Documente Academic

Documente Profesional

Documente Cultură

Relationship Between Cracking and Electrical Resistance in Reinforced and Unreinforced Concrete

Încărcat de

Matthew Smith0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări8 pagini22

Titlu original

284292

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest document22

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

18 vizualizări8 paginiRelationship Between Cracking and Electrical Resistance in Reinforced and Unreinforced Concrete

Încărcat de

Matthew Smith22

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

RELATIONSHIP BETWEEN CRACKING AND ELECTRICAL

RESISTANCE IN REINFORCED AND UNREINFORCED CONCRETE.

J. Pacheco

(1)

, B. avija

(1)

, E. Schlangen

(1)

and R.B. Polder

(1,2)

(1) Faculty of Civil Engineering and Geosciences, Delft University of Technology, The

Netherlands

(2) TNO Technical Sciences / Building Materials, The Netherlands

Abstract

Electrical resistivity of concrete is a material dependent property that has been used to

assess transport properties. Ions contained in the pore solution are responsible of carrying

electrical current through concretes pore network. Pore size and connectivity have an

influence on the transport properties of concrete. When concrete is subjected to environmental

and/or mechanical action, cracking of concrete cover is a serious threat for its durability.

Cracks represent fast routes for chloride ingress that lead to corrosion of reinforcement. In

concrete, cracks can be considered as spatial discontinuities between aggregates and concrete

hardened matrix. For concrete infrastructure, cracks are important for assessing the remaining

service life. Tensile cracks in bending have a tapered geometry, i.e. the widest crack occurs at

concretes surface with a decreasing opening as crack propagates towards the reinforcement.

This type of crack is critical for assessing the condition of a concrete structure. In this paper,

real-time measurements of concrete resistance during cracking of reinforced concrete

specimens were performed under laboratory conditions. A Modified Wedge Splitting Test

(MWST) was used in order to create controlled cracks in the specimens. Results show that the

load-displacement curves can be linked to the relationship between displacement and

resistance of concrete.

1. INTRODUCTION

Reinforced concrete is the most widely used construction material in the world. Because of

its cost-efficiency and capacity for withstanding severe environmental conditions, concrete

infrastructure is required. However, concrete durability is not permanent. Concrete is a porous

material that allows transport of matter through its pore structure. The connectivity and size of

pores have a significant influence on transport properties in concrete. Ions contained in the

pore solution are transported by the action of some mechanisms like diffusion, capillary

suction or convection. Also, these ions can carry electrical current through concretes pore

network. Electrical resistivity of concrete is a material dependent property that has been used

Second International Conference on Microstructural-related Durability of

Cementitious Composites, 11-13 April 2012, Amsterdam, The Netherlands

to assess transport properties of concrete. Measured values are usually between 10

1

to 10

5

m

and are dependent on concrete composition, age and environmental conditions [1]. The

chemical composition of concretes pore solution depends on the cement type and

composition and the presence of other binders like GGBFS or fly ash. Usually, the variation

of measured values of resistivity from different concretes is high. The influence of both mix

de-sign parameters and/or environmental conditions are the cause of such variation. High

values of water-to-binder ratio are related to wider and more connected pores. In this sense, it

is reasonable to assume that resistivity and durability are strongly related. A higher resistance

to chloride or CO

2

penetration; and slower deterioration (i.e. corrosion rate) should be

expected when high values of resistivity are found. This relationship between resistivity and

durability performance has been investigated extensively but remains still under debate [2-4].

Measurements of on-site resistivity have been used to assess the in-situ resistance to chloride

penetration [5] or as a quality control assessment [6] show other applications of concrete

resistivity.

One of the most inherent deterioration aspects of concrete is the presence of cracks. The

causes for concrete cracking are numerous during service of concrete infrastructure. When

concrete is subjected to environmental and/or mechanical action, cracking of concrete cover

can occur. Cracks represent fast routes for chloride ingress that leads to corrosion of

reinforcement. In concrete, cracks can be considered as spatial discontinuities of the ITZ

(Interface Transition Zone) between aggregates and concrete hardened matrix. Research

focused on the transport properties of cracks has revealed their strong influence on concrete

durability. A review on cracking methods in laboratory, the influence of cracks on chloride

penetration [7] and its influence on reinforcement corrosion [8] has been published recently.

Corrosion of reinforcement is also affected by cracking of concrete cover. For concrete

infrastructure, cracks are important for assessing the remaining service life. Tensile cracks in

bending have a tapered geometry, i.e. the largest displacement occurs at concretes surface

with a decreasing opening as crack propagates towards the reinforcement. This type of crack

is critical for assessing the condition of a concrete structure.

Schiel and Raupach [9] showed that transverse cracks induce a macro-cell on corrosion of

reinforcement, in which reinforcement intersected by cracks acts as anode. These findings

were later investigated [10,11] with similar results. A study carried out by Boulay et al. [12],

showed that the electrical resistance of concrete decreased as cracks occurred in disks subject

to Brazilian splitting. Each disk was placed between two reservoirs that released a solution

into the crack opening as cracking occurred. Measurements of resistance, and its inverse

conductance, showed a linear dependence on COD (Crack Opening Displacement). As the

crack became wider, more solution was allowed to fill the void, thus increasing the current

flow. A study focused on the permeability of cracks found a distinction between parallel-wall

cracks obtained from Brazilian splitting and V-shaped cracks from bending [13].

In this paper, real-time measurements of concrete resistance of reinforced concrete

specimens were performed under laboratory conditions. A Modified Wedge Splitting Test

(MWST) was used in order to control the crack opening in the specimens. By means of this

test, a V-shaped crack that is representative of those found in structures was obtained. Results

show that the load-displacement curves can be linked to the relationship between

displacement and resistance of concrete.

Second International Conference on Microstructural-related Durability of

Cementitious Composites, 11-13 April 2012, Amsterdam, The Netherlands

2. EXPERIMENTAL DESIGN

2.1 Concrete mix design and specimen fabrication

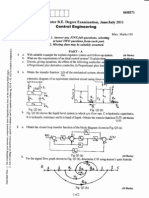

Reinforced concrete specimens were fabricated in standard cubic moulds of 150x150x150

mm

3

. Table 1 shows the materials and mix design for the concrete cubes. In total, 6 specimens

were tested: four with reinforcement and two without. Two reinforcing bars of 120 mm in

length were placed at the bottom of the mould as shown in Figure 1. Prior to casting the

specimens, a steel profile with a cross section of 40x40 mm

2

is mounted on the mould, with

two resistance electrodes attached to the sides to obtain the target geometry. The electrodes

were made from a strip of titanium mesh covered with non-conductive coating, leaving the tip

(2 mm in length) uncoated. Electrodes RA were placed at the level of the notch in all 6

specimens, while electrodes RB were only placed in unreinforced specimens, at the same

position as the reinforcement in the reinforced specimens. The horizontal distance between

the electrodes was 40 mm. After around 5 hours, the steel profile is removed.

Table 1. Concrete mix composition.

Material Quantity, kg/m

3

Portland Cement CEM I 52.5 R 368

Water 165.5

Fine aggregate (<4mm) 840

Coarse aggregate (4-16mm) 1027.5

Superplasticizer 5.1

a) b)

Figure 1. Reinforced concrete specimen (a) and tapered crack with reinforcement (b).

After 24 hours, the specimens were stored in a curing (fog) room (20C, >90% RH) for 27

days. At the end of the curing period, a notch (5 mm thick, 15 mm in depth) was sawn in the

specimen using a water-cooled diamond saw. The purpose of the notch is to guide the fracture

Second International Conference on Microstructural-related Durability of

Cementitious Composites, 11-13 April 2012, Amsterdam, The Netherlands

process; namely, the crack should typically start from the notch. The depth of this notch can

also be adjusted in order to achieve certain concrete cover depth.

2.2 Cracking and resistance measurements

At the age of 36 days, cracking procedure was performed. In order to control the obtained

crack width, LVDTs are placed on both sides of the specimen at the bottom of the notch,

where the crack is expected to initiate. Their average is used as a feedback signal for the ma-

chine, and controls the whole loading process. In this way, a stable cracking procedure is

performed. The COD (Crack Opening Displacement) is the measurement of the horizontal

displacement by the LVDT, which is related to the opening of the crack itself.

When the desired crack width has been achieved, hard plastic wedges are placed inside the

notch, in order to reduce the crack closing (recovery) after unloading. That way, the final

crack width after unloading, i.e. the crack width used as an input in the durability study, is

closer to the final crack width obtained in the test. This is important since, even though the

crack somewhat closes upon unloading, the area around the tip of the crack contains some

microcracks which do not vanish when the specimen is unloaded, and are more permeable

than sound concrete. These plastic wedges were able to reduce the crack recovery, but not

fully: the ideal solution would be to sustain the load during the subsequent durability

investigation, which is not possible due to the expected duration of the test.

Measurements of electrical resistance were carried out at the same time as the loading. For

this, a LCR meter was used and the electrical resistance (120 Hz AC) was stored with a scan

rate of 1 measurement per second. For the reinforced specimens, resistance measurements

were performed over the electrodes RA: both at the level of the notch. For the unreinforced

specimens RA and RB electrodes were measured.

3. RESULTS AND DISCUSSION

Figure 2 shows the results of the load-displacement curves obtained from the MWST and

the behaviour of resistance during the measurement of a reinforced specimen (Specimen 1).

With regard to the load-displacement curve Fig 2.a, results show that a maximum load of

nearly 2 kN is reached during the test. At this loading condition, the average displacement of

the LVDT is about 50 m. Some variations in resistance were found during the initial loading

part of the curve (COD < 50 m), which can be attributed to the formation of microcracks. As

the load is reaching the maximum level, these variations are more evident. This behaviour

corresponds then to the propagation of the crack towards the reinforcement. After reaching its

maximum point (the softening part of the curve), a combination of changes in both resistance

and applied load are observed. The behaviour in this part of the curve may be attributed to the

development of secondary cracks (debonding at the reinforcement interface). Finally, the part

between 150 m and 300 m is believed to only increase the width of cracks, but not their

depth. After the maximum displacement has been reached, the unloading of the specimen is

carried out. After recovery the crack width at the notch tip was about 180 m.

In the same figure, the relationship between COD and electrical resistance is shown. When

cracking occurs, the current flow is disturbed by the presence of a non-conductive medium

(crack void). In the period below the maximum load (COD ~ 50 m), there is almost no

variation in resistance. However, after the maximum load is reached, there is a sudden

Second International Conference on Microstructural-related Durability of

Cementitious Composites, 11-13 April 2012, Amsterdam, The Netherlands

increase in resistance that corresponds to the appearance of the first crack. This sudden

alteration on resistance is more evident in Figure 2.b After this, a gradual increase in

resistance is observed (COD 50 to 110 m), followed by another sudden increment. This

behaviour is repeated until the maximum resistance is obtained. This behaviour was also

found in Figure 2.b: sudden increments of resistance followed by gradual ones. It seems that

two distinct processes are occurring: gradual increase in resistance corresponding to crack

opening (increase in width); whereas sudden increase to crack propagation (debonding). Since

cracks obtained from the MWST had a V-shape (see Figure 1.b), the electrical resistance

increases as the cracked zone increases. Overall, its clear that there is a linear relationship

between cracking and the resistance. The equation that describes this relationship has the form

of:

y = ax+b (1)

where y is the measured electrical resistance (k), a is a parameter that describes the size

and connectivity of the pore structure, x is the disruption of the pore network (cracks) and b is

the initial resistance (k). There is a good correlation factor (R

2

) between load and resistance

in this curve. This linear relationship corresponds to that found by Boulay [12].

a) b)

Figure 2. Load-COD-Resistance (a) and Load-Resistance (b) curves of reinforced concrete.

Results of load-displacement and resistance for the four reinforced specimens are shown in

Table 2. In all four cases, the maximum load is on the range between 1.9 and 2.3 kN. The

COD at the maximum load was found in the range between 20 and 50 m. It seems that there

is no direct correlation between the maximum load and the COD: the maximum COD was

found at the lowest load and the maximum load had a narrow COD. For cracks below 300

m, the recovery after unloading was found to be above 40% or more. It seems logical that

wider cracks correspond to permanent damage that cannot be recovered during unloading

(Specimen 3, 20% of recovery). As for resistance increase, in three cases it was found to be

below 10%. Only in Specimen 3 the increase was above this level (15%). It seems to be that

as the damage becomes permanent, the increase in resistance will be higher.

Second International Conference on Microstructural-related Durability of

Cementitious Composites, 11-13 April 2012, Amsterdam, The Netherlands

Table 2. Results of load-displacement and resistance of reinforced specimens.

Spec. Max.

Load

(kN)

COD

Max

load

(m)

Max.

COD

(m)

Final

COD

(m)

Recovery

(%)

Initial

Resistance

(k)

Final

Resistance

(k)

Increase

(%)

R

2

1 1.93 50 300 180 40 6.4 7.0 9 0.94

2 2.02 30 200 120 40 7.1 7.4 4 0.94

3 2.26 27 500 400 20 6.2 7.1 15 0.97

4 2.04 23 150 80 47 5.7 6.2 8 0.83

Figure 3 shows the results of the load-displacement and resistance curves of an

unreinforced specimen. Figure 3.a shows that the maximum load is similar to those found on

reinforced specimens. However, it seems that for unreinforced specimens variations in the

load during the loading period (COD < 50 m) are absent. A reason for this behaviour is that

there are no grip disturbances between reinforcement and concrete. After the maximum load

has been reached, the softening part of the curve is similar as in Specimen 1. Also, the

recovery had roughly the same behaviour as in the reinforced case.

a) b)

Figure 3. Load-COD-Resistance (a) and Load-Resistance (b) curves of unreinforced

concrete. RA (R

2

= 0.98) is shown in both 3.a and 3.b . RB (R

2

= 0.25) only in curve in Fig

3.a

For resistance measurements, electrodes RA showed a behaviour somewhat similar to

Specimen 1, while electrode RB remained undisturbed over the whole measuring period. This

means that even after the maximum cracking occurs, the disturbed zone does not reach 100

mm from the top of the reinforcement. It seems that the first sudden increase in resistance did

not correspond to the displacement at the maximum load, but occurred at about 45 m. This is

also observed in Figure 3.b, the increase in resistance for electrode RA occurs when the load

in the specimen has already decreased. Compared to Specimen 1 the sudden changes in

resistance, which were attributed to crack propagation, were not so evident in unreinforced

concrete. In this case, the crack propagation and crack opening are closely related probably

Second International Conference on Microstructural-related Durability of

Cementitious Composites, 11-13 April 2012, Amsterdam, The Netherlands

occurring simultaneously. It seems that in reinforced concrete, the crack propagates towards

the reinforcement almost immediately, whereas in unreinforced penetrates slowly. This was

also found by Pease [11]. For electrodes RA the relationship between the electrical resistance

and COD had the same linear dependency as in reinforced concrete. Table 3 shows the results

of load-displacement and resistance in unreinforced specimen.

Table 3. Results of load-displacement and resistance of unreinforced specimens.

Spec. Max.

Load

(kN)

COD

Max

load

(m)

Max.

COD

(m)

Final

COD

(m)

Rec.

(%)

Initial

RA

(k)

Final

RA

(k)

(%)

R

2

Initial

RB

(k)

Final

RB

(k)

(%)

R

2

5 1.90 30 300 198 34 5.9 7.0 18 0.98 3.7 3.7 0 0.25

6 2.28 35 400 300 25 7.5 9.0 20 0.98 7.1 7.1 0 0.93

Results of unreinforced specimens show that for electrodes at the level of the notch (RA),

the increase in resistance was up to 20%. This is higher than in reinforced specimens. It seems

that unreinforced concrete is subject to higher deterioration from wide cracks (above 300 m).

For resistance at 100 mm deep (RB) there is no influence on resistance, meaning that for a

crack width of 300 m at the level of the notch the crack depth has not reached 100 mm from

the top of the specimen. In other words, cracking of unreinforced concrete occurs from the

combination of crack opening and propagation acting simultaneously. In the case of

reinforced specimens, this behaviour is not expected because cracks propagate first towards

the reinforcement and along it (Figure 1.b).

3.1 Forthcoming work

Future research on the relationship between concrete durability and cracks involve the

exposure and monitoring of transport properties, corrosion deterioration and different

materials (particularly CEM III/B). Research focused on studying the debonding of concrete

and steel will be included in future publications.

4. CONCLUSIONS

Reinforced and unreinforced concrete specimens were subject to loading in a Modified

(MWST) and ordinary Wedge Splitting Tests (WST). Displacement and electrical resistance

between two electrodes were monitored during loading. Results showed that resistance

variations found in reinforced concrete were attributed to crack opening and propagation,

independently. For unreinforced concrete, these two mechanisms were found to be acting at

the same time, leading to smaller variations of resistance and loading during the experiment.

The most important findings include:

1. Maximum load in reinforced and unreinforced specimens was about 2 kN. There was

no influence of reinforcement on the load at cracking

2. Electrical resistance showed a linear relationship with COD at the level of the notch

(electrodes RA) for reinforced and unreinforced concrete; no effect on resistance was

found at 100 mm deep (unreinforced, electrodes RB).

Second International Conference on Microstructural-related Durability of

Cementitious Composites, 11-13 April 2012, Amsterdam, The Netherlands

3. For reinforced concrete, sudden increments of resistance are probably attributed to

crack propagation towards and along the reinforcement. This will be confirmed with

further experiments.

4. In unreinforced concrete, electrical resistance did not show sudden increments but a

rather gradual behaviour.

5. Less recovery of COD at unloading was found in unreinforced specimens. Also, in the

same specimens a higher increase in resistance was found near the crack opening.

6. Monitoring electrical resistance provides a useful way of characterising cracking in

concrete.

ACKNOWLEDGEMENTS

Financial support by the Dutch Technology Foundation (STW) for the project 10978-

Measuring, Modelling, and Monitoring Chloride ingress and Corrosion initiation in Cracked

Concrete (M3C4) is gratefully acknowledged.

REFERENCES

[1] Polder, R.B. 2001. Test methods for on-site measurement of concrete resistivity a RILEM TC-

154 technical recommendation, Construction and Building Materials, 15(3): 125-131.

[2] Gulikers, J. 2005. Theoretical considerations on the supposed linear relationship between concrete

resistivity and corrosion rate of steel reinforcement. Materials and Corrosion 56(6): 393-403.

[3] Raupach, M. 2006. Models for the propagation phase of reinforcement corrosion - an overview.

Materials and Corrosion 57(8): 605-613.

[4] Andrade, C. 2010. Types of models of service life of reinforcement: the case of resistivity.

Concrete Research Letters 1(2): 73-80.

[5] Bryant Jr., J.W., Weyers, R.E., de la Garza, J.M. 2009. In-place resistivity of bridge deck concrete

mixtures. ACI Materials Journal, 106(2): 114-122.

[6] Rooij, M. de, Polder, R.B., Oosten, H. van, 2007, Validation of durability of cast in situ concrete

of the Groene Hart railway tunnel, HERON Vol. 52 (4), 225-238.

[7] avija, B. & Schlangen, E. 2011. Chloride ingress in cracked concrete a literature review. In C.

Andrade, J. Gulikers (eds.), Advances in Modeling Concrete Service Life: Proc. Of the 4

th

International RILEM PhD Workshop, Madrid, Spain, 19, November 2010. New York: Springer.

[8] Pacheco, J. & Polder, R.B. 2011. Corrosion initiation and propagation near cracks a literature

review. . In C. Andrade, J. Gulikers (eds.), Advances in Modeling Concrete Service Life: Proc. Of

the 4

th

International RILEM PhD Workshop, Madrid, Spain, 19, November 2010. New York:

Springer.

[9] Schiel, P. & Raupach, M. 1997. Laboratory studies and calculations on the influence of crack

width on chloride-induced corrosion of steel in concrete. ACI Materials Journal, 94(1): 56-60.

[10] Otieno, M.B., Alexander, M.G., Beushausen H.D. 2010. Corrosion in cracked and uncracked

concrete influence of crack width, concrete quality and crack reopening. Magazine of Concrete

Research, 62(6): 393-404.

[11] Pease, B.J., 2010. Influence of concrete cracking on ingress and reinforcement corrosion, PhD

Thesis, Technical University of Denmark.

[12] Boulay, C., Dal Pont, S., Belin, P. 2009. Real-time evolution of electrical resistance in cracking

concrete, Cement and Concrete Research 38(9): 825-831.

[13] Wang. K., Jansen, D.C., Shah, S.P. 1997. Permeability study of cracked concrete. Cement and

Concrete Research, 27(3): 381-393.

Second International Conference on Microstructural-related Durability of

Cementitious Composites, 11-13 April 2012, Amsterdam, The Netherlands

S-ar putea să vă placă și

- Lecture Notes on Reinforced Concrete DesignDe la EverandLecture Notes on Reinforced Concrete DesignÎncă nu există evaluări

- Reinforced Concrete Shear WallsDocument15 paginiReinforced Concrete Shear WallsJaime VegaÎncă nu există evaluări

- Electrical Resistivity of Concrete For Durability Evaluation: A ReviewDocument31 paginiElectrical Resistivity of Concrete For Durability Evaluation: A ReviewEhsanul KabirÎncă nu există evaluări

- Aci - 108-M04Document9 paginiAci - 108-M04Denglei TangÎncă nu există evaluări

- Comparison of Uniform and Non-Uniform Corrosion Induced Damage in Reinforced Concrete Based On A Gaussian Description of The Corrosion LayerDocument12 paginiComparison of Uniform and Non-Uniform Corrosion Induced Damage in Reinforced Concrete Based On A Gaussian Description of The Corrosion LayernagarajuÎncă nu există evaluări

- Durability of Concrete With Differential Concrete Mix DesignDocument10 paginiDurability of Concrete With Differential Concrete Mix Designshoyeeb ahmedÎncă nu există evaluări

- Impact of Crack Width On Bond Confined and Unconfined RebarDocument10 paginiImpact of Crack Width On Bond Confined and Unconfined RebarbrahmabulÎncă nu există evaluări

- 2 PaperDocument9 pagini2 PaperSaurav RukhaiyarÎncă nu există evaluări

- Paper - ST100 - 0611015158 Cracking Behavior of Base Restrained RC Walls Under Temperature and Shrinkage StrainsDocument10 paginiPaper - ST100 - 0611015158 Cracking Behavior of Base Restrained RC Walls Under Temperature and Shrinkage StrainswaynectwÎncă nu există evaluări

- Corrosion CinéticaDocument9 paginiCorrosion CinéticaOscar David Madera OzunaÎncă nu există evaluări

- Research On Different Types of Cracks in Plain and Reinforced ConcreteDocument3 paginiResearch On Different Types of Cracks in Plain and Reinforced ConcreteSnehal AbhyankarÎncă nu există evaluări

- MCI Protection of ConcreteDocument4 paginiMCI Protection of Concretejack21abÎncă nu există evaluări

- Application of Ductile FiberDocument8 paginiApplication of Ductile FiberAndreea BadulescuÎncă nu există evaluări

- OTIENO 2016 - Corrosion Rate Prediction Models PART IDocument13 paginiOTIENO 2016 - Corrosion Rate Prediction Models PART IVinícius RamosÎncă nu există evaluări

- Journal Inter 3 (Selesai 18)Document16 paginiJournal Inter 3 (Selesai 18)Putu DidiÎncă nu există evaluări

- Mathematical Model To Predict The Permeability of Water Transport in Concrete StructureDocument7 paginiMathematical Model To Predict The Permeability of Water Transport in Concrete StructureAntonioRodriguezÎncă nu există evaluări

- Experimental Study of Bond-Slip Performance of Corroded Reinforced Concrete Under Cyclic LoadingDocument10 paginiExperimental Study of Bond-Slip Performance of Corroded Reinforced Concrete Under Cyclic Loadingofreneo_joshua4437Încă nu există evaluări

- Fang, Lundgren, Chen, Zhu-Corrosion Influence On Bond in Reinforced ConcreteDocument9 paginiFang, Lundgren, Chen, Zhu-Corrosion Influence On Bond in Reinforced ConcretepinarinciÎncă nu există evaluări

- Assessment of The Durability of Concrete From Its Permeation Properties: A ReviewDocument11 paginiAssessment of The Durability of Concrete From Its Permeation Properties: A Reviewlahcen essÎncă nu există evaluări

- Crack Shape and Rust Distribution in Corrosion-Induced Cracking ConcreteDocument9 paginiCrack Shape and Rust Distribution in Corrosion-Induced Cracking ConcretenagarajuÎncă nu există evaluări

- Design of Composite Slabs With Profiled Steel Deck PDFDocument16 paginiDesign of Composite Slabs With Profiled Steel Deck PDFsourabh mahanaÎncă nu există evaluări

- In Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteDocument9 paginiIn Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement ConcreteA M Yasin ArmanÎncă nu există evaluări

- Corrosion Inhibitors PDFDocument9 paginiCorrosion Inhibitors PDFmanil_5100% (1)

- FulltextDocument17 paginiFulltextVarun SonkarÎncă nu există evaluări

- Water Absorption Capacity of Concrete Cubes With Sorptivity CoefficientDocument7 paginiWater Absorption Capacity of Concrete Cubes With Sorptivity CoefficientfurqanÎncă nu există evaluări

- 1321 3467 2 PBDocument8 pagini1321 3467 2 PBomed muhammadÎncă nu există evaluări

- Reinforcement-Concrete Bond Behavior - Experimentation in Drying Conditions and Meso-Scale ModelingDocument46 paginiReinforcement-Concrete Bond Behavior - Experimentation in Drying Conditions and Meso-Scale ModelingfaridÎncă nu există evaluări

- An Improved Tie Force Method For Progressive Collapse Resistance of Precast Concrete Cross Wall StructuresDocument9 paginiAn Improved Tie Force Method For Progressive Collapse Resistance of Precast Concrete Cross Wall StructuresCristina VlaicuÎncă nu există evaluări

- Simulation of Chloride Diffusivity For Cracked Concrete Based On RBSM and Truss Network ModelDocument13 paginiSimulation of Chloride Diffusivity For Cracked Concrete Based On RBSM and Truss Network ModelBandula PrasadÎncă nu există evaluări

- Analytical Theory of Flexural Behavior of Concrete Beam Reinforced With Textile-Combined SteelDocument11 paginiAnalytical Theory of Flexural Behavior of Concrete Beam Reinforced With Textile-Combined Steelmulenga mwenyaÎncă nu există evaluări

- Reinforced Concrete: TOLENTINO, Paul Diony S. CE133P/E01 Homework No. 1Document6 paginiReinforced Concrete: TOLENTINO, Paul Diony S. CE133P/E01 Homework No. 1Paul Diony TolentinoÎncă nu există evaluări

- Design of Composite Slabs With Profiled Steel Deck PDFDocument16 paginiDesign of Composite Slabs With Profiled Steel Deck PDFPanha MenhÎncă nu există evaluări

- Bridge Structures Cracks - What Made That PhenomenDocument10 paginiBridge Structures Cracks - What Made That PhenomenNguyễn Văn MinhÎncă nu există evaluări

- Nuclear Engineering and Design: Xuhui Zhang, Lei Wang, Jianren Zhang, Yafei Ma, Yongming LiuDocument11 paginiNuclear Engineering and Design: Xuhui Zhang, Lei Wang, Jianren Zhang, Yafei Ma, Yongming LiuJos PereÎncă nu există evaluări

- In Uence of Corrosion On The Bond Strength of Steel Rebars in ConcreteDocument18 paginiIn Uence of Corrosion On The Bond Strength of Steel Rebars in ConcretePABLO MAUROÎncă nu există evaluări

- Simulation Studies of Methods To Delay Corrosion and Increase Service Life For Cracked Concrete Exposed To Chlorides - Jones2015Document11 paginiSimulation Studies of Methods To Delay Corrosion and Increase Service Life For Cracked Concrete Exposed To Chlorides - Jones2015KY PengÎncă nu există evaluări

- Literature ReviewDocument3 paginiLiterature Reviewharshithak.cee21Încă nu există evaluări

- Construction and Building Materials: Yoon Suk Choi, Seong-Tae Yi, Myung Yu Kim, Woo Young Jung, Eun Ik YangDocument10 paginiConstruction and Building Materials: Yoon Suk Choi, Seong-Tae Yi, Myung Yu Kim, Woo Young Jung, Eun Ik YanggabrielfmeloÎncă nu există evaluări

- Materials: Effect Steel Fibre Content On The Load-Carrying Capacity of Fibre-Reinforced Concrete Expansion AnchorDocument14 paginiMaterials: Effect Steel Fibre Content On The Load-Carrying Capacity of Fibre-Reinforced Concrete Expansion AnchorInes Cajo MozoÎncă nu există evaluări

- Pengaruh Tebal Selimut Beton Normal Pada Laju Korosi Baja TulanganDocument15 paginiPengaruh Tebal Selimut Beton Normal Pada Laju Korosi Baja TulanganAbdul MalikÎncă nu există evaluări

- Construction and Building Materials: H.J. Zhou, X.B. Liang, X.L. Zhang, J.L. Lu, F. Xing, L. MeiDocument13 paginiConstruction and Building Materials: H.J. Zhou, X.B. Liang, X.L. Zhang, J.L. Lu, F. Xing, L. MeiAldair EPÎncă nu există evaluări

- Probabilistic Corrosion Initiation Model For Coastal Concrete StructuresDocument17 paginiProbabilistic Corrosion Initiation Model For Coastal Concrete StructuresLathifa Rahma AstutiÎncă nu există evaluări

- 2020 - CBM - 표면조도계 사용 참고Document14 pagini2020 - CBM - 표면조도계 사용 참고이호진Încă nu există evaluări

- Yuks El 2013Document22 paginiYuks El 2013R T.IÎncă nu există evaluări

- Construction and Building Materials: Ali Akbar Ramezanianpour, Amirreza Pilvar, Mahdi Mahdikhani, Faramarz MoodiDocument8 paginiConstruction and Building Materials: Ali Akbar Ramezanianpour, Amirreza Pilvar, Mahdi Mahdikhani, Faramarz Moodidevildriver_990Încă nu există evaluări

- Journal of Applied Polymer Science Volume 103 Issue 5 2007 (Doi 10.1002/app.25468) Sergul Acikalin Gulmus Ulku Yilmazer - Effect of The Surface Roughness and Construction Material On Wall Slip inDocument7 paginiJournal of Applied Polymer Science Volume 103 Issue 5 2007 (Doi 10.1002/app.25468) Sergul Acikalin Gulmus Ulku Yilmazer - Effect of The Surface Roughness and Construction Material On Wall Slip inMohamed MostafaÎncă nu există evaluări

- Engineering Structures: V. Sarhosis, S.W. Garrity, Y. ShengDocument11 paginiEngineering Structures: V. Sarhosis, S.W. Garrity, Y. ShengOktayÎncă nu există evaluări

- Seismic Failure Mode of Coastal Bridge Piers Considering The Effects of Corrosion-Induced Damage by (Sciencedirect) Wei Yuan, Anxin Guo, Hui LiDocument8 paginiSeismic Failure Mode of Coastal Bridge Piers Considering The Effects of Corrosion-Induced Damage by (Sciencedirect) Wei Yuan, Anxin Guo, Hui LiKanishka WijesekaraÎncă nu există evaluări

- Corrosion Protection Method and Perfocmance For PC StrandsDocument18 paginiCorrosion Protection Method and Perfocmance For PC Strandse.tociÎncă nu există evaluări

- Repair and Rehabilitation of Concrete PavementsDocument4 paginiRepair and Rehabilitation of Concrete PavementsIJERDÎncă nu există evaluări

- Introduction of Transition Zone Design For Bridge Deck Link Slabs Using Ductile ConcreteDocument10 paginiIntroduction of Transition Zone Design For Bridge Deck Link Slabs Using Ductile Concreteicv.xaviÎncă nu există evaluări

- Behavior of Interfaces Between Granular Soil and Structure: A State-Of-The-Art ReviewDocument12 paginiBehavior of Interfaces Between Granular Soil and Structure: A State-Of-The-Art ReviewMoharaÎncă nu există evaluări

- JPNR - S07 - 611Document12 paginiJPNR - S07 - 611Bien Thuy TranÎncă nu există evaluări

- 99-s38 - On Evaluation of Rotation Capacity For Reinforced Concrete BeamsDocument9 pagini99-s38 - On Evaluation of Rotation Capacity For Reinforced Concrete BeamsbllldÎncă nu există evaluări

- New Precast Wall Connection Subjected To Rotational Loading: Ŕ Periodica Polytechnica Civil EngineeringDocument14 paginiNew Precast Wall Connection Subjected To Rotational Loading: Ŕ Periodica Polytechnica Civil EngineeringrenishkavukattÎncă nu există evaluări

- Construction and Building MaterialsDocument12 paginiConstruction and Building Materialschristian ricaldiÎncă nu există evaluări

- Macrocell and Microcell Corrosion of Steel in Ordinary Portland Cement and High Performance ConcretesDocument5 paginiMacrocell and Microcell Corrosion of Steel in Ordinary Portland Cement and High Performance ConcretesEjazulhaq RahimiÎncă nu există evaluări

- Materials 15 01459 v2Document17 paginiMaterials 15 01459 v2Korrapati Pratyusha 19PHD0497Încă nu există evaluări

- Roziere 2015Document9 paginiRoziere 2015'Vanessa VogtÎncă nu există evaluări

- Behavior o Welded Plate Connections in Precast Concrete Panels Under Simulated Seismic LoadsDocument13 paginiBehavior o Welded Plate Connections in Precast Concrete Panels Under Simulated Seismic Loadslil_starÎncă nu există evaluări

- C 20 MTT 1 2 SemDocument165 paginiC 20 MTT 1 2 SemMatthew SmithÎncă nu există evaluări

- Material Science - CompressedDocument82 paginiMaterial Science - CompressedMatthew SmithÎncă nu există evaluări

- Combustion PDFDocument24 paginiCombustion PDFserkalemtÎncă nu există evaluări

- Maths 3 CompressedDocument208 paginiMaths 3 CompressedMatthew SmithÎncă nu există evaluări

- Combustion in Si EnginesDocument36 paginiCombustion in Si Enginesrgopi_83Încă nu există evaluări

- C 20 MY 3 4 SemDocument80 paginiC 20 MY 3 4 SemMatthew SmithÎncă nu există evaluări

- Time Management Conference 2019Document28 paginiTime Management Conference 2019Matthew SmithÎncă nu există evaluări

- 10 1 1 558 3354Document12 pagini10 1 1 558 3354Matthew SmithÎncă nu există evaluări

- 6Rph6Wxglhv RQ 0hfkdqlfdo 3urshuwlhv Ri (SR (/&7%1&od/ %Dvhg3Ro/Phu 1Dqrfrpsrvlwhv 31&Document8 pagini6Rph6Wxglhv RQ 0hfkdqlfdo 3urshuwlhv Ri (SR (/&7%1&od/ %Dvhg3Ro/Phu 1Dqrfrpsrvlwhv 31&Matthew SmithÎncă nu există evaluări

- Abst PHD EnotiadisDocument2 paginiAbst PHD EnotiadisMatthew SmithÎncă nu există evaluări

- 1 s2.0 S0263822315005164 MainDocument22 pagini1 s2.0 S0263822315005164 MainMatthew SmithÎncă nu există evaluări

- 1 s2.0 S2211812814005872 MainDocument7 pagini1 s2.0 S2211812814005872 MainMatthew SmithÎncă nu există evaluări

- Influence of Interface On Epoxy/clay Nanocomposites: 1. Morphology StructureDocument6 paginiInfluence of Interface On Epoxy/clay Nanocomposites: 1. Morphology StructureMatthew SmithÎncă nu există evaluări

- 813201113306Document10 pagini813201113306Matthew SmithÎncă nu există evaluări

- Front-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningDocument25 paginiFront-Wheel-Drive (Transaxle and CV Joint) Fundamentals: © 2012 Delmar, Cengage LearningMatthew SmithÎncă nu există evaluări

- Application of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing OperationDocument7 paginiApplication of Taguchi Method For Optimization of Process Parameters in Improving The Surface Roughness of Lathe Facing Operationwww.irjes.comÎncă nu există evaluări

- Basic Thermo 3Document65 paginiBasic Thermo 3Matthew SmithÎncă nu există evaluări

- Automatic Transmission SystemDocument21 paginiAutomatic Transmission SystemMamesh Mathankar100% (1)

- Automatic Transmission ApplicationsDocument26 paginiAutomatic Transmission ApplicationsMatthew SmithÎncă nu există evaluări

- Study of Friction and Wear of ABS/Zno Polymer Composite Using Taguchi TechniqueDocument10 paginiStudy of Friction and Wear of ABS/Zno Polymer Composite Using Taguchi TechniqueMatthew SmithÎncă nu există evaluări

- CE June 2011Document2 paginiCE June 2011sohan2902Încă nu există evaluări

- Fluid Mechanics Question Paper December 2014 January 2015Document2 paginiFluid Mechanics Question Paper December 2014 January 2015Matthew SmithÎncă nu există evaluări

- FM II AssaignmentDocument2 paginiFM II AssaignmentMatthew SmithÎncă nu există evaluări

- BTD - QBDocument25 paginiBTD - QBMatthew SmithÎncă nu există evaluări

- 1 PBDocument8 pagini1 PBMatthew SmithÎncă nu există evaluări

- 1 PBDocument8 pagini1 PBMatthew SmithÎncă nu există evaluări

- Automatic Transmission SystemDocument21 paginiAutomatic Transmission SystemMamesh Mathankar100% (1)

- Automobile EnginesDocument86 paginiAutomobile EnginesMatthew SmithÎncă nu există evaluări

- Describe The Construction and Operation of Manual and Semi-Automatic Transmissions Used On Light VehiclesDocument3 paginiDescribe The Construction and Operation of Manual and Semi-Automatic Transmissions Used On Light VehiclesMatthew SmithÎncă nu există evaluări

- Types of Chassis LayoutDocument8 paginiTypes of Chassis LayoutMatthew SmithÎncă nu există evaluări

- ACI 89-S15 Shrinkage Cracking in Fully Restrained Concrete MembersDocument9 paginiACI 89-S15 Shrinkage Cracking in Fully Restrained Concrete Membersvolmink50% (4)

- Nama Pemilik: Ronald Hidayat Marikar (Yayasan Cahaya Qian Santang) Kegiatan: Pembangunan Sekolah Desa Bojonggebang Kec. Babakan Kabupaten CirebonDocument42 paginiNama Pemilik: Ronald Hidayat Marikar (Yayasan Cahaya Qian Santang) Kegiatan: Pembangunan Sekolah Desa Bojonggebang Kec. Babakan Kabupaten CirebonAdit IshihaÎncă nu există evaluări

- Indian Standard: Code of Practice For Concrete Structures For The Storage of LiquidsDocument17 paginiIndian Standard: Code of Practice For Concrete Structures For The Storage of LiquidsChitharanjan VishnukripalÎncă nu există evaluări

- ACI 207.2R-95 Effect of Restraint, Volume Change, and Reinforcement On Cracking of Mass ConcreteDocument26 paginiACI 207.2R-95 Effect of Restraint, Volume Change, and Reinforcement On Cracking of Mass ConcreteAltin CeroÎncă nu există evaluări

- AnalysisDocument39 paginiAnalysislkovijayÎncă nu există evaluări

- Arcelor Mittal SlimFloor Steel Composite Floor StructureDocument36 paginiArcelor Mittal SlimFloor Steel Composite Floor Structurekatzan jammerÎncă nu există evaluări

- Reinforced Concrete Design-Krishnaraju PDFDocument318 paginiReinforced Concrete Design-Krishnaraju PDFJustin100% (3)

- Bamboo Reinforced Concrete PDFDocument24 paginiBamboo Reinforced Concrete PDFshahbaghi100% (1)

- 2006 Simplified Method For Concrete Pavement Design With DiscreteDocument10 pagini2006 Simplified Method For Concrete Pavement Design With DiscreteBakhtiyar Q.KhawajaÎncă nu există evaluări

- Bid Form - Munting Tubig - Balayan - Batangas - 062019 PDFDocument11 paginiBid Form - Munting Tubig - Balayan - Batangas - 062019 PDFPaul Zedric HerreraÎncă nu există evaluări

- Ircon Boq 2 A FinalDocument36 paginiIrcon Boq 2 A Finalsunil_rathore20073921Încă nu există evaluări

- A Comparitive Study of Solid Slab With Ribbed Slab in Bale Robe Town Ethiopia PDFDocument8 paginiA Comparitive Study of Solid Slab With Ribbed Slab in Bale Robe Town Ethiopia PDFeph100% (2)

- Silo Failures PDFDocument15 paginiSilo Failures PDFpalanipaaaaÎncă nu există evaluări

- Project WorkDocument112 paginiProject WorkGeraldÎncă nu există evaluări

- PCDDocument42 paginiPCDsalman khanÎncă nu există evaluări

- STRUCTURAL Design CriteriaDocument11 paginiSTRUCTURAL Design Criteriamdkml2Încă nu există evaluări

- The Seismic Response of Structural Outrigger SysteDocument9 paginiThe Seismic Response of Structural Outrigger SysteAbir DuttaÎncă nu există evaluări

- Bridge Strengthening Using Advanced Composite SystemDocument103 paginiBridge Strengthening Using Advanced Composite SystemSravaniChintalapani100% (1)

- Bq5-External Works (R)Document16 paginiBq5-External Works (R)TimÎncă nu există evaluări

- 6.5 ReinforcementDocument5 pagini6.5 ReinforcementMalith De SilvaÎncă nu există evaluări

- Project Data: Design InformationDocument8 paginiProject Data: Design InformationIbraheemÎncă nu există evaluări

- Structural Engineers Design ManualDocument304 paginiStructural Engineers Design ManualKhoa Lê ViếtÎncă nu există evaluări

- Impressed Current Cathodic Protection SectionDocument58 paginiImpressed Current Cathodic Protection Sectionbookbum100% (2)

- Ce2404 Pcs NotesDocument49 paginiCe2404 Pcs NotesChockalingamÎncă nu există evaluări

- One-Way Joist-Steel Lap Pan SystemEDR - 43Document4 paginiOne-Way Joist-Steel Lap Pan SystemEDR - 43AntonÎncă nu există evaluări

- Prediction of Shear Capacity and Mechanical Properties of Recycled Reinforced High Strength Concrete Beams Without StirrupsDocument37 paginiPrediction of Shear Capacity and Mechanical Properties of Recycled Reinforced High Strength Concrete Beams Without Stirrupsnagham tariqÎncă nu există evaluări

- Superfix Catalogue 2003Document148 paginiSuperfix Catalogue 2003Didin Dwi KristantoÎncă nu există evaluări

- s00-001 Index of Drawings 1Document1 paginăs00-001 Index of Drawings 1Sereyponleu KhunÎncă nu există evaluări

- Design of Piled FoundationDocument62 paginiDesign of Piled FoundationMaanvir SatyaÎncă nu există evaluări

- Flexural Behavior of RC Beams Strengthened With Steel Wire Mesh and Self-Compacting Concrete Jacketing D Experimental Investigation and Test ResultsDocument18 paginiFlexural Behavior of RC Beams Strengthened With Steel Wire Mesh and Self-Compacting Concrete Jacketing D Experimental Investigation and Test ResultsIbrahim HaddamÎncă nu există evaluări

- Marine Structural Design CalculationsDe la EverandMarine Structural Design CalculationsEvaluare: 4.5 din 5 stele4.5/5 (13)

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Structural Cross Sections: Analysis and DesignDe la EverandStructural Cross Sections: Analysis and DesignEvaluare: 4.5 din 5 stele4.5/5 (19)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDe la EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresEvaluare: 1 din 5 stele1/5 (2)

- Advanced Modelling Techniques in Structural DesignDe la EverandAdvanced Modelling Techniques in Structural DesignEvaluare: 5 din 5 stele5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignDe la EverandTo Engineer Is Human: The Role of Failure in Successful DesignEvaluare: 4 din 5 stele4/5 (138)

- Pile Design and Construction Rules of ThumbDe la EverandPile Design and Construction Rules of ThumbEvaluare: 4.5 din 5 stele4.5/5 (15)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsDe la EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsÎncă nu există evaluări

- Predicting Lifetime for Concrete StructureDe la EverandPredicting Lifetime for Concrete StructureÎncă nu există evaluări

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- Design and Construction of Soil Anchor PlatesDe la EverandDesign and Construction of Soil Anchor PlatesEvaluare: 5 din 5 stele5/5 (1)

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesDe la EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraEvaluare: 4.5 din 5 stele4.5/5 (4)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsDe la EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsEvaluare: 4 din 5 stele4/5 (16)

- Transmission Pipeline Calculations and Simulations ManualDe la EverandTransmission Pipeline Calculations and Simulations ManualEvaluare: 4.5 din 5 stele4.5/5 (10)

- Building Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareDe la EverandBuilding Support Structures, 2nd Ed., Analysis and Design with SAP2000 SoftwareEvaluare: 4.5 din 5 stele4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingDe la EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingÎncă nu există evaluări

- Modeling and Dimensioning of Structures: An IntroductionDe la EverandModeling and Dimensioning of Structures: An IntroductionÎncă nu există evaluări

- Concrete Structures: Repair, Rehabilitation and StrengtheningDe la EverandConcrete Structures: Repair, Rehabilitation and StrengtheningÎncă nu există evaluări