Documente Academic

Documente Profesional

Documente Cultură

ML-4500 Xac.0000051614.e.02

Încărcat de

RostocanieTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ML-4500 Xac.0000051614.e.02

Încărcat de

RostocanieDrepturi de autor:

Formate disponibile

1.

Precautions

Follow these safety, ESD, and servicing precautions to prevent personal injury and equipment damage.

1-1 Safety Precautions

1. Be sure that all built-in protective devices are in

place. Restore any missing protective shields.

2. Make sure there are no cabinet openings through

which people- particularly children- might insert

fingers or objects and contact dangerous voltages.

3. When re-installing chassis and assemblies, be

sure to restore all protective devices, including

control knobs and compartment covers.

4. Design Alteration Warning:

Never alter or add to the mechanical or electrical

design of this equipment, such as auxiliary

connectors, etc. Such alterations and

modifications will void the manufacturers

warranty.

5. Components, parts, and wiring that appear to

have overheated or are otherwise damaged

should be replaced with parts which meet the

original specifications. Always determine the

cause of damage or overheating, and correct any

potential hazards.

6. Observe the original lead dress, especially near

sharp edges, AC, and high voltage power

supplies. Always inspect for pinched, out-of-

place, or frayed wiring. Do not change the

spacing between components and the printed

circuit board.

7. Product Safety Notice:

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they provide could be

lost if a replacement component differs from the

original. This holds true, even though the

replacement may be rated for higher voltage,

wattage, etc.

Components critical for safety are indicated in

the parts list with symbols . Use only

replacement components that have the same

ratings, especially for flame resistance and

dielectric specifications. Areplacement part that

does not have the same safety characteristics as

the original may create shock, fire, or other safety

hazards.

Samsung Electronics 1-1

1-2 Samsung Electronics

Precautions

1-2 ESD Precautions

Certain semiconductor devices can be easily

damaged by static electricity. Such components are

commonly called Electrostatically Sensitive (ES)

Devices, or ESDs. Examples of typical ESDs are:

integrated circuits, some field effect transistors, and

semiconductor chip components.

The techniques outlined below should be followed

to help reduce the incidence of component damage

caused by static electricity.

CAUTION: Be sure no power is applied to the

chassis or circuit, and observe all other safety

precautions.

1. Immediately before handling a semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body

by touching a known earth ground. Alternatively,

employ a commercially available wrist strap

device, which should be removed for your personal

safety reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped

with ESDs, place the assembly on a conductive

surface, such as aluminum or copper foil, or

conductive foam, to prevent electrostatic charge

buildup in the vicinity of the assembly.

3. Use only a grounded tip soldering iron to solder

or desolder ESDs.

4. Use only an anti-static solder removal device.

Some solder removal devices not classified as

anti-static can generate electrical charges

sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When

sprayed, these can generate electrical charges

sufficient to damage ESDs.

6. Do not remove a replacement ESD from its

protective packaging until immediately before

installing it. Most replacement ESDs are

packaged with all leads shorted together by

conductive foam, aluminum foil, or a comparable

conductive material.

7. Immediately before removing the protective

shorting material from the leads of a replacement

ESD, touch the protective material to the chassis

or circuit assembly into which the device will be

installed.

8. Maintain continuous electrical contact between

the ESD and the assembly into which it will be

installed, until completely plugged or soldered

into the circuit.

9. Minimize bodily motions when handling

unpackaged replacement ESDs. Normal motions,

such as the brushing together of clothing fabric

and lifting ones foot from a carpeted floor, can

generate static electricity sufficient to damage an

ESD.

1. Exercise caution when replacing a super

capacitor or Lithium battery. There could be a

danger of explosion and subsequent operator

injury and/or equipment damage if incorrectly

installed.

2. Be sure to replace the battery with the same or

equivalent type recommended by the

manufacturer.

3. Super capacitor or Lithium batteries contain toxic

substances and should not be opened, crushed,

or burned for disposal.

1-3 Super Capacitor or Lithium Battery Precautions

S-ar putea să vă placă și

- 1-1 Safety PrecautionsDocument4 pagini1-1 Safety PrecautionsCarlos GonçalvesÎncă nu există evaluări

- 1-1 Safety PrecautionsDocument4 pagini1-1 Safety PrecautionsChirita ElenaÎncă nu există evaluări

- Sps 500 (STD) ProgramDocument164 paginiSps 500 (STD) Programwahyu100% (1)

- SPS 500 (STD) OperationDocument134 paginiSPS 500 (STD) OperationwahyuÎncă nu există evaluări

- ER-260 265 AU User ManualDocument109 paginiER-260 265 AU User ManualRadu Baciu-NiculescuÎncă nu există evaluări

- Samsung Gly26ke Gly32ke Gly37ke Gly40ke Chassis Le26r73bd r74bd Le32r73bd Le37r74bd Le40r73bd LCD TV SMDocument292 paginiSamsung Gly26ke Gly32ke Gly37ke Gly40ke Chassis Le26r73bd r74bd Le32r73bd Le37r74bd Le40r73bd LCD TV SMyomismoÎncă nu există evaluări

- 1-1 Safety PrecautionsDocument4 pagini1-1 Safety PrecautionsAdriano Alves Do NascimentoÎncă nu există evaluări

- HT P1200Document4 paginiHT P1200vantuyetphamÎncă nu există evaluări

- SRP-350 v2 SVC EngDocument125 paginiSRP-350 v2 SVC EngMichael HanniganÎncă nu există evaluări

- 01 PrecautionsDocument4 pagini01 PrecautionsJorge Fernando de TivantaÎncă nu există evaluări

- CW 21 Z 453 N S16G P PrecautionDocument6 paginiCW 21 Z 453 N S16G P PrecautionthorsharpÎncă nu există evaluări

- LE32S71 - Service ManualDocument160 paginiLE32S71 - Service Manualbidule78Încă nu există evaluări

- Er 180T (STD)Document92 paginiEr 180T (STD)luis morenoÎncă nu există evaluări

- 1-1 Safety PrecautionsDocument2 pagini1-1 Safety Precautionsyo9bmnÎncă nu există evaluări

- 1 Precautio: Ns 1-1 Safety PrecautionsDocument4 pagini1 Precautio: Ns 1-1 Safety PrecautionslvmottaÎncă nu există evaluări

- LDF900UR (sm-AFN74552044)Document51 paginiLDF900UR (sm-AFN74552044)Roberd MihailovÎncă nu există evaluări

- GENERALDocument2 paginiGENERALДмитрийÎncă nu există evaluări

- PrecautionDocument2 paginiPrecautionNita CatalinÎncă nu există evaluări

- Manual Er 350ii (Nos)Document111 paginiManual Er 350ii (Nos)Micky BozaÎncă nu există evaluări

- Samsung HT-Q9 Re Product or de DVD Manual de ServicioDocument51 paginiSamsung HT-Q9 Re Product or de DVD Manual de ServicionixrinÎncă nu există evaluări

- LG Cs310urDocument41 paginiLG Cs310urSabastian Nakai100% (2)

- LG LCS500UN Manual Servicio PDFDocument47 paginiLG LCS500UN Manual Servicio PDFaldo0% (1)

- Manual de Usuario y Programacion de La Caja Registradora Sam4s ER-650Document274 paginiManual de Usuario y Programacion de La Caja Registradora Sam4s ER-650ggstyleÎncă nu există evaluări

- Max220ub - Edeull Eespll Ehunll 75741202Document39 paginiMax220ub - Edeull Eespll Ehunll 75741202Josip Hrdan100% (1)

- Precaution PDFDocument4 paginiPrecaution PDFreis silvaÎncă nu există evaluări

- Samsung ER650MnlDocument272 paginiSamsung ER650MnlJulie InsyxÎncă nu există evaluări

- Samsung 540, 740, 940 Service ManualDocument98 paginiSamsung 540, 740, 940 Service Manualike4546Încă nu există evaluări

- FilesDocument97 paginiFilessyamsuddin semÎncă nu există evaluări

- XEROX WorkCentre WC-M15i Parts, Service ManualDocument192 paginiXEROX WorkCentre WC-M15i Parts, Service ManualArmando MarinÎncă nu există evaluări

- Sam Part 16Document1 paginăSam Part 16kswongÎncă nu există evaluări

- TV Samsung - Le27s73bd - Le32s73bd - Le37s73bd - Le40s73bd - Chassis - Gsd27-32-37-40se - LCD - TVDocument203 paginiTV Samsung - Le27s73bd - Le32s73bd - Le37s73bd - Le40s73bd - Chassis - Gsd27-32-37-40se - LCD - TVpepenasaÎncă nu există evaluări

- Samsung 550VDocument65 paginiSamsung 550VClaudio Hector ArrosaÎncă nu există evaluări

- Sam4s ER-380 Service ManualDocument110 paginiSam4s ER-380 Service Manualsupport-43Încă nu există evaluări

- Manual Servico Mini System Samsung Max g55td XazDocument70 paginiManual Servico Mini System Samsung Max g55td XazAntonio CunhaÎncă nu există evaluări

- Er-390m Manual ServicioDocument100 paginiEr-390m Manual ServiciovacyoÎncă nu există evaluări

- Samsung LE23-40R51B шасси RE23-40EO PDFDocument98 paginiSamsung LE23-40R51B шасси RE23-40EO PDFSledge HammerÎncă nu există evaluări

- Samsung Max-Dx75!76!79 Kx75 SMDocument41 paginiSamsung Max-Dx75!76!79 Kx75 SMJorch Ramirez Estrada50% (2)

- Le40 - 46n87bcx Chassis GTUxxDocument204 paginiLe40 - 46n87bcx Chassis GTUxxDarcio DarÎncă nu există evaluări

- Manual Servicio Er-250 y 350Document60 paginiManual Servicio Er-250 y 350Omar de la FuenteÎncă nu există evaluări

- ACTURA Flex 48330 PDFDocument96 paginiACTURA Flex 48330 PDFturand100Încă nu există evaluări

- Pinado RaisecomDocument18 paginiPinado RaisecomJonathan TerronesÎncă nu există evaluări

- Manual de Servicio Samsung MAX-X55!56!66Document44 paginiManual de Servicio Samsung MAX-X55!56!66Mauro Mangialavori0% (1)

- Videocon Mt5301b Chassis SDocument60 paginiVideocon Mt5301b Chassis Skanak100% (2)

- RNC Commissioning Guide 01-01 Safety InformationDocument14 paginiRNC Commissioning Guide 01-01 Safety InformationMohsenÎncă nu există evaluări

- 1-1 Safety PrecautionsDocument4 pagini1-1 Safety PrecautionsStephen OliekaÎncă nu există evaluări

- Samsung LE26S81BHX Chassis GJA26TSADocument159 paginiSamsung LE26S81BHX Chassis GJA26TSANina SeimeniÎncă nu există evaluări

- LG Portable DVD - DP271B, DP272, DP272B, DP273BDocument53 paginiLG Portable DVD - DP271B, DP272, DP272B, DP273BMaurilio CaetanoÎncă nu există evaluări

- Service: ManualDocument31 paginiService: ManualsumidinÎncă nu există evaluări

- RC3000-16&C6 PCM Multi-Service Multiplexer User ManualDocument49 paginiRC3000-16&C6 PCM Multi-Service Multiplexer User ManualjunniorbsbÎncă nu există evaluări

- 20eeo02 - Es&m Unit-3Document9 pagini20eeo02 - Es&m Unit-3Pappala ThanmaiÎncă nu există evaluări

- Led TV: Service ManualDocument77 paginiLed TV: Service ManualAshanabcdÎncă nu există evaluări

- User Manual Thermbox Lot5Document26 paginiUser Manual Thermbox Lot5andy_krskÎncă nu există evaluări

- R8005C MvawDocument20 paginiR8005C MvawRinda_RaynaÎncă nu există evaluări

- The IEE Wiring Regulations Explained and IllustratedDe la EverandThe IEE Wiring Regulations Explained and IllustratedEvaluare: 4 din 5 stele4/5 (14)

- Ultimate Guide: Wiring, 8th Updated EditionDe la EverandUltimate Guide: Wiring, 8th Updated EditionEvaluare: 3.5 din 5 stele3.5/5 (4)

- Electricity Unplugged: A Beginner's Guide to Electrical SafetyDe la EverandElectricity Unplugged: A Beginner's Guide to Electrical SafetyÎncă nu există evaluări

- DoubleChairBench DIYPETE PDFDocument20 paginiDoubleChairBench DIYPETE PDFRostocanieÎncă nu există evaluări

- Chasing Block MasonryDocument1 paginăChasing Block MasonryRostocanieÎncă nu există evaluări

- Manual GL Installation CompleteDocument43 paginiManual GL Installation CompleteRostocanieÎncă nu există evaluări

- Technical Doors PvcudoorhingeadjustmentDocument1 paginăTechnical Doors PvcudoorhingeadjustmentRostocanieÎncă nu există evaluări

- Black & Decker The Complete Outdoor BuilderDocument529 paginiBlack & Decker The Complete Outdoor BuilderRadu_IS100% (5)

- Installation Guide: Issue 1Document16 paginiInstallation Guide: Issue 1RostocanieÎncă nu există evaluări

- Sws Gates Technical Guide 2004 90321Document11 paginiSws Gates Technical Guide 2004 90321RostocanieÎncă nu există evaluări

- Sws Gates Technical Guide 2004 90321Document11 paginiSws Gates Technical Guide 2004 90321RostocanieÎncă nu există evaluări

- Diy Shelving Plans Supplies You Need Assemble: A Blog About Diy, How-To, Family + GadgetsDocument1 paginăDiy Shelving Plans Supplies You Need Assemble: A Blog About Diy, How-To, Family + GadgetsRostocanieÎncă nu există evaluări

- Prezentare E-BridgeDocument81 paginiPrezentare E-BridgeRostocanieÎncă nu există evaluări

- OKIPAGE 6e, 6ex (Parts, Circuit Diagram) Troubleshooting ManualDocument142 paginiOKIPAGE 6e, 6ex (Parts, Circuit Diagram) Troubleshooting ManualRostocanieÎncă nu există evaluări

- Pavilion User ManualDocument131 paginiPavilion User ManualRostocanieÎncă nu există evaluări

- E238 E240 E240n E340 E342nDocument259 paginiE238 E240 E240n E340 E342nradutranzy1Încă nu există evaluări

- Service: Laser Printer ML-1710PDocument3 paginiService: Laser Printer ML-1710PClint BainbridgeÎncă nu există evaluări

- TM 505 SGDocument104 paginiTM 505 SGRostocanieÎncă nu există evaluări

- Bizhub C300 C352 FieldSvcFW G4Document963 paginiBizhub C300 C352 FieldSvcFW G4Anonymous gn8qxxÎncă nu există evaluări

- Precautions: 1.1 Warning For SafetyDocument4 paginiPrecautions: 1.1 Warning For SafetyRostocanieÎncă nu există evaluări

- Armada 1500c SMDocument135 paginiArmada 1500c SMRostocanieÎncă nu există evaluări

- Extensa 60x & 65x Series Notebook Computers: Maintenance ManualDocument212 paginiExtensa 60x & 65x Series Notebook Computers: Maintenance ManualscribdermaniacÎncă nu există evaluări

- FC-3510C CG en 0000Document8 paginiFC-3510C CG en 0000RostocanieÎncă nu există evaluări

- FC 3510C InstalDocument10 paginiFC 3510C InstalRostocanieÎncă nu există evaluări

- FC-3510C Nag en 0000Document70 paginiFC-3510C Nag en 0000RostocanieÎncă nu există evaluări

- Chapter 4 Print Area Pres PDFDocument6 paginiChapter 4 Print Area Pres PDFRostocanieÎncă nu există evaluări

- Model S-C2 PtoP FinalDocument2 paginiModel S-C2 PtoP FinalRostocanieÎncă nu există evaluări

- Armada 110 SMDocument154 paginiArmada 110 SMRostocanieÎncă nu există evaluări

- T30810B AllDocument110 paginiT30810B AllElena UngureanuÎncă nu există evaluări

- OKIPAGE 6e, 6ex (Parts, Circuit Diagram) Troubleshooting ManualDocument142 paginiOKIPAGE 6e, 6ex (Parts, Circuit Diagram) Troubleshooting ManualRostocanieÎncă nu există evaluări

- 4412 X125 AioDocument88 pagini4412 X125 AioRostocanieÎncă nu există evaluări

- OKIPAGE 6e, 6ex Service Manual 2Document251 paginiOKIPAGE 6e, 6ex Service Manual 2RostocanieÎncă nu există evaluări

- 3 Phase CircuitsDocument37 pagini3 Phase Circuitsvasu_koneti5124100% (2)

- Varibles DIgSILENTDocument58 paginiVaribles DIgSILENTIsrael FonsecaÎncă nu există evaluări

- Stamford Uci274e1 Uci274e-311-Td-En Rev ADocument9 paginiStamford Uci274e1 Uci274e-311-Td-En Rev AJose Luis Galán AsunciónÎncă nu există evaluări

- Free Energy: Nikola Tesla Secrets For EverybodyDocument45 paginiFree Energy: Nikola Tesla Secrets For Everybodyflo2410Încă nu există evaluări

- Floating Power PlantDocument20 paginiFloating Power PlantNayan Raj ShandilyaÎncă nu există evaluări

- Inhemeter Smart Grid Solution-InheGrid-DA 180312Document63 paginiInhemeter Smart Grid Solution-InheGrid-DA 180312chykemanÎncă nu există evaluări

- Medium Voltage Smart Grid Sensors and PLC CouplersDocument4 paginiMedium Voltage Smart Grid Sensors and PLC CouplersAnonymous N13JdnÎncă nu există evaluări

- Esquema de MierdaDocument4 paginiEsquema de MierdaRaul RozasÎncă nu există evaluări

- BOOSt SEMINARDocument15 paginiBOOSt SEMINARZeny Ruth BecerroÎncă nu există evaluări

- PD ENEC 301 Annex B - January 2018Document30 paginiPD ENEC 301 Annex B - January 2018Abraham Seco ArmestoÎncă nu există evaluări

- 1MRK511361-BEN A en Product Guide Bay Control REC670 2.1Document113 pagini1MRK511361-BEN A en Product Guide Bay Control REC670 2.1Constantin PopescuÎncă nu există evaluări

- Nextek NPS 1000 Power Module 05252010 PDFDocument2 paginiNextek NPS 1000 Power Module 05252010 PDFHosam AlzubairyÎncă nu există evaluări

- Eaton 9355 UPS: Scalable. Compact. FlexibleDocument16 paginiEaton 9355 UPS: Scalable. Compact. FlexibleAldo Urrea PulgarÎncă nu există evaluări

- EPV-42 Module Product Specification: Physical CharacteristicsDocument2 paginiEPV-42 Module Product Specification: Physical CharacteristicsLuis SánchezÎncă nu există evaluări

- 15175fs Marking SMD CodeDocument8 pagini15175fs Marking SMD Code2dmsÎncă nu există evaluări

- Synopsis.h 041604Document4 paginiSynopsis.h 041604Hybrid Power systemÎncă nu există evaluări

- BOQDocument2 paginiBOQVasu BagganÎncă nu există evaluări

- Shoto Lithium User Manual-V3.7Document38 paginiShoto Lithium User Manual-V3.7Duy Chu100% (1)

- Distributed Generation Electric Distribution Systems Sensitivity AnalysisDocument4 paginiDistributed Generation Electric Distribution Systems Sensitivity AnalysisDrVikas Singh BhadoriaÎncă nu există evaluări

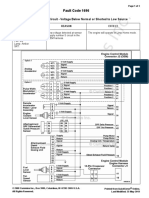

- 1696 Fault CodeDocument3 pagini1696 Fault CodeDeva KoyriÎncă nu există evaluări

- What Is The Difference Between 0.2 and 0.2S Class CTDocument5 paginiWhat Is The Difference Between 0.2 and 0.2S Class CTshaik abdulaleemÎncă nu există evaluări

- CL100D (6-10kVA) Service Manuel - English PDFDocument64 paginiCL100D (6-10kVA) Service Manuel - English PDFAbdulrhmanÎncă nu există evaluări

- Single Bus and Dual Bus Architectures of Electrical Power Systems For Small SpacecraftDocument15 paginiSingle Bus and Dual Bus Architectures of Electrical Power Systems For Small SpacecraftAminaÎncă nu există evaluări

- Catalog VCB - LS PDFDocument56 paginiCatalog VCB - LS PDFmuchamad yasinÎncă nu există evaluări

- Modicon OTB - OTB1C0DM9LPDocument9 paginiModicon OTB - OTB1C0DM9LPTrịnh Ngọc QuangÎncă nu există evaluări

- KIA278R15PIDocument7 paginiKIA278R15PIIdrissa NikiemaÎncă nu există evaluări

- Agilent E3632ADocument107 paginiAgilent E3632ACtopherÎncă nu există evaluări

- PUshbuttonsDocument361 paginiPUshbuttonsArmin Kovačević100% (1)

- 18200314-Thermo King Sr-4 Single Temp Trailer Diagnoses ManualDocument659 pagini18200314-Thermo King Sr-4 Single Temp Trailer Diagnoses Manualمعمر حميد100% (11)