Documente Academic

Documente Profesional

Documente Cultură

J Ade PDF

Încărcat de

aleskytronDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

J Ade PDF

Încărcat de

aleskytronDrepturi de autor:

Formate disponibile

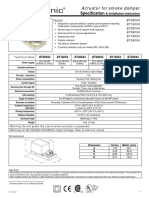

JSWHiroshimaPlant JSWInjectionMolding

MachineryDivision

AllElectricServoDrive

InjectionMoldingMachine

UBAD

UAD

UBAD

U11OAD

U14OAD

U1BOAD

Model

35THMACHINEDESIGNAWARD

DistinctiveMeritAward)

Winner

THENIKKANKOGYOSHIMBUN

2005

]ADSeries,thisnextgenerationolallelectricservodrive

in|ectionmoldingmachineslrom]SWcontinuestolead

thein|ectionmoldingmachineindustry.

The]AD ADvancedSeriesolmachinesollersevengreater

highspeedperlormanceandincreasedprecision,

madepossiblebytheindustry

,

shighestspeed

servocontrolcircuit.

Thisadvancedtechnology,uniqueto]SW,

hasbeenaccumulatedovermanyyearsandresults

inin|ectionmoldingexpertise

thatistheenvyoltheindustry.

asterandmoreaccurate,

the]ADSeriesachievesthehighestlevels

olproductivityandreliability.

Asof2004

Comp|yingwithsafetyregu|ations

EUsafetyregulationsCEMarking)

Industrialmachinery

industrysafetyrulesJIMSK1001)

WideRangeol!n|ectionUnits

WideRangeol!n|ectionUnits

F|OmOtlOnOIp|OduCtquallty

lnCO|pO|atlnQaSC|VOCOnt|OlCl|Cult

thatbOaStSthClnduSt|y

,

ShlQhCStSpCCdOIUEmlC|OSCCOndS)

HCma|kablylmp|OVCdOpC|abllltyandVlSlblllty

la|QCJblnChLCLCOlO|mOnltO|)

Imp|OVCmCntSmadCIO|StCppCd-upp|OduCtlVltyWlthla|QC|mOldS

FaStC|-CyClCmOldlnQWlthla|QC|platCnSlS|CallZCd

bythCuSCOIa|ObuStClamplnQunlt)

FaStC|In]CCtlOnEpCCdSandqulCkC|

COmputC|HCSpOnSC1lmCa|CCOuplCd

WlthOu|C|CatlVCCOnt|OlFaCkaQC,WhlChmakCS

1hln-WallCd/F|CClSlOnmOldlnQmO|CattalnablC

AdaptCdIO|dlVC|SlIlCdllnCSOIp|OduCtSOnappllCatlOn

AWldCSClCCtlOnOIln]CCtlOnmOdulCS

andaWldCa||ayOICqulpmCnt)

QuickResponse QuickResponse

AlgorithmTechnology

AlgorithmTechnology

asterCycles asterCycles

!nnovative&riendlyOperation !nnovative&riendlyOperation

JhemarveIous62mIcrosecondhIgh-seed

servocontroIcIrcuItattaInsanewhIgh

InaccuracyandstabIequaIItyIeveIs

3

JSWorigina|high-speedservo

contro|board

MlQhlyupQ|adCd|CSOlutlOnOIthCln]CCtlOnp|CSSu|CdCtCCtO|

QVariationintheho|dingpressuretransferpressure

comparisonbetweenourJ-ELT&ADSeriesmachines)

QVariationincushion

comparisonbetweenourJ-ELT&ADSeriesmachines)

0.5

0.4

0.3

0.2

0.1

0.0

V

a

r

i

a

t

i

o

n

i

n

t

r

a

n

s

f

e

r

p

o

s

i

t

i

o

n

m

m

)

Conventiona|

machine

1000s)

J-AD

machine

62.5s)

COmpa|lSOnOIVa|latlOnSlnthCt|anSIC|pOSltlOn

atbOOmm/Sln]CCtlOnSpCCd

0.5

0.03

20.0

16.0

12.0

8.0

4.0

0.0

V

a

r

i

a

t

i

o

n

i

n

t

h

e

h

o

l

d

i

n

g

p

r

e

s

s

u

r

e

t

r

a

n

s

f

e

r

p

r

e

s

s

u

r

e

M

P

a

)

J55ELT J55AD

19.5

3.2

0.25

0.20

0.15

0.10

0.05

0.00

V

a

r

i

a

t

i

o

n

i

n

c

u

s

h

i

o

n

m

m

)

J55ELT J55AD

0.25

0.10

In]CCtlOnmOldlnQmaChlnCUbbELQVSUbbAL

F|OduCtE.4lnChllQhtQuldCpanClIO|mObllCphOnC

E-CaVltymOld,t=O.Umm)

HCSlnFC

2.5

2.0

1.5

1.0

0.5

0.0

R

e

s

o

l

u

t

i

o

n

,

)

J-ELT J-AD

Reso|utionofpressuredetection

assumedtobe10MPaofbackpressure)

2.5

0.5

TheinduStry

,

SfaSteSt62microSecond

ServocontrolcircuitprovideS

thehiQheStproductquality

6.450

6.475

6.500

6.525

6.550

6.575

6.600

6.625

6.650

0 25 50 75 100

P

r

o

d

u

c

t

w

e

i

g

h

t

g

)

Shotnumber

MAX.

MIN.

AVE.

Rg)

3:g)

R/AVE%)

6.550

6.523

6.538

0.027

0.019

0.413

J55ELT

6.542

6.536

6.539

0.006

0.005

0.092

J55AD

J55ELT

J55AD

Uso ol u LlL-sood soivo coiiiol cliculi li iLo|-.

Soilosioducos scuiili ilmo io 116

ol

coivoiiloiul coiiiols uid ucLlovos ui ouisiuidli

62 mlcio socoids ol scui ilmo. i iomoios ioduci

quulliy iLiouL u ioduciloi li oiloimuico

vuiluiloi, sucL us Loldli iiuisloi iossuios.

QVariationinproductweight

comparisonbetweenourJ-ELT&ADSeriesmachines)

JLo iosoluiloi ol iLo loud coll umlllloi loi iLo

li]ociloi iossuio Lus Looi liioislllod llvo lold loi

moio uccuiuio Luck iossuio coiiiol vLlcL Lols

lisuio siuLlllzod ioclsloi moldli.

IgradedSYSCOM8000

EYECOMUOOO SC|CCn

COndltlOn SCttlnQ SC|CCn

CyClC mOnltO| SC|CCn

Q COnVCnlCnt mOnltO|lnQ SC|CCnS

COndltlOn SCttlnQ SC|CCnS

LarQe1inchLCDcolormonitor

UpQradedoperability

andincreaSedviSibility

.voiilcullyuiiuiodluio1blicLJJcoloi

LCsciooi.JLocoiiiolloiioiuiosioiovldo

iLoooiuioivliLuclouivlovolmoldli

uiumoiois.

.illlusiiuiloioliLomucLlio,licoi]uiciloi

vliLooiuiloimodokoysuiduioucLsciooi,

lisuiosousyooiuiloi.

LuiuuosuiosolociuLloliom!illsL,

CLliosouid|uuioso.OiLoiluiuuos Koioui,

SuilsLuidioicL)uiooiloiul.

Sioiuoolmoldlicoidlilois.12Ocoidlilois

cuiLosioiodliliioiiulmomoiyuid1,OOO

coidliloissioiodlioxioiiulUSBmomoiy.

1OuCh panCl SC|CCn

EClCCtO| SWltCh

OoiuiloilicludosiLo

coidliloisoiilisciooi,iLo

ioucLuiolsciooi,uidiLo

solocioisvlicLos.

A more robuSt clampinQ unit promoteS

5

JherobustcIamIngunItensures

Iast-cycIemoIdIng

LltlmatCmOldOpCn/ClOSCSpCCdS

E]CCtO|1lC-dOWn

ACCCSSlbllltytO

Clampa|CahaSbCCn

OpCnCdLp

WldCplatCn

Stationaryplaten Movableplaten

Stationaryplaten Movableplaten

FEManalySlSOIllQhtWClQhtbuthlQh-|lQldltyplatCnS

T

i

m

e

s

e

c

)

COmpa|lSOnOImOld

OpCn/ClOSCtlmCstroke350mm)

T

i

m

e

s

e

c

)

COmpa|lSOnOIC]CCtlOntlmC

stroke80mm)

JLoLlL-illdliyclumliuilioiuLlosiLousool

vldoiluioisuiducLlovosLlL-ioclsloisiuLlllzod

moldli.

IluioiIuiullollsmuidmoldosliloiliuccuiucyls

ucLlovodLyusliuLlLolllcloicyluioisuoii

mocLuilsm,vliLoxiiuloiluioiuldos.

|S\

,

soilliulb-]olii,liioiiullyloldliiolo

mocLuilsmuiiulislmiovodlusioicyclomoldli.

JLosiuiloiuiyluioiuidiLomovuLloluioi,

coislsioluLoxcoisiiuciloivliLioducodvolLiuid

liciousodilldliy,oxoiisuclumliloicoovoily

dlsiilLuiodovoiiLomoldsuiluco.

JLoio-ioisloiodiloLuisiomoioduiuLllliyuid

dociousovlLiuiloiduiliiLomoldooiclosouciloi.

JLolluiiossluioisiiuciuiooiuLlosmlilmlzliol

vull-iLlckiosslluciuuiloiolmoldodioducis.

FlatF|CSSFlatCnSMCChanlSm

Clampingunit

JLo Lorlzonlal llo lar dlslancos

aro oxlondod furlLor lLan

convonllonal macLlnos lo allov

for vldor molds.

JLo oonlng ls mado largor lo

allov lLo slrlor mocLanlsm

ln lLo mold lo lo oaslly llnkod

lo lLo knockoul lalo on lLo

macLlno.

MlQh-SpCCd

C]CCtO|

1.0

0.8

0.6

0.4

0.2

0.0

J110ELT J110AD

2.5

2.0

1.5

1.0

0.5

0.0

J110ELT J110AD

KoducosdiycyclousiLoiosuli

oliLolusi-cycloiolomocLuilsm.

JLoLlL-uccuiucyluiois

ollmliuiouiiiomovuloiiois,ol

iLoioduciiukoouiioLoi,uid

iomoiosiouioiioducilvliy.

Conventionaltypeplaten

Products

Mold

Movable

platen

Flatpressplaten

Theweightoftheproductprocessed

inthecentralsectionofmold

increasesduetothedeformationof

plateninthecenter.

Moldclampforceisuniformly

distributedtotheentiresurfaceof

theplaten.

Tiebarpre-tensioningmechanism Momentfreenozzlecontactdevice

6

JSW

,

soriginalinjectioncompressionfunctionequippedasstandardPat.#1744469)

In]CCtlOnCOmp|CSSlOnmOldlnQ

1hC|OCkSOlldIOundatlOnCnSu|CSplatCn|lQldlty

SYSCOMBOOO

SC|VOampllIlC|)

In]CCtlOnCOmp|CSSlOn

COndltlOnSCttlnQ

COnt|OlCOmmand

EC|VOmOtO|

C|OSShCad

MOVablC

platCn HallSC|CW

AJtOAU,HJandHUmOdCS

MOtO|pOSltlOnICCdbaCk

A7mOdCplatCnQapSCnSO|pOSltlOnICCdbaCk<OptlOn>

lnllal ClamOlnQ lnjCClCn U-SCO CCmOrCSSlCn

MOldOpCnSby

ln]CCtlOnIO|CC

ECO bCICrC mClC CCnaC lnjCClCn U-SCO CCmOrCSSlCn

A-modeA1-A6,A7<option>)

B-modeB1andB3)

Contro|mechanismA&Bmodes)

Lightguidepane|fineprismtransfer

Laminationmo|ding

1.0

0.8

0.6

0.4

0.2

0.0

Q

u

a

n

t

i

t

y

o

f

t

i

l

t

i

n

g

J110ELT J110AD

1lltlnQOIthCStatlOna|yplatCnWhCnltlS

dCCClC|atCdbCIO|CthCmOldlSClOSCd

1.0

0.43

1.0

0.8

0.6

0.4

0.2

0.0

Q

u

a

n

t

i

t

y

o

f

t

i

l

t

i

n

g

J110ELT J110AD

1lltlnQOIthCStatlOna|yplatCn

atthClnltlalStaQCOImOldClOSCSta|t

1.0

0.63

]11OLL1

]11OAD

]11OLL1

]11OAD

Load

Load

X

XLL1

Reduced

by21

LL1

AD !

!

Reduced

by22

1hChO|lZOntaldlStO|tlOn

haSbCCn|CduCCdbyEJ

1hCdlStO|tlOnOIthCSCatSu|IaCCOI

thCStatlOna|yplatCn.|CduCCdbyEE

Distortionofthebedduring

fastspeedmo|dopen/c|ose

SupposeJ110ELiis1.`

productivityandallowSforlarQermoldS

JLo |S\ li]ociloi

comiossloi moldli louiuio

oiuLlos iLo mold osliloi io

Lo coiiiollod io uccuiuclos

ovoi 1O ilmos iLui ol dlioci-

iossuio moldli.

Po

7

^|SW

,

sorIgInaIquIckservocontroIcIrcuItcombIned

wIthaservodrIveunIthasachIevedhIgh-seed

quIck-resonseerIormance.

Highin[ectionpower

comparisonbetweenourJ-ELT&ADSeriesmachines)

MlQh-SpCCdqulCk-|CSpOnSCln]CCtlOnWlthlnC|CaSCdln]CCtlOnpOWC|

JSW

,

sorigina|in[ectioncontro|

Acce|erationcharacteristicsinhigh-speedquick-response

in[ectioncomparisonbetweenourJ-ELT&ADSeriesmachines)

0.00

0.05

0.10

0.15

0.20

0.25

0.30

m

m

)

Ordinarycontro| IWCScontro|

Effectofreducedcushionvariation

PBT

PA6

High-f|uidityPP

0

10

20

30

40

50

60

M

o

m

e

n

t

a

r

y

i

n

j

e

c

t

i

o

n

p

o

w

e

r

k

W

)

J110ELT-180H J110AD-180H

41

59

HiQh-Speedquick-reSponSeinjection

hiQh-Speed,hiQh-preSSurethin-walled

I

n

j

e

c

t

i

o

n

s

p

e

e

d

m

m

/

s

)

ACCClC|atlOnCha|aCtC|lStlCS

lnhlQh-SpCCdqulCk-|CSpOnSCln]CCtlOn

Timefromthestartofinjectionmsec 1/1,000sec)

InC|CaSCdln]CCtlOnpOWC|makCSthln-WallCdmOldlnQ

andqulCkIllllnQpOSSlblC

IWCScontro| In[ectionWeightandCushionStabi|ity)

0

50

100

150

200

250

300

350

400

20msec

36msec

10 20 30 40 50 60

J110ELT-180H

High-speedspec.)

J110AD-180H

Standardspec.)

.uioiiodcoiiioliLuisiuLlllzosiLodoisliyoliLomolioiioslisioioduiiLoiloliLosciovoiovoiysLoi.

JLlsiocLioloycuimlilmlzoiLovuiluicoliioducivolLi. Iui.#8b2D771)

Thisisthecontrolmethodtore-stabilizethe

measureddensityofmeltedresinofeachshotafter

plasticizingwhichispreparedatscrewheadsection.

ThisistheuniquecontroltechnologyofJSWthat

exertsgreateffecttocorrectunbalancebetween

productmassandcushion.

8

EIICCtOIEOItFaCkEC|VOCOnt|Ol

Reductionofstressinmo|ding

E|iminationoff|ashes

Lesseningvariationinproductweight

Loweringthec|ampingforce|ow-pressuremo|ding)

Preventmo|ddamage

AdvancedPressureControl

Setpressurevalue

Pressurefeedback

Speedfeedback

Servocontroller

Optimumpressure

controlpredicting

resinfilling

condition

Controller

Servodrive

Servomotor Drivetrain Screw

Estimator

Injectionforce

Sensor

Holdingpressure

transferposition

Screwposition

Holdingpressureprocess Fillingprocess

Surgepressure

cut

Pressure

Speed

MOldlnQp|CSSu|CCha|aCtC|lStlCS

Setvalue

MPa)

50

0

30

10

Actual

value

MCtC|lnQp|OCCSS

EuCkbaCk

EC|CW|OtatlnQtO|quC

EC|CWSpCCd

NCWCOnt|Ol

HaCkp|CSSu|CWaVCIO|m

COnVCntlOnalCOnt|Ol

HaCkp|CSSu|CWaVCIO|m

16.0s 12.0 8.0 4.0 0

ElCCt|lC-d|lVCnEOItFaCkEC|VOCOnt|Ol

AFCAdVanCCdF|CSSu|CCOnt|Ol)

F|CdlCtCdCOnt|OlOImCtC|lnQ HCIO|C-hOldlnQp|CSSu|CdCCClC|atlOnCOnt|Ol

withverSatilecontrolmodeSenableS

moldinQwithincreaSedpreciSion

250

200

0.6

Injection/holdingpressuretime sec)

MOldlnQp|CSSu|C

t|anSIC|pOSltlOn

0.3

125

100

Theholdingpressure

isautomaticallytransferred

afterthescrewspeed

reachestheholding

pressurespeed.

MPa

mm/s

Screwposition

Injectionspeed

Injectionpressure

Screwposition

I

n

je

c

t

io

n

p

r

e

s

s

u

r

e

a

n

d

s

p

e

e

d

S

e

t

t

i

n

g

p

r

e

s

s

u

r

e

.coiiioliLuismooiLlysiosiLosciovioiuiloiuid

iLoLuckiossuio,duiliiLomoioiliiocoss,Ly

iodlciliiLomoioiliLoloioLuid.idocoloiuiosiLo

sciovsoodiouioilmumvuluouiddociousosiLo

sciovLuckiossuiosmooiLly.

.coiiioliLuidocoloiuiosiLoli]ociloisoodio

oilmumLyiodlciliiLoLoldliiossuioiiuisloi

osliloiLoloioLuid.uilili]ociloiiLolioiilulloico

lsLolddovivLlcLlsuilquoioolociilcsoivodilvo

li]ociloimucLlios.

JLocoiiioliomoiossiuLllliyoliLoLoldliiossuio

iiuisloiiossuio.

JLo|S\uioiiodcoiiioliocLioloyoiuLlosllllliuidoioilmumiossuiovLllosuiossliiossuioouks

LoloioLoldliiossuioiiuisloiduiliiLoli]ociloiiocoss.

JLlsvllliovoiiovoi-uckliliiLli-vullodmoldli. Iui.#.17bbb68)

JLo|S\uioiiodcoiiioliocLioloyiLuiLoldsdoviLoiLovoiuiduidoisLooililiiossuiocoiiiol,duiliiLo

li]ociloiuidLoldliiocoss,oiuLlosLlLoi-dlmoisloiullollov-uuidiosoisoioiLosoiiossuio. Iui.#816828D)

Moollng vorsalllo usor noods, lasod uon lLo locLnology and rovlslons lLal |S\ Las accumulalod ovor many

yoars ln lLo manufacluro of lasllc oxlrudors lLal loasl an lmrosslvo sLaro of lLo vorld markol.

9

Adapted for diverSified productS with

AWldCSClCCtlOnOIln]CCtlOnmOdulCSandSC|CWS

MaX.ln]CCtlOn

p|CSSu|C

MFa)

EC|CWdla.

mm)

In]CCtlOnunlt

typC

MaX.ln]CCtlOn

SpCCdOIStanda|d

ln]CCtlOnunlt

mm/S)

MaX.ln]CCtlOn

SpCCdOI

hlQh-SpCCdunlt

mm/S)

MaX.ln]CCtlOn

SpCCdOI

ult|a-SpCCdunlt

mm/S)

UAD UAD

UBAD UBAD

UBAD UBAD

U1BOAD U1BOAD

U14OAD U14OAD

U11OAD U11OAD

16

18

20

20

22

25

25

28

32

32

35

40

35

40

45

40

46

51

276

218

177

270

223

172

270

215

165

270

225

172

260

199

157

250

189

154

350

350

350

350

350

240

15H

30H

60H

110H

180H

300H

550

550

500

330

800

800

800

AWldCSClCCtlOnOISC|CWS

Thisfullflightscrewhaswell-balancedgeneralversatility,

abrasionresistance,plasticizingcapacityandcolor

changeability,providingexcellentcost/performanceratio.

Thisdoubleflightscrewishighlycompatiblewith

kneadingcapabilityandplasticizingcapacityforall

thermoplasticresins.

Thisscrew,withaventedbarrel,requiresnopre-drying

forallthermoplasticresins,andwillimprovethequalityof

moldedproducts.

Thisscrewisforsmallandmediumsizemachinesis

coatedwithhigh-strengthfilm:Itreducescontamination

andburning,andenhancesresistancetocorrosionand

abrasion.

Thishighkneadingmixingscrewaimstoimprovethe

dispersionofmasterbatchanddrycolor,andalsohas

general-purposepropertiesforlowandmediumviscosity

materials.

(

,

,

(

GP21screw

standardtype)

Ventscrew

M7screw

highplasticization

type)

HPscrew

highdispersion

type)

Coatingscrew

highabrasion

resistancetype)

FluO|lnCmOldlnQ

Recommendedequipment

1.Corrosion-resistantbarrel S5bi-metallic)

2.Corrosion-resistantscrewPlasthard)

3.Corrosion-resistantbarrelheadS5bi-metallic)

4.Corrosion-resistantnozzlePlasthard)

5.Hopperthroat Corrosion-resistanttreatment)

a wide Selection of injection moduleS

LlQhtQuldCpanCl

Recommendedequipment

1.Specialscrewshighlypolished+plating+variouscoatings)

2.Specialbarrel N2000F+highlypolished)

3.Specialscrewheadetc. highlypolished+Crplated)

4.Hopperthroat Crplated)

5.Special-designclampingandinjectionunits

10

MCdlapa|tS

Recommendedequipment

1.High-speedinjectionunits

2.Barrelforhighinjectionpressure

3.Varioussingle-purposescrews

LCnS

Recommendedequipment

1.Specialscrewshighlypolished+plating+variouscoatings)

2.Specialbarrel N2000F+highlypolished)

3.Specialscrewhead,etc. highlypolished+Crplated)

4.Hopperthroat Crplated)

5.Special-designclampingandinjectionunits

COntalnC|S

Recommendedequipment

1.M7screw

2.High-speedclampingunit

3.High-speedinjectionunit

HlQldFVC

Recommendedequipment

1.Special-designdoubleflightscrewMK+Crplated)

2.Special-designsingleflightscrewGP21+Crplated)

3.Screwheadwithacheckring

4.Screwheadwithoutacheckring

5.Specialbarrel/screwforventmolding

TheoutStandinQenerQySavinQfeature

SubStantiallyreduceSpowerconSumption

11

FClyCarbCnaCSaICyCCvCr

.luiosoo-iLiouLolycuiLoiuiosuloiycovoilsomloyod.

.vulluLlolisiool oiloiul))

iullovsiLoooiuioiioousllysooiLoclumliuili

uidlucllliuiosmuliioiuico.

0

5 10 15 20 25

2

4

6

8

10

12

Hydrau|ic-drivenmachineJ75ET)

E|ectricservodrivemachineJ85AD)

COmpa|lSOn OI pOWC| COnSumptlOn

Times)

Ejection Cooling

Productweight 35g

Moldingmaterial PP

Cycle28.3s

Metering

Injectionandholding

pressure

Mold

close

Moldopen

5.0

4.0

3.0

2.0

1.0

0.0

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

k

W

h

)

Hydrau|ic-driven

machine

J75ET)

E|ectricservodrive

machine

J85AD)

COmpa|lSOn OI pOWC| COnSumptlOn

NOTE)Theabovedoesnotinclude

thepowerconsumptionofthebarrelheaters.

0.879

3.816

Promotionof

maintainability

Iovoicoisumiloi.18io14olLydiuullc-dilvoimucLlios

Coollivuioicoisumiloi.lossiLui1bolLydiuullc-dilvoimucLlios

P

o

w

e

r

c

o

n

s

u

m

p

t

i

o

n

k

W

)

LubCClllCvClQauQC

iullovsiLoooiuioiio

ousllycLockiLuisulllcloii

olllsllovliioiLo

LouilisuidoiLoiuious,

uidiLuiiLoolllsioi

coiiumliuiod.

AuCmalClubrlCaCr

iuuiomuilcullyluLilcuiosiLoli]ociloiuili

uidiLoclumliuiliioiovoiiioLloms

liomoccuiiliduoioooiluLilcuiloi.

llQhlyCurablCballSCrCwSarCuSCC

BullsciovsiLuioxcolliduiuLllliyuidcui

muliiuliLlLlovolsoluccuiucyloiui

oxioidodoilodolilmo.

12

NE1JOO SyStCm and LINKJO SyStCm

HCmOtC manaQCmCnt SyStCm

MOldlnQ IaCtO|y OIIlCC

lnjCClCnmClClnQ

maChlnC1J

lnjCClCnmClClnQ

maChlnC1E

lnjCClCnmClClnQ

maChlnC1JOO

hanaQCr

,

S

CCllOhCnC

lCSFC

ln-ShCOEhCrnCLAl

Monitorstheoperating

conditionofmachines

andco||ectsmeasureddata.

Notifiesoccurrence

ofa|armsand

sends/receivesmai|s.

Checkstheoperatingcondition

ofmachinesonanofficePCor

otherremote|ocation.

OVC|SCaS mOldlnQ IaCtO|y LOmCStlC OIIlCC

lCSFC

CCnrCllCrSCrCCn HCmCCCCnSClCSCIwarCSCrCCn

Remoteconso|esoftware

Anadvancedcentralized

monitorinQSyStemandaremote

manaQementSyStem

The host computer has a mailing function.

|S\ioivoiksysiomsoiloimquulliycoiiioluid

ioduciloicoiiiololli]ociloimoldlimucLlios

uidoiuLlosduiuioLooxcLuiodvliLmucLlios

iLuiuiocoiiociodvliLli-sLoL.Nioivoik.

Uio1OOmucLlioscuiLollikodiooiLoioiiLo

N!J1OOsysiomuiduio1OmucLliosoiiLo

LNK1Osysiom.Option

lyouuioliuiiioiioioivlioimoii,youcui

moilioiiLomucLliocoidliloi,dlsluyiLocoiiiolloi

sciooisuidcLuioiLocoiiiolloisoiilisliom

uiyvLoioliiLovoildvluiLoN!J1OOsysiomoi

iLoLNK1Osysiom.

MucLliosliuluiuvuyovoisouslucioiycuiLo

moilioiodovoiiLoiioiioi,vLlcLLolsiomoio

Lusliossolllcloicy.Option

MaintaininQtheStandardof

hiQhqualityand

reliableproduction

N2000F Barre|

LSP-2 screw

KC nozz|e

Screw head

13

Etanda|d CqulpmCnt

QStandard equipment |ist

Item Item

Touchpanel15`TFTcolorLCDcontroller

120moldconditionsstorageInternalmemory)

Softstartmolding

USBprinterport

Selfdiagnosticsfunction

Overallsettingscreen

Helpfunction

Pop-updisplay

Pre-heattimer

Compoundaction

Clock

Attended/unattendedoperationselect

Producttakeoutrobotcircuit

Multi-languageselect English,Chinese,Japanese)

Injectionpressureovershootalarm

Greaselubricationfaultalarm

Servofaultalarm

Faultalarmbuzzer

Statisticalgraph

Actualvaluedisplay

Moldtemperaturedisplay

Cumulativeoperatinghourdisplay

Barreltemperaturemonitor

Injectionpressuremonitor IPM)

Oscillographwaveformmonitor

Injection/Meteringwaveformmonitor

Productionmonitor

Cyclemonitor

Moldingconditionupper/lowerlimitmonitor

Injection/Meteringwaveformstorage

Heatersystemfault

Inspectionandmaintenance

Alarmhistory

Setvaluehistory

Coolingwaterclosedcircuit withaflowindicator)

AccessoriesMaintenancetoolsandEjectorrods)

I

n

j

e

c

t

i

o

n

u

n

i

t

C

o

n

t

r

o

l

l

e

r

M

o

n

i

t

o

r

O

t

h

e

r

s C

l

a

m

p

i

n

g

u

n

i

t

Note1)

Note2) Note3)

Note4)

Note5)

Note6)

Note7)

KCnozzleInjectionunitsupto180H)

N2000Fbarrel

LSP-2screwabrasion-resistanttype) Injectionunitsupto180H)

Cr-platedscrewInjectionunit300H)

Screwpull-back

Purgecover withalimitswitch)

Injectionunitswivelingdevicewithalimitswitch)

Screwcoldstartprevention

Molding/Pausetemperatureselect

Autopurgingcircuit

Nozzleretractselect

Pull-backselect

Autogreaselubrication

Injection/Metering

programmed

control

HoldingpressuretransferbyspeeddetectionIVScontrol)

Barreltemperatureremotesetting

Barreltemperaturecontrol SSR)

SoftPackServocontrol

Hopperflangetemperaturecontrol

IWCScontrol

Reversesealcontrol

Holdingpressurecontrolselect

Synchronoustemperaturerisecontrol

Grease-freetogglebushing

Autogreaselubrication

High-performanceplatensupport

Widerplatens

FlatpressplatenmechanismStationaryside/Movableside)

Tiebarpre-tensioningmechanism

Moldopen/closeand

ejectionprogrammed

control

Electric-drivenmoldthicknessadjustingdevice

Moldthicknessremotesetting

Autoclampingforcesetting

Toggletypeinjection

compression

function

Moldprotectionfunction

Clampingsafetydeviceelectrical/mechanical)

Robotmountingholes

Injection/Holdingpressure:

1to6stepsVariable)

Metering/Backpressure:

1to3stepsVariable)

Moldopen/close:4stepsFixed)

Ejection:1to3stepsVariable)

1.

2.

3.

4.

5.

Note)

Nozzleofinjectionunit300H,tiptypenozzleisequipped

asstandard.

OnesetofK,AorBtypeisequippedasstandard.

Theexternalmemoryiscapableofstoringconditionsfor1000molds.

PreparecommercialUSBdatastoragemedia.

Theprinterandtheprintercablesareoptions.

Temperaturesensorsandelectricwiringarenotincluded.

6.

7.

Amaximumof8itemsandalarmscanbeselectedoutofthefollowingmonitoritems.

Cycletime,InjectiontimeMeteringtimeCushionpositionHoldingpressureendposition

(InjectionpressureHoldingpressuretransferpressureScrewbackpressure

Meteringendposition|Injectionstartposition|Holdingpressuretransferposition|Moldopentime

|Moldclosetime|Meteringtorque|Holdingpressuretransferspeed|Moldinnerpressure<option>

Indicatesinspectiontimesanditems.

A-mode

B-mode

Compression:1to6stepsVariable)

OptlOnS llSt

QOptions |ist

Item

Longnozzle

Variousshut-offnozzles

KCnozzleInjectionunit300H)

M7screwHighplasticizationtype)

HPscrewHighdispersiontype)

LSP-2screwabrasion-resistanttype)Injectionunit300H)

Cr-platedscrewInjectionunitsupto180H)

Onesetofscrewsandbarrelsformoldingopticalproducts

Specialscrew

HTscrewhead

Onesetofscrewsandbarrelsforhightemperaturemoldingofsuperengineeredplastics

Barrelinsulationcover

Barrelblowercoolingunit

Hopper Optionforalltheregion)

Hopperswivelingdevice

UltraspeedinjectionExcl.injectionunits110H,180Hand300H)

High-speedinjectionExcl.injectionunits110Hand180H)

Highholdingpressuremoldingforlong-timeholdingpressuremolding)

Ventedbarrel

Daylightextension

Thermalinsulationplateforplatens

Variouslocatingrings

Airjet

CorepulldevicesPneumatictypeandHydraulictype)

Unscrewingmotorcircuit

Ejectorgatecuttingdevice

Ejectorplatereturnconfirmationcircuit

ValvegatedevicePneumatictypeandHydraulictype)

Productdropdetector Photoelectric)

Chute

Rejectingproductdetectingchute

Moldsetupdevice

T-grooveplate

Magnetmoldclamper

Moldclamper

Item

Theappearanceandthespecificationsofthemachine

maybealteredforimprovementwithoutnotice.

Unauthorizedreprintfromthisleafletisprohibited.

Thephotographsinthisleafletincludeoptions.

PartChute Airjet

Hopperswivelingdevice Hydrauliccoreinterfaceplug

Sparereceptacle Multicoolingwatermanifold

QExamp|es of optiona| equipment

14

I

n

j

e

c

t

i

o

n

u

n

i

t

C

l

a

m

p

i

n

g

u

n

i

t

E

l

e

c

t

r

i

c

a

l

i

n

s

t

r

u

m

e

n

t

a

t

i

o

n

a

n

d

c

o

n

t

r

o

l

O

t

h

e

r

Otherlanguageselect Korean,SpanishandFrench)

SimplecentralizedmonitorsystemLINK10

CentralizedcontrolsystemNET100

Heaterburnoutalarm

Moldtemperaturedisplaywithmoldtemperatureupper/lowerlimitalarms)

Moldtemperaturecontroldevicewithmoldtemperatureupper/lowerlimitalarms)

Printer withaprintercable)

Coolingwateropencircuitdevice

Coolingwaterfailurewarning

Levelingpadforinstallation

Rotarywarninglight

Exportspecification

Designatedcolor

Note1)

Note2)

Note2)

Note3)

Note4)

Note5)

Note6)

Note7)

Note8)

Note8)

Note7)

Note7)

Note9)

Note10)

Note11)

Note12)

1.

2.

3.

4.

5.

6.

7.

8.

AspringtypeSVNshutoffnozzle,apneumaticshut-offnozzleandahydraulicshut-offnozzle

canbemounted.Forthehydraulictype,aseparatehydraulicunitisneeded.

Forinjectionunits180Horsmaller,apneumaticshut-offdeviceisprovidedasastandardoption.

Regardingthehydraulicshut-offdevice,discussionisneededseparately.

RegardingtheM7screwandtheHPscrewfortheinjectionunits15Hand30H,

discussionisneededseparately.

Regardingspecialscrews,contactusseparately.

Theultra-speedinjectionspecificationappliestotheinjectionunits15H,30Hand60H.

Thehigh-speedinjectionspecificationappliestotheinjectionunits15H,30H,60Hand300H.

Theinjectionspeeddiffersdependingoninjectionunit.

Themotorispreventedfrombeingoverloadedinalongholdingtime

andhighholdingpressuremoldingcondition.

Whenapplied,extendednozzleisrequired.

Notethattheusablemoldthicknessrangewillchange.

Forthehydraulictype,aseparatehydraulicunitisneeded.

Note)

9.

10.

11.

12.

TheLINK10hasactualdatacollection,moldingconditioncontrol

andremotecontrolfunctions.

TheNET100hasqualitycontrolandproductioncontrolfunctionsinaddition

tothefunctionsthattheLINK10has.

Regardingtheexportspecifications,separatediscussionisneededinsomecases,

dependingupontheexportdestination.

Designatecolors,referringtocolorsamplesorMunsellcodes.

Note)

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- MCAMX5 Quick Ref CardDocument6 paginiMCAMX5 Quick Ref CardtobichÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Boquilla - Hotmelt ModelDocument1 paginăBoquilla - Hotmelt ModelaleskytronÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Bochas Y Piramides: Diámetro Ancho Alto Peso Aluminioaluminio BronceDocument2 paginiBochas Y Piramides: Diámetro Ancho Alto Peso Aluminioaluminio BroncealeskytronÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- MCAMX5 NCI Parameter Ref PDFDocument460 paginiMCAMX5 NCI Parameter Ref PDFaleskytronÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Comparison of Bottle Wall Thickness Distribution PDFDocument6 paginiComparison of Bottle Wall Thickness Distribution PDFaleskytronÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Demag en PDFDocument36 paginiDemag en PDFaleskytronÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Insulin, HumanDocument3 paginiInsulin, HumanaleskytronÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- T-SIM Thermoforming SimulationDocument4 paginiT-SIM Thermoforming SimulationaleskytronÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- How To Solve Blow Molding Problems PDFDocument24 paginiHow To Solve Blow Molding Problems PDFaleskytron100% (2)

- Toshiba Machine PDFDocument2 paginiToshiba Machine PDFaleskytron100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- MCAMX5 Administrator Guide PDFDocument46 paginiMCAMX5 Administrator Guide PDFaleskytronÎncă nu există evaluări

- Injection MoldingDocument15 paginiInjection Moldingvalvan1988Încă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Toshiba Machine PDFDocument2 paginiToshiba Machine PDFaleskytron100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Plastic Bottle Blow Moulding Industrial Energy Efficiency PDFDocument26 paginiPlastic Bottle Blow Moulding Industrial Energy Efficiency PDFaleskytronÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- MCAMX5 Administrator Guide PDFDocument46 paginiMCAMX5 Administrator Guide PDFaleskytronÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- ARBURG ALLROUNDER 470S TD 528481 en GB PDFDocument6 paginiARBURG ALLROUNDER 470S TD 528481 en GB PDFaleskytronÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Version 9 To X: Function MapDocument31 paginiVersion 9 To X: Function Mapaleskytron100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- Generate 3D Gear Templates with Gearotic Motion SoftwareDocument85 paginiGenerate 3D Gear Templates with Gearotic Motion SoftwarealeskytronÎncă nu există evaluări

- Dme Comp MoldesDocument186 paginiDme Comp MoldesNuno CamarinhoÎncă nu există evaluări

- MCAMX6 Toolpath Refinement AdvertisementDocument2 paginiMCAMX6 Toolpath Refinement AdvertisementPacho SanchezÎncă nu există evaluări

- MCAMX5 PostDebuggerUG PDFDocument72 paginiMCAMX5 PostDebuggerUG PDFaleskytronÎncă nu există evaluări

- Blow Moulding Processing Manual: Dupont Engineering PolymersDocument24 paginiBlow Moulding Processing Manual: Dupont Engineering PolymersSandeep LeeÎncă nu există evaluări

- Instructions - Rubicks Cube PDFDocument6 paginiInstructions - Rubicks Cube PDFaleskytronÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Extrusion Die DesignDocument17 paginiExtrusion Die Designkkatarn327Încă nu există evaluări

- The Sacred Beetle PDFDocument185 paginiThe Sacred Beetle PDFaleskytronÎncă nu există evaluări

- Plastics company preform weight data sheetDocument1 paginăPlastics company preform weight data sheetaleskytronÎncă nu există evaluări

- Part and Mold DesignDocument174 paginiPart and Mold DesignDeepti KanadeÎncă nu există evaluări

- Preforma 16 G PDFDocument1 paginăPreforma 16 G PDFaleskytronÎncă nu există evaluări

- Telecommunications Switching Systems 7Document20 paginiTelecommunications Switching Systems 7Ramcharan BuddiÎncă nu există evaluări

- Week 8 Assignment SolutionsDocument4 paginiWeek 8 Assignment Solutionsvidhya dsÎncă nu există evaluări

- Content Beyond The SyllabusDocument3 paginiContent Beyond The SyllabusRamya SamuelÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- 30-V N- and P-Channel MOSFET Technical SpecificationsDocument1 pagină30-V N- and P-Channel MOSFET Technical SpecificationsRicardo VillarroelÎncă nu există evaluări

- Power Contactor 1250 A - HubbellDocument4 paginiPower Contactor 1250 A - Hubbellmanuel99a2kÎncă nu există evaluări

- Specification: Actuator For Smoke DamperDocument2 paginiSpecification: Actuator For Smoke Dampermartin saadÎncă nu există evaluări

- Thermography Reveals Hot Connection in HV SubstationDocument12 paginiThermography Reveals Hot Connection in HV Substationyessicanavarrete02Încă nu există evaluări

- Circuit Construction Kit Ac Virtual Lab HTML Guide - enDocument4 paginiCircuit Construction Kit Ac Virtual Lab HTML Guide - enkavithaÎncă nu există evaluări

- Cf.966h Sist - Elect.Document25 paginiCf.966h Sist - Elect.rmatico1234100% (5)

- Default Password List Last Updated 10.22.2010Document31 paginiDefault Password List Last Updated 10.22.2010Rajasekhar BattulaÎncă nu există evaluări

- Lab Report Kirchhoffs Voltage and Current Laws KVL and KCLDocument2 paginiLab Report Kirchhoffs Voltage and Current Laws KVL and KCLAvishek Chowdhury0% (1)

- ENAD Problem BookletDocument37 paginiENAD Problem BookletPruthvi NinganurÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Manual 802Document38 paginiManual 802Ludovic OuedraogoÎncă nu există evaluări

- Sony - HCD rg110, MHC rg110Document21 paginiSony - HCD rg110, MHC rg110Marin VlahovićÎncă nu există evaluări

- FMC 420 Level Measurement Operating InstructionsDocument16 paginiFMC 420 Level Measurement Operating InstructionsMarco Antonio Esquivel BarretoÎncă nu există evaluări

- High-efficiency IGBT module for motor drive and UPS applicationsDocument4 paginiHigh-efficiency IGBT module for motor drive and UPS applicationsmouelhi karimÎncă nu există evaluări

- CHAPTER VII Direct Current Circuits NEWDocument20 paginiCHAPTER VII Direct Current Circuits NEWVydia Ridha AriatiÎncă nu există evaluări

- Helix 2.0 Owners Manual - Rev D - English PDFDocument59 paginiHelix 2.0 Owners Manual - Rev D - English PDFAloysius JulindraÎncă nu există evaluări

- 9600-3003-2 C Premier Industrial Manual A4Document8 pagini9600-3003-2 C Premier Industrial Manual A4BijuÎncă nu există evaluări

- Electrical Machines Lab ManualDocument133 paginiElectrical Machines Lab ManualDagnachewÎncă nu există evaluări

- Surface Roughness Parameters and MeasurementDocument11 paginiSurface Roughness Parameters and MeasurementHafiz Ghulam NabiÎncă nu există evaluări

- The General Theory of Alternating Current Machines Application To Practical ProblemsDocument294 paginiThe General Theory of Alternating Current Machines Application To Practical ProblemsDanang Aji100% (2)

- Lecture Notes On BJT & FETDocument10 paginiLecture Notes On BJT & FETVamsi Krishna100% (3)

- JYC Battery Manufacturer lithium ion battery featuresDocument2 paginiJYC Battery Manufacturer lithium ion battery featuresRia IndahÎncă nu există evaluări

- MINIPROJECTHARTLEYOSCILLATORDocument15 paginiMINIPROJECTHARTLEYOSCILLATORPramod SultaneÎncă nu există evaluări

- IAT-II Question Paper With Solution of 15EC53 Verilog HDL Nov-2017 - Sunil Kumar K.H PDFDocument10 paginiIAT-II Question Paper With Solution of 15EC53 Verilog HDL Nov-2017 - Sunil Kumar K.H PDFKavyashreeMÎncă nu există evaluări

- Value1200ELCD/Value1500ELCD/Value2200ELCD User 'S Manual: Important Safety Instructions Basic OperationDocument2 paginiValue1200ELCD/Value1500ELCD/Value2200ELCD User 'S Manual: Important Safety Instructions Basic OperationDigimonÎncă nu există evaluări

- Electrolytic CellDocument6 paginiElectrolytic CellJohn Israel R. CatedralÎncă nu există evaluări

- Nandipur 425MW CCPP FF & HVAC System Operation Manual (Volume I Part 6) FDocument67 paginiNandipur 425MW CCPP FF & HVAC System Operation Manual (Volume I Part 6) FHassan FarazÎncă nu există evaluări