Documente Academic

Documente Profesional

Documente Cultură

Lecture

Încărcat de

fieraminaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lecture

Încărcat de

fieraminaDrepturi de autor:

Formate disponibile

Copy Right : Ra i Unive rsit y

7.152 57

W

O

R

K

S

H

O

P

P

R

A

C

T

I

C

E

LESSON 22:

What is Welding?

How one should define Welding?

Introduction

Welding can be defined as a process, of joining two dissimilar

metals or similar metals in a way it can be said as a coalescence

between two metals with or without use of filler metal with

application of heat or pressure or combination of both. So a

weld occurs when pieces of metal are joined by causing the

interface to melt and blend prior to solidifying as a uniform

metal joint. This process may be caused by heat, pressure or a

combination of both. The electric arc or gas flame can also be

used to heat the metals. When heat alone is used the process is

called fusion welding.

Pressure welding usually involves heating the surfaces to a

plastic state and then forcing the metal together. The heating

can be by electric current of by friction resulting from moving

one surface relative to the other.

The methods and equipment used for welding metal are also

associated with cutting metal. There are a large number of

welding and allied processes including the following.

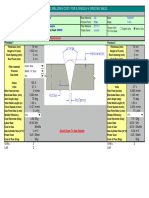

Gas Welding Arc Welding Brazing Soldering

Solid State

Welding

Other Welding

Allied processes

Adhesive

Bonding

Thermal

Spraying

Oxygen

Cutting

Thermal

Cutting

Arc Cutting

Electron

Beam

Cutting

Laser

Cutting

So, by this time you all must have got clear idea of a weld or

concept of welding. Lets us move ahead and classify the various

welding processes which are based on BS EN ISO 4063 and are

used when identifying welds to BS EN 22553.

Arc welding

Metal-arc welding without gas protection

Metal-arc welding with covered electrode

Gravity arc welding with covered electrode

Bare wire metal-arc welding

Flux cored wire metal-arc welding

Coated wire metal-arc welding

Firecracker welding

Gas-shielded metal-arc welding

MIG welding: metal-arc inert gas welding

MAG welding: metal-arc active gas welding

Flux-cored wire metal-arc weldingwith active gas shield

Gas-shielded welding with non-consumable electrode

TIG welding: tungsten inert gas arc welding

Atomic-hydrogen welding

Plasma arc welding

Other arc welding processes

Carbon-arc welding

Rotating arc welding

Resistance Welding

Spot welding

Seam welding

Lap seam welding

Seam welding with strip

Projection welding

Flash welding

Resistance butt welding

Other resistance welding processes

HF (High-Frequency) resistance welding

Gas welding

Oxy-fuel gas welding

Oxy-acetylene welding

Oxy-propane welding

Oxy-hydrogen welding

Air-fuel gas welding

Air-acetylene welding

Air-propane welding

Pressure welding

Ultrasonic welding

Friction welding

Forge welding

Welding by high mechanical energy

Explosive welding

Diffusion welding

Gas pressure welding ]

Cold pressure welding

Other welding processes

Thermit welding

Electro-slag welding

Electro-gas welding

Induction welding

Light radiation welding

Laser beam welding

Arc image welding

Infrared welding

Electron beam welding

Percussion welding

Arc stud welding

Resistance stud welding

58 7.152

Copy Right : Ra i Unive rsit y

W

O

R

K

S

H

O

P

P

R

A

C

T

I

C

E

How welding processes are classified?

What is the basis for classification?

Broad Classification of Welding Processes

The two types of welding processes, the electric welding and the

gas welding explained in above, were divided on the basis of

the sources of heat generation during welding.

Welding processes are sometimes categorized based on the

material of filler rod used during welding, for example, (a)

autogenous welding in which no filler rod is used (such as in

resistance welding or cold welding processes), (b) homogeneous

welding wherein the filler rod used is of the same material and

composition as that of the base metals being welded (such as in

are welding processes) and (c) heterogeneous welding in which

the filler rod used is of different material than the base metal

welded (such as in soldering or brazing).

However, a more widely accepted classification of welding

processes is given in the following:

Fusion Welding Processes (or Non-pressure Welding Processes)

Pressure Welding Processes (Resistance Welding Processes and

Solid State Welding Processes)

Thermo-Chemical Welding Processes

Radiant Energy Welding Processes

Under Water Welding Processes

Fusion (or Non-pressure) Welding Processes

These involve heating the work-pieces to be joined to molten

state and allowing their molten portions to fuse and flow

together to develop coalescence, which on cooling results into a

strong joint. No pressure is exerted on the work-pieces to make

a joint. Further, the welded joint may be obtained with or

without the use of a filler rod (or electrode).

Fusion welding processes are further classified as below:

Are Welding Processes such as Shielded metal are welding, Flux

cored-are welding, Carbon are welding, Submerged are welding,

Tungsten inert gas (TIG) welding, Metal inert gas (MIG)

welding, Electroslag welding, Electrogas welding, Plasma are

welding.Gas Welding Processes include Oxy-fuel gas welding

such as Oxy-acetylene welding, Oxy-hydrogen welding etc.

Brazing and Soldering

Pressure Welding Processes

Gas Welding Processes include Oxy-fuel gas welding such as

Oxy-acetylene welding, Oxy-hydrogen welding etc.

Pressure welding processes are further divided as below:

Resistance Welding Processes such as Spot welding, Seam

welding, Projection welding, Resistance (upset) butt welding,

Flash butt welding, Percussion welding and Stud welding.

Solid State Welding Processes

A Solid state welding process produces coalescence at tempera-

tures below the melting point of the base metals being joined,

without the addition of a filler metal but with application of

pressure only. Various types of Solid state welding processes

include:

Cold welding

Diffusion welding

Explosive welding

Friction welding and Inertia welding

Ultrasonic welding

Forge welding

Thermo chemical Welding Processes

The two main Thermo chemical welding processes are (a)

Thermit welding and (b) Atomic hydrogen welding. Thermo

chemical welding is, in a way, a fusion welding process in which

no outside heat source is required for melting the work pieces to

be joined, for example, the exothermic reaction of the burning

thermit mixture in Thermit welding, provides heat required for

melting the joint edges of the work-pieces. Similarly, Atomic

hydrogen welding possesses the features of both are and flame

welding processes. Are is struck between two non-consumable

tungsten electrodes in an atmosphere of hydrogen where

dissociation of hydrogen results in an exothermic reaction

providing heat for welding.

Radiant Energy Welding Processes

Radiant energy Welding processes involve focussing an energy

beam on the mating edges (or surfaces) of the two work-pieces

to be joined. Heat is generated as a consequence of the energy

beam striking the work-pieces.

Radiant energy welding processes include:

(a) Electron Beam welding

(b) Beam welding

Brazing and Soldering

These involve heating of work-pieces to the temperature range

in which the base metal -of the work-pieces become plastic and

then the two work-pieces are joined together by applying

pressure on them. The work-pieces are heated only along the

edges where the joint is to be formed. Heating may be some-

times concentrated only at a spot (or number of spots) on the

edges of the joint. No additional filler metal (or electrode) is

used in forming the weld.

Now, we have little understanding of basic definition of

welding and the various categories, now lets understand various

types of welding one by one with relevant application.

Diversity of welding processes Diversity of welding processes

welding

Solid state welding Soldering and brazing Fusion welding

Electrical energy Chemical energy

Other processes Non consumable

electrode

Consumable electrode

Resistance welding

Cold welding

Friction welding

Diffusion welding

Flash welding

Ultrasonic welding

Explosion welding

Gas metal arc welding

Shielded metal arc welding

Submerged arc welding

Flux cored arc welding

Electrogas welding

Electroslag welding

Gas tungsten arc welding

Atomic hydrogen welding

Plasma arc welding

Oxyacetylene welding

Oxyfuel gas welding

Laser beam welding

Thermit welding

Electron beam welding

Soldering

Brazing

Copy Right : Ra i Unive rsit y

7.152 59

W

O

R

K

S

H

O

P

P

R

A

C

T

I

C

E

Mind Teasers

Suppose you are production engineer and have been asked

to fabricate a structure. Which method would you like to

select?

Why welding is preferred over other joining processes.

Discuss.

Discuss welding process in detail. Give an example to

support your answer.

Give broad classifications of welding process?

Ref erences

1. Manufacturing Technology (Vol. 1) by- PN Rao

2. Workshop Technology (Vol.1) by- Hajra Chodhry

3. Workshop Technology by- BS Raghuwanshi

4. Workshop Technology by- OP Khanna

5. Workshop technology by- B.S.Raghuvanshi

6. Workshop technology by- W A J Chapman

S-ar putea să vă placă și

- Lecture 6Document72 paginiLecture 6fieraminaÎncă nu există evaluări

- Lecture 5Document80 paginiLecture 5fieraminaÎncă nu există evaluări

- Lecture 2Document93 paginiLecture 2fieraminaÎncă nu există evaluări

- 3 Phase Induction Machines 1 (Construction)Document75 pagini3 Phase Induction Machines 1 (Construction)fieraminaÎncă nu există evaluări

- Single PhaseDocument23 paginiSingle PhasefieraminaÎncă nu există evaluări

- Lecture 1Document56 paginiLecture 1fieramina100% (1)

- Action Plan For The Project2Document1 paginăAction Plan For The Project2fieraminaÎncă nu există evaluări

- Dongshin PRO-WD Series High Precision Intelligent Injection Molding Machines GuideDocument60 paginiDongshin PRO-WD Series High Precision Intelligent Injection Molding Machines Guidefieramina100% (1)

- Book Review On Linsu Kim's Imitation To InnovationDocument3 paginiBook Review On Linsu Kim's Imitation To InnovationdonghaoliÎncă nu există evaluări

- Plastic Injection Mold CalculationsDocument10 paginiPlastic Injection Mold CalculationsfieraminaÎncă nu există evaluări

- Design Guidelines for Turned Parts and Rapid Prototyping MethodsDocument19 paginiDesign Guidelines for Turned Parts and Rapid Prototyping MethodsfieraminaÎncă nu există evaluări

- 8 JoiningDocument7 pagini8 Joiningdawoodabdullah56Încă nu există evaluări

- Metals Industry Development Institute Inter Transfer Note: Description Unit of Measure QTY RemarkDocument4 paginiMetals Industry Development Institute Inter Transfer Note: Description Unit of Measure QTY RemarkfieraminaÎncă nu există evaluări

- DCDocument25 paginiDCfieraminaÎncă nu există evaluări

- Example of Different DC MotorsDocument22 paginiExample of Different DC MotorsfieraminaÎncă nu există evaluări

- Terazzo Two - Sheet1 PDFDocument1 paginăTerazzo Two - Sheet1 PDFfieraminaÎncă nu există evaluări

- DC Motor and Magnetism GuideDocument18 paginiDC Motor and Magnetism GuidefieraminaÎncă nu există evaluări

- Synchronous Machine Fundamentals and Static Stability AnalysisDocument32 paginiSynchronous Machine Fundamentals and Static Stability AnalysisfieraminaÎncă nu există evaluări

- Absolute MotionDocument1 paginăAbsolute MotionfieraminaÎncă nu există evaluări

- Starter MotorDocument15 paginiStarter MotorfieraminaÎncă nu există evaluări

- Rotational Dynamics and Motor ModelsDocument22 paginiRotational Dynamics and Motor ModelsfieraminaÎncă nu există evaluări

- Three Phase TransformerDocument27 paginiThree Phase Transformerfieramina100% (1)

- Engineering Drawing Handbook PDFDocument120 paginiEngineering Drawing Handbook PDFRobert Nixon100% (1)

- Cabo de Mão GoproDocument1 paginăCabo de Mão GoproTiago BorinÎncă nu există evaluări

- 23 Shaft and Its Design Based On StrengthDocument9 pagini23 Shaft and Its Design Based On StrengthPRASAD326Încă nu există evaluări

- Bags, Boxes, Bowls, and Beyond: Portable Collections ProgramDocument20 paginiBags, Boxes, Bowls, and Beyond: Portable Collections ProgramfieraminaÎncă nu există evaluări

- 19 Introduction To Design of Helical SpringsDocument12 pagini19 Introduction To Design of Helical SpringsPRASAD326100% (3)

- Cane Sugar PDFDocument633 paginiCane Sugar PDFbernie_bph50% (2)

- Briefcases and Bags4 PDFDocument22 paginiBriefcases and Bags4 PDFfieraminaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Welding (Cadet Training)Document41 paginiWelding (Cadet Training)Kyaw Bhone WinÎncă nu există evaluări

- Welding Procedure Specification SMAW LH 355-60Document1 paginăWelding Procedure Specification SMAW LH 355-60rexÎncă nu există evaluări

- Welding Terms and Definitions PDFDocument6 paginiWelding Terms and Definitions PDFtomj9104Încă nu există evaluări

- American Welding Soceity 5.9Document33 paginiAmerican Welding Soceity 5.9Hư VôÎncă nu există evaluări

- Laporan Welding ProsmanDocument20 paginiLaporan Welding Prosmannadia frizaÎncă nu există evaluări

- Manual Weldoffice PDFDocument51 paginiManual Weldoffice PDFAnonymous wKvJXBJ2iÎncă nu există evaluări

- Competency Based Curriculum for Sheet Metal WorkerDocument35 paginiCompetency Based Curriculum for Sheet Metal Workerudi969Încă nu există evaluări

- Brazing BPS 107-1 PDocument5 paginiBrazing BPS 107-1 Pmbe josephÎncă nu există evaluări

- Engineering Encyclopedia: Fabrication, Inspection, and Testing of Pressure VesselsDocument70 paginiEngineering Encyclopedia: Fabrication, Inspection, and Testing of Pressure VesselsAfzaalUmairÎncă nu există evaluări

- Welding of Stainless SteelDocument103 paginiWelding of Stainless SteelJaime Iván Vera Melgar100% (4)

- 7-Welding Consumable Handling and Storage - WC007Document11 pagini7-Welding Consumable Handling and Storage - WC007mohd as shahiddin jafriÎncă nu există evaluări

- Specification For Low-Alloy Steel Electrodes For Shielded Metal Arc WeldingDocument48 paginiSpecification For Low-Alloy Steel Electrodes For Shielded Metal Arc WeldingArmando Lujan Velazquez100% (2)

- Esab Welding Filler Metal Databook - Usa 2016-ComprimidoDocument426 paginiEsab Welding Filler Metal Databook - Usa 2016-ComprimidoFelipe CarreonÎncă nu există evaluări

- Engineering MaterialsDocument43 paginiEngineering MaterialsKristine SantosÎncă nu există evaluări

- BRIDGE Steel Welding GuideDocument2 paginiBRIDGE Steel Welding GuideANTONYLEOÎncă nu există evaluări

- p22MNVMB MN Gtaw+Smaw (Pipe)Document2 paginip22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1Încă nu există evaluări

- Basic Mechanical Engineering: Manufacturing ProcessesDocument49 paginiBasic Mechanical Engineering: Manufacturing Processespritam goleÎncă nu există evaluări

- Ch32 Brazing, Soldering, Adhesive Bonding, Mechanical Fastening HO 2Document9 paginiCh32 Brazing, Soldering, Adhesive Bonding, Mechanical Fastening HO 2Yasir MumtazÎncă nu există evaluări

- Striking ArcDocument96 paginiStriking ArcJohn Wilner DirectoÎncă nu există evaluări

- ASME IIC SFA5.3 - AlDocument14 paginiASME IIC SFA5.3 - AltragaldabasÎncă nu există evaluări

- Stub Loss Correction Table For Coated ElectrodesDocument1 paginăStub Loss Correction Table For Coated ElectrodesTAMILÎncă nu există evaluări

- 5 6100259431964999893Document34 pagini5 6100259431964999893Hardik ChaudhariÎncă nu există evaluări

- AWS D3.7 2004, Guide For Aluminum Hull WeldingDocument87 paginiAWS D3.7 2004, Guide For Aluminum Hull WeldingPAOLO GIANNELLI100% (1)

- Soldering, Brazing, Braze Welding, Wearfacing: TopicsDocument42 paginiSoldering, Brazing, Braze Welding, Wearfacing: Topicsyared BeleteÎncă nu există evaluări

- Dental SolderingDocument69 paginiDental Solderingstgdc100% (6)

- WC9Document5 paginiWC9Suresh KrishnanÎncă nu există evaluări

- Weld Cost Calc XL1.3.2mmDocument3 paginiWeld Cost Calc XL1.3.2mmAdrian DavidÎncă nu există evaluări

- Aws D15.2Document49 paginiAws D15.2pablitochoa100% (4)

- SPECIFICATION FOR SOLID SURFACING WELDING RODSDocument23 paginiSPECIFICATION FOR SOLID SURFACING WELDING RODSDmitriyÎncă nu există evaluări

- Wps Format Asme Sec - IxDocument2 paginiWps Format Asme Sec - IxDeepu ChandranÎncă nu există evaluări