Documente Academic

Documente Profesional

Documente Cultură

SPM Dart Valve Manual PDF

Încărcat de

YM Edwin Gil BeltranDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

SPM Dart Valve Manual PDF

Încărcat de

YM Edwin Gil BeltranDrepturi de autor:

Formate disponibile

Copyright S.P.M. Flow Control, Inc. 2013. All rights reserved.

. The manual must not be copied in whole or in part, in any form or by any means, and the information in it must

not be disclosed to any person, or used for any purpose other than the specific purpose for which the manual has been provided, without the prior written consent of the

company. SPM, DESTINY, Safety Iron, and DURALAST are trademarks of S.P.M. Flow Control, Inc.; WEIR is a trademark of Weir Engineering Services Limited

Document P/N: 2P36709

Release Date: 1/30/2013

Revision: B

SPM

Well Service Pumps & Flow Control Products

High Pressure Dart Style Check Valve

Operation Instruction and Service Manual

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

2

WARNING:IMPORTANT SAFETY INFORMATION ENCLOSED. READ THIS OPERATING AND MAINTENANCE

INSTRUCTIONS MANUAL BEFORE OPERATING PRODUCT.

WARNING: THIS INFORMATION MUST BE AVAILABLE TO ALL PRESONNEL THAT WILL OPERATE AND

MAINTAIN EQUIPMENT. FAILURE TO READ, UNDERSTAND AND FOLLOW THE OPERATING AND

MAINTENANCE INSTRUCTIONS MANUAL COULD RESULT IN SEVERE PERSONAL INJURY OR DEATH!

Most SPM

products generate, control or direct pressurized fluids; therefore, it is critical that those who work

with these products be thoroughly trained in their proper application and safe handling. It is also critical that

these products be used and maintained properly!!

WARNING: MISUSE, SIDE LOADING, IMPROPER MAINTENANCE, OR DISASSEMBLY UNDER PRESSURE CAN

CAUSE SERIOUS INJURY OR DEATH!

The following information is given in good faith and should aid in the safe use of your SPM

products. This

information is not meant to replace existing Company's safety policies or practices.

Personal Responsibilities:

1. When working on SPM

flow control products, safety glasses, approved safety shoes and hard hat must

be worn.

2. Personnel should never hammer on any component when pressure is present. Hammering on any part

or component may also cause foreign material or steel slags to become airborne.

3. It is a personal responsibility to use the proper tools when servicing the valve. It is a personal

responsibility to be knowledgeable and trained in the use and handling of tools for all maintenance of

the valve.

4. Hot surface may be present; it is a persons own responsibility to protect against burn injury.

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

3

On Location:

1. Each valve is clearly marked with a maximum pressure rating. This pressure must not be exceeded or

SERIOUS INJURY OR DEATH CAN OCCUR!

2. The valve discharge connections should be properly cleaned and lightly oiled before the downstream

piping is attached. Any worn, damaged or missing seals should be replaced.

3. Welding, brazing or heating any part of the valve is prohibited. If accessories must be attached, consult

Weir Oil & Gas factory prior to installation.

4. A complete visual inspection of the valve must be made prior to each use. Any leaking seals, broken

bolts, leaking hoses or improperly tightened parts must be remedied prior to using.

5. Any repairs or service (even routine maintenance) performed on the valve must be performed by a

trained service technician who is qualified to work on high pressure flow control valves. All such service

and repairs must be supervised by qualified management personnel or returned to Weir Oil & Gas for

service. Only SPM

replacement parts should be utilized. Failure to do so may result in loss of warranty

as well as SERIOUS INJURY OR DEATH!

Special Precautions:

1. The modifications to or unauthorized repair of any part of a SPM

valve, or use of components not

qualified by Weir Oil & Gas, can lead to valve damage or failure and SERIOUS INJURY OR DEATH!

2. All SPM

threaded components are right hand threaded unless specifically designated otherwise. Any

turning counterclockwise will unscrew the assembly. Make sure all threaded components are assembled

to the correct torque value.

3. All products should be properly cleaned, greased or oiled after each use and inspected prior to each use.

4. Each integral union connection is clearly marked with a pressure code (i.e. 1502, 15,000 psi). This

pressure must not be exceeded. This code should also be used with mating unions. Improper mating

can result in failures. All integral union connections used must match (according to size, pressure

rating, etc.). These connections must also match the service of the designated string they are installed

in.

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

4

CONTENTS

SECTION I: GENERAL INFORMATION ............................................................................................................. 5

THIS SERVICE MANUAL COVERS: ........................................................................................................................... 5

REBUILD KITS: .................................................................................................................................................. 5

PRODUCT DESCRIPTION: ................................................................................................................................... 7

GENERAL DESCRIPTION OF DART CHECK VALVE OPERATION: .................................................................................... 8

END CONNECTION OPTIONS: ............................................................................................................................ 9

SECTION II: INSTALLATION AND OPERATION .............................................................................................. 10

INSTALLATION: .............................................................................................................................................. 10

CALIBRATION GUIDE: ...................................................................................................................................... 12

PRESSURE/ TEMPERATURE RATINGS: ................................................................................................................... 12

SECTION III: MAINTENANCE AND REPAIR .................................................................................................... 13

MAINTENANCE REQUIREMENTS: ........................................................................................................................ 14

PREVENTATIVE MAINTENANCE DISASSEMBLY: .................................................................................................... 18

PREVENTATIVE MAINTENANCE DISASSEMBLY: .................................................................................................... 19

PREVENTATIVE MAINTENANCE INSPECTING COMPONENTS: .................................................................................. 21

PREVENTATIVE MAINTENANCE REPLACEMENT AND ASSEMBLY: .............................................................................. 25

VESSEL TEST PROCEDURES: ............................................................................................................................... 28

TROUBLESHOOTING GUIDE: ............................................................................................................................. 30

SECTION IV: SERVICE AND SUPPORT ........................................................................................................... 31

SERVICE CENTER ORDER INFORMATION: ............................................................................................................. 31

WEIR OIL & GAS LOCATIONS: .......................................................................................................................... 32

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

5

SECTION I: General Information

This service manual covers:

1A20958C CHK VA/DRT/1-1502FXM/LT/C TYPE

1A20958CV CHK VA/DRT/1-1502FXM/LT/VIT/C

1A23773C CHK VA/DRT/1-1502MXF/METAL SEAL

1A20980C CHK VA/DRT/1.5-1502FXM/LT/C TY

1A20980CV CHK VA/DRT/1.5-1502FXM/LT/VIT/

1A22423C CHK VA/DRT/1.5-1502MXF/LT/C TY

1A23444C CHK VA/DRT/1.5-1502MXF/METAL SEAL

1A18471C CHK VA/DRT/2-1502MXF/C TYPE

1A19467C CHK VA/DRT/2-1502FXM/C TYPE/H2S

1A19485C CHK VA/DRT/2-1502MXF/C TYPE/H2S

1A19660C CHK VA/DRT/2-1502MXF/LT/C TYPE

1A19662C CHK VA/DRT/2-1502FXM/LT/C TYPE

1A23085CLT CHK VA/DRT/2-1502FXM/METAL SEAL/C TYPE/L

1A24137C CHK VA/DRT/2-1502MXF/METAL SEAL

1A18611C CHK VA/DRT/3-1502FXM/C TYPE

1A18614C CHK VA/DRT/3-1502MXF/C TYPE

1A19826C CHK VA/DRT/3-1502FXM/C TYPE/H2S

1A19827C CHK VA/DRT/3-1502MXF/C TYPE/H2S

1A19843C CHK VA/DRT/3-1502FXM/LT/C TYPE

1A19845C CHK VA/DRT/3-1502MXF/LT/C TYPE

Rebuild Kits:

Full Parts Kits (Dart Kit and Valve stop, Valve stop O-ring, Body seal, set screw)

2L20823C KIT/PARTS/DRT/CHK VA/2& 1.5/C TYPE STD SERVICE 15K

4L20823CV KIT/PARTS/DRT/CHK VA/2/VIT/C TYPE STD SERVICE 15K

4L23935C KIT/PARTS/DRT/CHK VA/2/METAL SEAL STD SERVICE METAL TO METAL

4L20824C KIT/PARTS/DRT/CHK VA/2/C TYPE/H2S H2S SERVICE 10K

4L20825C KIT/PARTS/DRT/CHK VA/3/C TYPE STD SERVICE 15K

4L20826C KIT/PARTS/DRT/CHK VA/3/C TYPE/H2S H2S SERVICE 10K

Seal Kits (Seal O-ring, Valve seal, Valve stop o-ring, Body seal

4L20828C KIT/SEAL/DRT/CHK VA/1.5"&2"/C TYPE STD SERVICE/ VITON 15K

4L20828CV KIT/SEAL/DRT/CHK VA/1.5"&2"/C TYPE STD SERVICE/ VITON 15K

4L23939C KIT/PARTS/DRT/CHK VA/2/METAL SEAL STD SERVICE METAL TO METAL

4L20829C KIT/SEAL/DRT/CHK VA/2/C TYPE/H2S H2S SERVICE 10K

4L27355C KIT/SEAL/DRT/CHK VA/2/C TYPE/H2S H2S SERVICE 15K

4L20830C KIT/SEAL/DRT/CHK VA/3/C TYPE STD SERVICE 15K

4L20831C KIT/SEAL/DRT/CHK VA/3/C TYPE/H2S H2S SERVICE 10K

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

6

Rebuild Kits Continued:

Dart Kits (Dart, Seal O-ring, Retainer Ring, Valve Seal, Nut, Spring)

4L19959 KIT/DRT/CHK VA/2 & 1.5 STD SERVICE 15K

4L19959V KIT/DRT/CHK VA/2& 1.5/VIT STD SERVICE/VITON

4L23938 KIT/DRT/CHK VA/2& 1.5/METAL SEAL

4L18824 KIT/DRT/CHK VA/2/H2S H2S SERVICE 10K

4L18821 KIT/DRT/CHK VA/3 STD SERVICE 15K

4L18818 KIT/DRT/CHK VA/3/H2S H2S SERVICE 10K

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

7

Product Description:

SPM

Dart Style Check Valves must be installed and maintained properly to perform as expected. When

followed correctly, the information in this manual can both increase the working life of the Dart Style Check

Valve and greatly reduce any risks involved during operation.

The SPM

Dart Style Check Valve prevents flow in an undesired direction in high pressure lines, and is

commonly placed in treating lines. This permits fluid to flow towards the well, while impeding back flow from

traveling upstream the check valve. This independent pressure actuated response system works immediately

following a pressure loss, requiring no operator to be present for initiation. This provides a safety device at

various locations in the flow line and assures that pressure and fluid cannot backup into the manifold area or

into the pumps.

Manufactured to Weir Oil & Gas stringent Quality Assurance System, the Standard Service components are

made from the appropriate heat treated, low alloy steels. Sour Gas components are made in accordance with

American Petroleum Institute (API), Standard RP14-E, and National Association of Corrosion Engineers (NACE),

std. MR0175-90.

The SPM

Dart Style Check Valves are manufactured in 1 inch, 1.5 inch, 2 inch and 3 inch sizes. Each size

features a standard and reverse flow version. The SPM

Dart Style Check Valve is available for both standard

service and for sour gas (H2S) environments.

The SPM

Dart Check Valves are available in various max pressure ranges from 10,000 to 15,000 psi. The valve

is intended for well service applications such as acidizing, cementing, and fracturing, utilizing slick water frac

fluids (containing no proppants), gels, mud, nitrogen (N2/Gas) or CO2.

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

8

General Description of Dart Check Valve Operation:

The SPM

dart valve is constructed of a two piece body that houses an in-line spring loaded dart. When fluid

enters from the inlet side, it will overcome the low spring force on the dart. The dart will travel away from the

inlet and allow the fluid to flow around towards the outlet. When flow fluid stops, the light spring force closes

the dart against its seat. If the pressure on the inlet side drops below that of the outlet, the fluid is kept from

reversing its flow by the dart. The dart seal acts as a backup and creates a bubble-tight seal to eliminate any

backflow.

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

9

End Connection Options:

The SPM

2 inch or 3 inch Dart Style Check Valves are available with SPM

wing union (integral) connections

on the inlet and outlet sides. The inlet side will have a female wing union connection if a standard flow is

specified or a male wing union connection for reverse flow. The outlet side will have the correspondingly

opposite gender (i.e. Inlet/Female = Outlet/Male or Inlet/Male = Outlet/Female).

Each Valve has a size and pressure code designated on the valve. The nameplate will indicate the cold working

pressure allowable for each assembly. This working pressure corresponds to the maximum pressure acceptable

for either end connection. Use this information for proper mating and pressure limits.

Wing union connections on check valves are interchangeable with other union connections of the same size

and pressure rating. Caution must be taken to avoid mixing different pressure ratings of wing connections.

These connections must also match the service of the designated string in which they are installed. Distraction

or inability to observe good judgment may result in damage to components and create a life threatening

situation. Always verify working pressure ratings of each connection before use.

WARNING: OBSERVE ALL INSTRUCTIONS, CAUTIONS AND WARNINGS AS NOTED IN THIS MANUAL. FAILURE

TO DO SO CAN LEAD TO EQUIPMENT DAMAGE AND PERSONAL INJURY OR DEATH!

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

10

SECTION II: Installation and Operation

Installation:

The following information is given in good faith and should aid the safe use of your SPM

products. This

information is not meant to replace any existing Companys safety policies or practices, which should be strictly

followed.

The SPM

Dart Style Check Valve should be installed in a branch where a flow control device is necessary to

prevent flow in one direction. For complete fluid shut-off, an isolator valve (such as the SPM

plug valve) should

be installed in series with the dart check valve.

Before assembly into a fluid line, check the direction of flow indicated by the arrow on the body and make sure

the valve is properly oriented in the line. Improperly directed check valves will shut off fluid flow and can result

in SERIOUS INJURY OR DEATH!

The SPM

dart valve can be installed in any orientation and still function properly. The internal spring

constantly applies light pressure on the dart that prevents any effect gravity might have on the darts operation.

The SPM

dart valve is specifically designed to be used with liquid frac, acidizing, cementing fluids, nitrogen

(N2/Gas) or CO2. The SPM

Dart Style Check Valve is not intended for fluids that contain solids, such as

proppants or ball sealers. Consult Weir Oil & Gas Engineering for information on substituting SPM

Clapper

Style Check valves for those applications.

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

11

Installation (Cont.):

WARNING: OBSERVE ALL INSTRUCTIONS, CAUTIONS AND WARNINGS AS NOTED IN THIS MANUAL. FAILURE

TO DO SO CAN LEAD TO EQUIPMENT DAMAGE AND PERSONAL INJURY OR DEATH!

Care must be taken when installing the SPM

Dart Style Check Valve so that a hammer never strikes the valve

body. The body is not intended for severe forces, such as a hammer blow, and there is the danger that the

valve could crack under such circumstances, which increases the chance of premature failure that could cause

serious injury or death.

Do not attempt to work on or repair any equipment isolated by the SPM

Dart Check Valve while the check

valve has pressure or energized fluid behind it. A positive shut off device (i.e. plug valve) must be placed in the

line to guarantee isolation from the system. Failure to do so could put operators in extremely hazardous

situations without them being aware of the potential danger.

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

12

Calibration Guide:

Refer to Vessel Testing section on page 28.

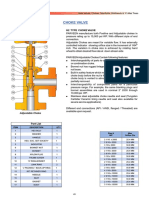

Pressure/ Temperature Ratings:

SPM

Dart Style Check Valves are available in the following configurations:

Valve

Size

Inlet Outlet

Flow

Direction

Pressure SVC

Temperature

Range (F)

Bore GPM BPM

1.5

1.5-

1502F

1.5-

1502M Standard 15000 Std (-22 to 230) 1.25 160 3.8

2" 2"-1502F

2"-

1502M Standard 15000 Std (-22 to 230) 1.75 315 7.5

2"

2"-

1502M 2"-1502F Reverse 15000 Std (-22 to 230) 1.75 315 7.5

2" 2"-1502F

2"-

1502M Standard 10000 H2S (-22 to 230) 1.75 315 7.5

2"

2"-

1502M 2"-1502F Reverse 10000 H2S (-22 to 230) 1.75 315 7.5

3" 3"-1502F

3"-

1502M Standard 15000 Std (-22 to 230) 2.5 643 15.3

3"

3"-

1502M 3"-1502F Reverse 15000 Std (-22 to 230) 2.5 643 15.3

3" 3"-1502F

3"-

1502M Standard 10000 H2S (-22 to 230) 2.5 643 15.3

3"

3"-

1502M 3"-1502F Reverse 10000 H2S (-22 to 230) 2.5 643 15.3

Note: Some of the SPM

dart valve models are offered with a higher temperature VITON seal that operates

between temperatures of 0F - 390F. Ask our nearest service center about availability if desired parts are to be

used in higher temperature applications.

WARNING: DISASSEMBLY UNDER PRESSURE CAN CAUSE SERIOUS INJURY OR DEATH!

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

13

SECTION III: Maintenance and Repair

WARNING: DISASSEMBLY UNDER PRESSURE CAN CAUSE SERIOUS INJURY OR DEATH!

WARNING: OBSERVE ALL INSTRUCTIONS, CAUTIONS AND WARNINGS AS NOTED IN THIS MANUAL. FAILURE

TO DO SO CAN LEAD TO EQUIPMENT DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

ALWAYS REMEMBER:

1. Always wear PPE (personal protective equipment).

2. Only qualified technicians should perform maintenance on Weir Oil & Gas products.

3. Always use SPM

supplied new parts kit for reassembly.

4. Clean all components thoroughly prior to reassembly.

5. Check sealing surface area of valve gate and nozzle for pitting, erosion or other flaws. Failure in sealing

can result if these areas are not smooth.

6. Use only SPM

dart valve parts on SPM

dart valves.

7. This device is intended to discharge atmospherically when it relieves.

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

14

Maintenance Requirements:

SPM

Dart Check valves are well designed, dependable components that should provide long term, reliable

performance for the user. Like any device, however, they do require routine inspection and servicing to assure

that they are fully functional. The more severe the usage, the more often maintenance is required.

It is recommended that a flow rate in excess of 42 ft/sec be avoided. Rates above this will cause more rapid

wear and erosion. Any check valve that has been exposed to high shock loads (i.e. overpressure, standoffs, etc.)

should be removed from service until ultrasonic checks and pressure testing can be performed. Valves used in

areas of high acid concentrations require special attention to inspection and maintenance. Due to the harsh

field environment where this dart check valve will be used, it is imperative that maintenance of this valve be

HIGH Priority to ensure repeatability.

WELDING, BRAZING OR HEATING CHECK VALVES IS PROHIBITED. Material Damage will occur.

Valve unions should be clean and lightly oiled prior to each use. Union seals should be checked and replaced

when worn or damaged. Always flush valve with water, then oil after each use. If valves are used with acid,

services, they should be washed with fresh water as soon as possible. After washing, it is recommended that it is

submersed in light oil for 5 minutes.

It is impossible to visually inspect components from the outside. Consequently, the valves should be

disassembled and inspected at least every 90 days. Any signs of pitting or washing on the body and

components require replacement. Dart assemblies should be replaced regularly (approx. every 90 days or

sooner depending the type and amount of use). Dart valve seats should be checked for corrosion. If evidence

exists, replace valve inlet.

There are wear surfaces on this device and elastomeric seals that require maintenance. For the valve to operate

properly and safely, these items must be kept in good condition. Inspection and servicing should be conducted

in accordance with a recognized program. The components that require inspecting are listed below and

referenced on the bill of materials on page 14 and 15. (The components that must be replaced during a re-

kitting are highlighted in yellow)

Seal O-ring (10)

Valve Seal (8)

Valve Stop O-ring (14)

Body Seal (15)

Union Seal (6)

Dart (7)

Valve Stop (13)

Valve Spring (12)

Seal Retainer (9)

Hex Nut (11)

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

15

Maintenance Requirements (Cont.):

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

16

BOM TABLE 1A19662C

BOM ID QTY PART NUM DESCRIPTION

1 1 2P19652 INLET/CHK VA/DRT/2-1502F

2 1 1P19658 OUTLET/CHK VA/DRT/2-1502M

3 1 3P10228 WING NUT/2-1502

4 3 3P10231 RET SEG/2-1502

5 1 P10232 RET RNG/2-1502

6 1 4P10229 SEAL RNG/UNION/2

7 1 3P19650 DART/CHK VA/2

8 1 3P18476 SEAL/CHK VA/DRT/2/BUNA

9 1 3P18477 RET/SEAL/CHK VA/DRT/2

10 1 P19185 SEAL/OR21323813

11 1 3P23924 NUT/CHK VA/DRT/2-3/MECH LOCK

12 1 3P18478 SPRNG/CHK VA/DRT/2

13 1 3P18479 STOP CHK VA DRT 2

14 1 P18481 SEAL/OR36338813

15 1 2P25478 SEAL/D-RING/1.5-2/DART CHK VA

16 1 P19275 SCRW/HHCS/ .50-13NC X 1.00/G8

17 1 3P22546 KEY CHK VA DRT 2-3 LONG

18 1 3P14871 NAMEPLT/VALVE

19 2 P18055 SCRW/DRV/4 X 3/16/TYPE U

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

17

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

18

Preventative Maintenance Disassembly:

WARNING: MAKE SURE THAT THERE IS NO PRESSURE ON THE VALVE!

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

19

Preventative Maintenance Disassembly:

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

20

NOTE: This was the disassembly procedure for the 2 dart valve. The ASSEMBLY and DISASSEMBLY

procedures for the 2 and 3 Dart Check Valves are virtually identical. Other than component size, there is only

one main difference:

The 2 inlet has male threads that thread INTO the female threads of the 2 outlet

The 3 inlet has female threads that thread OVER the male threads of the 3 outlet

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

21

Preventative Maintenance Inspecting components:

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

22

Preventative Maintenance- Inspecting components (Cont.):

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

23

Preventative Maintenance- Inspecting components (Cont.):

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

24

Preventative Maintenance- Inspecting components (Cont.):

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

25

Preventative Maintenance Replacement and assembly:

2 & 3 Sizes. Also see SPECIAL NOTE for 3

-See ALWAYS REMEMBER Section on page 11 before disassembling or assembling.

-The reassembly of the valve is in approximate reverse order to the disassembly process.

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

26

Preventative Maintenance Replacement and assembly (Cont.):

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

27

Preventative Maintenance Replacement and assembly (Cont.):

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

28

Vessel Test Procedures:

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

29

Field Testing

When pressure testing, the pressure should be applied to the total body as well as the check system side.

Pressure testing should be done with cold water. Personnel should wear proper safety equipment and avoid

any area of danger while pressure is present. Prior to any pressure testing, all air must be evacuated from the

system. Failure to do so could result in PRESONAL INSURY OR DEATH.

THE RATED WORKING PRESSURE IS NEVER TO BE EXCEEDED DURING FIELD SERVIVE OR FIELD TESTING.

OBSERVE ALL INSTRUCTIONS, CAUTIONS AND WARNINGS AS NOTED IN THIS BROCHURE. FAILURE TO DO

SO CAN LEAD TO EQUIPMENT DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

Pressure testing (and ultrasonic test) should be performed every 6 months or more frequently if service is

severe or low temperature.

It is necessary to test each valve for leaks after they are refurbished. To test for leaks:

Fill the valve with liquid (Water)

Make sure that all air is out of the system

o This is extremely important as stored air compresses at high pressures and stores energy,

increasing the danger involved with a failure.

Pressurize the system up to slightly less than working pressure (to prevent exceeding working pressure)

With the valve near working pressure, carefully examine for leaks

If no leaks are observed, the valve is now ready for service.

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

30

Troubleshooting Guide:

Always follow existing Weir Oil & Gas procedures concerning identifying equipment for inspection, and removing equipment

from service. The following is intended as a general guide in helping resolve most problems encountered in repairing SPM

Dart Valves. If problems not covered here are encountered, contact Weir Oil & Gas for assistance at (817) 246 2461

SYMPTOM PROBLEM SOLUTION

1.

Valve leaks past threads

between valve inlet and outlet

a) Polypak seal damaged and will not

seal

a) Replace and reinstall damaged olypak

seal correctly. See proper seal

orientation.

b) Polypak seal installed incorrectly b) Replace and reinstall damaged olypak

seal correctly. See proper seal

orientation.

2.

Valve leaks from dart seal area

but dart appears to be seating

correctly

a) Dart seal area or inlet area where

dart makes contact is worn out or

damaged.

a) Remove valve from service. Inspect parts

and replace inlet or dart as needed.

b) Valve seal or seal o-ring have worn

out or are damaged

b) Rubber components are considered

expendable and should be replaced

c) Obstruction between dart (and or

seals) and valve inlet is preventing

complete seal

c) Flush dart valve assembly with clean

water. If necessary, disassemble valve

and clean individual parts. Remove all

debris. Replace rubber components,

reassemble.

3.

Valve leaks from dart seal area

and dart valve appears to fully

close or seat

a) Dart cannot fully close because

rust exists between dart shaft and

valve stop guide hole.

a) Disassemble the valve. Clean rust

affected parts with fine steel wool or

sandpaper. If rust pits or other damage

to parts exist, replace parts as needed.

Dart should slide freely through guide

hold in valve stop.

b) Obstruction between dart

assembly and valve inlet seal

surface prevents dart from sealing

b) Flush dart valve assembly with clean

water. If necessary, disassemble valve

and clean individual parts. Remove all

debris. Replace rubber components and

reassemble.

c) Valve spring is damaged or worn

and cannot apply enough force to

fully close dart assembly.

c) Replace valve spring.

4.

Dart assembly does not open

fully to allow flow

a) Obstruction preventing dart to

fully open

a) Flush dart valve assembly with clean

water. Disassemble valve and examine

for debris. Remove any obstructions &

reassemble.

b) Dart shaft and valve stop guide

hold are rusted together

b) Clean components with fine steel wool

or sandpaper. Oil lightly. Replace as

needed.

5.

Dart and or seals experience

rapid deterioration

a) Excessive component wear caused

by excessive flow rate

a) Reduce flow rate (or contact Weir Oil &

Gas representative for a heavier spring

recommendation)

Document P/N: 2P36709

Release Date 1/30/2013

Revision: B

31

SECTION IV: Service and Support

Service Center Order Information:

Weir Oil & Gas stocks a large inventory of genuine original equipment replacement parts. In order to

expedite a parts order and avoid any delays, please provide the following information with your order:

The part number and description (refer to drawings and parts lists in this section) of each item ordered.

The quantity of each part, kit, or assembly ordered.

The model number and serial number

Your purchase order number.

Specify method of shipment, complete shipping address, complete billing address and telephone

number at the destination of the shipment.

Parts and service may be ordered through the following locations.

Copyright S.P.M. Flow Control, Inc. 2013. All rights reserved. The manual must not be copied in whole or in part, in any form or by any means, and the information in it must

not be disclosed to any person, or used for any purpose other than the specific purpose for which the manual has been provided, without the prior written consent of the

company. SPM, DESTINY, Safety Iron, and DURALAST are trademarks of S.P.M. Flow Control, Inc.; WEIR is a trademark of Weir Engineering Services Limited

Weir Oil & Gas

601 Weir Way Tel: (817) 246 2461

Fort Worth Fax (817) 246 6324

TX 76108

USA www.weiroilandgas.com

S-ar putea să vă placă și

- HHF-1000-partsDocument37 paginiHHF-1000-partsJorge Vásquez Carreño100% (2)

- Manual Hydrill K20-5000Document16 paginiManual Hydrill K20-5000IgorCencič100% (3)

- Tech Manual 1314C: 3.06", 10M, Side Door Stripper PackerDocument13 paginiTech Manual 1314C: 3.06", 10M, Side Door Stripper PackerAngel MarinÎncă nu există evaluări

- B+V ELEVATOR SIDE DOOR Collar Type VS09 A4Document19 paginiB+V ELEVATOR SIDE DOOR Collar Type VS09 A4Игорь ШиренинÎncă nu există evaluări

- #HB-13-59 22SR Face Manual PDFDocument27 pagini#HB-13-59 22SR Face Manual PDFLucas MaldonadoÎncă nu există evaluări

- ADocument12 paginiAJulio ReisÎncă nu există evaluări

- Cold and .N2Document24 paginiCold and .N2IVAN ARNULFO BUITRAGO LOZANO100% (3)

- Advance Statistics ProjectDocument9 paginiAdvance Statistics Projectrishit100% (7)

- Bomba Reciprocante Mud Pump JWS340 PDFDocument10 paginiBomba Reciprocante Mud Pump JWS340 PDFAlexander Bohórquez Martínez100% (1)

- Tech Manual: Tech-5.12 10M Ec Combi Large SHRDocument260 paginiTech Manual: Tech-5.12 10M Ec Combi Large SHROvRrj AhmedÎncă nu există evaluări

- Serva PumpDocument72 paginiServa Pumppengepul rosok100% (1)

- GE HY Kellyguard FS 080709-2Document2 paginiGE HY Kellyguard FS 080709-2caballero_tigreÎncă nu există evaluări

- 966GII - Accumulator Charging Valve (Brake) - Test and Adjust PDFDocument4 pagini966GII - Accumulator Charging Valve (Brake) - Test and Adjust PDFOfftap's100% (2)

- BS en 1593-1999 NDT - Leak Testing - Bubble EmissionDocument14 paginiBS en 1593-1999 NDT - Leak Testing - Bubble Emissionrinshad100% (1)

- Washpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)Document12 paginiWashpipe WPT00070 (NOV Etc.7.50 Inch Thread X 4 Tapered To 3 Inch Bore)osvaldoÎncă nu există evaluări

- Annular Bops D Bop DL Bop: To Contents PageDocument6 paginiAnnular Bops D Bop DL Bop: To Contents PageJohn Alexander Bonilla AngelÎncă nu există evaluări

- EXPRO Policies and Safety: Section 1Document29 paginiEXPRO Policies and Safety: Section 1RyanÎncă nu există evaluări

- PM PumpDocument46 paginiPM PumpDiyaNegi100% (2)

- 2P36606 Spring Loaded ERVDocument42 pagini2P36606 Spring Loaded ERVYM Edwin Gil BeltranÎncă nu există evaluări

- 2P36606 Spring Loaded ERVDocument42 pagini2P36606 Spring Loaded ERVYM Edwin Gil BeltranÎncă nu există evaluări

- Maintenance and Operation Manual: Ultra Flow Type 'E-Fc' Gate ValvesDocument32 paginiMaintenance and Operation Manual: Ultra Flow Type 'E-Fc' Gate ValvesNeilton Junior100% (2)

- BOP Manual Nexus 3in 10K Quad - REV 6Document23 paginiBOP Manual Nexus 3in 10K Quad - REV 6Cristian BarbuceanuÎncă nu există evaluări

- Chiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFDocument2 paginiChiksan Swivel Joints Repacking Instructions Longsweep Standard Service PDFCikalong Yard100% (1)

- BJ Services - Standard Spare PartDocument32 paginiBJ Services - Standard Spare Partibnu100% (1)

- BOPs Bulletins PDFDocument538 paginiBOPs Bulletins PDFOvRrj AhmedÎncă nu există evaluări

- Manual-0002 CDocument87 paginiManual-0002 CBoedi SyafiqÎncă nu există evaluări

- Operation and Maintenance Manual SEBU8407 06Document190 paginiOperation and Maintenance Manual SEBU8407 06henry omeÎncă nu există evaluări

- Spare Parts Catalogue: DrawworksDocument167 paginiSpare Parts Catalogue: DrawworksHector BarriosÎncă nu există evaluări

- Operations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0Document18 paginiOperations and Parts Manual - Vanoil 3 1/16" - 10ksi Quad Bop MAN P306QB00-A, REV. 0dowel hernandezÎncă nu există evaluări

- Tc1350 Drilling ChokeDocument26 paginiTc1350 Drilling ChokeazeazeazeÎncă nu există evaluări

- JWS-165 Well Service Pump: Parts ListDocument13 paginiJWS-165 Well Service Pump: Parts ListGildardo Mora100% (2)

- Operation & Maintenance Manual: T3 Model 6012 Ram BOPDocument21 paginiOperation & Maintenance Manual: T3 Model 6012 Ram BOPerickson nievesÎncă nu există evaluări

- Tech Manual: Tech-5.12 10K Es54 Dual QcmaDocument24 paginiTech Manual: Tech-5.12 10K Es54 Dual QcmaRiski KurniawanÎncă nu există evaluări

- Tc148-2 Manual GV O&mDocument20 paginiTc148-2 Manual GV O&mFam Escalante OnofreÎncă nu există evaluări

- Anson E Typs Gate Valve With Fail Safe Closed ActuatorDocument12 paginiAnson E Typs Gate Valve With Fail Safe Closed ActuatorWeniton Oliveira0% (1)

- Emsco F 350 Pump PartsDocument2 paginiEmsco F 350 Pump Partschymax3mÎncă nu există evaluări

- Mud King Products CatalogDocument181 paginiMud King Products CatalogAnonymous VNu3ODGav100% (1)

- CPC+MCM+ACM Error Codes ListDocument40 paginiCPC+MCM+ACM Error Codes ListMiguel Ángel Ortega CotrinaÎncă nu există evaluări

- T3-FC & T3-F Gate Valve BrochureDocument32 paginiT3-FC & T3-F Gate Valve BrochureKalpana BansalÎncă nu există evaluări

- HT-400 Parts ListDocument3 paginiHT-400 Parts ListlionelÎncă nu există evaluări

- Tech 1396 ManDocument58 paginiTech 1396 Manامسيديل رامو0% (1)

- Badger: Installation, Operation, and Maintenance Instructions For Badger 2.5" PumpsDocument33 paginiBadger: Installation, Operation, and Maintenance Instructions For Badger 2.5" PumpsFrancisco Wilson Bezerra Francisco50% (2)

- FMC Swivel Joint PDFDocument22 paginiFMC Swivel Joint PDFramudo Z100% (1)

- CARRIER Ducted InstallationDocument32 paginiCARRIER Ducted InstallationEuro-klima BitolaÎncă nu există evaluări

- Parts List EMI 450Document185 paginiParts List EMI 450Mauricio Garcia100% (1)

- 2P36784 Plug ValveDocument36 pagini2P36784 Plug ValveYM Edwin Gil BeltranÎncă nu există evaluări

- SERVA Pumps C-Pumps 052918p en Screen 0711Document50 paginiSERVA Pumps C-Pumps 052918p en Screen 0711Ilham Nugroho100% (2)

- 5.DD9701971846 - Lub Assy 4.06 E12 LW 10K H2SDocument2 pagini5.DD9701971846 - Lub Assy 4.06 E12 LW 10K H2SAbhinav KumarÎncă nu există evaluări

- Spare Parts Catalogue: Triplex Mud PumpDocument87 paginiSpare Parts Catalogue: Triplex Mud PumpemilianoÎncă nu există evaluări

- Section 4: Pressure Control EquipmentDocument47 paginiSection 4: Pressure Control Equipmentgonzalito777Încă nu există evaluări

- VR Lubricator ToolDocument2 paginiVR Lubricator ToolChrisÎncă nu există evaluări

- Field Failure Analysis ProceduresDocument41 paginiField Failure Analysis Proceduresmohamed abd eldayem100% (1)

- Well Control Equipment Catalogue: IntegrityDocument21 paginiWell Control Equipment Catalogue: Integritycrni rokoÎncă nu există evaluări

- Manual Motor Cat 3406 Volumen 02Document731 paginiManual Motor Cat 3406 Volumen 02YM Edwin Gil Beltran100% (8)

- 4.06 10M-15M Striper PackerDocument16 pagini4.06 10M-15M Striper Packeroswaldo58100% (1)

- USER & MAINTENACE MANUAL (189028) - Preliminary - Compressed PDFDocument182 paginiUSER & MAINTENACE MANUAL (189028) - Preliminary - Compressed PDFElsomarx Marx100% (1)

- SJ Petro-ZJ40 Truck-Mounted Drilling RigDocument58 paginiSJ Petro-ZJ40 Truck-Mounted Drilling Rigchtoil2020Încă nu există evaluări

- Gardener Denver PZ8 SpecsDocument2 paginiGardener Denver PZ8 SpecsExpertum99Încă nu există evaluări

- 2a33687 Exl Back Pressure Relief Valve PDFDocument51 pagini2a33687 Exl Back Pressure Relief Valve PDFEnrique HortaÎncă nu există evaluări

- Ram Wear PadsDocument2 paginiRam Wear PadskrishnsgkÎncă nu există evaluări

- FMC Flowline Products and Services CatalogDocument74 paginiFMC Flowline Products and Services Catalogisamelgq100% (1)

- 3.50'' TWS600S 1 Yr Recommended Spare PartsDocument1 pagină3.50'' TWS600S 1 Yr Recommended Spare PartsOvRrj Ahmed100% (2)

- BS6364 1984Document15 paginiBS6364 1984Brian MayÎncă nu există evaluări

- Skid Mounted HT-400 Pumping Unit - Drilling ExchangeDocument2 paginiSkid Mounted HT-400 Pumping Unit - Drilling ExchangeIng DimatiguzÎncă nu există evaluări

- 4.06in Tech Illustration (DRAWINGS)Document39 pagini4.06in Tech Illustration (DRAWINGS)usamakhattakÎncă nu există evaluări

- IRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Document68 paginiIRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Tanyawat Sahsakmontri100% (2)

- Catalgos BombaDocument433 paginiCatalgos BombadantezanamÎncă nu există evaluări

- M60dsu4 0445XB Man 001Document13 paginiM60dsu4 0445XB Man 001Riski KurniawanÎncă nu există evaluări

- NXT-M Bop TMSDocument1 paginăNXT-M Bop TMSSasan Abbasi100% (1)

- Control PanelDocument202 paginiControl PanelVladyslavÎncă nu există evaluări

- Cameron - DL-Annular BopDocument1 paginăCameron - DL-Annular BopAnonymous 48jYxR1CÎncă nu există evaluări

- Core International QuicklistDocument10 paginiCore International QuicklistJonathan SumimsaÎncă nu există evaluări

- Valvula Chek Cameron PDFDocument4 paginiValvula Chek Cameron PDFelisanaÎncă nu există evaluări

- This Is An Uncontrolled Copy of An Official Kemper Valve & Fittings Corp. Document. Generated On January 22nd, 2016 at 7:53 Am CSTDocument1 paginăThis Is An Uncontrolled Copy of An Official Kemper Valve & Fittings Corp. Document. Generated On January 22nd, 2016 at 7:53 Am CSTYM Edwin Gil BeltranÎncă nu există evaluări

- Choke ParveenDocument3 paginiChoke ParveenYM Edwin Gil BeltranÎncă nu există evaluări

- Calendario 213Document14 paginiCalendario 213YM Edwin Gil BeltranÎncă nu există evaluări

- LT Plug ValvesDocument1 paginăLT Plug ValvesYM Edwin Gil BeltranÎncă nu există evaluări

- Company Name CHECK LIST 1Document24 paginiCompany Name CHECK LIST 1ikponmwonsaÎncă nu există evaluări

- MIL 41000 New - Heavy Duty Cage Guided Control ValvesDocument36 paginiMIL 41000 New - Heavy Duty Cage Guided Control ValvesGovarthanan GopalanÎncă nu există evaluări

- VQ400 HoneywellDocument10 paginiVQ400 HoneywelladamsvillanuevaÎncă nu există evaluări

- The Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8TDocument3 paginiThe Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8Tpyrolysisoil100% (1)

- 09 Subsurface Safety Equip PDFDocument40 pagini09 Subsurface Safety Equip PDFFalokid RaboÎncă nu există evaluări

- Corsair FSMDocument894 paginiCorsair FSMDanny MannoÎncă nu există evaluări

- Australia PSC Inspection: 1. GeneralDocument8 paginiAustralia PSC Inspection: 1. GeneralRiddhi DasÎncă nu există evaluări

- ASAHI Gate ValveDocument26 paginiASAHI Gate ValveOdik PranotoÎncă nu există evaluări

- Curapipe Brochure (DD)Document2 paginiCurapipe Brochure (DD)Mihai DiaconuÎncă nu există evaluări

- Api 653 Tank Inspection, Tank Maintenance, AND Causes of Tank FailureDocument43 paginiApi 653 Tank Inspection, Tank Maintenance, AND Causes of Tank FailureArif PriyadiÎncă nu există evaluări

- Instruction Manual: Controlled Evaporator and Mixer (CEM)Document22 paginiInstruction Manual: Controlled Evaporator and Mixer (CEM)mahradÎncă nu există evaluări

- Cleaning and Inspection of HP HeaterDocument6 paginiCleaning and Inspection of HP HeaterMuhammad Hasbi AsidiqiÎncă nu există evaluări

- 2TWR2 Install GuideDocument8 pagini2TWR2 Install GuideedwcsdÎncă nu există evaluări

- PCL List of Tests 3-7-16Document1 paginăPCL List of Tests 3-7-16Vanessa DuzÎncă nu există evaluări

- 18 Ah41d1 2 - 1206Document8 pagini18 Ah41d1 2 - 1206scribdquyÎncă nu există evaluări

- Minerva BlueprintDocument46 paginiMinerva BlueprintRaraInsyiraÎncă nu există evaluări

- RTG Kalmar MainternanceDocument356 paginiRTG Kalmar MainternanceMIKELAM09Încă nu există evaluări

- PRO-03-31 FOR LINE BLOCKAGE NewDocument7 paginiPRO-03-31 FOR LINE BLOCKAGE NewNikhil DangariyaÎncă nu există evaluări

- Ryan Gillespie ReDocument6 paginiRyan Gillespie RechumonglamÎncă nu există evaluări

- Valve Standards ANSI ASME PDFDocument6 paginiValve Standards ANSI ASME PDFChi JoyÎncă nu există evaluări

- SPAN Part H - Particular Construction...Document8 paginiSPAN Part H - Particular Construction...ang.xicongÎncă nu există evaluări