Documente Academic

Documente Profesional

Documente Cultură

Hydraulic Free Piston Engines

Încărcat de

Prabir Kumar PatiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hydraulic Free Piston Engines

Încărcat de

Prabir Kumar PatiDrepturi de autor:

Formate disponibile

NORTH MAHARASHTRA UNIVERSITY,

JALGAON.

AN

SEMINAR REPORT

AT

HYDRAULIC FREE PISTON ENGINES

SUBMITTED BY

Mr. KALPESH D. PATIL

DEPARTMENT OF MECHANICALENGINEERING

(*N.B.A.* ACCREDITED)

P.S.G.V.P.MANDALS

D.N.PATEL COLLEGE OF ENGINEERING

SHAHADA, DIST: NANDURBAR (M.S.) 4!4"#

(ACADEMIC YEAR "$"%"$$)

1

P.S.G.V.P. MANDALS

D.N.PATEL COLLEGE OF ENGINEERING

SHAHADA, DIST. NANDURBAR (M.S.) 4!4"#

CERTIFICATE

This is to be certify that the seminar report at

HYDRAULIC FREE PISTON ENGINES

SUBMITTED BY

Mr. KALPESH D. PATIL

As a part of syllabus of

NORTH MAHARASHTRA UNIVERSITY, &ALGAON

For the partial fulfillment

FINAL YEAR OF ENGINEERING IN ME!ANIAL IN T!E AA"EMI

YEAR #$1$%#$11

H.O.D. GUIDE PRINCIPAL

Pr'(. S. U. PATEL Pr'(. S. U. PATEL Pr'(. P. D. PATIL

#

ABSTRACT

The !IRON is a hy&raulic free piston en'ine &e(elope& by the "utch companies

NOA) an& Innas* In the !IRON the ener'y of the combustion process is almost &irectly

con(erte& into hy&raulic ener'y* The !IRON features a &irect electronic control of the

in+ection parameters, the flo- an& the compression ratio* The flo- output is controlle& by

means of .ulse .ause Mo&ulation of the piston fre/uency* The !IRON is &esi'ne& for

application in common pressure rail systems* In these systems the hy&raulic ener'y is

supplie& throu'h a common rail* This paper &escribes the &esi'n of the !IRON* 0pecial

attention -ill be pai& on the specific characteristics of the !IRON compare& to

con(entional en'ines an& pumps*

1

ABSTRACT

The !IRON is a hy&raulic free piston en'ine &e(elope& by the "utch companies

NOA) an& Innas* In the !IRON the ener'y of the combustion process is almost &irectly

con(erte& into hy&raulic ener'y* The !IRON features a &irect electronic control of the

in+ection parameters, the flo- an& the compression ratio* The flo- output is controlle& by

means of .ulse .ause Mo&ulation of the piston fre/uency* The !IRON is &esi'ne& for

application in common pressure rail systems* In these systems the hy&raulic ener'y is

supplie& throu'h a common rail* This paper &escribes the &esi'n of the !IRON* 0pecial

attention -ill be pai& on the specific characteristics of the !IRON compare& to

con(entional en'ines an& pumps*

2

INTRODUCTION

A Free .iston En'ine % almost e(erybo&y has some i&ea -hat it coul& be, but -hat are typical

features of the free piston en'ines3 There are t-o &efinitions, -hich are typical for all free

piston en'ines4

A combustion en'ine, -hich piston motion is not restricte& by any mechanical

lin5a'es*

The po-er is ta5en out by me&ia, not by shaft

The reason -hy en'ineers ha(e been intereste& in free piston en'ines since &eca&es is the

basic i&ea of a (ery simple en'ine* The simple &esi'n enables minimum amount of ener'y

transformations from fuel ener'y into form, -hich is use& by actuators*

The research in free piston en'ines has recently concentrate& on hy&raulic (ersions but some

&e(elopment in electric (ersion has also been reporte&* !y&raulic free piston en'ine &esi'ns

are possible an& are &i(i&e& into three cate'ories accor&in' to the number an& location of the

pistons4

0in'le piston

Oppose& piston

"ual piston

The basic operation principle of each concept is similar i*e* the ener'y of the fuel is

transforme& into hy&raulic ener'y by means of linearly mo(in' piston assembly* "ifferences

bet-een the concepts are the number of combustion chambers an& hy&raulic pistons an&

compression stro5e reali6ation* The schematic &ra-in's of the concepts are sho-n in fi'ure

on the ne7t pa'e*

8

The hydraulic free i!"#$ e$%i$e c#$ce"!& a'#(e) The !i$%le i!"#$& *iddle) The ##!ed

i!"#$& 'el#+) The dual i!"#$, Par" $u*'er!) -) C#*'u!"i#$ cyli$der& .) C#*re!!i#$

cyli$der& /) Pu* cyli$der,

The combustion en'ine part is a t-o%stro5e &iesel en'ine because this 5in& of an en'ine

re/uires po-er stro5e once per each cycle* In or&er to achie(e hi'h combustion of the en'ine

units un&er efficiency, &iesel process -ith &irect fuel in+ection is utili6e&* The po-er le(els

&e(elopment are 18 9 8$ 5:, the total po-er is possible to raise by increasin' the number of

the en'ine units* The &iameter of the combustion piston is ;$ 9 18$ mm an& operation

fre/uency is up to 8$ !6*

<

FREE PISTON ENGINE V) CONVENTIONAL ENGINES

Reasons, -hy there are research an& &e(elopment acti(ities concernin' the hy&raulic free

piston en'ine, are base& on the benefits -hich coul& be achie(e& by the free piston concept*

The !F.E=!y&raulic Free .iston En'ine> has some fascinatin' a&(anta'es o(er the

con(entional cran5shaft en'ine 9 hy&raulic pump combination, 0E.=ran5 0haft .iston

En'ine>

The po-er &ensity of the !F.E is hi'her than the 0E.? this means less -ei'ht an&

less space re/uire& by the en'ine*

Lo-er friction losses, because of fe-er parts an& piston has no si&e forces, -hich are

in&uce& by cran5 mechanisms*

The last but not least is the price of the en'ine because of pro&uction costs, -hich are

much lo-er in the !F.E because of simple &esi'n*

The efficiency of the !F.E is in the same le(el as in 0E. or e(en better* The lac5 of cran5

mechanism creates some &isa&(anta'es as -ell, the control system ha(e to be more

complicate& than in the con(entional en'ines* The compression ratio is in&efinite an& it

&epen&s on the ener'y balance of each stro5e* The lo- emission le(el an& efficient burnin'

re/uire controlle& piston motion* On the other han& reliable compression ratio control enables

the optimi6ation of the compression ratio in &ifferent operation con&itions, -hich is not

possible -ith con(entional en'ines* The other &isa&(anta'e of the !F.E is the lac5 of

controllability of the output of the !F.E compare& to con(entional en'ine%pump

combination because the pump is constant &isplacement or step -isely (ariable &isplacement

pump*

@

A BRIEF INTRODUCTION*

This seminar mainly &iscusses the stu&y of the !IRON =.ronunciation 5yArahn>

Free .iston En'ines, -hich is a hy&raulic free piston en'ine* !IRON in Gree5 mytholo'y

-as a centaur? neither a horse nor a man but a synthesis of both* 0imilarly, the !IRON

&iscusse& in here is neither an en'ine nor a pump? but an inte'ration of an en'ine an& a pump*

In !IRON the combustion ener'y is &irectly con(erte& into hy&raulic ener'y* The !IRON

features &irect electronic control of the in+ection parameters, the flo- an& the compression

ratio* The !IRON is &esi'ne& for ommon .ressure Rail =.R> systems* In these systems,

the hy&raulic ener'y is supplie& throu'h a common rail* 0pecial attention -ill be pai& to

specific characteristics of the !IRON compare& to con(entional en'ines an& pumps.

The hiron free piston en'ine is an inte'rate& combination of an internal combustion en'ine

an& a hy&raulic pump* The core of this en'ine is a combustion piston &irectly couple& to a

hy&raulic plun'er* The piston is not connecte& to any mechanism but is free to mo(e -ithin

the limitations of the cylin&ers* In this -ay the ener'y of the combustion process is almost

&irectly con(erte& into hy&raulic ener'y* ompare& to a con(entional combination of a pump

an& a combustion en'ine, the number of parts is re&uce& to appro7imately 2$B*

;

Fi'* Cie- of !IRON =len'th, -i&th D hei'ht of en'ine is $*;#mm, $*1mmD$*18mm>

1> ylin&er !ea&*

#> ombustion ylin&er D sca(en'e pump*

1> .iston*

2> 0ealin' rin' bet-een hy&raulic D combustion part*

8> !y&raulic part*

E

+ORKING PRINCIPLE

A cycle starts -ith the piston9plun'er combination in the bottom &ea& centre4 most to

the ri'ht* The electronic control opens the fre/uency control (al(e* This increases the

pressure in the compressor cylin&er, mo(in' the piston%plun'er to the left* 0imultaneously, air

is compresse& in the combustion cylin&er an& oil is suc5e& into the po-er cylin&er*

:hen the piston%plun'er arri(es in the top &ea& centre the fuel is in+ecte& an& i'nites,

the e7pan&in' 'ases -ill force the piston plun'er to mo(e bac5 to the bottom &ea& centre* Oil

is pumpe& to the hi'h pressure si&e*

The burne& 'ases are replace& by fresh air &ue to the loop sca(en'in' process* In the

bottom &ea& centre the piston%plun'er -ill -ait until the electronic control 'i(es a ne-

startin' si'nal to the fre/uency control (al(e*

1$

FUEL INJECTION

The !IRON is t-o%stro5e &iesel en'ine D &irect fuel in+ection system* For the

hiron a !EFI =!y&raulic%Electronic Fnit In+ector*> of aterpillar Inc* -as chosen* The

control of the in+ector is inte'rate& in the control mo&ule of the hiron* The !EFI in+ector is

hy&raulically actuate& an& the ener'y is ta5en from the hy&raulic ener'y &eli(ere& by the

hy&raulic pump part*

The use& !EFI in+ector pressures up to 1<$ Mpa* Fuel can be in+ecte& -ithin

1 millisecon& an& is atomi6e& into (ery small &roplets*

Fi'4 Fuel In+ection of ylin&er Gloc5 in !IRON en'ine*

11

CONTROL

The control of the hiron is reali6e& by means of sensors, actuators an& electronics*

0ynchroni6ation of piston mo(ement an& fuel in+ection can only be reali6e& by electronic

control* T-o simple an& robust in&ucti(e sensors are use& to &etermine the position of the

plun'er* The control har&-are is built aroun& an off the shelf 0IEMEN0 2$ M!6 1< bit

processor*

The compression ratio is controlle& by chan'in' the pressure le(el in the

compression accumulator? the G"%position of the piston is 5ept as constant as possible* A

pilot operate& &i'ital (al(e is use& to start each pump cycle* This (al(e initiates the po-er

control -hich is calle& .ulse .ause Mo&ulation*

1#

PULSE PAUSE MODULATION (PPM) F,'- C'./r',:

The principle of pulse%pause%mo&ulation can be illustrate& by loo5in' at the piston

&isplacement cur(es4 at ma7imum fre/uency an& at re&uce& fre/uency*

At ma7imum fre/uency, each pulse =mar5e& yello-> is &irectly follo-e& by a ne- pulse* At a

re&uce& fre/uency, e7actly the same pulses can be seen, but in bet-een these pulses, a pause

is intro&uce&* The &uration of this perio& can be (arie&* Gy increasin' the pause the number

of pulses -ill be re&uce&, thus &ecreasin' the flo- output of the hiron* Gy re&ucin' the

pause%perio& -e can increase the fre/uency an& therefore also increase the flo- output* In

this -ay the flo-%output can be (arie& bet-een 6ero an& ma7imum flo- output, only by

controllin' a small electronically operate& pilot (al(e* The result is a (ery fle7ible, hi'hly

&ynamic electronic control of the flo- output*

Fi'* !y&ro pneumatic bla&&er

accumulator*

11

DIGITALLY CONTROLLED VALVE

To (ary the en'ineAs po-er output, the stro5e fre/uency is (arie& by the fre/uency

control (al(e* Innas &e(elope& a lar'e (al(e -ith an e7tremely fast openin' response time*

The (al(e is pilot operate&* The main (al(e consists of t-o (al(e bo&ies* After s-itchin' the

pilot (al(e the main (al(e opens -ithin 1*8 millisecon&s*

12

COMBUSTION

The combustion part of the hiron is t-o%stro5e naturally aspire& &iesel en'ines -ith

a simple port controlle& sca(en'e process =loop sca(en'in'>* The bac5si&e of the combustion

piston is use& as the sca(en'e pump* This results in a compact an& cost%effecti(e

construction* If the combustion in !IRON en'ine ha(e a &uration of 8 millisecon&s, -hich

-oul& ha(e normal for an en'ine of this si6e*

on(entional compression is starte& -ith an electrical starter motor, at a spee& of 1$$%

18$ rpm* This spee& 'i(es t-o problems4 'as lea5a'e throu'h the 'aps of the piston rin's an&

slo- piston mo(ement lea&in' to hi'her heat losses* Goth effects lea& to a &ecrease of the

cylin&er pressure an& temperature at the en& of the compression, an& therefore startin'

problems*

18

Fi'* onstruction of the ompression section in the hy&raulic part of the !IRON*

In the hiron the compression accumulator pro(i&es the ener'y to the 'ases of the

combustion cylin&er* At a col& start, the hy&ro%mechanical losses are hi'her* This can be

compensate& by choosin' a hi'her pressure in the accumulator* The pressure is e(en ele(ate&

e7tra to raise the compression ratio a little more at col& start* This compensates the effect of a

lon'er i'nition &elay as an effect of the col&er combustion air* Asi&e from this compensation,

the piston mo(ement at col& start is the same &urin' normal operation* ol& start problems as

mentione& abo(e are not rele(ant for the hiron4 the en'ine starts -ithout startin' ai&*

1<

COOLING

The combustion cylin&er an& cylin&er hea& are li/ui& coole&* The coolin' channels

are inte'rate& in the castin's* The li/ui& is supplie& at the bottom si&e, coolin' the e7haust

ports first* :ater can be use& as coolin' me&ium

1@

CHARACTERISTICS

EFFICIENCY

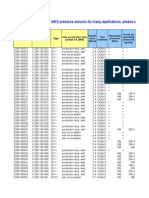

This graph of efficiency (%) Vs Flow (liter/min) compares the CHIRON with the

reglar !iesel engine"

1;

APPLICATIONS

The

hiron free

.iston

En'ine is

&e(elope& as a po-er source for all 5in&s of mobile machinery li5e for e7ample lift truc5s,

e7ca(ators etceteras* The a&(anta'es of the hiron are put to an optimal effect -hen

applie& in a ommon .ressure Rail =.R>* This .R is a ne- approach in the &esi'n of

hy&raulic net-or5s* In these systems all hy&raulic loa&s can be connecte& to a sin'le

pressure rail* !y&raulic transformers =I!T> enable the control of the loa&s almost -ithout

ener'y loss* In these systems, the po-er source only has to maintain a certain =semi%>

constant pressure in the po-er line* "ue to its hi'h &ynamic control possibilities, the

hiron is the i&eal lo-%cost ener'y source for .R systems*

1E

COMMON PRESSURE RAIL (CPR)

The ommon pressure Rail or .R can be seen as a hy&raulic e/ui(alent of the

electricity 'ri&* It is easy to attach an& a&& &ifferent loa&s to the po-er 'ri&* The common

pressure rail separates the hy&raulic po-er plants =the pumps> from the loa&s =motors an&

cylin&ers>* Loa&s &o not influence each other* Gy means of hy&ro pneumatic accumulators the

pressure le(el of the common pressure rail can be (arie& in a controlle& -ay* The ener'y that

is store& in these accumulators can be use& for po-er mana'ement an& ener'y recuperation*

The pressure &oes not necessarily ha(e to be constant, as !y&raulic Transformers are use& as

control &e(ices* The transformers can transform hy&raulic ener'y almost -ithout ener'y loss*

.R technolo'y enables a much simpler an& more fle7ible Hplu'%an&%playA approach of

hy&raulic circuits, in analo'y to the ease of use of an electricity 'ri&*

Actually, any type of pump can be use& for the .R system* !o-e(er, for mobile

applications, the !IRON offers most effecti(e Hpo-er plantA* This en'ine can also utili6e

the same techni/ue as use& by the cran5shaft en'ines li5e the hi'h%pressure in+ection,

alternati(e fuels, superchar'in' an& the after treatment of e7haust 'ases* Abo(e all, the

!IRON pro(i&es controlle& compression ratio as -ell as intrinsically &ifferent

combustion processes*

#$

FORKLIFTS

In or&er to &emonstrate an& test the technolo'ies Innas an& NOA) fitte& a Lift

truc5 -ith a .R system* T-o transformers -ere use& in this &ri(e system, one four%

/ua&rant transformer for the hy&rostatic -heel &ri(e, an& a #%/ua&rant for the control of the

lift cylin&ers* Throttle (al(es are use& for the other cylin&ers* Althou'h this results in some

ener'y losses, the ener'y consumption of these loa&s is lo- compare& to the liftin' an&

&ri(e functions* The po-er source consists of a hiron Free .iston En'ine &eli(erin' 1@

5: net hy&raulic ener'y* Grea5in' ener'y an& ener'y of lo-erin' the loa& are recuperate&*

This combine& -ith po-er mana'ement =pea5 sha(in'> ma&e it possible to re&uce the

installe& En'ine po-er -ith 1$B*

The .R%system has a&(anta'e only if multiple hy&raulic loa&s ha(e to be

controlle& in the hy&raulic system* This a&(anta'e is use& in the for5lift truc5* This system

has been foun& to -or5 effecti(ely, in this t-o hy&raulic transformers are use&, one for the

hy&rostatic -heel &ri(e an& one for the lift cylin&er* Althou'h this results in ener'y losses,

#1

the ener'y consumption of these loa&s is lo- compare& to the other loa&s, an& the throttle

losses -ill not ha(e a lar'e effect on the total fuel consumption of the lift truc5*

CONCLUSION

Althou'h much -or5 still has to be &one, it has been pro(en that it is possible to a(oi& the

mechanical comple7ity of the current cran5shaft en'ines an& hy&raulic pumps an& to buil& a

ne- hy&raulic unit -ith e7tra electronic control possibilities* These en'ines allo- a better

optimi6ation to-ar&s lo-er fuel consumption an& re&uce& e7haust emissions than the current

&ri(e lines* Lea&in' companies in the fiel&s of construction machines an& hy&raulic

components no- continue the &e(elopment of these Free .iston En'ines* These Free .iston

En'ines -ill turn out to be the best alternati(e for the I en'ine &ri(en pumps an& -ill

re(olutioni6e the ol& concept of usin' a rotatin' shaft or pump -here a much simpler piston

an& plun'er arran'ement can suffice*

##

REFERENCES

1* Achten .*A*I* JA re(ie- of .iston En'ine onceptsK 0AE paper E21@@<

#* J!orse po-er -ith brainsK 9"esi'n of !IRON free piston en'ine 0AE paper%

#$$$%$1%#828

1* ---*iha*tut*fiLresearchLmoreMinfoMonMhfpe*shtml

2* ---*innas*com

#1

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Dual-Bridge DC-DC Converter Thesis Certification PKACE BargarhDocument1 paginăDual-Bridge DC-DC Converter Thesis Certification PKACE BargarhPrabir Kumar PatiÎncă nu există evaluări

- PrefaceDocument3 paginiPrefacePrabir Kumar PatiÎncă nu există evaluări

- HJH.Document1 paginăHJH.Prabir Kumar PatiÎncă nu există evaluări

- CouplingDocument9 paginiCouplingPrabir Kumar PatiÎncă nu există evaluări

- (DS) ABHISHEK AND SOURAVokDocument8 pagini(DS) ABHISHEK AND SOURAVokPrabir Kumar PatiÎncă nu există evaluări

- Feed Back Report For R&D Center Bargarh OdishaDocument6 paginiFeed Back Report For R&D Center Bargarh OdishaPrabir Kumar PatiÎncă nu există evaluări

- Box DesignDocument1 paginăBox DesignPrabir Kumar PatiÎncă nu există evaluări

- Air BagDocument17 paginiAir BagPrabir Kumar PatiÎncă nu există evaluări

- Submitted To: - Submitted ByDocument1 paginăSubmitted To: - Submitted ByPrabir Kumar PatiÎncă nu există evaluări

- Election Process in India: A Project EssayDocument2 paginiElection Process in India: A Project EssayPrabir Kumar PatiÎncă nu există evaluări

- Create A Table (MDB) Using MS-AccessDocument3 paginiCreate A Table (MDB) Using MS-AccessPrabir Kumar PatiÎncă nu există evaluări

- (DS) Sigma and SriastikaokDocument8 pagini(DS) Sigma and SriastikaokPrabir Kumar PatiÎncă nu există evaluări

- MCOM 1st Year English PDFDocument8 paginiMCOM 1st Year English PDFakshaykr1189Încă nu există evaluări

- Rajesh Kumar Bagarti: BA (Education) Passed Out in 2008 With 48% From Jagannath Collage Sahaj Bahal, BalangirDocument1 paginăRajesh Kumar Bagarti: BA (Education) Passed Out in 2008 With 48% From Jagannath Collage Sahaj Bahal, BalangirPrabir Kumar PatiÎncă nu există evaluări

- Smith Chart From Black Magic DesignDocument1 paginăSmith Chart From Black Magic DesignkgrhoadsÎncă nu există evaluări

- 2 Modern Periodic TableDocument30 pagini2 Modern Periodic TablePrabir Kumar PatiÎncă nu există evaluări

- Study XL Indian Bank, Bodi-FormatDocument34 paginiStudy XL Indian Bank, Bodi-FormatPrabir Kumar PatiÎncă nu există evaluări

- Subham 1Document2 paginiSubham 1Prabir Kumar PatiÎncă nu există evaluări

- BordersDocument3 paginiBordersPrabir Kumar PatiÎncă nu există evaluări

- Agri Study DO Annex3 FormatDocument1 paginăAgri Study DO Annex3 FormatPrabir Kumar PatiÎncă nu există evaluări

- (DS) Swagatika and RuchiokDocument8 pagini(DS) Swagatika and RuchiokPrabir Kumar PatiÎncă nu există evaluări

- (DS) ABHISHEK AND SOURAVokDocument8 pagini(DS) ABHISHEK AND SOURAVokPrabir Kumar PatiÎncă nu există evaluări

- Sneha and NamrataokDocument8 paginiSneha and NamrataokPrabir Kumar PatiÎncă nu există evaluări

- SKT Clerk Paper PatternDocument10 paginiSKT Clerk Paper PatternPrabir Kumar PatiÎncă nu există evaluări

- HumanoidsDocument20 paginiHumanoidsPrabir Kumar PatiÎncă nu există evaluări

- Indian Army Soldiers Clerks Exam Questions I Am Giving HereDocument4 paginiIndian Army Soldiers Clerks Exam Questions I Am Giving HerePrabir Kumar PatiÎncă nu există evaluări

- AntimatterDocument24 paginiAntimatterPrabir Kumar PatiÎncă nu există evaluări

- High Speed TrainsDocument17 paginiHigh Speed TrainsPrabir Kumar PatiÎncă nu există evaluări

- Heat TreatmentDocument16 paginiHeat TreatmentPrabir Kumar Pati100% (1)

- Automatic Gear Shift MechanismDocument14 paginiAutomatic Gear Shift MechanismPrabir Kumar PatiÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Fundamental Behavior of FireDocument1 paginăFundamental Behavior of FireirfanÎncă nu există evaluări

- V-3111-002-A-711 - 2 Method Statement For Water Well WorkDocument14 paginiV-3111-002-A-711 - 2 Method Statement For Water Well WorkWidya PrasetyaÎncă nu există evaluări

- Pump Inlet Piping DesignDocument2 paginiPump Inlet Piping DesignWayaya WaziwupyaÎncă nu există evaluări

- Timing Chain InstallationDocument5 paginiTiming Chain InstallationToriTo LevyÎncă nu există evaluări

- Bum 60 S: Single Power UnitDocument62 paginiBum 60 S: Single Power UnitBruno CardosoÎncă nu există evaluări

- Diagrama Electr 325c ExcavaDocument2 paginiDiagrama Electr 325c ExcavaTecnicos-mexicanos Soto100% (3)

- LV Rating Factors in GroundDocument3 paginiLV Rating Factors in GroundChris MostertÎncă nu există evaluări

- MS - Tank Cleaning and DesludgingDocument7 paginiMS - Tank Cleaning and DesludgingkoyahassanÎncă nu există evaluări

- Quat KrugerDocument52 paginiQuat Krugerruby0808Încă nu există evaluări

- ATSDocument8 paginiATSserban_elÎncă nu există evaluări

- Luminous PDFDocument1 paginăLuminous PDFKushal AkbariÎncă nu există evaluări

- LED Catalog2020Document61 paginiLED Catalog2020VincentÎncă nu există evaluări

- Manta To Richmond SIMOPS Risk Matrix FINALDocument1 paginăManta To Richmond SIMOPS Risk Matrix FINALDesmond Chang50% (2)

- SUNSLATES™ 6 PV Roof Tile - Award Winning Architectural AppealDocument2 paginiSUNSLATES™ 6 PV Roof Tile - Award Winning Architectural AppealFaeria20Încă nu există evaluări

- EV Technology QPDocument3 paginiEV Technology QPvcetnaac c6Încă nu există evaluări

- Alok Mitra NotesDocument5 paginiAlok Mitra NotesSukanya GuhaÎncă nu există evaluări

- LevyDocument4 paginiLevyRamon FerreiraÎncă nu există evaluări

- Biofuel For Sri LankaDocument0 paginiBiofuel For Sri LankaJaanu SanthiranÎncă nu există evaluări

- Fcu Pressure Drop PDFDocument18 paginiFcu Pressure Drop PDFvishalÎncă nu există evaluări

- Bosch Injector Data SheetDocument124 paginiBosch Injector Data SheetThibaut Lrt56% (9)

- DCVDocument35 paginiDCVTanoj Patro100% (1)

- Seismic Acquisition and Processing BWDocument33 paginiSeismic Acquisition and Processing BWghassen laouiniÎncă nu există evaluări

- EHS Compliance Scope of Work for Ather EnergyDocument4 paginiEHS Compliance Scope of Work for Ather EnergyFazal AhmadÎncă nu există evaluări

- Enigma Motors: Mobility Company That Sticks To GrassrootsDocument14 paginiEnigma Motors: Mobility Company That Sticks To GrassrootsUmangÎncă nu există evaluări

- Sugar Industry in Pakistan (17-UGLC-650)Document16 paginiSugar Industry in Pakistan (17-UGLC-650)Waqar IbrahimÎncă nu există evaluări

- 9 - Free Point and Backoff - (Houston)Document29 pagini9 - Free Point and Backoff - (Houston)Usama Bin Sabir100% (2)

- Calibration of Refractory Metal Thermocouples Using A Radiation ThermometerDocument14 paginiCalibration of Refractory Metal Thermocouples Using A Radiation ThermometerleonxjhonÎncă nu există evaluări

- Busway SpecificationDocument6 paginiBusway SpecificationNATHANÎncă nu există evaluări

- Ogjournal20150706 DLDocument136 paginiOgjournal20150706 DLrasyid93Încă nu există evaluări

- Atomic Nucleus Facts and ConceptsDocument24 paginiAtomic Nucleus Facts and ConceptsKashyap PatelÎncă nu există evaluări