into the model

Tooling

Enter line item detail of all tooling needed for Trim Series. Make sure to include any leather tooling required

Section I: Raw Materials - Fabric, Vinyl, Leather, Non-wovens & Lamination/Plus Pad

For lamination & plus pads:

not be need if entered correctly

Step II: Purchased Parts

Step III: Manufacturing

spreadsheet will calculate the number of sew minutes

Step IV: Total Manufacturing Cost

Step V: Mark-up

Step VI: Inbound Freight

Step VII: Packaging

Input packaging cost per kit required for transportation of materials

Step VIII: Customs/Duties (if applicable)

Step IX: Other costs (if applicable)

Step X: Total Piece Price

Automatically sums Steps I - IX

Vinyl: Select material name & Grain from drop down menus, the Ford-negotiated material prices with corresponding lamination pricing will be automatically populated. Input net

square yards of material used in trim kit with ACTUAL material efficiencies. Upon request, Supplier will submit actual layouts (including die board effeciency % and material utilization

%) to Ford Purchasing and Cost Estimating to verify and apply actual utilization percentages. Supplier will adhere to the Ford Optimized Nesting Parameters on all quote submissions

Agreed up rate, applied to all incoming materials

Input $/component for customs/duties and associated countries requiring these fees

Input activity driving other costs and $/component for any additional costs not captured in the model, if applicable

* Leather: Plus pads required for leather are to be entered in the "Non-Woven" section under the Lamination & Foam heading - an additional line item for inbound freight will

Select component from drop down list. If component is not listed please select Other and specify in the Comment column

Cutting: Input actual quantity of cut mins associated with component. Leather cutting cost is assumed to be in the price of the leather as noted previously.

Sewing: Input the number of inches of each seam type. Input the number of obtain and position, stops, and cut and dispose for each. The formulas in the

Automatically sumes Steps I to IV

Agreed upon rate for scrap, SG&A, and Profit on a percent-basis of manufacturing cost

Leather: Select material spec & grain from drop down menus. Input Leather supplier component price (price includes cutting & perf); input net and gross square feet of material

used in trim it

SEAT TRIM AGREED COST MODEL

* Fabric & Vinyl: supplier-negotiated material price will automatically populate with selected material; net sq yards will also automatically populate

Acronyms/Abbreviations Used

Green: Supplier Inputs

Blue: Ford Inputs - Fixed

Tan: Fixed Formulas

Purple: Subtotals

Fabrics: Select material name from drop down menu, the Ford-negotiated material prices with corresponding lamination pricing will be automatically populated. Input net square

yards of material used in trim kit with ACTUAL material efficiencies. Upon request, Supplier will submit actual layouts (including die board effeciency % and material utilization %) to

Ford Purchasing and Cost Estimating to verify and apply actual utilization percentages. Supplier will adhere to the Ford Optimized Nesting Parameters on all quote submissions

Non-wovens: Select material type from drop down menu, if not listed select Other and specify in Name Column. Input Name, supplier-negotiated material price, roll width, & net

square yards of material used in trim kit with ACTUAL efficiencies. Upon request, Supplier will submit actual die board layouts (including die board effeciency % and material utilization

%) to Ford Purchasing and Cost Estimating to verify and apply actual utilization percentage. Supplier will adhere to the Ford Optimized Nesting Parameters on all quote submissions.

PROGRAM:

MODEL YEAR:

TRIM STYLE:

Tab # Row Part Number Component

Check if

Needed Price Each

11 R1 0 LH HR 5.22 $

12 R1 0 RH HR - $

28 R2 0 Rear Outer HR LH - $

29 R2 0 Rear Outer HR RH - $

30 R2 0 Rear Center HR - $

35 R3 0 Third Row Rear Outer HR LH - $

36 R3 0 Third Row Rear Outer HR RH - $

37 R3 0 Third Row Rear Center HR - $

5.22 $

Tooling - $

SEAT TRIM AGREED COST MODEL

Total Kit Cost

NO ROLLED GOODS TOOLING - CNC CUTTING ASSUMED

Provide full cost details below for trim tooling required to support the vehicle program. Provide line item detail of all tooling required

Production Tooling

Quantity

Max Wkly

Capacity

Per Tool Cost Total Cost Tool Source

Example: Leather Dies 5 $ 250.00 1,250.00 $ Eagle Ottawa

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

Total Tooling - $

Description

Vinyl

Flat Stock

Price/LYD

Flat Stock

Price/SQ YD

Lamination

Thickness

Lamination

Price/SQ YD

Roll Width

(inches)

Supplier

9.00 $ 5.49 $ 10 2.19 $ 59 TBD

9.00 $ 5.49 $ 6 1.74 $ 59 TBD

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59 **Lam FXI

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

Cloth

Alcantara 48.69 $ 31.30 $ 0 - $ 56 Alcantara

- $ 59

Nova/3mm 3.15 $ 1.89 $ 3 1.18 $ 60

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

Bolsters

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

- $ 59

Low Visibility Areas

Nova/3mm 3.15 $ 1.89 $ 3 1.18 $ 60 Guilford

- $ 60

- $ 60

- $ 60

- $ 60

- $ 60

- $ 60 **Lam FXI

- $ 60

- $ 60

- $ 60

Leather

Inserts

27-B

27-B/Perf

30-B

30-B/Perf

Bolsters

27-B

30-B

Other

Specification/Grain/Perf Utilization

Roll Width

(inches)

Flat Stock

Price/SQ YD

Lamination

Price/SQ YD

Material Specification

Prem/10mm

Prem/6mm

FORD DIRECTED PRICING

Lamination

Thickness

Inserts

Flat Stock

Price/LYD

FORD MOTOR COMPANY CONFIDENTIAL

246299564.xls.ms_office - 3) Directed Materials & Prices

6 of 27

Trim ACM 2.0 (February 2012)

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Duon Supplier $0.91 60 $0.54 0.1320 0.1320 78% 0.1694 0.0922 $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $9.00 59.00 $5.49 0.2430 $2.19 10.00 0.2430 82% 0.2967 2.2791 $

Ford $9.00 59.00 $5.49 0.2260 $1.74 6.00 0.2260 78% 0.2901 2.0980 $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials 4.4693 $

Cost per

Unit

Unit of

Measure

# Units Total

0.0281 $ EA 2 0.0562 $

0.0071 $ EA 2 0.0142 $

0.0937 $ EA 2 0.1874 $

0.009 $ EA 2 0.0188 $

0.1176 $ LY 0.3026311 0.0356 $

0.0032 $ LY 51.96477 0.1682 $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials 0.4804 $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 2.91 $0.15 0.4365 $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 1.0 0.2718 $0.15 0.0408 $

French Seam French 0.2718 2.0 0.5436 $0.15 0.0815 $

All Other All Other 0.2418 16.0 3.8688 $0.15 0.5803 $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 10.22 0.1022 $0.15 Aplix Velcro 0.0153 $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 185.65 1.1881 $0.15 0.1782 $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 10.22 0.1022 $0.15 0.0153 $

French seam French 0.0106 82.04 0.8696 $0.15 0.1304 $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 - $0.15 - $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 69.67 0.4877 $0.15 0.0732 $

Embroidery 0.0180 - $0.15 - $

357.79 2.7498

Total Stops/Adjustments 0.0320 52.00 1.6640 $0.15 0.2496 $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) 9.0980

Subtotal Processing 1.8012 $

IV. 6.75 $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% 0.9114 $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% 0.1350 $

Mark-Ups Scrap, SG&A, Profit, & Freight 0.1350 $

VII. Packaging $/kit

> Returnable 0.0600 $ 0.0600 $

> Expendable - $

Total Packaging 0.0600 $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

Material Pricing &

Roll Dimensions

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Measure-

ment

Cutting

Efficiency %

Gross

sq. yards

Net sq.

yards

$/sq.

yard

0

0

0

Blue: Ford Inputs - Fixed

$/linear

yard

Tan: Fixed Formulas

- $

Total Sewing Operations

- $0.15 All Operation Types

All Stitch

Types

180.0 mm Long

45.0 mm Long

Total

Purple: Subtotals

Die Board

Utilization

Lamination

Thickness

Roll width

(inches) Specification

Prem/10mm

Prem/6mm

Green: Supplier Inputs

$/sq.

yard

Net sq.

yards

I. Raw Materials Sourcing

Manufacturing Region Select

Comment

Specification/Grain/Perf

Vinyl

Ford or

Supplier

600.0 mm Long

Thread

J-Retainer

J-Retainer

180.0 mm Long

Sewing

Operations

VIX. Other Costs

Each Additional Piece

Obtain & Position

J-Retainer

II. Other Materials

J-Retainer

Other - Please Specify

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

0.0600

Total Manufacturing Cost ( I + II + III )

APLIX #624 Loop

T-90

IX. All Other Costs (if any) Describe $/Each

0.37

Number 1.00 Total Other 0.3667 $

X. 8.22 $ TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Gerber Machine Cost

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $9.00 59.00 $5.49 0.0710 $2.19 10.00 0.0710 80% 0.0890 0.6834 $

Ford $9.00 59.00 $5.49 0.1960 $1.74 6.00 0.1960 79% 0.2486 1.7976 $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials 2.4810 $

Cost per

Unit

Unit of

Measure

# Units Total

0.03 $ EA 2 0.0655 $

0.03 $ EA 2 0.0699 $

0.07 $ EA 1 0.0656 $

0.47 $ EA 1 0.4660 $

0.0032 $ LY 27.23193 0.0882 $

- $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials 0.7552 $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 1.32 $0.15 0.1982 $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 - $0.15 - $

French Seam French 0.2718 2.0 0.5436 $0.15 0.0815 $

All Other All Other 0.2418 13.0 3.1434 $0.15 0.4715 $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 - $0.15 - $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 66.87 0.4280 $0.15 0.0642 $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 - $0.15 - $

French seam French 0.0106 36.72 0.3892 $0.15 0.0584 $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 21.93 0.1097 $0.15 0.0165 $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 64.38 0.4507 $0.15 0.0676 $

Embroidery 0.0180 - $0.15 - $

189.90 1.3775

Total Stops/Adjustments 0.0320 28.00 0.8960 $0.15 0.1344 $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) 6.0805

Subtotal Processing 1.1103 $

IV. 4.35 $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% 0.5868 $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% 0.0869 $

Mark-Ups Scrap, SG&A, Profit, & Freight 0.0869 $

VII. Packaging $/kit

> Returnable 0.0300 $ 0.0300 $

> Expendable - $

Total Packaging 0.0300 $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

T-90

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

0.0600

Total Manufacturing Cost ( I + II + III )

Sewing

Operations

VIX. Other Costs

Each Additional Piece

Obtain & Position

J-Retainer

285.0 mm Long

J-Retainer

J-Retainer

Aplix Loop-a-Stick 25.4 x 240.0 Other - Please Specify

Thread

Comment

Specification/Grain/Perf

Vinyl

Ford or

Supplier

II. Other Materials

Specification

Prem/10mm

Prem/6mm

Manufacturing Region

Green: Supplier Inputs

210.0 mm Long

225.0 mm Long

Total

Purple: Subtotals

Die Board

Utilization

Select

0.0180 $

Total Sewing Operations

2.0 0.1200 $0.15

Lamination

Thickness

Roll width

(inches)

$/sq.

yard

Net sq.

yards

All Operation Types

All Stitch

Types

Net sq.

yards

$/sq.

yard

0

0

0

Blue: Ford Inputs - Fixed

$/linear

yard

Tan: Fixed Formulas

I. Raw Materials Sourcing

Material Pricing &

Roll Dimensions

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Measure-

ment

Cutting

Efficiency %

Gross

sq. yards

IX. All Other Costs (if any) Describe $/Each

0.17

Number 1.00 Total Other 0.1665 $

X. 5.22 $

Gerber Machine Cost

TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert XLT Insert A 6mm Ford $0.00 $0.00 1.0000 $0.00 0 mm 1.0000 85% 1.1765 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials - $

Cost per

Unit

Unit of

Measure

# Units Total

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials - $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 0.00 $0.15 - $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 - $0.15 - $

French Seam French 0.2718 - $0.15 - $

All Other All Other 0.2418 - $0.15 - $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 - $0.15 - $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 - $0.15 - $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 - $0.15 - $

French seam French 0.0106 - $0.15 - $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 - $0.15 - $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 - $0.15 - $

Embroidery 0.0180 - $0.15 - $

- -

Total Stops/Adjustments 0.0320 0.00 - $0.15 - $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) -

Subtotal Processing - $

IV. - $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% - $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% - $

Mark-Ups Scrap, SG&A, Profit, & Freight - $

VII. Packaging $/kit

> Returnable - $

> Expendable - $

Total Packaging - $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

II. Other Materials

Sourcing

Material Pricing &

Roll Dimensions

$/linear

yard

Roll width

(inches)

$/sq.

yard

Ford or

Supplier

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Net sq.

yards

$/sq.

yard

0

0

0

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Manufacturing Region

Blue: Ford Inputs - Fixed

Total

Purple: Subtotals

Die Board

Utilization

Tan: Fixed Formulas

Measure-

ment

Green: Supplier Inputs

I. Raw Materials

Select

- $

Total Sewing Operations

$0.15

Comment

Specification/Grain/Perf

Sewing

Operations

VIX. Other Costs

-

Each Additional Piece

Obtain & Position

All Operation Types

Total Manufacturing Cost ( I + II + III )

Vinyl

Lamination

Thickness Specification

0.0600

All Stitch

Types

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

IX. All Other Costs (if any) Describe $/Each Number Total Other - $

X. - $ TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert XLT Insert A 6mm Ford $0.00 $0.00 1.0000 $0.00 0 mm 1.0000 85% 1.1765 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials - $

Cost per

Unit

Unit of

Measure

# Units Total

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials - $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 0.00 $0.15 - $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 - $0.15 - $

French Seam French 0.2718 - $0.15 - $

All Other All Other 0.2418 - $0.15 - $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 - $0.15 - $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 - $0.15 - $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 - $0.15 - $

French seam French 0.0106 - $0.15 - $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 - $0.15 - $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 - $0.15 - $

Embroidery 0.0180 - $0.15 - $

- -

Total Stops/Adjustments 0.0320 0.00 - $0.15 - $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) -

Subtotal Processing - $

IV. - $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% - $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% - $

Mark-Ups Scrap, SG&A, Profit, & Freight - $

VII. Packaging $/kit

> Returnable - $

> Expendable - $

Total Packaging - $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

II. Other Materials

Sourcing

Material Pricing &

Roll Dimensions

$/linear

yard

Roll width

(inches)

$/sq.

yard

Ford or

Supplier

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Net sq.

yards

$/sq.

yard

0

0

0

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Manufacturing Region

Blue: Ford Inputs - Fixed

Total

Purple: Subtotals

Die Board

Utilization

Tan: Fixed Formulas

Measure-

ment

Green: Supplier Inputs

I. Raw Materials

Select

- $

Total Sewing Operations

$0.15

Comment

Specification/Grain/Perf

Sewing

Operations

VIX. Other Costs

-

Each Additional Piece

Obtain & Position

All Operation Types

Total Manufacturing Cost ( I + II + III )

Vinyl

Lamination

Thickness Specification

0.0600

All Stitch

Types

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

IX. All Other Costs (if any) Describe $/Each Number Total Other - $

X. - $ TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert XLT Insert A 6mm Ford $0.00 $0.00 1.0000 $0.00 0 mm 1.0000 85% 1.1765 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials - $

Cost per

Unit

Unit of

Measure

# Units Total

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials - $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 0.00 $0.15 - $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 - $0.15 - $

French Seam French 0.2718 - $0.15 - $

All Other All Other 0.2418 - $0.15 - $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 - $0.15 - $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 - $0.15 - $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 - $0.15 - $

French seam French 0.0106 - $0.15 - $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 - $0.15 - $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 - $0.15 - $

Embroidery 0.0180 - $0.15 - $

- -

Total Stops/Adjustments 0.0320 0.00 - $0.15 - $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) -

Subtotal Processing - $

IV. - $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% - $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% - $

Mark-Ups Scrap, SG&A, Profit, & Freight - $

VII. Packaging $/kit

> Returnable - $

> Expendable - $

Total Packaging - $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

II. Other Materials

Sourcing

Material Pricing &

Roll Dimensions

$/linear

yard

Roll width

(inches)

$/sq.

yard

Ford or

Supplier

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Net sq.

yards

$/sq.

yard

0

0

0

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Manufacturing Region

Blue: Ford Inputs - Fixed

Total

Purple: Subtotals

Die Board

Utilization

Tan: Fixed Formulas

Measure-

ment

Green: Supplier Inputs

I. Raw Materials

Select

- $

Total Sewing Operations

$0.15

Comment

Specification/Grain/Perf

Sewing

Operations

VIX. Other Costs

-

Each Additional Piece

Obtain & Position

All Operation Types

Total Manufacturing Cost ( I + II + III )

Vinyl

Lamination

Thickness Specification

0.0600

All Stitch

Types

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

IX. All Other Costs (if any) Describe $/Each Number Total Other - $

X. - $ TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert XLT Insert A 6mm Ford $0.00 $0.00 1.0000 $0.00 0 mm 1.0000 85% 1.1765 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials - $

Cost per

Unit

Unit of

Measure

# Units Total

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials - $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 0.00 $0.15 - $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 - $0.15 - $

French Seam French 0.2718 - $0.15 - $

All Other All Other 0.2418 - $0.15 - $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 - $0.15 - $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 - $0.15 - $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 - $0.15 - $

French seam French 0.0106 - $0.15 - $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 - $0.15 - $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 - $0.15 - $

Embroidery 0.0180 - $0.15 - $

- -

Total Stops/Adjustments 0.0320 0.00 - $0.15 - $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) -

Subtotal Processing - $

IV. - $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% - $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% - $

Mark-Ups Scrap, SG&A, Profit, & Freight - $

VII. Packaging $/kit

> Returnable - $

> Expendable - $

Total Packaging - $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

0.0600

Total Manufacturing Cost ( I + II + III )

Sewing

Operations

VIX. Other Costs

Each Additional Piece

Obtain & Position

Comment

Specification/Grain/Perf

Vinyl

Ford or

Supplier

II. Other Materials

Specification

Manufacturing Region

Green: Supplier Inputs

Total

Purple: Subtotals

Die Board

Utilization

Select

- $

Total Sewing Operations

- $0.15

Lamination

Thickness

Roll width

(inches)

$/sq.

yard

Net sq.

yards

All Operation Types

All Stitch

Types

Net sq.

yards

$/sq.

yard

0

0

0

Blue: Ford Inputs - Fixed

$/linear

yard

Tan: Fixed Formulas

I. Raw Materials Sourcing

Material Pricing &

Roll Dimensions

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Measure-

ment

Cutting

Efficiency %

Gross

sq. yards

IX. All Other Costs (if any) Describe $/Each Number Total Other - $

X. - $ TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert XLT Insert A 6mm Ford $0.00 $0.00 1.0000 $0.00 0 mm 1.0000 85% 1.1765 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials - $

Cost per

Unit

Unit of

Measure

# Units Total

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials - $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 0.00 $0.15 - $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 - $0.15 - $

French Seam French 0.2718 - $0.15 - $

All Other All Other 0.2418 - $0.15 - $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 - $0.15 - $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 - $0.15 - $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 - $0.15 - $

French seam French 0.0106 - $0.15 - $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 - $0.15 - $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 - $0.15 - $

Embroidery 0.0180 - $0.15 - $

- -

Total Stops/Adjustments 0.0320 0.00 - $0.15 - $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) -

Subtotal Processing - $

IV. - $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% - $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% - $

Mark-Ups Scrap, SG&A, Profit, & Freight - $

VII. Packaging $/kit

> Returnable - $

> Expendable - $

Total Packaging - $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

II. Other Materials

Sourcing

Material Pricing &

Roll Dimensions

$/linear

yard

Roll width

(inches)

$/sq.

yard

Ford or

Supplier

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Net sq.

yards

$/sq.

yard

0

0

0

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Manufacturing Region

Blue: Ford Inputs - Fixed

Total

Purple: Subtotals

Die Board

Utilization

Tan: Fixed Formulas

Measure-

ment

Green: Supplier Inputs

I. Raw Materials

Select

- $

Total Sewing Operations

$0.15

Comment

Specification/Grain/Perf

Sewing

Operations

VIX. Other Costs

-

Each Additional Piece

Obtain & Position

All Operation Types

Total Manufacturing Cost ( I + II + III )

Vinyl

Lamination

Thickness Specification

0.0600

All Stitch

Types

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

IX. All Other Costs (if any) Describe $/Each Number Total Other - $

X. - $ TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert XLT Insert A 6mm Ford $0.00 $0.00 1.0000 $0.00 0 mm 1.0000 85% 1.1765 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials - $

Cost per

Unit

Unit of

Measure

# Units Total

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials - $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 0.00 $0.15 - $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 - $0.15 - $

French Seam French 0.2718 - $0.15 - $

All Other All Other 0.2418 - $0.15 - $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 - $0.15 - $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 - $0.15 - $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 - $0.15 - $

French seam French 0.0106 - $0.15 - $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 - $0.15 - $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 - $0.15 - $

Embroidery 0.0180 - $0.15 - $

- -

Total Stops/Adjustments 0.0320 0.00 - $0.15 - $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) -

Subtotal Processing - $

IV. - $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% - $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% - $

Mark-Ups Scrap, SG&A, Profit, & Freight - $

VII. Packaging $/kit

> Returnable - $

> Expendable - $

Total Packaging - $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

0.0600

Total Manufacturing Cost ( I + II + III )

Sewing

Operations

VIX. Other Costs

Each Additional Piece

Obtain & Position

Comment

Specification/Grain/Perf

Vinyl

Ford or

Supplier

II. Other Materials

Specification

Manufacturing Region

Green: Supplier Inputs

Total

Purple: Subtotals

Die Board

Utilization

Select

- $

Total Sewing Operations

- $0.15

Lamination

Thickness

Roll width

(inches)

$/sq.

yard

Net sq.

yards

All Operation Types

All Stitch

Types

Net sq.

yards

$/sq.

yard

0

0

0

Blue: Ford Inputs - Fixed

$/linear

yard

Tan: Fixed Formulas

I. Raw Materials Sourcing

Material Pricing &

Roll Dimensions

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Measure-

ment

Cutting

Efficiency %

Gross

sq. yards

IX. All Other Costs (if any) Describe $/Each Number Total Other - $

X. - $ TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert XLT Insert A 6mm Ford $0.00 $0.00 1.0000 $0.00 0 mm 1.0000 85% 1.1765 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials - $

Cost per

Unit

Unit of

Measure

# Units Total

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials - $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 0.00 $0.15 - $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 - $0.15 - $

French Seam French 0.2718 - $0.15 - $

All Other All Other 0.2418 - $0.15 - $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 - $0.15 - $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 - $0.15 - $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 - $0.15 - $

French seam French 0.0106 - $0.15 - $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 - $0.15 - $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 - $0.15 - $

Embroidery 0.0180 - $0.15 - $

- -

Total Stops/Adjustments 0.0320 0.00 - $0.15 - $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) -

Subtotal Processing - $

IV. - $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% - $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% - $

Mark-Ups Scrap, SG&A, Profit, & Freight - $

VII. Packaging $/kit

> Returnable - $

> Expendable - $

Total Packaging - $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

II. Other Materials

Sourcing

Material Pricing &

Roll Dimensions

$/linear

yard

Roll width

(inches)

$/sq.

yard

Ford or

Supplier

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Net sq.

yards

$/sq.

yard

0

0

0

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Manufacturing Region

Blue: Ford Inputs - Fixed

Total

Purple: Subtotals

Die Board

Utilization

Tan: Fixed Formulas

Measure-

ment

Green: Supplier Inputs

I. Raw Materials

Select

- $

Total Sewing Operations

$0.15

Comment

Specification/Grain/Perf

Sewing

Operations

VIX. Other Costs

-

Each Additional Piece

Obtain & Position

All Operation Types

Total Manufacturing Cost ( I + II + III )

Vinyl

Lamination

Thickness Specification

0.0600

All Stitch

Types

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

IX. All Other Costs (if any) Describe $/Each Number Total Other - $

X. - $ TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Program

Model Year

Trim Style

Kit Component

Part Number

Fabrics Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

> Insert XLT Insert A 6mm Ford $0.00 $0.00 1.0000 $0.00 0 mm 1.0000 85% 1.1765 - $

> Insert Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Bolster Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

> Other Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Non-wovens Name

Ford or

Supplier

$/linear

yard

Roll width

(inches)

$/sq.

yard

Net sq.

yards

$/sq.

yard

Lamination

Thickness

Net sq.

yards

Cutting

Efficiency %

Gross

sq. yards

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Supplier 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Ford $0.00 $0.00 $0.00 0 mm 0.0000 0.0000 - $

Leather

Ford or

Supplier

$/sq.

foot**

Net sq.

feet

$/kit

Plus Pad

Thickness

#

pieces

Use

Efficiency %

Gross

sq. feet

> Insert Ford - $

> Insert Ford - $

> Bolster Ford - $

> Other Ford - $

** Note: Leather $/sq. foot includes all cutting (w/ material utilizations) and perf costs. Input if available Subtotal Raw Materials - $

Cost per

Unit

Unit of

Measure

# Units Total

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

- $

Subtotal Other Materials - $

Total

> Cutting Cut Min. $ / Min.

CNC Cutting 0.00 $0.15 - $

> Sewing

Stitch

Type

Minutes

Each

Quantity/

Kit

Sew

Minutes

$ /

Minute

Deck Seam Lock 0.2718 - $0.15 - $

French Seam French 0.2718 - $0.15 - $

All Other All Other 0.2418 - $0.15 - $

Tack sew - regular Lock 0.0050 - $0.15 - $

Tack sew - serging Serge 0.0100 - $0.15 - $

Shirring - cloth Chain 0.0090 - $0.15 - $

Shirring - leather Chain 0.0120 - $0.15 - $

Sew-thru - single Chain 0.0038 - $0.15 - $

Sew-thru - multiple Multi 0.0038 - $0.15 - $

Join/pinch seam Lock 0.0064 - $0.15 - $

Join seam - leather Lock 0.0064 - $0.15 - $

Join seam w/ welt Lock 0.0090 - $0.15 - $

Deck seam Lock 0.0100 - $0.15 - $

French seam French 0.0106 - $0.15 - $

Blind stitch Blind 0.0100 - $0.15 - $

Serge stitch Serge 0.0150 - $0.15 - $

Hem Lock 0.0050 - $0.15 - $

Continuous sew Chain 0.0038 - $0.15 - $

Tie-down (J-clips) Lock 0.0070 - $0.15 - $

Embroidery 0.0180 - $0.15 - $

- -

Total Stops/Adjustments 0.0320 0.00 - $0.15 - $

Inch/Stop + Adjustments 7.00

Total Sew Minutes (including Stop & Adjustments) -

Subtotal Processing - $

IV. - $

Amount

V. Mark-Up Scrap, SG&A, Profit 13.5% - $

VI. Mark-Up Freight ((Including any NAFTA-Warehouse expense)

> Inbound (All incoming materials) 2.0% - $

Mark-Ups Scrap, SG&A, Profit, & Freight - $

VII. Packaging $/kit

> Returnable - $

> Expendable - $

Total Packaging - $

VIII. Customs/Duties (if any) Country $/Cmpnt Total Customs / Duties - $

1-2 Piece Initial

Obtain / Position / Cut

& Dispose

III. Manufacturing

0.0600

Total Manufacturing Cost ( I + II + III )

Sewing

Operations

VIX. Other Costs

Each Additional Piece

Obtain & Position

Comment

Specification/Grain/Perf

Vinyl

Ford or

Supplier

II. Other Materials

Specification

Manufacturing Region

Green: Supplier Inputs

Total

Purple: Subtotals

Die Board

Utilization

Select

- $

Total Sewing Operations

- $0.15

Lamination

Thickness

Roll width

(inches)

$/sq.

yard

Net sq.

yards

All Operation Types

All Stitch

Types

Net sq.

yards

$/sq.

yard

0

0

0

Blue: Ford Inputs - Fixed

$/linear

yard

Tan: Fixed Formulas

I. Raw Materials Sourcing

Material Pricing &

Roll Dimensions

Lamination & Foam

(Plus Pad)

Agreed Cost Model (ACM)

Seat Trim

Measure-

ment

Cutting

Efficiency %

Gross

sq. yards

IX. All Other Costs (if any) Describe $/Each Number Total Other - $

X. - $ TOTAL PIECE PRICE ( I + II + III + IV + V + VI + VII + VIII )

Lamination Thickness Options $/min Select Purchased Materials

2mm Select Select

3mm $0.11 Thread

4mm $0.15 Hook

5mm 0.05 Carpet

6mm 0.33 Webbing

7mm 0.57 Milliloop

8mm 0.78 Levi Tag

9mm 0.51 ISO Button

10mm 0.22 Welt

12mm 0.16 Elastic

Select RON 0.36 Paper Cord

HUF 38.88 Beaded Duon

TRY 0.25 J-Retainer

Roll Width CZK 5.34 Airbag Label

42 PLN 0.79 Sew Label

43 INR 1.79 Zipper Coil

44 1.82 Zipper Slide/Stop

45 GBP 0.41 Special Zipper Coil

46 Special Zipper Slide/Stop

47 Nylon Air Bag Cloth

48 Velcro

49 Other - Please Specify

50

51 Units of Measurement Non-Wovens

52 LY Select

53 SY Duon

54 SF Carpet

55 LI Other - Please Specify

56 EA 8mm TB16

57 4mm TB16

58 4mm A300

59 4mm Foam w/Dow

60 8mm Foam w/scrim

61 6mm Foam w/scrim

62 Leather Specs 4mm Foam w/scrim

63 Select 12mm Foam w/TB16

64 M2F127-B 10mm Spacer

65 M2F128-B 3mm Foam w/Dow

Select M2F129-B 10mm Foam /.TB16

M2F130-B

Vinyl Specs

Select

WSS-M2F156-B Grains

WSS-M2F156-C Select

WSS-M2F186-A1 Soho

WSS-M2F186-A2 Luxury

WSS-M2F178-A1 Milled Pebble

WSS-M2F178-A2 Titan

WSS-M2F209-A Suede

Verona

Salerno

Region Santa Cruz

Select Cuir

United States Taurus

China Structure

Croatia

Czech Republic

France

Germany

Great Britain

Hungary

India

Italy

Mexico

Moldova

Morocco

Poland

Portugal

Romania

Slovakia

Slovenia

South Africa

Spain

Thailand

Turkey

FORD MOTOR COMPANY CONFIDENTIAL Page 27 of 27

FMC Trim Cost Model V.2 (06.05.07)

NA Seats Purchasing

S-ar putea să vă placă și

- Rubber Products for Mechanical Use World Summary: Market Values & Financials by CountryDe la EverandRubber Products for Mechanical Use World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- Draft 1Document6 paginiDraft 1Shaina Claire Q. PulidoÎncă nu există evaluări

- Directorate General Mis/Fabs: IslamabadDocument7 paginiDirectorate General Mis/Fabs: IslamabadnaveedÎncă nu există evaluări

- Nonmetallic Coated Abrasive Products, Buffing & Polishing Wheels & Laps World Summary: Market Sector Values & Financials by CountryDe la EverandNonmetallic Coated Abrasive Products, Buffing & Polishing Wheels & Laps World Summary: Market Sector Values & Financials by CountryÎncă nu există evaluări

- Case Goodweek Tires Excel OutlineDocument1 paginăCase Goodweek Tires Excel Outlineycheikh26Încă nu există evaluări

- OEM Paints & Finishes World Summary: Market Sector Values & Financials by CountryDe la EverandOEM Paints & Finishes World Summary: Market Sector Values & Financials by CountryÎncă nu există evaluări

- Demo Weld Cost Calc XL (Recovered)Document9 paginiDemo Weld Cost Calc XL (Recovered)Bhagyesh B. MaskeÎncă nu există evaluări

- Feasibility Study ExampleDocument17 paginiFeasibility Study Exampleanon-66920991% (23)

- Modelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleDe la EverandModelling a Focke-Wulf Fw 190A-8/R8: In 1/32 scaleEvaluare: 5 din 5 stele5/5 (1)

- Dokumen - Tips - Transfer Pricing QuizDocument5 paginiDokumen - Tips - Transfer Pricing QuizSaeym SegoviaÎncă nu există evaluări

- RecommendationDocument1 paginăRecommendationMacImranÎncă nu există evaluări

- Income Statement - MonthlyDocument11 paginiIncome Statement - MonthlyRickyÎncă nu există evaluări

- Manual DDocument98 paginiManual DRafyss Rodriguez100% (4)

- Tsf-Cost Per Unit Calculation Tool 0Document5 paginiTsf-Cost Per Unit Calculation Tool 0SandaraÎncă nu există evaluări

- Ford Tractor Operators Manual Fo o 2 5000Document8 paginiFord Tractor Operators Manual Fo o 2 5000Abdullah AcisuÎncă nu există evaluări

- Ford Tractor Service Manual Fo S 2000Document15 paginiFord Tractor Service Manual Fo S 2000Abdullah AcisuÎncă nu există evaluări

- Pricing Template Growers PricingDocument4 paginiPricing Template Growers Pricingmoatazz.tarek96Încă nu există evaluări

- Demo Weld Cost Calc XLDocument10 paginiDemo Weld Cost Calc XLMarcelo Simão Do ValeÎncă nu există evaluări

- International Harvester Parts Manual 784Document21 paginiInternational Harvester Parts Manual 784Qwerty100% (1)

- PIRA - 2022 - ESTIMATED FMV As of October 2022Document48 paginiPIRA - 2022 - ESTIMATED FMV As of October 2022Aggy ReynadoÎncă nu există evaluări

- Data Acquisition PythonDocument12 paginiData Acquisition PythonOdiseo PyÎncă nu există evaluări

- The Most Comprehensive Product Offering For Remanufactured Brother CartridgesDocument10 paginiThe Most Comprehensive Product Offering For Remanufactured Brother CartridgesIcs AsomÎncă nu există evaluări

- Massey-Ferguson-298-Tractor de Llantas-Parts-ManualDocument22 paginiMassey-Ferguson-298-Tractor de Llantas-Parts-ManualELKIN MAURICIO RAMIREZ PEREZÎncă nu există evaluări

- Cee 109 - First ExamDocument43 paginiCee 109 - First ExamRonald Renon QuiranteÎncă nu există evaluări

- Copia de Polymer Reactions (Tiamat)Document15 paginiCopia de Polymer Reactions (Tiamat)basselisk123Încă nu există evaluări

- Unit or Output Costing: BDKBZ Vfkok Mriknu Ykxr Fof/KDocument92 paginiUnit or Output Costing: BDKBZ Vfkok Mriknu Ykxr Fof/KAman ulla jinnahÎncă nu există evaluări

- Classification of CostDocument45 paginiClassification of CostManish RanaÎncă nu există evaluări

- Massey Ferguson MF290 Parts ManualDocument22 paginiMassey Ferguson MF290 Parts Manualgabriel100% (1)

- f5 Class Test 1Document5 paginif5 Class Test 1Emon D' CostaÎncă nu există evaluări

- Final Cost Reporting and Procurement TemplateDocument3 paginiFinal Cost Reporting and Procurement TemplateSuresh Kannan MurugesanÎncă nu există evaluări

- Zetor Tractor Service ManualDocument13 paginiZetor Tractor Service ManualAntun JuratovićÎncă nu există evaluări

- CSC343 Database Assignment 3 SolutionsDocument18 paginiCSC343 Database Assignment 3 SolutionsSyed Mohammad RizwanÎncă nu există evaluări

- Comparing production costs and profitability of NVT and Honda motorcyclesDocument7 paginiComparing production costs and profitability of NVT and Honda motorcyclesrk85mishra100% (1)

- Clean Fleets LCC Tool - enDocument5 paginiClean Fleets LCC Tool - endanutzuÎncă nu există evaluări

- Me - CaDocument7 paginiMe - CaCJ ManaloÎncă nu există evaluări

- Cost Sheet: Raw Material ConsumedDocument5 paginiCost Sheet: Raw Material Consumedjyotidevi09Încă nu există evaluări

- Please Use A Separate Page For Each of Your Business Locations.Document2 paginiPlease Use A Separate Page For Each of Your Business Locations.gary haysÎncă nu există evaluări

- ACCY122 Fa09 Notes15 StratCost Other MethodsDocument3 paginiACCY122 Fa09 Notes15 StratCost Other MethodsGladys Fortin CabugonÎncă nu există evaluări

- IMPA Stores CatalogueDocument1.352 paginiIMPA Stores CatalogueErwin100% (1)

- Massey Ferguson Tractor Service Manual MH S Mf240Document18 paginiMassey Ferguson Tractor Service Manual MH S Mf240Moises Caleb Bautista Gómez75% (4)

- Compare Maintenance Costs Over 12 YearsDocument4 paginiCompare Maintenance Costs Over 12 YearsHatim EzziÎncă nu există evaluări

- Compare Maintenance Costs Over 12 YearsDocument4 paginiCompare Maintenance Costs Over 12 YearsGeo BuzatuÎncă nu există evaluări

- Fairmarketvaluecar 2022Document46 paginiFairmarketvaluecar 2022Paniqui Car TradeÎncă nu există evaluări

- John Deere Crawler Service Manual 2Document8 paginiJohn Deere Crawler Service Manual 2Brian SpraysonÎncă nu există evaluări

- Week 7-9Document28 paginiWeek 7-9Sohaib IrfanÎncă nu există evaluări

- Vibration Roller Assembly Parts CatalogDocument220 paginiVibration Roller Assembly Parts Catalognkr4726923100% (3)

- Belarus Tractor Service Manual Be S 5-8-900Document22 paginiBelarus Tractor Service Manual Be S 5-8-900Kim Teng0% (1)

- (N-Ab) (1-A) : To Tariffs)Document16 pagini(N-Ab) (1-A) : To Tariffs)Amelia JÎncă nu există evaluări

- International-Industrial-Tractor-Parts-Manual - IH454-2400Document20 paginiInternational-Industrial-Tractor-Parts-Manual - IH454-2400Jasmin DesmaraisÎncă nu există evaluări

- Product Cost - CostingDocument84 paginiProduct Cost - CostingpankajmayÎncă nu există evaluări

- Answers To Homework 5 Fall 2010Document9 paginiAnswers To Homework 5 Fall 2010Sri Harsha Challa100% (1)

- CLASSIFICATION OF COSTS: ManufacturingDocument84 paginiCLASSIFICATION OF COSTS: Manufacturingbhartu10Încă nu există evaluări

- 2the NotesDocument85 pagini2the Notesnairpooja94Încă nu există evaluări

- 350210en-B XP and XMDocument28 pagini350210en-B XP and XMRoberto RevinsacÎncă nu există evaluări

- Numerical Integration - Part-06a, Edition-1, 2018 - r1Document22 paginiNumerical Integration - Part-06a, Edition-1, 2018 - r1N. T. DadlaniÎncă nu există evaluări

- Fixing of Sum Insured Under Fire Insurance PoliciesDocument17 paginiFixing of Sum Insured Under Fire Insurance PoliciesShayak Kumar GhoshÎncă nu există evaluări

- Versatile Tractor Service Manual Ve S 835 855Document21 paginiVersatile Tractor Service Manual Ve S 835 855jperez_mseÎncă nu există evaluări

- Lumafusion Shortcuts LandscapeDocument2 paginiLumafusion Shortcuts Landscapepocho clashÎncă nu există evaluări

- Practise Active and Passive Voice History of Central Europe: I Lead-InDocument4 paginiPractise Active and Passive Voice History of Central Europe: I Lead-InCorina LuchianaÎncă nu există evaluări

- ABAP Program Types and System FieldsDocument9 paginiABAP Program Types and System FieldsJo MallickÎncă nu există evaluări

- Bioassay Techniques For Drug Development by Atta-Ur RahmanDocument214 paginiBioassay Techniques For Drug Development by Atta-Ur RahmanEmpress_MaripossaÎncă nu există evaluări

- The Ethics of Sexual Reorientation What Should Clinicians and Researchers DoDocument8 paginiThe Ethics of Sexual Reorientation What Should Clinicians and Researchers DoLanny Dwi ChandraÎncă nu există evaluări

- Mini Lecture and Activity Sheets in English For Academic and Professional Purposes Quarter 4, Week 5Document11 paginiMini Lecture and Activity Sheets in English For Academic and Professional Purposes Quarter 4, Week 5EllaÎncă nu există evaluări

- PERDEV - Lesson 3 ReadingsDocument6 paginiPERDEV - Lesson 3 ReadingsSofiaÎncă nu există evaluări

- VT JCXDocument35 paginiVT JCXAkshay WingriderÎncă nu există evaluări

- Accounting Notes - 1Document55 paginiAccounting Notes - 1Rahim MashaalÎncă nu există evaluări

- Epitalon, An Anti-Aging Serum Proven To WorkDocument39 paginiEpitalon, An Anti-Aging Serum Proven To Workonæss100% (1)

- Synthesis of The ArtDocument2 paginiSynthesis of The ArtPiolo Vincent Fernandez100% (1)

- Good Paper On Time SerisDocument15 paginiGood Paper On Time SerisNamdev UpadhyayÎncă nu există evaluări

- Case Digest For Labor Relations 2Document40 paginiCase Digest For Labor Relations 2zeigfred badanaÎncă nu există evaluări

- 04 - JTC Template On Project ProposalDocument10 pagini04 - JTC Template On Project Proposalbakelm alqamisÎncă nu există evaluări

- Introduction To ResearchDocument5 paginiIntroduction To Researchapi-385504653Încă nu există evaluări

- Chapter 3 - The Role of Multimedia in EducationDocument37 paginiChapter 3 - The Role of Multimedia in EducationGellie Ann Silvestre RapinÎncă nu există evaluări

- Magnetic Suspension System With Electricity Generation Ijariie5381Document11 paginiMagnetic Suspension System With Electricity Generation Ijariie5381Jahnavi ChinnuÎncă nu există evaluări

- Salzer Panel Accessories Price List - 01st January 2019Document40 paginiSalzer Panel Accessories Price List - 01st January 2019Chandra SekaranÎncă nu există evaluări

- Module 1 in Contemporary Arts First MonthDocument12 paginiModule 1 in Contemporary Arts First MonthMiles Bugtong CagalpinÎncă nu există evaluări

- Connotative Vs Denotative Lesson Plan PDFDocument5 paginiConnotative Vs Denotative Lesson Plan PDFangiela goc-ongÎncă nu există evaluări

- The Magnificent 10 For Men by MrLocario-1Document31 paginiThe Magnificent 10 For Men by MrLocario-1Mauricio Cesar Molina Arteta100% (1)

- Guest Speaker SpeechDocument12 paginiGuest Speaker SpeechNorhana Manas83% (82)