Documente Academic

Documente Profesional

Documente Cultură

Superaleaciones PDF

Încărcat de

Yuber Buitrago0 evaluări0% au considerat acest document util (0 voturi)

50 vizualizări24 paginiHigh manganese Heat Resisting steel improved in order to obtain an alloy having excellent high temperature properties, contain a large amount of nitrogen. Effects of various elements and heat treatment on the high temperature properties of this type alloys are to be described.

Descriere originală:

Titlu original

superaleaciones.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentHigh manganese Heat Resisting steel improved in order to obtain an alloy having excellent high temperature properties, contain a large amount of nitrogen. Effects of various elements and heat treatment on the high temperature properties of this type alloys are to be described.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

50 vizualizări24 paginiSuperaleaciones PDF

Încărcat de

Yuber BuitragoHigh manganese Heat Resisting steel improved in order to obtain an alloy having excellent high temperature properties, contain a large amount of nitrogen. Effects of various elements and heat treatment on the high temperature properties of this type alloys are to be described.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 24

HIGH TEMPERATURE PROPERTIES AND FINE STRUCTURE

OF HIGH FdaNbANESE HEAT-RESISTING STEEL

H. Yoshida

K. Koike

Abstract

High manganese heat resisting steel improved in order

to obtain an alloy having excellent high temperature

properties, contain a large amount of manganese and

nitrogen.

The reason why the alloy &m contairi a.Large amount of

nitrogen, the effects of various elements and heat

treatment on the high temperature properties of this

type alloys and grain boundary reaction recognized in

this type alloys are to be described.

H. Yoshida and K. Koike are metallurgist at National

Research Institute for Metals, Tokyo, Japan,

I. Introductirm

In order to improve an alloy which is not inferior to E155'alloy

---a typical iron base heat resisting alloy---regarding the high

temperature strength, and which contains expensive elements as smali

amount as possible, furthermore, 'can be easily forged, we .examined the

effects of austenite former such as manganese, nickel and nitrogen and

those of ferrite former such as chromium, molybdenum, tungsten,

niobium on the high temperature properties of the alloy eliminated

cobalt from R-155 alloy.

From these experiments, an alloy which fits the purpose could be

improved when 1% manganese and more than '06% nitrogen are contained

and the proper amounts of various elements are chosen to be gammer

single phase in solutiqn treatment, though nickel content is reduced

only to 6%. (1)

This high manganese, nitrogen heat resisting alloy was named

lOB86N alloy (10$&n, 6$&i, 207&r, 2$&o, 2.5$&Y, lab, 0.2@, 1~20.6%

'balance Fe ).

When small amount of boron is added to this alloy, 'its high temper-

ature properties can be more improved.

In this report, four items are to be described---first; the reasons

why 10~68 alloy can oontain such a large amount of nitrogen as more

than 0.6&, second; the effects of nitrogen, niobium and boronon the

high temperature properties and structures of 10~6~ alloys,. third;

the grain boundary reaction recognized in this type alloys, fourth;

the effects of heat treatment on the high temperature properties of

10~86~ type alloys.

II* Why Can a Heat Resisting lOlur6N Allox

Contain a Large Amount of Nitrogen?

10~616 alloy is special in containing a large amount of manganese

and nitrogen, so, we explaia the reason why this alloy can contain a

large amount of nitrogen. If we keep the melt of,lCM61 type alloy

added no nitrogen for 3Omin,, nitrogen content of this alloy increases

with the lapse of time, due to absorbing of nitrogen from the atmos-

phere.

On the other hand, if we keep the melt of 19~6N type alloy added

l,O$ nitrogen for X&in., the nitrogen content reduces to nearly 0.6%

with the lapse of time.'

Nitrogen content of this type alloys are affected by the oooling

velocity, the melting amount etc.,

is added.

even if the same amount of nitrogen

But, it mainly depends on the nitrogen contant of the melt

which is in equilibrium in the.melt atmosphere.

This is recognized from the facts that the nitrogen content of the

ingots ooincides with the one in equilibrium in the melt of 10~6~ alloy

which is caloulafed from the activity coefficient, obtained by u&ing

the interaction,coefficients of various elements. (2)

The reason why lOM618 alloy can aontain a large amount of nitrogen,

is considered to,be due to the facts that the nitrogen solubility of

the melt is large because- the alloy oontains a large amount of

ohromium and manganese.

next, we are to describe the effects of various elements on the

high temperature properties and structures of lOM6R type alloys.

r

368

III-1 Effects of nitrogen

The compositions which nitrogen is eliminated from IO&N alloy

was selected as the base compositions. Various amounts ,of nitrogen

were added to this composition, using Fe-Cr-N (6,2%N, 43$&r).

Nine ingots (N-O-N-~) containing nitrogen in the range of 0.084%

melted in air by using high frequency induction

e compositions of alloys are shown in Table 1.

These ingots were forged, water quenched after heating for lhr.

at 1200C as solution treatment and then cooled in air after heating

for 4hr, at 800C. Then,.the creep rupture testing was conducted.

Solution treated alloysv hardness increases nearly in proportion

to the nitrogen content. About 22% and 6% of .delta ferrite are

respectively recognized in the solution treated alloys containing

0.08% and 0.38$ nitrogen,

The creep rupture life and rupture elongation at the test

condition of 7OO"C, 26kg/&, are shown in Fig.1, from which it is

recognized that the creep rupture life is remarkably short, in the

range of nitrogen up to 0.38$, because delta ferrites are easily

transformed into sigma phase and M,,&,by heating, but in the range of

nitrogen content more than 0,38% where the alloys* matrix becomes

gammer single phase without containing delta ferrite, the creep

rupture life increases in proportion to nitrogen content, and is

improved to 4OOhr. at 0.98% nitrogen. That is to say, the increase

of 0,6$ nitrogen from 03B%to 0.98$, cause the rupture life to

as twenty five times,

show the electron microscopic structures of

at 7OOOC.

containing 0.084$'$ nitrigen,

From photo.l(a) of N-O alloy

delta ferrite is recognized to be trans-

formed into &I&&and sigma phase, and I&C, is found to be precipitated

in the matrix. nn,C, and Cr,N precipitate with Nb(C,N) as undissolved

phase, in the alloy containing 0.615% nitrogen, 0.754% nitrogen,

0,979s nitrogen. (Photos. l(b)-(d) >

Further, from the comparison of photo.l(b) and photo.l(c),-(d),

these precipitates are found to be more finely distributed with the

increase of nitrogen from 0.615% to 0.754% and 0.979%

From these results, the increase of nitrogen content of this type

alloys may be concluded to contribute to the improvement of the high

temperature properties, because the matrix become to be gammer single

phase and to be strengthened, furthermore, the precipitates.are more-

finely distributed with the increase of nitrogen content.

III-2 Effects of niobium

The alloy having composition which is eliminated niobium from

lOM6N alloy was'melted and the half was cast. Then, l$ niobium was

added to the rest of the melt and was cast, The former was named NbO

alloy, the latter Nbl alloy,

As shown in Table 1, S.N. decrease and I.N. increase from the

comparison of these two alloys by niobium addition.

Table 2 shows the grain size and the hardness of Mb0 and Nbl

--

1

-alloys solution treated at various temperatures. At the same I

/ solution temperature, the hardness is higher and the grain size is

smaller in Nbl alloy than in RbO alloy.

th Fig, 2 shows e age hardening properties of the two alloys

solution treated at 1200C. Nbl alloy is yet in the hardening

process after 25Ohr. at all heating temperatures and the hardness

increase obtained by aging is about 30-40 in V,H.N. and the harden-

ing process is not different so much at all temperatures. But, NbO

alloyqs .hardness increases obtained by 250hro heating are about 40 in

V.H.N. at 650"~~ and about 100-110 in V,H.N. at 700C and 750C.

NbO alloy hardens more than Nbl alloy at all aging temperatures and

its tendency is more remarkable at 700C and 750C.

Photos. Z(a), (bl are the microstructures of NbO and Nbl alloys

heated for 25Ohr, at 700C. Grain boundary reaction( afterwards,

denote G,B.R.),is recognized in NbO alloy, and the grain size of Nbl

alloy finer very much than-that of NbO alloy. The precipitates at

the grain boundary and in the grain are slightly found in Nbl alloy.

That is to say, the remarkable hardening behaviour of NbO alloy is to

be due to the G.B,R, and the addition of niobium to this type alloy

suppresses the remarkable age hardening,

Then, the niobium addition to pure iron (3),.to carbon steel, to

Ni-Cr, Ni-Cr-Co alloys (4) is reported to cause their recrystalli-

zation temperatures to be higher. The same phenomenon is recognized

in this type alloy.

Namely, from the hardness change of Nbl,. NbO alloys coid rolled

to the degree of &I$, when heated in the temperature range of 4OO"c-

llOO"C, T& ---the temperature at which the average hardness of the

maximum one and the minimum one (the hardness at 1100C where the

recrystallization is completed) is shown---was measured*

From the fact that T% of NbO alloy is about 850"~ and the one of

Nbl alloy is about 875"C, the niobium addition to this type alloy can

be concluded to cause, the recrystallization temperature to be higher,

that

The tensile strength of NbO,alloy at 700C is 54.6kg/mm , whereas

of Nbl alloy is 58,3lcg/mm _-- the latter is clearly more

excellent.

Then, it is reported that the creep rate and the kecrystallixation

temperature are to a certain degree related in 15Cr-13Ni steel. (5)

So, the high temperature properties of this type alloy is supposed to

be improved by niobium addition;

th Fig. 3 shows e creep rupture properties of Mb0 and Nbl alloys

solution treated at 12OOOC and the immerical values written in the

figure are the creep rupture elongation,

The creep rupture stress and

the creep rupture elongation of Nbl alloy are more excellent than

those of NbO alloy.

Prom these facts, the improvement of creep rupture properties of

lOM6N type alloy by addition of niobium, is explained to be due to the

,increase of solution treated hardness, the suppression of age harden-

ing properties brought about by the G.B.R.9

the grain size refinement

and the rise of.the recrystallization temperature etc.

111-3 Effects of boron

The creep rupture lives of the ferritic and austenitic heat

resisting steels, nickel base and cobalt base heat resisting alloys

__

370

[ELXW reproved by addition of boron,

I

n, in order $0 ~x~rn~~e of boron addition to 10&16N alloy, about

2Qkg of 10~6?~ alloy was melted and the.half of the melt was cast and

then S,Ol.$ b~~~~ was added to the rest and was cast. Thus, IIlIN alloy

ere obtained. Prom the compari-

the boron addition to lOl!&N alloy is

ve in the ~m~rov~rne~t of the high,temperature

on adckitioa more than a certain content is

to the fo~g~~bi~~ty~ So, in order to

~~~~% of boron to the alloy, in considering of

s the f~r~e~b~~~ty~ the oxidation resistance

vakmb four kinds of allOys~-~5OA(~~~6N alloy), 50B

~d~%~~~~* ~~~(0~~5~ boron addition), 56~ (0.15% boron

addition of boron one after another to the

er as the one by which MN and Dw alloys

Tne of these alloys are shown in Table 1.

of soluble nitrogen, the decrease

phases of 508, 50Bs 50133, 5OF alloys

'the %%rn~%~at~~e range of 115O"C-1250C. The

espeetively mean that is recognized

ds to remain in the solutiqn treat-

This is due to the fact that

ition of boron, as reported by V.V.

of boron bring about the

rease of insoluble nitrogen and

the matrix,

to be Fe-Cr-Nb found in the

tested at 850C by H.Hu& (7).

in not only Ni-Cr steel but also in

e beeome clear to oe Cr-ho

%~ex%, from the ~orn~~~~so~ of aging hardness of &II? and MB alloys

is found to be operative

operties of this type alloy.

tures of MN and ME3 alloys

al%oy, precipitates of MIII,Cb are

in the mats grain boundary, but in MB alloy, only

nd 2 phase are found, and the

gamely, addition of boron is effect-

~~~~~~~~~~~~~ of %he ~~~~~~~ta%~~n at the grain boundary and in

alloys aged for 6h.r. at 7OOOC

e precipitate from the grain

Q between the undissolved

the of F&I?+ MB alloys heated

alloy, but not in MB alloy.

tive in suppression of

P boumrdary and iB retarding

sf O,B,R,

~.~~~~ the bar % 0f p HIB alloys cold rolled to the

agree

ff

of 50$, when heated in the tsmperature range of 5oOC-IOW*C .'

as measured, The behaviour of the hardness change between two alloys

iis scarcely different.

!

The solutioned hardness of the two alloys and their hardness,cold i _

rolled to the degree of 5% are almost same, and the age hardening is '

supnressed to some extent by addition of boron, and furthermore there

I$ little difference between two alloys in the hardness change of cold.

rolled specimens when heated in the temperature range of 5~O'C-Sl.OOO'C.

From these facts, addition of 0.01% boron to 1OPdbN alloy may be

concluded to be scarcely effective to the solut$on.hardening, as

pointed by Kawabe etc. (9) regardi ng the effect of addition of boron

to 18Cr-12Ni-0,2$&I steel.

The short time tensile test of the two alloys was carried out at

0.72mm/min. The rupture elongation of MN alloy was 22.5$, and that of

MB alloy was 29.2%. Namely, boron is effective in the improvement of

the high temperature du&tility.

Fig. J,,shows the creep Pupture:properties of I&, MB alloys heat

treated---water quenched after heating for' lhr. at1200"C(MN), at

115O"c(MB) and then air cooled after heating .for 4i-w. at 800C. The

numerical values written in the figure mean the creep rupture elonga-'

ti0n. It is recognized that the creep rupture life and elongation

are both improved remarkably by addition-of boron.

From.measuring of the elongation between the pull rods, addition

of boron was found to alter scarcely the minimum creep rate and to

improve the creep rupture life, chiefly due to that it delaysthe

shifting. from the second stage to the 3rd stage in the,creep process.

The improvement of high temperature ductility by addition of boron,

fs reported by R.F.Decker (10) to. be due to that boron cause the

precipitates atthe grain boundary to be finer and to supress their

coagulation.

In this ,type alloy, addition of boron suppress the diffusion of

various. element8 to the grain boundary and formation of G.&R,

These

effects are thought to cause the high temperature ductility of this

type allo,y to improve.

Next, proper amount of boron in this type alloy is to be related,

The forging of 508 alloy is as easy as 50A all'oy, but that of 5OD

alloy becomes difficult to some extent, and further, that of 5OF alloy

becomes more difficult in comparison to 5OD alloy.

As the result of the oxidation test, at the test condition of

heating for 1OOhr. at 800C!, 900C and lOOO"C, it is recognized that

the oxidation resistance of 50B alloy is nearly equal to that 5OA

alloy, but that of 50F alloy become to be oonsiderably poor.

From

these results, addition of boron to this type alloy is desirable to be

less than 0.01%.

An alloy added a small amount of boron to 101&N alloy is named

10MGNB alloy.

IV. Grain Boundary Reaction

1$/e already described-that the precipitation of 1OfJrGN type alloy

consists of two types---one is general precipitation, the other G,B,R.

and that latter was suppressed by addition of,niobium or boron.

Then, G.B.R. has been hitherto mainly investigated regarding non-

ferrous alloys, but recently G.B.R. is reported to be recognized in

vgrious kinds of ferrous alloys (11) and to be regarded as import&t to.

Sa in this chapter, the i~for~tions obtained regarding G.B.R. of i

tk3.h fype alloy, 2s to be described,

%oto 4. (a) shows the microstrucixares of NbC alloy heated for

n treatment at 1200C. Prom this photo.,

d that G,B,R, tends to occur at the triple points of

4 (b), (c) respectively show G.B.R. from

k~~~k~ and that from the regions where the twin

Photo. 4 (d) shows G.B,R. at t

%ha B~ont of the twirs, amd the G,B,W, is considered to occur from the

XWgiCXi If&CD3 tW0 t~~~~S Snt3et g?aCh other,

PF$arn th photos, 9 G,B,R, in this type alloy is recognized to

tend to occur from the r gions where the lattice is disordered.

,,,J&,,.>m :3how t h3 effect .sl j,.61

ss and heating time on the amount of

:; ? 3 o 2: 5 in the -$eEs% a=onditio load is applied at the same time

~dwm i;hct ~~~~~~e~sat~~~ of the s~eo~en is reached to 75O"C, using of the

cxop rupture ~~~~~rn~~~ of B alloy eliminated niobium from 10~6~ alloy.

:;; ,b

is s~xgnizsd that the amount of G,B,R. increases with increase of

f$ j;, '" (5. f$ $j ayad f

ther the effect of stress becomes to disappear with the

~,J~<;*ycacJz;; of J&aatip$

ime,

gx?LZ t&e same BX ~~irn~~t was tested, using 50s alloy which has

aZno 3.3 e s ilar as B alloy and contains niobium. In this

(JCL,&8 p

_ the amount of G,B,R, was also recognized to be increased by

g$j"ya(zjf~*

of S,R, in B alloy and in 50s alloy,are nearly

e L$mz!- 0 but out of G,$,R, i less in 50s alloy than in B alloy

a% Lha saJm3 % condition, yp also when the contents of S.N.

a_".;r3 aaarly equa in 183hN type alloys, niobium is recognized to be

~~~~~%~~~ in the suppression of G,R,R.

Phes%;o, 4 (e) shows the microstructure of alloys heated for 20 min.

a$; c$"jQ"C

* aP$er ~~a~~~nes~ measuri by Vickers Hardness Tester. In this

.B,R, is %wand to occw re kably around the trace of

G,B4,R, is ac slated by stzwss, is reported regarding 25$Cr

~~.~~"~~~~~.~~~ steel, BP- g* ana a1-zn allQYs, R. Blower(l2) reports that

G w B @ R * of ~~~~~~~~~~~~~~~3~~ steel is not recognized by heating after small

amor%n% of WOFki~~ g but recognized after large amount of working.

p ?2 -R

..z.l.J*-..

tends to occur from the regions where the lattice is

a~st~~~~i~ steel, non ferrous alloys are all

So, G,B,R. can be generally concluded to be

ar ~t~ve~y the microstructures

etively forged to the d@gree of about

r lhr, at '900C after water quenching

of

1.5,

from

!-

As the forging ratio becomes larger, G.B.R. and the uncissolved 1

phase becom,e to distribute parallel to the forging direction.

/

so, G.B,R, in this type alloy is considered to be related to i

'1Fzj(C,R) of the undissolved phase at the grain boundary, Therefore, i -

we examined it true or not by electron microscope. Such behariour

could scarcely be recognized,

' Photo, 5 (c) shows that the grain size tends to become smaller in

the regfons where Eb(C,N) exists.

So,,the fact that G.B.R. tends to distribute parallel to the

i

forging direction with increase of the forging ratio, is thought to '&

be partly due to the existence of Nb(C,N), but chiefly due to that

the grain size does not become coarse owing to Eb(C,N) and that fine

'grain has larger grain boundary energy than the coarse .one.

IV-4 Effect of solution temperature on the amount of G.B.R.

Fig. 6 shows the effect of solution t,emperatures on the amount of

G.&R, omxrred at test conditions of heating for 4hr. at 8OO'C and

for L5hr. a% 9OO"Cd

When solution temperature is 1200C, the amounts of G.B.R. become.

imum in aXl test conditfons, In this type alloy, as the solution

perature becomes higher, S,N. &crease and G.B.R. tends to easily

occur as nitrogen content increasese

So, the reason why the amounts of G,B,R. increases when the

solution %empe~~%~es become higher from 115O'C to 1200vC,~is consider-

ed to be due to the increase of S.N., on %he contrary, the reason why

the unt of G,B,R, decrease as the solution temperatures become

from 80C to 125O"C, 1300C is considered to be due to the enlarge-

ment of grain size, because G',B.R. tends to occur easily in the fine

alin than in the coarse grain,

That is to say, the reason why the amount of G.B.R, show maximum

in the above mentioned test condition when the solution temperature is

12OC"C, is considered to be due to the balance of the ppposite factors

as the aolutfon temperature becomes .higher, regarding the amount of G,

B.R.

'$hus, %he behav%our of G.B.R. found in this type,alloys depend on

the stress* forging:' , ratio and solution temperature etc. at the

~~nd~t~o~ of the earns heating time and temperature. As already

described, addition of niobium.and boron to this type alloys suppress

the G,B.R, and improve the creep rupture elongation and the creep

rupture life,

B. Effects of Heat; Treatment on the High

In this ohap%er, the effects of heat tres%meat on the high

%~m~eratu~e properties of this type alloys and the faotors governing

the high temperature strength, are to be described.

'~OAIIGR~ lOr!&RR alloys were melted by the same manner as that of MR

and BF33 alloys,

A8 solu%ion treatment, four temperatures---l150C, 1200*C, 1250~~

and 1308C~--were selected and the alloys were water quenched after

for lhr, a% each temperatures.

-.

As preag+g treatment, three

fog 4h-h at 7506, heath3 for

at BOb"C---were adopted.

r solution treatment were suitably

%y at the test condition

thexmo~e, in order to

e properties and the

short time tensile

The analysis of the

the examination of the structures

treatment on the hardness change

the solution temperatures become

alloys falls, because such phases

into the matrix,

s solution treatment and the

spe~tively 52, 52, 89 and 105

*Cg 12OO'C, 1250aC and 13OO'C.

come higher, the hardness

hardness of the alloy solution

b9y after 3h.r. Further, the

at 800C after solution treat-

sting for lOOOhr,

ized in I.OMGNB alloy and the

53 alloy than in lOMbI? alloy from

he same condition.

respectively the microstructures of

OQOC, after solution treatment at

~ost~ctur@ of lOM6I? alloy which is

en heated for 4hr. at 8004C as prsaging

From this phota, the

The reason why the age

the increase of solution tempera-

5 the fact that the precipitates of

BACK aad e;?r,;N texd to ~~~~~~ more finely,

Phcs"~~c~, & (ejy (S) show rs ctively the microstructures of lOM6NB

tiL:lsys at 115O"C, 1300C and heated for

ASS ths s~~~t~~~ temperature becomes higher, the

txibute finer as in PCN~N alloy. Further-

the alloys solution treated at 13bO"C, tend

6~s alloy than in alO~6~ alloy,

ime tensile properties

3

e tensile properties at 700'~:, regarding

aged for 2Ohr. at 7OO"C, after solution treat-

rn@D% bn

13aoF c,

58C in the tempexat~~e range of 1150C -

As -khe ~~~~-~~~~~~ ~~~perat~re bes: mes higher, the tensile strength

n&i to ~~~~sas~ only a little, 0,2$ yield stress clearly

I-

!

1 increases and this tendency is remarkable in the alloy solution treat-

ed at 1300C. On the other handi the rupture elongation and reduction

of area decrease.

Hardness of ~OMGNH alloys at 700C is higher than that of lOM6N

alloy heat treated at same condition. Hardness of lOM6NB alloy at

700C when it is solution treated at 1300C and aged for 2Ohr. at

7OO"C, is about 220 in V.H.N., but that of the other test 'pieces of

two alloys at various conditions is less than 200 in V.H.N.

Photos. 7 (a)-(c) show the microstructures of lOM6NB alloys

ruptured at 'TOO'C, Kith the increase of the solution temperatures,

the precipitates distribute more finely and this begaviour is consider-

ed to be due to the increase of yield stress. The fine precipitates

found in photo. '7 (c) are thought to be MJ$,.

V-3 Creep rupture properties

Fig. 9, 10 respectively show the effects of' solution temperatures

on the creep rupture properties of lOM6N and, lOM6NB alloys. It is

recognized that the creep rupture lives are improved and the rupture

elongations become poorer as the solution temperatures become higher.

The creep ru;?ture elongations of lON6N alloys solution treated at

1300'C,.are both less than 7% at the test condition of 700C, 26kg/mm'

and 20kg/mm: but the creep rupture life of ~OMGNR alloy solution

treated at 13OO'C is about 2200hr. which is about five times,as long

as 433hr. of lOM6N alloy solution treated at 1150C and the rupture

elongation is 17.75 at the test condition of 7OO"C, 26kg/mmz.

Further, the creep rupture life of lOM6NB alloy solution treated at

1300 C"is about 98OOhr. and the creep rupture elongation is about

26.4% at the test condition of 700C, 20kg/mm: -That is to say, 1OOOOhr

creep rupture strength of lOM6NB alloy at 700C is about 20kg/mrn2 and

shows fairly ductility. This rupture strength is thought to belong

to the strongest group in the austenitic heat resisting steels.

Yamazaki(k3) reports that the minimum creep rates of 18Cr-12Ni

steel containing various amount of carbon are improved as the

solution temperatures become higher, on the other han.d, failure tends

to occur due to the enlargement of grain size, and that the optimum

solution temperature regarding creep rupture life, is recognized due

to the balance of these two opposite factors.

Then, the relation between the creep rupture elongation and

solution temperature in lOM6N type alloy is as same as that in above-

mentioned 18Cr-12Ni steel. Rut, though lOM6N type alloy is solution

treated at 13009C, its grain size number is in the range of 3-5 in

A.S.T,M. No., due to Nb(C,N) of undissolved phase. So it is

remarkably smaller than that of the above-mentioned 18Cr-12Ni steel

heat treated at the same condition. This is considered to be the

reason why the creep rupture lives of lOM6N type alloys are improved

with incre$sing of solution temperature in the terhperature range of

up to 1300 c. The creep rupture elongation of 10~6~~ allpy is longer

than that of lOM6Nalloy solution treated at the same temperature.

This may be thought to be due to that G.B.R. is suppressed by addition

of boron.

Then, the minimum creep rate of lOM6NB alloy is more excellent

than that of lOM6N alloy when they are only solution treated at same

temperature.

. ._

This may be due to the strengthening effect obtained by

c-

-

C

.-

Lp

II

M-W

I

k

I

I

i -

'~retxkatiol? of' precii)itati.can process due to addition of boron.

Tile '

~r~zitsom w;iy the creep ,wpture iife and elongation are both more

excellent in lOM6m alloy than in ~OF,I~N alloy, is thought to be,due to

the above-mentioned two factors.

The ,notch creep rupture test was carried out at the test condition

of 700'@, 26kgJm: using the test piece of&=3.7. These results are

shxm in Tab18 4, The xdues in the pare&he&s are the creep rupture

life and elongation of the plain specimen. Except lOX6N alloy

solution tsaated at 13OO"C, the notched specimens show longer creep

rupture life than the plain speekmens. Namely,' in this type alloy,

st~~~th~n~~ by notch can be concluded to be obtained when the creep

rupture elongation of the plain test piece shows more than 7%.

effects of aging on the creep rupture properties

heating temperature becomes higher at constant

and as the heating time becomes longer at constant

heating temperature, as aging process is preceded--- the

creap rupture life b This is considered to be due to

the i~e~atiQ~ of th ngthening owing to the decrease of

the amount of ~~b~~ and ~it~~~~~ saluted in the matrix, and also to

be due to the ~~~~~~~~~~ of precipitation strengthening owing to rapid

growth of the p~~Qip~,~a.~~ This behaviour is also so in 10~6~ alloy.

~~~o~d~~~ly~ ~r~~~~~~ t~eat~e~~t of heating for long time at higher

te~~e~at~e than testing teaperature9. is not hopeful.

Further, the higher the solution temperature in the range, of up to

l.JOO"C, the longer the creep rupture life, in this type alloy. But

as solu%ion t~~psrat~~e~ about 1200C is suitable kn 10~6N alloy in

point of view of ep ~~pt~r~~ ductility.

hopeful that t,kle

But, in lOM6NB alloy, it is

rature is as high as possible in the

t~~~~~a~ure range of up to lWO"C, because it has excellent creep

eruptus aLle-l;ility,

vs. Conclusion

-

The process how the high ~~a~~a~sse heat resisting 10M6N type

alloys were ~~~~v~~* was to be described, The reason why this type

aPloys can ~o~t~~~ a barge amount of nitrogen; the effects of various

elements and heat ~r~at~e~t on the high temperature properties; and

G,B,R, ~~~o~~~~~d in this type alloy ware examinedr

results ~~~a~g~~d am 8s follows.

1, This type a%'loy contains a large amount of manganese and nitrogen,

z3Jla fhe prope%p avocet of ~Qlyl~ae~~, tungsten and niobium were selected

so Lb% the ~o~~~,sts of ga r single phase when the alloy was

solu-kLun tre The xwason why is type alloys contain such a large

t of ~it~ege~ than Q,6$, is due to that they contain a large

t sf imnganas

With inereas the matrix becomes to consist of o&y

d the precipitates of MJ& and Cr,N beoome to

when heated for 1OOOhr. at qO0.C. These

of the, matrix,

p rupture strength to increase with strengthening

By ition of niobium to this type alloy, the solutione

the grain size becomes finer, and G.B,R., the

es are suppressed.

ad~t~o~ of boron to this type alloy, G,B.R, is

s~~~~essed and the high ~~~~~~at~e ductility is improved and also _

._

-.

377

Kffective precipitation s;tlCQtkningin high temperature strength is 1

- -".. _~ -. _

bonsidered to be obtained. These.are thought to be the reason why the 1

creep rupture life and elongation are improved by addition of boron. i

3. G.B.R. reeognised in-this type alloy, tends to occur at such a ~

region where the lattice is disordered as the triple potit region of

the grain boundaries, and the region where twin and grain boundary

meet each other.

4. Preaging is not hppeful from the point of view of high tempera-

ture strength. As the solution temperature becomes higher, the creep ~

rupture life is improved, on the contrary, creep rupture elongation

decreases. So, solution temperature of about 12OO'C is suitable in

low1611 alloy regarding creep rupture ductility. But, 101~6ti alloy

solution treated at 1300C show the excellent creep rupture ductility

and also show about 20kg/mma of the creep ruptuq strength at 7OO"C,

loooohr. So, it is desirable that the solution 6emperature is as

high as possible in the temperature range of.up to 1300C in 1OMbRB

alloy. The excellent high temperature strength of this type alloys

is considered to be due to the solution hardening by molybdenum,

tungsten.and nitrogen; increase of solutioned'hardness and refinement

of grain size by niobium; improvement of creep rupture ductility due

to suppression of G.B.R. by boron and niobium; fine distribution of

such precipitatesas I&C,, f&N, eta., and so on.

REFERENCES

1. R. Yoda, H, Yoshida and KB Koike, Study of High &Iangasese

Heat Resisting Steels, Journal of Iron and Steel Institute

of Japan, 51, 1965, pp* 1152-1162,

2. R. Yoda, H. Yoshida and K1 Koike, Effect of Nitrogen on the

High Temperature Properties of 10~6~ Type Alloys, Transaction

of Rational Research Institute for Metals, 8, 1966, ~0.3,

pp. 77-37.

3. E,P, Abrahamson and B. S. Blackeney, Effect of Dilute

Transition Element Additions on the Recrystallization of

Iron, Trans. of Metallurgical Sot, of A.I.M.E., 218,1960,

pp. 1101-1104.

4. We Jellinghaus und \h/. i'iink, Recrystallisation in

Hochwarmfesten ';;erkstoffen auf Nickel-Chrom und Kobalt-

Nickel-C,hrom Grundlage, Arch. fur Eisenhuttenw., 29,1958,

ppe 559~566.

5. I!,[. I!L Shteynberg, V, K. Farafanov, E. G. Tretyakova and D. A.

.

Uiazoyev, Effect of Alloying on the Softening and Creep

Resistance of Chromium-Nickel Austenite, Physics of Xetals

and 1:Tetallography, 19, 1965, N0.3, pp. 87-92.

6. V. V. Levitin, Investigation of the Influence of Boron on the

Decomposition of a Saturated Solid Solution at Grain

Boundaries, Physics of Metals and Metallohraphy, 11, 1961,

Noe3) ppe 67-73.

7. a. c. Bagel and H. J. Beattie, Jr,, Aging Reactions in Certain

SuperallOyS, Transaction of Amer, Sot, for Met., 49, 1957,

pp. 978-1004.

8.

9.

10.

H, Hughes, Complex Nitride in Cr-Ni-Nb Steels, Journal of Iron

and Steel Institute, gp, -775-778.

Y. Kawabe, R. Nakagawa and T, Mukoyama, The Strengthening

Effects of B, N and &IO Additions on the High Temperature

Strength of l&X-12Ni-0.2C Austenitic Heat Resisting Steels,

Jl. of Iron and Steel Institute of Japan, 54, 1968, pp.473-

489.

R.F. Decker and Je L0 Freeman, The Xechanism of Benefical

Effects of Boron and Zirconium on Creep Properties of a

Complex Heat-Resisting Xloy, Trans. of ?~1etallurgical Sot. of

A.I.!.I.E.; 218, 1960, ppr 277-285.

I

/

11. K. J. Irvine, D. T. Llewellyn and F. B. Pickering, Eigh-.

Strength Austenitic Stainless Steels, Jl. of Iron and Steel

Institute, 204, ,1966, pp. 628-637.

12. R. 3loi;'er and G. Mayer,

Austenitic Stainless Steels

Frecipitation Hardened with Titanium,. ~1. of Iron and Steel

Institute, 201, 1963, pp. 933-943. ;

13. XL Yamazaki, Effect of Heat Treatment on High Temperature

Strength (Properties of 18Cr-12Mi Stainless Steels with

Varied Carbon Contents), Jl. of SOC. of Materials Science of

Japan, 15, 1966,'pp. 24-30.

Table 1 c Chemical compositions of alloys ( * chitrpd composition )

Alloy c Mn Cr

K-0 0.20 10.23-lE-EF

N-l 0.23 10.18 19.98

N-Z 0.23 10.33 20.44

M-3 0.23 10.48 20.36

x-4 0.22 9.48 20.24

:;- 5 0.22 10.13 19.87

S-6 0.25 9.68 19.27

N-7 0.25 9.72 20.63

N-8 0.23 PO.31 19.35

SbO 0.26 9.85 19.45

Nbl 0:.27 10.0' 20 .OQ

f!!N 0.17 10.21 19.16

VB 0.17 10.26 19.04

50.A 0.26 l:.O* 22 .o+

5OC 0.35 9.41 21.67

50D 0.?45 9.40 Tl.64

rIoi: 0.24 10 .n* 32.0*

3 0.24 R. ,"I 19.50

1 OMGN 0.2C 10.0* 2O.W

1 OM6NU 0.21 10.0* 20.0*

Ni

6.59

6.03

6.48

5.92

5.98

5.88

6.42

6.04

5.87

5.88

6.0"

5.82

5.90

6.0*

5.73

5.67

G.OQ

5.92

5.95

C.0"

MO W ?ib S.N.

--

1.96 2.45 0.54 0.0654

1.83 2.38

2.03 2.15

2.21 2.72

1.87 2.63

1.92 2.24

1.87 2.37

2.13 2.21

I.97 2.45

2.0s 2.79

2 .o* 2.5'

1.90 2.34

1.85 2.32

2.0s 2.5*

1.90 2.43

1.9? !?.4?

2.0* 2.s*

?.('F( 2.38 _

qo q.5*

2.0s 2.5'

0.74 0.2975

0.56 0.5096

0.77 0.5348

0.66 0.5495

0.75 0.6013

C.98 0.8017

0.84 0.7701

0.78 0.8749

0.588

1.01 0.455

0.61 0.434

0.62 0.377

1 .o+ 0.50

0.65 0.483

O.GQ 0.147

1.v 0.2:

o.fx?-

1.1 0.571

1 .o* 0.497

Table 2. Effect of niobium on the relation

betwe en the solution temperature

and the grain size, hardness

I.N. n

0.0187 -

0.0825 -

0.1050 -

0.1204 -

0.1149 -

0.1531 -

0.1230 -

0.1631 -

0.1040 -

0.022 -

0.115 -

0.102 -

0.133 0.02

0.11 -

0.133 n.ma

0.144 P.04

0.20 0.11

0.023 -

0.169 -

0.187 O.OCR3

Table 3. X-ray~analyrit of undisrrolvwd pbrae 02 5OA, !IOC,

5OD and SOP alloy8 solution treated et 115O"C,

12oO'C and P2SO*C

note:, A, detected clearly

B,

detected n little

c,

detected not any ,'

sol. temp. Alloy Nb(C,ti) BN MC L

!%I 4 A C C A

1160C 5oc

'50D

5af?

50A

120u"c 5oc

5oF

50A

12scm 5m

50D

\ 50F

A

A

A

.A

.A

A

A

A

.A'

A.

A

c

A

C

A

c \

C

A

c"

C

c

A A

A A

ii

A

A

C A

A

A

A B

C, B

C B

A B

A

C.

Table 4.

Creep rupture properties of lOMeN. IoM~NB alloys

of notched specimens at 7OoC, 26 kg/knm

note: d*=17 R.A. : reduction of area

numerical numbers in parenthesis mean creep

rupture !ife and elongation of Plain specimen

382

1 icredp Ark lltd-

I !

+ 11

I

)-

-

:- -&

L-

0

.i

+I,

+

200

C&J rupture elongation

+

I_

100

I I I Y I I I I

t-

I 1 I 1 1

01

0 0.1 0.2 0.3 0.4 0.50.6 0.7 0.8 0.9 1

90

80

70

60 g

20

10

N (%I

Fig. 1. Effect of nitrogen on the creep rupture life and the

creep rupture elongation of 10 M 6 N type alloys.

Heating time (hr)

FIN. 2. Eeftect of niobium on the age

hardness of IOM6N type alloy

-

Rupture life (hr.)

Rupture life (hr.1

Ms. 3. EffWi of niobium on the creep

Fig. 4. Effect of boron on the creep rupture

ruputure properties of 10M6N

properties of loM6N type alloys

/

type alloys at 700C at 700C

-

/?H I

0 : 0 kg/mm j

I O-II

Heating time ( hr.)

Fig. 5.

Effect of stress on the amount of G. B.R. of

B. alloy at 7 50 C

Sol temp(C)

fig. 6.. Effect of solution temp

on amount of GER.

Heating time ( hc)

Fig. 7.

Effect of heat treatment on age hardenlng

Propertres of 1 OM 6 N alloy

1

I I

1130 1200 1250 1305

Sol. temp (Co)

Fig. 8.

Effect of SOI temp

0 short time tenstle

Properties of 10MGNB

alloy

40. I

T 30

E

&I

20

1

;

!?*+id

10 275 __

t I 1

;; 0: 1150VC

P

3

x : 12ooOc

3 2 4 : 125OC

a 0 : 13ooOc

g 1,

I I

Id 3x10* IO 3x6 lo* 3xd

Ng. 10.

RuPuture life (hc)

Effect of sdution tempemtures on the

creep ruputure pmperties of 10M6EJB

alloys

- -

; _I ;f.:i.;r

IO 3x10 IO 3Xld l\?

Ruputure life ( hc)

i Fig. 9. Effect of scbtion tempemtwes

c

on the creep ruputwe PrOPenes

0: !Cl/rGN alloys

0: II 5OC As sol.

*; 75dCX4hr ~

1: 8@OCX4hr:

2 D : B C0C X20bt

K

1

I I

10 3x16 I 0 3x10> IO

Fig. 11.

Ruputure life ( hc)

Effect of aging on the creep

rupture properties of lOM6EiB

alloyssolution treated at IISIC

,!,** $+ ,.* ) -

&A: ~~l,Z~,:C7~ ,j

,-

1

- q . p-/

>a

i,+ i >;

.*:/ )I5 y*,

\>

1

*\7-*- a

\ J

=n 2~ . -- ,

II,; y&

/ - , t t ,L r _

-2 a3

1) _ ,*-Jr I

$

7)

1

.; I_ -I- , )

14,C <

L

1-J

*> i:

f 1) ; \; -~~$+

*\I ,.--/ -1 _I

v

/

(a) N-O (0.0849)

(b) N-2 (0.615%)

_-

:, -

& * : T bJ, ; *.*-- *d

I, r

7 /

, : [ -w-5, * . J-.,.

: +-A.

/

1 -: \c

1;; /; ,tJ;;-+..*+3,;:

c,/ I *+:,.

/)Jd b--/l

JV /x1

-IL _ L -3

;,-. VT I

F,/ J-

A. / : .

I\ $&g d1

2 \N;-

I 5

-;\~xj).- ,-,&/,

-w-i , -u j , %,. fl

I, /

> :!.- , --;T

p-e ,j _ / t.47;:. : :++/;*

c - (- ; c

4; 2 7% .

; * _ ; ;;.,+ . -

72 4/,

I 22. c

. ,

//I ..;/- _ p,.- ,,,- --a-, -7, ,

--,

.,,l: . ,; * - ---.._v

*;-

.?-

- \ ,-4 llf$ Lp * y/

, 72. I-/ , _

L-1

, y- zfi

_ y-, +;*_l.;,: -., 772, ,. 7 _ .

\ , i ;; * 7 / _(-. *+,,; .<j-(!

(c) N-5 (0.?54$%)

(3) N-8 (0.979SN)

Photo. 1 Microstructures of alloys aged for

1OOOhr. at 7OO'C.(X3000)

(a) NbO

(b) Nbl

Photo. 2 Microstructures of KbO, Nbl alloys

aged for 250hr.

at 7OO"C.( X400)

386

I?

c

A a %

(a) MN 700% 1.5hr.

'"r"; "5.;' -

> .

*

(c) ?@J 700C 6hr.

* -s

(e) MI? 800C 1.5hr.

at

?

-s

I

m-b* ,

. * I**

i

i *

. *

.

(bi) Ml3 700C 1.5hr.

(cl) ME3 700C 6hr.

I

t

N :

.I

a

*

. 9-

.

, ,

. .

.

&

(f)

800C 1.5hr.

Photo. 3 Microstructures of MB allays

aged at 7OOY and 800&,(X 3000)

387

-.

j, *.

.I

VT: - ..:, #Y. *;

* /

.-_ _ ._

\

/

I-

:;.

.*

4

.

w

.,

. -I

.?.l., - .,. *

I

(a) 800C 4hr.(X 100)

(b) 800C 4hr.(X 400)

(c) 8OO'C 4hr.(X400)

(cl) 800C 4hr.i X1000)

(e) QOO*C ZOmin.(X 250)

Photo. 4 fficrostruetures of NbO alloy aged

at 8OO'C and QOO'C.

388

Photo. 5 Micrastructures of lOM6N alloy heated for lhr. at

900C after solution treated at 125O"C.(Y 63)

(a) forging ratio, about 1.5

(b) forging ratio, about 4

(c) forging ratio, about 9

W (b)

lOM6N lOY6N

solution treated

solution treated

at 1150C

at 1200C

(c)

lOM6N

solution treated

at 1300C

389

r

:

* !< L ;;.: ;t, :, ,-T-J,, , $5 <

;, ),;q:; t, I

,

-

! /, \.~ -. * 1

s i .,:.,

, I 0, s ?

, , y/,1 b

J.

. \

, hi \ .I.,(, ;,:,!f

I , \ -,.

L.

. :

I

\?,I . b _ -

* ;..*j i

h,h. * , ,

Y 1. ,, I 1

<:I

i

-- I(

,;,: . :-:;, .,\,; +; 4.: , .,

, ,>\,K ;(,?*p ( - y

L.1, L.2, i.\- ,;-

p-j.;*,t:,(

\ I-I. c

+

y;+, \

\ .fi i ,.n

,/

/

, ,,z (Y:lf;Tt,,*

. ;i,,&< -\

Y>l,~. !

c, $-;, :!

--

\

\

\ /

c al / $ i/;.,/,!

I

. ,..=,I

;i f,+>~~:../:),!, :.,p

-r, -i-y; 1:

,A\$ *.,.1\

j-y>;;, \ ; f;;~~;:Llr/,a* .+ ;

(d) (el

lOk469 lOM6SB

solution treated solution treated

at 1200C and heated at 1150C

for 4hr. at 8OO*C

Photo, 6 Microstructures of 10346Ff type alloys

1000hr. at 700rC, after heat treated

conditions. (x 3000)

@I * * .+ _ ,)

)

< p .

*t \,

c J

r ,I

_

i-

1 I

8

-,

t

z

,

a ,

I i /. I,

* _ -,- d

s!

.I _.

y

5

I

- .- _.

w

10".!6NB

solution treated

at 13OO'C

heated for

at various

Photo, 7 Slicrostructures of 10?.'6N alloy aged for 20hr.

at ?OO'C.(X 3000)

a: solution treated at 1150C

b: solution treated at 1250C

c: solution treated at 13OO'C

390

S-ar putea să vă placă și

- Solutions Manual to accompany Engineering Materials ScienceDe la EverandSolutions Manual to accompany Engineering Materials ScienceEvaluare: 4 din 5 stele4/5 (1)

- 055Document28 pagini055Mohamed WahidÎncă nu există evaluări

- The Effect of Niobium On The Corrosion Resistance of Nickel-Base AlloysDocument12 paginiThe Effect of Niobium On The Corrosion Resistance of Nickel-Base Alloysrnd.spÎncă nu există evaluări

- Quality - Ash Fusion TempDocument30 paginiQuality - Ash Fusion TempNoviandryÎncă nu există evaluări

- Energy Conversion and ManagementDocument43 paginiEnergy Conversion and ManagementnursyifaaÎncă nu există evaluări

- Primary Carbides in Alloy 718Document7 paginiPrimary Carbides in Alloy 718Sinan YıldızÎncă nu există evaluări

- Primary Carbides in Alloy 718Document7 paginiPrimary Carbides in Alloy 718Julio Cesar Garcia GuerreroÎncă nu există evaluări

- Evolution of Texture Nanocrystalline Electroless: During Annealing of Nickel Alloy DepositsDocument15 paginiEvolution of Texture Nanocrystalline Electroless: During Annealing of Nickel Alloy Depositscesarj29Încă nu există evaluări

- p91 OxidDocument11 paginip91 OxidTibor KeményÎncă nu există evaluări

- High-Temperature Oxidation Behavior of Zircaloy-4Document6 paginiHigh-Temperature Oxidation Behavior of Zircaloy-4raknaver8461Încă nu există evaluări

- 1992 - Niobium Additions in HP Heat-Resistant Cast Stainless SteelsDocument10 pagini1992 - Niobium Additions in HP Heat-Resistant Cast Stainless SteelsLuiz Gustavo LimaÎncă nu există evaluări

- Report PDFDocument10 paginiReport PDFShubham GoelÎncă nu există evaluări

- 49 2 Philadelphia 10-04 1148Document3 pagini49 2 Philadelphia 10-04 1148Niraj_Singh_988Încă nu există evaluări

- Catalysts 05 01289 CompleteDocument17 paginiCatalysts 05 01289 Completerazor75apÎncă nu există evaluări

- Roqtuf PDFDocument6 paginiRoqtuf PDFLeonidio CamposÎncă nu există evaluări

- A2BO4 Type PerovskiteDocument11 paginiA2BO4 Type PerovskiteMahmoud ȜliÎncă nu există evaluări

- Effect of Iron Ore-Coal Pellets During Reduction With Hydrogen and Carbon MonoxideDocument18 paginiEffect of Iron Ore-Coal Pellets During Reduction With Hydrogen and Carbon MonoxideAdrian Cruz EspinozaÎncă nu există evaluări

- Metal Dusting in A Laboratory Environment - Alloying Addition EffectsDocument15 paginiMetal Dusting in A Laboratory Environment - Alloying Addition EffectsClaudia MmsÎncă nu există evaluări

- Fundamental Metallurgy of Niobium in SteelDocument74 paginiFundamental Metallurgy of Niobium in SteelCarlos Viana100% (1)

- Less-Common Metals Elsevier Sequoia S.A., Lausanne - Printed in The NetherlandsDocument11 paginiLess-Common Metals Elsevier Sequoia S.A., Lausanne - Printed in The NetherlandsInaamÎncă nu există evaluări

- Copper Ion-Exchanged Zeolite Catalysts in Deno Reaction: Hidenori Yahiro, Masakazu IwamotoDocument19 paginiCopper Ion-Exchanged Zeolite Catalysts in Deno Reaction: Hidenori Yahiro, Masakazu IwamotoborgiamatriceÎncă nu există evaluări

- Efeito Do NióbioDocument4 paginiEfeito Do NióbiomatheusÎncă nu există evaluări

- Aiche-33-01Catalyst Poisoning6Document17 paginiAiche-33-01Catalyst Poisoning6Hsein WangÎncă nu există evaluări

- Marina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. KuvshinovDocument15 paginiMarina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. Kuvshinovjocy1989Încă nu există evaluări

- Artikel 8 PDFDocument6 paginiArtikel 8 PDFumidwijayantiÎncă nu există evaluări

- Sodium Sulfuate Depositionand Dissolutionof SilicaDocument14 paginiSodium Sulfuate Depositionand Dissolutionof SilicaEugênia PheganÎncă nu există evaluări

- Precipitation in The Ni-Cu-Base Alloy Monel K-500Document13 paginiPrecipitation in The Ni-Cu-Base Alloy Monel K-500farhadeeÎncă nu există evaluări

- RWoodhouse ECS Paper FinalDocument12 paginiRWoodhouse ECS Paper FinalMawa MutazÎncă nu există evaluări

- Calcination of Nickel-Alumina CatalystsDocument4 paginiCalcination of Nickel-Alumina CatalystsAnonymous 4PuFzAR100% (1)

- Catalytic Application of Niobium CompoundsDocument13 paginiCatalytic Application of Niobium CompoundsGuilherme Esteves100% (1)

- Mo2C-HYDocument11 paginiMo2C-HYioanaandra5690Încă nu există evaluări

- Mechanical Properties of Biomedical Co-33Cr-5Mo-0.3N Alloy at Elevated TemperaturesDocument7 paginiMechanical Properties of Biomedical Co-33Cr-5Mo-0.3N Alloy at Elevated TemperaturesDeva RajÎncă nu există evaluări

- Ix-C-1066-16 Banno PDFDocument11 paginiIx-C-1066-16 Banno PDFClaude BouillotÎncă nu există evaluări

- Niobium ProcessingDocument4 paginiNiobium ProcessingqualidadesiderÎncă nu există evaluări

- AdvancedNickelmetalcatalsytWGS Park 2010Document4 paginiAdvancedNickelmetalcatalsytWGS Park 2010leonardoÎncă nu există evaluări

- Low-Density Nanoporous Iron Foams Synthesized by Sol-Gel AutocombustionDocument7 paginiLow-Density Nanoporous Iron Foams Synthesized by Sol-Gel AutocombustionJahidul IslamÎncă nu există evaluări

- Bokov Et Al. - 2021 - Interplay Between Decarburization, Oxide Segregation, and DensificationDocument12 paginiBokov Et Al. - 2021 - Interplay Between Decarburization, Oxide Segregation, and DensificationAnna ShelyugÎncă nu există evaluări

- Phase Diagram Study of Alloys in Iron Carbon Chromium Mo-NiDocument13 paginiPhase Diagram Study of Alloys in Iron Carbon Chromium Mo-NiRavichandran JayaprakashÎncă nu există evaluări

- Applied Catalysis B: EnvironmentalDocument10 paginiApplied Catalysis B: EnvironmentalnguyencyberchemÎncă nu există evaluări

- Ammonia Oxidation Into Nitrous Oxide Over Mn-Bi-Al Catalyst I Pokrovskaya Et Al Chem Eng J 2003 PDFDocument8 paginiAmmonia Oxidation Into Nitrous Oxide Over Mn-Bi-Al Catalyst I Pokrovskaya Et Al Chem Eng J 2003 PDFjuan davidÎncă nu există evaluări

- XRD Applications in Relevant PapersDocument31 paginiXRD Applications in Relevant PapersMerve Ayvaz KöroğluÎncă nu există evaluări

- 4 CF 0Document7 pagini4 CF 0reza haghjooÎncă nu există evaluări

- Corosion PDFDocument12 paginiCorosion PDFeid elsayedÎncă nu există evaluări

- Sarma V - Pisupati: For T H e Research Boiler TestsDocument5 paginiSarma V - Pisupati: For T H e Research Boiler TestsPiyush AgarwalÎncă nu există evaluări

- Boiler Corrosion MagnetiteDocument14 paginiBoiler Corrosion MagnetiteJakeTheSnake69Încă nu există evaluări

- Fireside Corrosion of Alloys For Combustion Power PlantsDocument11 paginiFireside Corrosion of Alloys For Combustion Power Plantsdealer82Încă nu există evaluări

- Articulo Oscar CuevasDocument4 paginiArticulo Oscar CuevasAndres PedrozaÎncă nu există evaluări

- Study On High Performance Sm2Fe17N X Magnets: ' and Comfo D5Document4 paginiStudy On High Performance Sm2Fe17N X Magnets: ' and Comfo D5Selvakumar JanakiramanÎncă nu există evaluări

- Carbon Dioxide Reforming of Methane Over Ni/ - Al O Catalysts: Effect of Ni ContentDocument3 paginiCarbon Dioxide Reforming of Methane Over Ni/ - Al O Catalysts: Effect of Ni ContentDzulfadhli King AlghifariÎncă nu există evaluări

- Conductivité de LN Dopé Au ZNDocument7 paginiConductivité de LN Dopé Au ZNمحمدÎncă nu există evaluări

- Stud Surf Sci Studies 751993pages12571272Document17 paginiStud Surf Sci Studies 751993pages12571272Daniel Alfonso GamezÎncă nu există evaluări

- Hydrogen Retention in High-Z Materials With Various Contents of CarbonDocument6 paginiHydrogen Retention in High-Z Materials With Various Contents of CarbonPrashant ThankeyÎncă nu există evaluări

- Diat HTT Lect 22 To 24Document13 paginiDiat HTT Lect 22 To 24prakush01975225403Încă nu există evaluări

- Calcium-Aluminothermal Production of Niobium and Mineral Composition of The Slag - GorkunovDocument15 paginiCalcium-Aluminothermal Production of Niobium and Mineral Composition of The Slag - Gorkunovmaa bloÎncă nu există evaluări

- MgO Effect TGDocument3 paginiMgO Effect TGBiswanath senÎncă nu există evaluări

- 03 - An Alloy Design Concept For Better Matching of Strength and Toughness in Pipeline SteelDocument7 pagini03 - An Alloy Design Concept For Better Matching of Strength and Toughness in Pipeline SteelŞarîngă George AlexandruÎncă nu există evaluări

- Austenitic Stainless SteelDocument3 paginiAustenitic Stainless SteelGeorge MarkasÎncă nu există evaluări

- Steel DeoxidationDocument12 paginiSteel DeoxidationUlises Quintana CarhuanchoÎncă nu există evaluări

- Lecture 7Document5 paginiLecture 7Abhijeet BhagavatulaÎncă nu există evaluări

- The Hot Workability of Croma NiteDocument9 paginiThe Hot Workability of Croma NiteRajan NPÎncă nu există evaluări

- Alloy Steel Pipe Price List IndonesiaDocument14 paginiAlloy Steel Pipe Price List Indonesiaiandegs2010Încă nu există evaluări

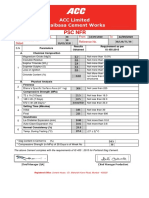

- Acc PSC - NFR - 38 - 2020Document1 paginăAcc PSC - NFR - 38 - 2020kartick adhikaryÎncă nu există evaluări

- GU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Document48 paginiGU-629 Application and Selection of Standard Pipe Supports (Formerly SP1187)Ibrahim Naguib100% (1)

- PCM-Based Building Envelope Systems: Benjamin DurakovićDocument201 paginiPCM-Based Building Envelope Systems: Benjamin DurakovićLam DesmondÎncă nu există evaluări

- SR - No Description Unit Qty Unit Price Total PriceDocument4 paginiSR - No Description Unit Qty Unit Price Total Priceatwik EnterprisesÎncă nu există evaluări

- Hvac Air Balance Report FormDocument8 paginiHvac Air Balance Report FormAbdullah.N FAAliÎncă nu există evaluări

- Meyco Segment HR PDFDocument16 paginiMeyco Segment HR PDFFabioSoaresÎncă nu există evaluări

- The Problem and Its Background: PAGE - 1Document85 paginiThe Problem and Its Background: PAGE - 1Gigi SalesÎncă nu există evaluări

- Model: 1. General DescriptionDocument4 paginiModel: 1. General DescriptionWalterHuÎncă nu există evaluări

- Nanofold Solar BrochureDocument8 paginiNanofold Solar BrochureNanofoldÎncă nu există evaluări

- Lindapter Hollo-Bolt Flyer A4 UK 2013 734Document2 paginiLindapter Hollo-Bolt Flyer A4 UK 2013 734su_diverseÎncă nu există evaluări

- Rockassist TrainingDocument18 paginiRockassist TrainingDương HoàngÎncă nu există evaluări

- Fakulti Kejuruteraan Awam Universiti Teknologi Mara Pahang Laboratory ManualDocument6 paginiFakulti Kejuruteraan Awam Universiti Teknologi Mara Pahang Laboratory ManualAMIRUL MUSTAQIM BIN ABDULLAHÎncă nu există evaluări

- Evergreen Modular Kitchen KitplyDocument1 paginăEvergreen Modular Kitchen KitplydhineshÎncă nu există evaluări

- Orifice Flange Union Assembly and Orifice Run Installation and Operation ManualDocument8 paginiOrifice Flange Union Assembly and Orifice Run Installation and Operation ManualNithin CpÎncă nu există evaluări

- Brick Work: Laurie BakerDocument22 paginiBrick Work: Laurie BakerShaiwal_2997Încă nu există evaluări

- Avalon Astoria Service Manual PDFDocument106 paginiAvalon Astoria Service Manual PDFexchangenriÎncă nu există evaluări

- M Tech I Sem II Mid TDDocument4 paginiM Tech I Sem II Mid TDMir Mustafa AliÎncă nu există evaluări

- PL - 400-Hydrant LT Atap - Denah AtapDocument2 paginiPL - 400-Hydrant LT Atap - Denah AtapMuh SanadÎncă nu există evaluări

- Tutorial 2 Thermo PDFDocument3 paginiTutorial 2 Thermo PDFFattihiEkhmalÎncă nu există evaluări

- A Solar Powered Adsorption Freezer: A Case Study For Egypt's ClimateDocument9 paginiA Solar Powered Adsorption Freezer: A Case Study For Egypt's Climateali105Încă nu există evaluări

- Asco - Jkh8551g401mmsDocument4 paginiAsco - Jkh8551g401mmsBiến tần MICNOÎncă nu există evaluări

- Chap. 3 - Split Air Conditioning SystemDocument17 paginiChap. 3 - Split Air Conditioning SystemSparsh ShukalÎncă nu există evaluări

- Sikagrout - 200Document3 paginiSikagrout - 200Tan TounÎncă nu există evaluări

- Ashrae Isbd ReportDocument35 paginiAshrae Isbd ReportLuciano EbangÎncă nu există evaluări

- Analysis of Timber Joints With Punched Metal Plate FastenersDocument4 paginiAnalysis of Timber Joints With Punched Metal Plate FastenersBatuhan DerÎncă nu există evaluări

- Internal Flow: Mehmet KanogluDocument115 paginiInternal Flow: Mehmet Kanogluizzet9696Încă nu există evaluări

- Cere 131.2 EditedDocument3 paginiCere 131.2 EditedMary Elizabeth SolasÎncă nu există evaluări

- Sika MonoTop 612&620 Data SheetDocument19 paginiSika MonoTop 612&620 Data SheetasdfghÎncă nu există evaluări

- Hot BoltingDocument6 paginiHot BoltingNickath Banu100% (1)