Documente Academic

Documente Profesional

Documente Cultură

M360content Chain Conveyor

Încărcat de

Ashish MoreTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

M360content Chain Conveyor

Încărcat de

Ashish MoreDrepturi de autor:

Formate disponibile

An Approved Continuing Education Provider

PDHonline Course M360 (1 PDH)

Chain Conveyors

Practical Calculations

J urandir Primo, P.E.

2009

PDH Online | PDH Center

5272 Meadow Estates Drive

Fairfax, VA 22030-6658

Phone & Fax: 703-988-0088

www.PDHonline.org

www.PDHcenter.com

1

R

a

m

T

d

A

D

P

T

sp

T

tw

www.PD

1. INTRODU

Roller Chain

another. This m

metric and imp

The main fun

dynamics of th

Arrangement

Drive chains a

Position of Sp

The sprockets

procket. In th

The two shaft

wo sprockets

DHcenter.com

Jurandir Pri

UCTION:

Conveyors o

manual for pr

perial system

nction is inf

his segment o

t:

are ideally ins

prockets:

s should be "k

his way the sp

ts should be p

are installed

m

imo

Chain

or Apron Cha

ractical applic

m.

formative for

of Material Ha

stalled with th

key-wayed a

procket can po

parallel and t

along the sam

PDHonl

n Conveyo

ain Conveyor

cation indicat

r both experi

andling.

he shaft in the

and matched

osition itself i

the sprockets

me horizontal

ine Course

ors - Pract

rs are used t

tes the chain c

ienced profe

e horizontal p

in pairs. Sinc

if uneven wea

should be fir

level. This is

M360

tical Calcu

to transfer he

conveyor basi

ssionals and

osition, as sh

ce the tail sha

ar takes place

rmly installed

s illustrated in

w

ulations

eavy bulk ma

ic calculation

beginners in

hown below:

aft is an idlin

e in the chain

d. Use a strai

n Figure 1 and

www.PDHon

2 of

aterials from

ns for Bulk M

nterested in

ng shaft, key i

strands.

ight edge to c

d 2 below:

nline.org

10

one point to

Materials in the

knowing the

it to only one

check that the

o

e

e

e

e

C

C

d

2

A

fo

T

u

o

T

c

re

T

m

V

A

C

www.PD

Chain Convey

Commonly th

during convey

CONVEYO

Continuous B

Centrifugal B

Slat or flat to

Assembly lin

Drag and Scr

Apron Conve

2. APRON CH

Apron feeders

for the most h

These types o

up to 2000 mm

of the skirts. T

The presence

conditions of

eserve of mot

The basic fo

manufacturing

Velocity, Wid

As the transpo

Considering th

DHcenter.com

Jurandir Pri

yor Speed:

he Chain Con

ying. The tabl

R

Bucket Elevat

Bucket Elevat

op Conveyor

ne Conveyor

raper Convey

eyors

HAIN CONV

s are used in t

ard condition

f conveyors h

m. The large

The presence

of receiving

exploatation

tor power.

rmulae for A

g has its own

dth an Heigh

orted material

he following d

m

imo

nveyor speed

le below show

SP

tor

tor

yors

2

VEYORS

the mining in

ns of exploata

have capacitie

size of materi

of fixed skirts

g hopper caus

and the gre

Apron Chain

n methodology

ht of Skirts

l is lumpy, it

data:

PDHonl

is dictated b

ws the basic c

PEED (fpm)

75 to150

200 to 300

50 to 150

5 to 15

50 to 100

10 to 60

ndustry for the

tion to feed th

es up to 6000

ial lumps is th

s cause additi

ses additiona

at starting re

n Feeders ca

y for calculat

s maximum lu

ine Course

by how it is

onveyors and

e transportatio

he crushers at

0 t/h and are a

he cause for t

ional resistanc

al resistance d

esistances are

alculation are

tion.

ump size will

M360

loaded and u

d their typical

on of heavy a

t quarry and s

able to transp

the increase o

ces due to ski

due to the pr

e the cause f

e given for

l determine th

w

unloaded and

operating sp

and lumpy ma

storage bins.

port materials

of the width o

irt friction.

ressure of the

for the introd

references, s

he apron widt

www.PDHon

3 of

d what is don

eeds.

aterials. They

s with maxim

f the aprons a

e material in

duction of a c

since that ea

th B [m]:

nline.org

10

ne to the load

y are designed

mum lump size

and the heigh

n it. The hard

coefficient of

ach company

d

d

e

t

d

f

y

T

W

th

w

Q

c

T

T

m

S

g

If

v

th

www.PD

The formula fo

When width B

he capacity:

where:

Qh = capacity

= density of

= 0,75 ext

c = 100 - i

100

The coefficien

The reason fo

material will f

Speed is limit

great dynamic

f the calculat

variation of th

he use of var

DHcenter.com

Jurandir Pri

for the determ

(1 m = 3.28

B and height

y in t/h

f the transport

traction effici

inclination fac

nt c, as indi

or the inclina

fall directly on

ed to 0.25 m/

c loads in the

ed speed is g

he speed in th

iable speed D

m

imo

mination of the

8 ft)

of the skirts

(1 m/s = 3.2

ted material in

iency factor

ctor ( ang

icated above,

ation is the fa

n it.

/s (0.82 ft/s),

track chains a

greater than lim

he work diapa

DC, AC and h

PDHonl

e height of the

h are determ

28 ft/s)

n t/m (t/ft)

le of inclinati

must be take

acilitation of

and in some

and the high a

mited, the sk

ason v = 0.03

hydraulic mo

ine Course

e skirts h, is

mined, the apr

ion).

en into accoun

f truck discha

e cases to 0,4

abrasion wear

kirt height h

3 0.16 m/s (

otors.

M360

given h for ap

ron speed v is

nt, when feed

arge and the

m/s (1.3 ft/s)

r of the apron

must be inc

(0.1 0.5 ft/s

w

pron conveyo

s determined

ding are inclin

protection of

). The reason

ns.

creased. The c

s) for differen

www.PDHon

4 of

ors, as:

by the know

ned (usually

f the equipm

ns for the limi

contemporary

nt capacities,

nline.org

10

wn formula for

= 15 - 25)

ment when the

itation are the

y drives allow

realized with

r

.

e

e

w

h

www.PDHcenter.com PDHonline Course M360 www.PDHonline.org

Jurandir Primo 5 of 10

Apron Chain and Rollers:

Apron feeders use heavy duty crawler tractor chains (Caterpillar tractor type), commonly sized to suit the

application. The chain links are forged for increased load capacity. Pins and bushes are hardened on the wearing

surface.

The carrying rollers are spaced to eliminate the sag, mounted on support frames to permit easy removal for

maintenance and replacement. The apron plates are bolted on flat top of the chain links, as shown below:

Special design and exclusive metal to metal allows continuous pan contact through articulation minimizes spillage

and leakage, as indicated below:

Drag and Flight Conveyors

Drag conveyors are used where multiple loading or discharge points are required and a totally enclosed conveyor is

needed for dust containment, capable of handling ne materials ranging from dust to 6 inch (150 mm) lumps, where

capacity requirements are high, 200 - 400 TPH.

They are used and when the material is somewhat uid. The typical materials conveyed are TSP (fertilizer), raw meal,

and nish cement.

www.PDHcenter.com PDHonline Course M360 www.PDHonline.org

Jurandir Primo 6 of 10

3. FORMULAS FOR EASY CALCULATIONS:

1) Chain conveyor or apron chain conveyor calculation system. The load tensions are calculated as indicated below:

T = Fs + Fi + Fk (Kgf) (lbf)

Fs = (Qt x L) + (Pch x L) x f =

Fi = Pch x L x f1 =

2

Fk = (Qt + Pch) x L1 x sen x f2

2) To calculate the driving power (CV or HP), use the following formulas:

N = T x v (m/s) (metric) and T x v (fpm) (imperial).

75 33000

Where:

T = Total chain force or total work chain tension (kgf) (lbf);

Fs = Upper chain tension (kgf) (lbf)

Fi = Under chain tension (kgf) (lbf)

Fk = Lift chain tension (kgf) (lbf)

Q = Conveyor total load - (t/h) (tph)

Qt = Conveyed material weight (kg/m) (lb/ft)

L = Total conveyor direct length (including inclined/declined) - (m) (ft)

L1 = Conveyor horizontal direct length (m) (ft)

L2 = Conveyor slope (inclined / declined) extension direct length (m) (ft)

Pch = Total chain weight (see manufacturers tables according to chain types);

N = Driving power (kW) - (HP)

f = Upper chain friction factor 0.25 ~ 0.35;

f1 = Down chain friction factor 0.10 ~ 0.15;

f2 = Lift chain friction factor 0.25 ~ 0.35;

v = Chain conveyor speed (m/s) - (fpm)

= Driving sprocket diameter (mm) - (in)

= Conveyor slope angle;

= Bulk density of conveyed material (kg/m) - (lb/ft)

www.PDHcenter.com PDHonline Course M360 www.PDHonline.org

Jurandir Primo 7 of 10

4. PRACTICAL EXAMPLE:

Calculate the driving power of a Drag Roller Chain Conveyor, commonly used in Sugar Plants considering the

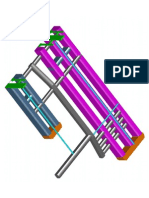

following sketch below:

Where:

Q - Chain conveyor capacity = 90 tph

- Sugar cane bulk density = 900 kg/m - (56 lb/ft)

v Conveyor speed = 5 m/min (0.083 m/s) (16.3 fpm)

- Driving sprocket diameter = 270 mm (10.6 in)

1 Driving pulley on driving shaft = 290 mm (11.4 in)

Pch -Total drag chain weight = 160 kg/m (both sides) (107.5 lb/ft)

L1 - Conveyor horizontal direct length = 2.5 m (8.2 ft)

L2 = Conveyor slope (inclined) direct length = 14.5 m (47,5 ft)

= Conveyor slope angle = 28

Solution:

1). CALCULATION ACCORDING TO MATERIAL FLOW:

kg/h = kg/m or lb/h = lb/ft

m/h ft/h

Q - 90 tph = 90,000 kg/h (198,450 lb/h)

v 5 m/min = 5 x 60 = 300 m/h (984 ft/h)

Qt = 90,000 kg/h = 300 kg/m Qt = 198,450 lb/h = 202 lb/ft

300 m/h 984 ft/h

1

4

5

0

0

(

4

7

,

5

f

t

)

2500 (8,2 ft)

2

7

0

m

m

PESO DO MATERIAL = 300 kg/m

CONVEYOR CAPACITY = 90 tph

DRIVING PULLEY DIA = 270 mm

TOTAL CHAIN WEIGHT = 160 kg/m

SPROCKETS DIAMETER = 270 mm

CONVEYOR SPEED = 6 m/min

2

8

www.PDHcenter.com PDHonline Course M360 www.PDHonline.org

Jurandir Primo 8 of 10

L = L1 + L2 = 17.0 m (55.7 ft)

a) Fs = (Qt x L) + (Pch x L) x f =

Fs = (300 x 17.0) + (160 x 17.0) x 0.25 = 1955 kgf (4310 lbf)

b) Fi = Pch x L x f1 = 160 x 17.0 x 0.15 =

2 2

Fi = 2720 x 0.15 = 204 kgf (450 lbf)

2

c) Fk = (Qt + Pch) x L2 x sin 28 x f2 =

Fk = (300 + 160) x 14.5 x sin 28 x 0.35 = 1096 kgf (2416 lbf)

d) T = Fs + Fi + Fk = 1955 + 204 + 1096 =

T = 3255 kgf (7177 lb.ft)

N = T x v = 3255 x 0.083 = 3.6 ~ 5.0 CV

75 75

Or:

N = T x v = 7177 x 16.3 = 3.5 ~ 5.0 HP

33000 33000

2). CALCULATION ACCORDING TO TSUBAKI FORMULA:

T = [(Qt + 2.1.Pch) x f1 x L1] + [(Qt + Pch) x (f1 x L2 x cos + L2 x sin ) + [1.1.Pch (f1 x L2 x cos L2 x sin )]

= (kgf) (lbf)

Using the data above, calculate the tension using the Tsubaki formula:

T = [(300 + 2.1x 160) x 0.15 x 2,5] + [(300 +160) x (0.15 x 14.5 x cos 28 + 14.5 x sin 28)]+ [1.1 x 160 (0.15 x 14,5

x cos 28 - 14.5 x sin 28)] =

T = 4254 kgf (9380 lbf)

N = T x v = 4254 x 0.083 = 4.7 ~ 5.0 CV

75 75

N = T x v = 9380 x 16.3 = 4.6 ~ 5,0 HP

33000 33000

3

A

w

W

P

R

F

R

C

a

b

c

W

P

F

N

N

www.PD

3) CALCULA

According to

windlass arm t

F x R

Where:

P = Conveyor

R = Driving sp

F = Pulley per

R1 = Driving

Calculate the d

F x R

a) P is the forc

P = Fs + F

P = 3255

Or,

P = 4254

b) The convey

c) The diamete

We need to fin

P = R1 = 3255

F R F

N = F x v = 30

75

N = F x v = 6

33000 3

DHcenter.com

Jurandir Pri

ATION ACC

applied mec

to pull the bu

1 = P x R

r chain force t

procket radiu

ripheral force

pulley radius

driving chain

1 = P x R

ce to carry up

Fi + Fk = 195

kgf (7177 lbf

(9380 lbf) ac

yor data abov

er of the drivi

nd the force F

5 = 0,145 = F

0, 135

030 x 0,083 =

75

6673 x 16.3 =

33000

m

imo

CORDING T

chanics the to

ucket is:

to pull the loa

us, m;

e on driving sh

s, m

n conveyor po

p the sugar ca

55 + 204 +10

f)

ccording to Ts

e indicate the

ing pulley on

F to move the

F = 3030 kgf

= 3,35 ~ 5.0 C

3.3 ~ 5.0 HP

PDHonl

TO THE WIN

orque calcula

ad, kgf;

haft, m

wer, using th

ne plus the ch

96 =

subaki formul

e sprockets di

n driving shaft

driving shaft

and, 7177 =

F

CV

P

ine Course

NDLASS TO

ation to revol

he data above.

hain weight, a

la.

ameters, =

t is, 1 = 290

t, so:

5.7 = 6673 lb

5.3

M360

ORQUE:

lve the drivin

as we calculat

270 mm, the

0 mm, then: R

bf

w

ng chain con

ted before:

n: R = 0,135

R1 = 0,145 (5

www.PDHon

9 of

nveyor pulley

(5.3 in).

.7 in).

nline.org

10

y just like thee

www.PDHcenter.com PDHonline Course M360 www.PDHonline.org

Jurandir Primo 10 of 10

SUMMARY:

Chain Conveyors:

Chain conveyors are commonly used in siderurgy and mining industries to transport heavy minerals The

manufacturing industry also use widely chain conveyors to carry unit loads, pallets, grid boxes and general industrial

containers. These conveyors can be single or double chain strand or Catterpillar type chains. Single chain conveyors

are generally easy to install and have very minimun maintenance for users.

Many industry sectors use chain conveyor technology in their production lines.The automotive industry commonly

use chain conveyor systems to convey car parts through paint plants. Chain conveyors also have widespread use in the

white and brown goods, metal finishing and distribution industries.

Chain conveyors are also used in the painting and coating industry, ceramics, thermal treatment of metals, feed and

discharge systems of boilers. In automatic painting systems the products are attached to an above head chain

conveyor, keeping products off of the floor allows for higher productivity levels.

References:

Sugar Cane Handling and Process Equipment, Dedini, 1

st

Edition, 1975

Tsubaki Manufacturer, Chain Conveyor Calculations

Grinding Manual, Technical Publication, Fao/Allis-Chalmers, 4th Edition, 1985

S-ar putea să vă placă și

- Conveyor CalculationsDocument10 paginiConveyor CalculationsCristhian PortocarreroÎncă nu există evaluări

- Chain Conveyors Design Calculation 400 TDocument3 paginiChain Conveyors Design Calculation 400 TAbderrahim AbarayÎncă nu există evaluări

- Drag and Flight Conveyors Design CalculationDocument3 paginiDrag and Flight Conveyors Design Calculationsudip giriÎncă nu există evaluări

- ConveyDocument6 paginiConveyAbnetastroÎncă nu există evaluări

- Conveyor Design CalcDocument6 paginiConveyor Design CalcGregory Nick Toledo VelizÎncă nu există evaluări

- Konveyör Hesabı 7.24Document9 paginiKonveyör Hesabı 7.24Salih HasÎncă nu există evaluări

- Martin Sprocket CalculationDocument3 paginiMartin Sprocket CalculationKiran Kumar K T100% (1)

- Energy SavingDocument38 paginiEnergy SavingLokesh Kumar ByricaÎncă nu există evaluări

- Belt ConveyorDocument11 paginiBelt Conveyormishra_1982Încă nu există evaluări

- Conveyor Chain SelectionDocument2 paginiConveyor Chain SelectionAmeya Datrange100% (3)

- SH E096qDocument24 paginiSH E096qkanstopthankÎncă nu există evaluări

- 3.2 Design SystemDocument48 pagini3.2 Design SystemMahmoud RababahÎncă nu există evaluări

- Rotary Actuator Guide FileDocument20 paginiRotary Actuator Guide Filenikospg9427Încă nu există evaluări

- Chain Conveyor ExampleDocument4 paginiChain Conveyor ExampledeeptidhaÎncă nu există evaluări

- Free Conveyor DesignDocument12 paginiFree Conveyor DesignRyukiÎncă nu există evaluări

- Topic BeltsDocument20 paginiTopic BeltsAstri Ngent100% (1)

- Station KeepingDocument67 paginiStation KeepingSagar MhatreÎncă nu există evaluări

- Helix Chute Design Sample Report 2Document26 paginiHelix Chute Design Sample Report 2Sergio Diaz DuarteÎncă nu există evaluări

- Xiaotong Li, Liqin Xie, Hongbing Wang, Fangfang Zhai, Hong Wang and Lijie ZhaoDocument5 paginiXiaotong Li, Liqin Xie, Hongbing Wang, Fangfang Zhai, Hong Wang and Lijie ZhaoTâm DươngÎncă nu există evaluări

- 20985A0314 Belt ConveyorsDocument23 pagini20985A0314 Belt Conveyorsmaddy maniÎncă nu există evaluări

- PND1000-3 Technical DataDocument10 paginiPND1000-3 Technical DataPartsGopher.comÎncă nu există evaluări

- Design of Belt Conveyor System: Prepared By: Ankit Kumar Dept of Mechanical Engineering Wbut University (West Bengal)Document14 paginiDesign of Belt Conveyor System: Prepared By: Ankit Kumar Dept of Mechanical Engineering Wbut University (West Bengal)Murugesan kÎncă nu există evaluări

- Conveyor Chain Selection: P (2.1W + M) F CDocument2 paginiConveyor Chain Selection: P (2.1W + M) F Cmanoj983@gmail.comÎncă nu există evaluări

- Rubber Belt ConveyorDocument4 paginiRubber Belt ConveyorMohamed ShehataÎncă nu există evaluări

- Uj 21619+SOURCE1+SOURCE1.2Document6 paginiUj 21619+SOURCE1+SOURCE1.2Thobani Arnold MwandlaÎncă nu există evaluări

- Faculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageDocument14 paginiFaculty of Engineering Petroleum Engineering Department: Drilling Engineering I Third StageOmer IkhlasÎncă nu există evaluări

- Session 9 - HoistingDocument92 paginiSession 9 - HoistingGonzalo GarciaÎncă nu există evaluări

- Screw ConveyorsDocument4 paginiScrew ConveyorsAshish SharmaÎncă nu există evaluări

- Beltconveyor 160117145350Document20 paginiBeltconveyor 160117145350Walther LaricoÎncă nu există evaluări

- 415 Hitachi Hoist SH FH Monorail TrolleyDocument24 pagini415 Hitachi Hoist SH FH Monorail TrolleyPhillip FrencilloÎncă nu există evaluări

- Sample - Belt Bucket Elevator DesignDocument7 paginiSample - Belt Bucket Elevator DesignAli DandamunÎncă nu există evaluări

- Proracun Hidrdinamicke SpojniceDocument8 paginiProracun Hidrdinamicke SpojniceVojkan DamjanovićÎncă nu există evaluări

- Pressing Station 1Document65 paginiPressing Station 1huhuÎncă nu există evaluări

- Conveyor Tension and Trajectory CalculationDocument8 paginiConveyor Tension and Trajectory CalculationGregory Nick Toledo Veliz50% (2)

- 31-RR-400 - New2)Document1 pagină31-RR-400 - New2)Chozha Rajan100% (2)

- Overview:: RemarksDocument5 paginiOverview:: RemarksThinh ViproÎncă nu există evaluări

- 38 Design of Flat Belt DrivesDocument9 pagini38 Design of Flat Belt DrivesPRASAD326100% (1)

- Design and Fabrication of Telescopic Conveyor: Mr. Abhijith T J, Mr. Ajith C R Mr. Aravind V, Mr.A.Gokul KarthikDocument4 paginiDesign and Fabrication of Telescopic Conveyor: Mr. Abhijith T J, Mr. Ajith C R Mr. Aravind V, Mr.A.Gokul Karthikregi friyadaÎncă nu există evaluări

- Conveyor Belt CalculationsDocument4 paginiConveyor Belt CalculationsSk Irfan AhmedÎncă nu există evaluări

- Board Solved Problems & FormulasDocument6 paginiBoard Solved Problems & FormulasJC YabisÎncă nu există evaluări

- Plant Eng Part 2 - ConveyorsDocument30 paginiPlant Eng Part 2 - ConveyorsLehlohonoloÎncă nu există evaluări

- Rig ComponentsDocument3 paginiRig ComponentsUgochukwu Kelvin NsakaÎncă nu există evaluări

- Object 2. Manual 3 Container Trailer Trucks 4. Reach Stacker For Whasing FacilitiesDocument8 paginiObject 2. Manual 3 Container Trailer Trucks 4. Reach Stacker For Whasing FacilitiesAntonio SaldivarÎncă nu există evaluări

- V-BELTS Web 2012 9 0Document58 paginiV-BELTS Web 2012 9 0Zohaib AlamÎncă nu există evaluări

- 2010optimal Control of Operation Efficiency of Belt Conveyor SystemsDocument9 pagini2010optimal Control of Operation Efficiency of Belt Conveyor SystemsSanjiv Kumar SinghÎncă nu există evaluări

- Agri ProcessDocument63 paginiAgri ProcessAlfredo Jr FortuÎncă nu există evaluări

- CBG Floating Cranes en 12629-0Document16 paginiCBG Floating Cranes en 12629-0Diana Anghelache100% (1)

- Liebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFDocument8 paginiLiebherr LHM 420 Mobile Harbour Crane Data Sheet EN 10492-0 PDFJuan David Cabrera CardonaÎncă nu există evaluări

- Rack and Pinion MechanismDocument13 paginiRack and Pinion MechanismImmad100% (2)

- Three Way Tipper MechanismDocument5 paginiThree Way Tipper MechanismAunkumar0% (1)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideDe la EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideEvaluare: 4 din 5 stele4/5 (8)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlDe la EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlEvaluare: 5 din 5 stele5/5 (1)

- Study of a reluctance magnetic gearbox for energy storage system applicationDe la EverandStudy of a reluctance magnetic gearbox for energy storage system applicationEvaluare: 1 din 5 stele1/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDe la EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsEvaluare: 3.5 din 5 stele3.5/5 (3)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshDe la EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Railroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975De la EverandRailroad Track Mechanics and Technology: Proceedings of a Symposium Held at Princeton University, April 21 - 23, 1975Arnold D. KerrEvaluare: 5 din 5 stele5/5 (1)

- Mughal Family Tree PDFDocument1 paginăMughal Family Tree PDFnandi_scr0% (3)

- How Windbreak Wall Work?Document1 paginăHow Windbreak Wall Work?Monu SharmaÎncă nu există evaluări

- AkbarDocument16 paginiAkbarKristine Reyes0% (1)

- Pipe Details User Wise: No. of Pipes OJ1 OJ2 OJ3 OJ4 OJ5 2 9 4 Total No. of Pipes User WiseDocument1 paginăPipe Details User Wise: No. of Pipes OJ1 OJ2 OJ3 OJ4 OJ5 2 9 4 Total No. of Pipes User WiseMonu SharmaÎncă nu există evaluări

- Endorsement List 2016Document1 paginăEndorsement List 2016Monu SharmaÎncă nu există evaluări

- 1.0 Drainage System For Collection Pit For Spill Prevention: PipelinesDocument3 pagini1.0 Drainage System For Collection Pit For Spill Prevention: PipelinesMonu SharmaÎncă nu există evaluări

- Pipe Detail Product Wise Total No of PipesDocument1 paginăPipe Detail Product Wise Total No of PipesMonu SharmaÎncă nu există evaluări

- Additional Measures To Prevent Dust: 1. Windbeak Fence / Wind Screen SystemsDocument1 paginăAdditional Measures To Prevent Dust: 1. Windbeak Fence / Wind Screen SystemsMonu SharmaÎncă nu există evaluări

- Stock Share Price - Get Quote - BSEDocument2 paginiStock Share Price - Get Quote - BSEMonu SharmaÎncă nu există evaluări

- Handbook On Building Fire CodesDocument287 paginiHandbook On Building Fire Codesmz1234567100% (1)

- AnnexuresDocument1 paginăAnnexuresMonu SharmaÎncă nu există evaluări

- Tariff Advisory Committee ManualDocument113 paginiTariff Advisory Committee ManualArunTomar100% (4)

- Marg - BSEDocument2 paginiMarg - BSEMonu SharmaÎncă nu există evaluări

- 149Document1 pagină149Monu SharmaÎncă nu există evaluări

- Investigation of Port Capacity Under A New Approach by Computer SimulationDocument8 paginiInvestigation of Port Capacity Under A New Approach by Computer Simulationதமிழ் மகன்Încă nu există evaluări

- 123123Document1 pagină123123Monu SharmaÎncă nu există evaluări

- Reply To Queries:: S.No Clause No. / Page No. Comment ReplyDocument1 paginăReply To Queries:: S.No Clause No. / Page No. Comment ReplyMonu SharmaÎncă nu există evaluări

- AnnexuresDocument1 paginăAnnexuresMonu SharmaÎncă nu există evaluări

- Handbook On Building Fire CodesDocument1 paginăHandbook On Building Fire CodesMonu SharmaÎncă nu există evaluări

- Rationcard DigitizationDocument2 paginiRationcard DigitizationMonu SharmaÎncă nu există evaluări

- Basics of Conveyor Engineering HardwareDocument17 paginiBasics of Conveyor Engineering HardwareTerence Tan100% (1)

- Advt AE 7 09 2015Document10 paginiAdvt AE 7 09 2015Jayanta Kumar NathÎncă nu există evaluări

- IntrpyDocument5 paginiIntrpyMonu SharmaÎncă nu există evaluări

- 114 PDFDocument73 pagini114 PDFMonu SharmaÎncă nu există evaluări

- PhysicstDocument17 paginiPhysicstMonu SharmaÎncă nu există evaluări

- Cavern ModelDocument1 paginăCavern ModelMonu SharmaÎncă nu există evaluări

- ThermodynamicsDocument1 paginăThermodynamicsMonu SharmaÎncă nu există evaluări

- Engineering Mathematics III 2015 Solved Question Papers For VTU All Semester 3Document25 paginiEngineering Mathematics III 2015 Solved Question Papers For VTU All Semester 3RajKumarÎncă nu există evaluări

- Cert OverrideDocument1 paginăCert OverrideviquezejinÎncă nu există evaluări