Documente Academic

Documente Profesional

Documente Cultură

Using A Greenhouse For Controlling Plant Growth PDF

Încărcat de

dya97Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Using A Greenhouse For Controlling Plant Growth PDF

Încărcat de

dya97Drepturi de autor:

Formate disponibile

Combined Proceedings International Plant Propagators Society, Volume 57, 2007

126

Using a Greenhouse for Controlling Plant Growth

Elly M. Nederhoff

Technolutionz Ltd., P.O. Box 521, Palmerston North

Email: Elly@crophouse.co.nz

INTRODUCTION

Greenhouses protect the plants from adverse conditions and enable the grower

to control the growing conditions. Good control helps achieving a high yield, good

quality, uniformity, and precise timing of delivery. A wide range of crops is grown

in greenhouses; the end product can be leaves, roots, bulbs, tubers, fowers, fruit,

seed, young plants, mature plants (herbs, salad plants, bedding plants, pot plants,

garden plants), and more.

Controlling the growing conditions requires technology, primarily for heating and

venting, and optionally also for root-zone heating, cooling, fogging, misting, CO

2

en-

richment, shading, assimilation light, day-length extension, black-out, and more.

Greenhouses come in degrees of sophistication: from uncontrolled plastic tunnels

to completely automated and robotised plant factories. Simple greenhouses can be

manually operated, but advanced greenhouses with a lot of technology require a

good control computer. In New Zealand, most greenhouses used for plant propaga-

tion are relatively basic compared to some highly specialised greenhouses overseas.

This paper looks at using greenhouses for plant propagation and plant growth.

The main growth factors are identifed and the three main factors are described in

some detail: light, temperature, and humidity. We discuss how they infuence plant

growth, and the principles of how they are controlled. The presentation will discuss

these aspects as well as show examples of advanced greenhouse technology.

GROWTH FACTORS

The main environmental factors affecting plant growth are:

1) Light or photosynthetic active radiation (PAR).

2) Temperature.

3) Humidity.

4) CO

2

.

In addition, plant growth can be infuenced by:

1) Root-zone temperature.

2) Irrigation (frequency and volume of watering, average wetness

of root zone).

3) Electric conductivity (EC) or conductivity factor (CF) in the root-zone.

4) Concentration of particular nutrients in the root zone.

LIGHT (PAR)

Light or PAR is the driving force for plant growth. Effects include:

1) More light more photosynthesis more biomass more yield.

2) Low light level at high temperature elongation (stretching)

of plants.

127

3) More light further opening of pores (stomata) in the leaves.

Combined with more solar radiation higher plant temperature

more transpiration.

4) Day length photoperiodic effects such as fower initiation

(related to certain wavelengths only, namely red and far-red light).

The Value of Light. Without light, green plants dont grow. An old rule of thumb

is: 1% light equals 1% production. The effect is less drastic in some conditions,

and therefore we quote a more conservative version of this rule of thumb, namely:

1% light equals 0.75 % growth (or yield).

This rule demonstrates the effect of light loss. In a greenhouse, natural light is

inevitably lost due to shading by construction parts and cladding. More light is

lost due to poor cladding or dirt on the roof, e.g., a bit of soot on the cladding can

easily cause 10% light loss, which causes 7.5% yield loss. Some greenhouses are so

old or dirty that they catch only 25% of the outside light. In comparison, a modern

glasshouse can catch 85% of the outside light. By missing 60% light that could have

come in, the yield will be 45% lower than it could be. Such dark greenhouses cant

be economic. If they are heated, they cost more than they produce.

Solar Radiation Versus PAR. Light is only a part of the solar radiation, roughly

about 45%50%. The rest is heat and a very small percentage is UV radiation.

Light is characterised by wavelength 400 to 700 nanometer (nm). Light in relation

to plant growth is often called PAR. Ideally it should be measured by a PAR meter,

and expressed in watt or joule (e.g., intensity in Wm

-2

and light sums in Jcm

-2

d

-1

).

However, simple controllers and small computers mostly use a luxmeter, which

produces readings in Lux or kiloLux (kLux).

Screening (Shading). First we considered natural light only. Sun light is a given

and can only be lost by shading of the greenhouse structure (see above) or tem-

pered by screening, shading, etc. Solar radiation contains about 50% to 55% heat

(radiation with a longer wavelength than light). In addition, a large part of the

light caught in the greenhouse is converted to heat as well. As a result, high levels

of natural light in a greenhouse are accompanied by high temperature. This is un-

desirable and therefore screening can be applied during strong sunshine to avoid

damage caused by too high a plant temperature. Screening is especially required

for young plants with little roots (seedlings, cuttings), because young plants cannot

take up enough water to cool themselves. Sometimes screening is meant to temper

the light level, for example some ornamental pot plants need screening to maintain

their typical leaf colour or other particular features. A simple form of shading is

by white washing the roof. This is cheap, but the disadvantage is that it blocks

light and causes yield loss at all times. Another method is installing a fxed screen

or shade cloth. But this has the same disadvantage of permanent light loss. The

ideal way would be installing a screen installation or shutters on the outside of the

roof, which can be opened and closed as required. Shutters outside would block any

radiation before it enters the greenhouse, so heating up would be avoided. Outside

screens can be damaged by wind, so the practical solution is a controllable screen or

curtain inside the greenhouse. It can be closed when required, and can be opened

during dull weather. Screens can also be used for energy saving in winter. However,

energy-saving screen requires high light transmission (instead of low light trans-

mission of a shade screen) and a high insulation factor. There are screen materials

Using a Greenhouse for Controlling Plant Growth

Combined Proceedings International Plant Propagators Society, Volume 57, 2007

128

available aiming at combining both functions (dual purpose screens). They are a

compromise and achieve only half the energy saving that the specialised energy

saving screen materials achieve.

Possible side effects of screening (shading) include:

1) Loss of growth and production. If 70% of the radiation is blocked

by shading, then also 70% of PAR is excluded, reducing photosyn-

thesis and growth by roughly 50% in that period.

2) Shading makes plants lush, soft, and vulnerable. In a shaded

greenhouse, the roots and water transport systems of the plants

are not challenged to withstand harsh radiation. Then, if the

plants are accidentally exposed to high radiation or low humidity,

their water uptake capacities will be too low and the plants will

wilt and burn.

3) Shading stretches the plants. Low light level makes plants

elongated. High temperature during day-time stimulates stretch-

ing even more (see below under temperature). Due to reduced

photosynthesis under the shade screen, there is little biomass to

give any substance to this stretching. Hence the warmth and dark

conditions under a screen may result in soft, foppy tall plants.

Artifcial Lighting. Overseas it is common practice to increase the light level by

using artifcial light, in two ways:

1) Assimilation Light. Addition of extra PAR can increase plant

growth and production. However, a very high intensity is required

to have any effect. This is extremely expensive in investments and

running costs. This is only cost effective in countries with long

dark winters, and/or low electricity costs.

2) Photoperiod Light. The photoperiodic effect or day-length sen-

sitivity is brought about by red and far-red radiation. A low level

radiation from simple incandescent lamps (cheap) is suffcient to

create this effect. It can extend the day length to stimulate fower-

ing in long-day plants, or prevent fowering in short-day plants.

Black-out screens can be used in other periods to shorten the day.

TEMPERATURE

Effects on Plants. In the range of roughly 10 to 30

o

C, temperature has the

following effects:

Higher temperature stimulates the rate of development (rate of

appearance of leaves and fowers).

Higher temperature increases the rate of respiration (burning of

assimilates) less biomass less yield.

In Fruit Crops Such as Tomatoes:

Higher temperature favours distribution of assimilates to the fruit

higher fruit yield.

Higher temperature speeds up fruit ripening stimulates earliness.

Day-Time Temperature:

Higher day-time temperature strongly stimulates cell expansion

stretching increased plant length and leaf area.

129

Night-Time Temperature:

May affect fruit set (e.g., in capsicum optimum fruits set at 18

o

C

night temperature).

May affect fruit growth.

Other Effects:

Too low or too high temperature reduces the success rate of germi-

nation.

Reversed temperature (higher night than day temperature) results

in shorter, more compact plants. DIF is used to indicate the differ-

ence between day and night temperature. Negative DIF indicates

reversed temperature. It is used in some greenhouse climate

control computers.

At very low or very high temperature (say below 4

o

C and over

35

o

C depending on species) plant processes stand still and/or plant

cell organs get damaged. Close to these temperatures the plants

dont perform very well.

Temperature Control. Temperature control is based on utilising solar radiation

and applying heating and venting and optionally cooling.

Heating devices can be hot-air heaters, hot-water pipes, hot-steam pipes, possibly

infra-red radiators, and for root-zone heating the main options are pipes, tubes, and

mats. Overseas the use of heat exchangers for greenhouse heating is being trialled.

Hot-Air Heaters. These are a cheap form of air heating. Its often suffcient when

only little heating is required, but they have some disadvantages. Many hot-air heat-

ers release the fue gases directly inside the greenhouse. Although this can have the

positive effect of CO

2

enrichment, it has more risks than benefts. The heaters are

often used at night when there is no photosynthesis, and hence no need for CO

2

en-

richment. So the CO

2

accumulates to an extreme level. Moreover, the fue gases often

contain traces of harmful gases (carbon monoxide, ethylene, nitrous oxides), which

accumulate when the greenhouse is not vented. Other disadvantages include uneven

heat distribution. Also, hot-air heaters release the heat in the top of the greenhouse,

so that quite a bit of heat is lost through the roof before it reaches the plants.

Hot-Water Pipe Heating. A central boiler is the best controllable and most ef-

fcient way of heating. The number of pipes per area can be adjusted to the heating

requirements and climatic zone. In crops such as tomatoes and capsicums, the heat-

ing pipes are positioned on the ground and used as tracks for internal transport

systems and for trolleys to work on.

The position of the heat source relative to the plants is important:

1) Below the plants (close to the ground, on or under a bench)

stimulates root activity increases transpiration (e.g., guttation

at night).

2) Between the plants (tubes or pipes) stimulates roots and shoots,

and keeps the plants dry (reducing fungal infections).

3) Overhead warm shoots stimulates shoot growth but leaves

roots cold.

4) Separate nets below the plants and overhead root growth and

shoot growth can be infuenced separately, which gives best control.

Using a Greenhouse for Controlling Plant Growth

Combined Proceedings International Plant Propagators Society, Volume 57, 2007

130

Root-zone heating is often used for ornamental pot plants, bedding plants, young

plants, and nursery stock plants. They are often grown in heated beds, on heated

foors or on benches with under-bench or in-bench heating. Heating tubes, mats, or

pipes are located close to the roots. Root-zone temperature inside the bed or pot can

be 2326

o

C (or even higher depending on species and conditions). The pipes must

be placed in a fairly fne grid and must run at a moderate temperature in order

to achieve even temperature distribution without burning nearby plants. Because

root-zone heating may dry out the pots and cause low air humidity, the watering

needs to be adjusted. In cold conditions, root-zone heating alone can lead to growth

problems and diseases. Root-zone heating responds slowly to a change in temper-

ature setting. In these cases additional air heating may be necessary. Root-zone

heating is then the base-load heating, which is controlled on the basis of tempera-

ture measurements in the beds or pots. The additional heating is controlled on the

basis of temperature near the top of the plants.

Heating Control. It can be done in many ways: manually or by a simple thermostat,

analogue controller, digital controller, or advanced computer. The following applies

primarily to heating the greenhouse air, and sometimes to root-zone heating.

In its basic form, the controller strives to maintain a certain set-point for air tem-

perature, e.g., a thermostat does the on/off control of a heater (e.g., hot-air heater).

With heating pipes, the controller steers a mixing valve for mixing hot water with

cold return water, so that a certain pipe temperature is achieved. This is not on/off

control but proportional control.

Advanced computers do the same: maintaining a certain set-point for air tem-

perature. But in addition a computer frst calculates what the best set-points are for

temperature, humidity, CO

2

,

etc. The computer can optimise the performance of the

whole system by controlling the boiler, heat storage, venting, and other devices.

Venting. Venting is needed when the greenhouse gets too hot and/or too humid.

Vents can be opened either manually or by a thermostat, controller, or advanced

computer. A setting in the computer called a P-band is used to determine how far

the vents should open depending on temperature inside the greenhouse. If it is way

too hot or humid inside, it seems appropriate to open the vents very wide. But if

the outside conditions are cold, wet, or windy, a small vent opening is suffcient.

Hence the P-band must be modifed depending on the outdoor conditions. Simple

controllers only have a fxed P-band, so the grower has to adjust the P-band be-

tween seasons or when the weather changes. Advanced computers have all sorts of

modifcation and safety measures in place, including modifcations of P-bands and

limitations. The simple forms are frost protection, rain protection, wind protection,

but they do much more. Venting is also used a lot for humidity control.

In winter conditions, it is best to open the vents on the leeside only, to avoid infux

of a large volume of cold dry air. In milder weather conditions, frst the vents on the

lee-side are opened, and those on the wind-side follow when more venting is needed.

In hot conditions both sides need to be opened wide.

Cooling. This is meant here in the sense of active cooling or evaporative cooling

(some computers use the word cooling for just opening vents). Evaporation (water

changing from liquid to vapour) requires energy, so it removes heat from the sur-

roundings. Plant leaves evaporate water and thereby cool themselves. Leaf temper-

ature can be several degrees below air temperature, and a greenhouse with plants

131

is a lot cooler than a greenhouse without plants. If plants have no water available

for evaporation they will get hot and they burn. Evaporative cooling in a green-

house can be achieved by pad and fan, fogging, misting, or roof sprinklers.

Roof sprinklers are underrated in New Zealand. It is a simple but effective system

with irrigation lines or sprinklers on the roof of the greenhouse. In hot conditions

they spray a flm of water over the roof. The hot air makes the water evaporate,

thereby heat is absorbed and moisture added to the air. This creates a cool fresh

breeze into the greenhouse (the vents are meant to be open). It works especially

well in conditions of low outside air humidity. The effect can be a temperature drop

of as many as 10

o

C. Roof sprinklers require a stream of clean water, but this water

can be recollected. Water sprayed on the roof should not contain iron, as that will

stain the glass and cause light loss.

Solar Energy. Solar energy is used in greenhouses in New Zealand only passively,

the sun heats the greenhouse (and if it gets too hot the surplus heat is vented out).

In the Netherlands some large-scale trial greenhouses make active use of solar

energy. They catch an excessive amount of heat in summer, while special heat ex-

changers transfer the surplus heat to cold ground water that is pumped up. The

then luke-warm ground water is pumped back into underground aquifers. Half of a

year later, the luke-warm water is pumped up from the aquifer and used for heat-

ing in winter. The surplus can be so great that a number of houses can be heated

from a 1-ha glasshouse. Unfortunately this is unlikely to happen in the near future

in New Zealand, due to extreme costs and resource management issues.

AIR HUMIDITY

Effects of Humidity. For seeds, seedlings, and cuttings:

High humidity is needed for seed germination and for avoiding

water loss from seedlings or cuttings.

In established plants, including garden plants and ornamental pot plants:

High humidity reduces transpiration, and hence reduces uptake of

certain nutrients (e.g., calcium).

High humidity may stimulate leaf stretching and makes plants

lush and soft.

High humidity increases fungal infection which increases the risk

of moulds, rots, and diseases.

Condensation and disease outbreak is a real risk in any greenhouse. In an un-

heated greenhouse condensation is almost inevitable. In heated greenhouses there

are always cold spots where condensation occurs too, especially at night and in

early mornings. At sunrise the plants slowly warm up, but more massive plants

parts (e.g., stems and fruit) are very slow to warm up. These are cold bodies that

will attract condensation and will stay wet for much longer. Spores of fungal dis-

eases, such as botrytis, are ever-present in the greenhouse, and wet plants offer

the perfect conditions for spore germination and infection. The incidence of fungal

diseases can be reduced by avoiding very high air humidity.

Humidity Control. Increasing the humidity can be required in very hot dry sum-

mer conditions when plants are under stress, or in winter in frosty conditions when

the relative humidity of the air is low. Humidity can be increased in summer by fog-

ging, misting, roof-sprinklers, (sometimes by screening) and in winter by screening,

Using a Greenhouse for Controlling Plant Growth

Combined Proceedings International Plant Propagators Society, Volume 57, 2007

132

reducing venting, or keeping the vents shut. For seeds, seedlings, and cuttings, high

humidity can be maintained in small enclosed environment (e.g., under plastic).

Lowering the humidity can be achieved by heating and venting. Heating for humid-

ity control can be complicated because heating affects humidity and temperature.

Moreover, relative humidity (RH) is strongly linked to temperature. The linkage is

that RH is the moisture content of air as a percentage of the maximum moisture

content of air at a certain temperature. Warmer air can hold much more moisture

than cold air. Heating obviously increases the temperature, and since warmer air

can potentially hold more moisture, the relative humidity drops (assuming that no

moisture is added). This is a very effective way of reducing the RH.

However, after some time, the lower RH will stimulate plant transpiration. This

will then increase the humidity. Then the vents have to be opened. The warm and

now humid air will be replaced by cold dry air (cold air is by defnition drier, since cold

air can only hold a limited amount of water vapour). Continued heating and venting

will result in lower air humidity, while plant transpiration is higher than without

heating. Temperature control and the location of heating pipes (under the tables,

overhead, etc.) can have signifcant effect on humidity and plant transpiration.

MISCELLANEOUS

Stretched Plants Under Screens. Shading may result in foppy plants because

under shade it is dark and warm (although not as hot as without shading). Higher

day-time temperature strongly stimulates stretching. Due to shading, photosyn-

thesis is reduced, so there is little biomass to give any substance to this stretching.

Low light level also makes plants stretch. Hence the combination of warm and dark

conditions under a screen may result in very foppy tall plants.

Making Plants Compact by Using Reversed Temperature. Plants can be

made more compact by reversing the day and night temperature, i.e., giving higher

night temperature than day temperature. This is only possible in winter and shoul-

der seasons, and is hard to achieve in milder climates and on sunny days. But the

plants can be kept fairly compact by having little difference between day and night

temperature, giving a bit of heating at night and keeping temperature low during

the day.

Advanced Climate Control Computers. Some advanced greenhouse climate

computers determine the optimum temperature, humidity, and CO

2

level, based

on plant requirements, season, time of the day, light level, and other factors. Some

computers can also consider the weather forecast. Most modern computers have

facilities to strive for energy effciency. They try to optimise the performance of

the whole system by controlling all devices in an optimal way: burner speed, boiler

temperature, pump speed, pipe temperature, heat storage, heat retrieval, vents,

cooling, screening, CO

2

unit, and more. This can never be done manually, partly

because the weather conditions always change. Obviously such computers are

expensive and very complicated. Although greenhouse climate control computers

have become very powerful, the grower is still in control, but indirectly. The grower

chooses the settings that the computer programme needs for the calculations and

control actions. These settings can stay the same for months (many growers leave

them for years) but it is wise to review the settings every season. In this way the

133

growers keep up their understanding of the (complicated) computers and can put

in place new insights.

Fuel and Energy Saving. Energy is required for heating to control temperature

and humidity in hours with insuffcient solar radiation. Most commonly used fuels

are gas, coal, and oil, and less common are diesel, LPG, propane, butane while a few

greenhouses are heated by geothermal energy. Electricity is rarely used for green-

house heating in New Zealand as it is too expensive. Since energy prices are rapidly

rising, it is becoming increasingly important to employ energy-wise control strate-

gies. There is a wide range of energy-saving measures that growers can implement.

Some require investments, while others are cost-free energy-saving actions, such

as improved control. Advanced control computers offer many options for optimising

plant growth as well as energy effciency.

Crop Recording. A way to learn more about climate control and its effect on

plants, and about growing more effciently, is to do crop recording. This is doing

certain observations and using a specially designed spreadsheet for recording in-

put factors, such as climate, irrigation, fertiliser, energy and output such as crop

growth and production. By recording and studying the tables and graphs produced

by the spreadsheet, the grower can discover links between input and output. It can

help fnd out which conditions give the best results in terms of yield, quality, uni-

formity, timing, and effciency.

Using a Greenhouse for Controlling Plant Growth

S-ar putea să vă placă și

- Citrus Propagation: Fact Sheet HS-86Document6 paginiCitrus Propagation: Fact Sheet HS-86Dorjee WangÎncă nu există evaluări

- Greenhouse ManagementDocument49 paginiGreenhouse ManagementAnouer Belkadi43% (14)

- Polyhouse AgricultureDocument37 paginiPolyhouse AgricultureNeha ThakurÎncă nu există evaluări

- Basic Grafting TechniquesDocument21 paginiBasic Grafting Techniquesjeff opagdavaosurÎncă nu există evaluări

- (Gardening) TomatoesDocument4 pagini(Gardening) TomatoesJuan CarlosÎncă nu există evaluări

- CXC - Past - Paper - 2022 Solutions PDFDocument17 paginiCXC - Past - Paper - 2022 Solutions PDFDarren Fraser100% (1)

- Mango Cultural MGT PDFDocument12 paginiMango Cultural MGT PDFsher_mykoÎncă nu există evaluări

- Spirulina Farming Project Report, Extraction Process - Agri FarmingDocument8 paginiSpirulina Farming Project Report, Extraction Process - Agri Farmingdya97Încă nu există evaluări

- Greenhouse Gardening: The Ultimate Guide to Start Building Your Inexpensive Green House to Finally Grow Fruits, Vegetables and Herbs All Year Round.De la EverandGreenhouse Gardening: The Ultimate Guide to Start Building Your Inexpensive Green House to Finally Grow Fruits, Vegetables and Herbs All Year Round.Încă nu există evaluări

- Irrigation SystemDocument22 paginiIrrigation SystemshriramuluÎncă nu există evaluări

- Window Mounted Solar Hot Air FurnaceDocument14 paginiWindow Mounted Solar Hot Air FurnaceEduardo J Villalobos GÎncă nu există evaluări

- Nutrition & You - Chapter 6Document40 paginiNutrition & You - Chapter 6Bridget KathleenÎncă nu există evaluări

- Green HouseDocument30 paginiGreen HousePrathap ReddyÎncă nu există evaluări

- Real Plant Propagation WorkshopDocument20 paginiReal Plant Propagation WorkshopMs. J. WilliamsÎncă nu există evaluări

- Hoop GardenDocument5 paginiHoop GardenKraft DinnerÎncă nu există evaluări

- Seed Saving: An Illustrated GuideDocument19 paginiSeed Saving: An Illustrated GuideLeonardo CotacioÎncă nu există evaluări

- Plant Propagation: Adapted From Texas Master Gardener Manual Curtis W. Smith, NMSU Extension Horticulture SpecialistDocument19 paginiPlant Propagation: Adapted From Texas Master Gardener Manual Curtis W. Smith, NMSU Extension Horticulture SpecialistZachary BartonÎncă nu există evaluări

- Care of Clients With Problems in OxygenationDocument5 paginiCare of Clients With Problems in OxygenationSkyla FiestaÎncă nu există evaluări

- Goals in LifeDocument4 paginiGoals in LifeNessa Layos MorilloÎncă nu există evaluări

- Hydroponics TechnologyDocument19 paginiHydroponics TechnologyfrlkhldÎncă nu există evaluări

- Home Gardeners Guide To Soils and Fertilizers - WSUpdfDocument26 paginiHome Gardeners Guide To Soils and Fertilizers - WSUpdfDÎncă nu există evaluări

- Permaculture Is A Set of Design Principles Centered On: ResilientDocument12 paginiPermaculture Is A Set of Design Principles Centered On: ResilientAaron Jae Mendoza CaraosÎncă nu există evaluări

- My Personal Experience With Goji: Care of Your Goji PlantsDocument7 paginiMy Personal Experience With Goji: Care of Your Goji PlantsΛαόνικος ΤσάγκοςÎncă nu există evaluări

- Impact of Employee Motivation in The Banking SectorDocument48 paginiImpact of Employee Motivation in The Banking Sectormohd talalÎncă nu există evaluări

- Aeroponics: An Alternative Production System For High-Value Root CropsDocument8 paginiAeroponics: An Alternative Production System For High-Value Root CropsAlfatehan SeptiantaÎncă nu există evaluări

- How To Build PDFDocument3 paginiHow To Build PDFMIrfanRaharjoÎncă nu există evaluări

- Compost Thermal in Passive Solar GreenhouseDocument2 paginiCompost Thermal in Passive Solar GreenhouseCompost Heated Greenhouses100% (1)

- Given The Simulation Area For Room ServiceDocument3 paginiGiven The Simulation Area For Room ServiceRico EsponillaÎncă nu există evaluări

- Green RevoltionDocument14 paginiGreen RevoltionSubhanÎncă nu există evaluări

- Compartment SyndromeDocument14 paginiCompartment SyndromedokteraanÎncă nu există evaluări

- Rules and Regulations, Pleasanton Community Garden, CaliforniaDocument3 paginiRules and Regulations, Pleasanton Community Garden, CaliforniaZafiriou MavrogianniÎncă nu există evaluări

- Making Policy For Community Gardens: Steps Beyond The Physical GardenDocument28 paginiMaking Policy For Community Gardens: Steps Beyond The Physical GardenGreater Charlotte Harbor Sierra ClubÎncă nu există evaluări

- Tower Garden GrantDocument6 paginiTower Garden Grantapi-344435585Încă nu există evaluări

- Rules of Round Hill Community Garden - Round Hill, VirginiaDocument4 paginiRules of Round Hill Community Garden - Round Hill, VirginiaZafiriou MavrogianniÎncă nu există evaluări

- Sample Community Garden Contract From Los Angeles, CaliforniaDocument2 paginiSample Community Garden Contract From Los Angeles, CaliforniaZafiriou MavrogianniÎncă nu există evaluări

- Community Gardening Action Plan 4.27.15 PDFDocument7 paginiCommunity Gardening Action Plan 4.27.15 PDFbigjon1359Încă nu există evaluări

- 05-Postharvest Handling of AvocadoDocument14 pagini05-Postharvest Handling of AvocadolangtuduongsonttÎncă nu există evaluări

- Influence of Vermicomposted Soil Amendments On Plant Growth and Dry Matter Partitioning in Seedling ProductionDocument10 paginiInfluence of Vermicomposted Soil Amendments On Plant Growth and Dry Matter Partitioning in Seedling ProductionPremier PublishersÎncă nu există evaluări

- Adopt-a-Plot and Share The Harvest Community Garden ProgramDocument3 paginiAdopt-a-Plot and Share The Harvest Community Garden ProgramRoyal Forest and Bird Protecton SocietyÎncă nu există evaluări

- Farmington Community Gardens ByLaws 2013Document6 paginiFarmington Community Gardens ByLaws 2013Kyle100% (1)

- Fertilizer Recommendation Based On MOETDocument3 paginiFertilizer Recommendation Based On MOETdelacruzjobyÎncă nu există evaluări

- Community Gardens: Lessons Learned From California Healthy Cities and CommunitiesDocument5 paginiCommunity Gardens: Lessons Learned From California Healthy Cities and CommunitiesGustoffÎncă nu există evaluări

- By Joline Vretenar: Strawberry JamDocument6 paginiBy Joline Vretenar: Strawberry JamJoline2005100% (3)

- Rutgers Solar Heating System For GreenhousesDocument78 paginiRutgers Solar Heating System For GreenhousesGreen Action Sustainable Technology Group100% (1)

- Trebuchet Coursework For Website PDFDocument75 paginiTrebuchet Coursework For Website PDFkeraizÎncă nu există evaluări

- Commercial Flower Farms and The Resulting Environmental Pollution Consequences in UgandaDocument4 paginiCommercial Flower Farms and The Resulting Environmental Pollution Consequences in UgandaAllona ReasolÎncă nu există evaluări

- Greenhouse Heating Using Geothermal EnergyDocument9 paginiGreenhouse Heating Using Geothermal EnergyHenokh PrasetyoÎncă nu există evaluări

- 6 - Letter of Commitment, New Community Garden, Chicago ParksDocument2 pagini6 - Letter of Commitment, New Community Garden, Chicago ParksCelandine CharaÎncă nu există evaluări

- Plant Protestion EquipmentsDocument9 paginiPlant Protestion EquipmentsSreo Sree Roy ʘ‿ʘÎncă nu există evaluări

- Hydroponic FarmingDocument5 paginiHydroponic FarmingInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Book1 PDFDocument115 paginiBook1 PDFReshmaÎncă nu există evaluări

- Intercultural Operations PDFDocument1 paginăIntercultural Operations PDFsam100% (1)

- Organic Goji Seeds - 200 Ready For Planting. 4.50: Grow Your Own Goji's!Document11 paginiOrganic Goji Seeds - 200 Ready For Planting. 4.50: Grow Your Own Goji's!Cristi PascalÎncă nu există evaluări

- CompostingDocument12 paginiCompostingVinod BhargavÎncă nu există evaluări

- Green HouseDocument6 paginiGreen HouseG_KrithikaÎncă nu există evaluări

- Importance of Organic MatterDocument6 paginiImportance of Organic Matterapi-3737745Încă nu există evaluări

- Trebuchet in T RuctionsDocument6 paginiTrebuchet in T RuctionsJonatan PerezÎncă nu există evaluări

- Bountea Catalog 2015Document21 paginiBountea Catalog 2015Roland EvansÎncă nu există evaluări

- Agroforestry: Presentation by G.AISHWARYA (BSC, (AGRI) ) 1 YearDocument23 paginiAgroforestry: Presentation by G.AISHWARYA (BSC, (AGRI) ) 1 Yearvignesh waran100% (1)

- The Factors That Affect Plant Growth Can Be Classified As Genetic or EnvironmentalDocument16 paginiThe Factors That Affect Plant Growth Can Be Classified As Genetic or EnvironmentalshadoworacleÎncă nu există evaluări

- Field Tomato Production Guide 2016 PDFDocument6 paginiField Tomato Production Guide 2016 PDFJonathan de JongÎncă nu există evaluări

- Handbook For Starting A New Community Garden - Community Action Coalition, WisconsinDocument22 paginiHandbook For Starting A New Community Garden - Community Action Coalition, Wisconsinfriends of the Native Plant Society of New Mexico0% (1)

- Nutrient Film Technique Lettuce - LMorganDocument3 paginiNutrient Film Technique Lettuce - LMorgankhawarÎncă nu există evaluări

- Thermal Modeling of A Ridge-Ventilated Greenhouse Equipped With Longitudinally Distributed Evaporative Cooling PadsDocument8 paginiThermal Modeling of A Ridge-Ventilated Greenhouse Equipped With Longitudinally Distributed Evaporative Cooling PadsPurushotham PaspuletiÎncă nu există evaluări

- Materials List For Micro Aquaponics Systems 64 and 128 - Friendly AquaponicsDocument3 paginiMaterials List For Micro Aquaponics Systems 64 and 128 - Friendly AquaponicsAquaponics100% (2)

- Hobby Greenhouse Operations and Practices: The Plant EnvironmentDocument8 paginiHobby Greenhouse Operations and Practices: The Plant EnvironmentrubinianÎncă nu există evaluări

- Whitepaper EN Plant-Empowerment Hoogendoorn-Growth-Management 042017Document10 paginiWhitepaper EN Plant-Empowerment Hoogendoorn-Growth-Management 042017tachetÎncă nu există evaluări

- Supp Lighting PaperDocument10 paginiSupp Lighting Papertung_tran_thanh13Încă nu există evaluări

- If You Somehow Manage To Understand How Things WorksDocument14 paginiIf You Somehow Manage To Understand How Things Workstest emailÎncă nu există evaluări

- Cucumber Growers Association Cucumber Conference 2022 - Herman-Hermans - Low Energy GrowingDocument22 paginiCucumber Growers Association Cucumber Conference 2022 - Herman-Hermans - Low Energy Growingdya97Încă nu există evaluări

- Greenhouse Tomato Yields in Soilless CulDocument4 paginiGreenhouse Tomato Yields in Soilless Culdya97Încă nu există evaluări

- Cucumber Growers Association Cucumber Conference 2022 - Joe-Shepherdson - Cucumber Varieties Enza Zaden 2023Document8 paginiCucumber Growers Association Cucumber Conference 2022 - Joe-Shepherdson - Cucumber Varieties Enza Zaden 2023dya97Încă nu există evaluări

- Carbon Dioxide Concentration in Mediterranean Gre-Wageningen University and Research 36304Document8 paginiCarbon Dioxide Concentration in Mediterranean Gre-Wageningen University and Research 36304dya97Încă nu există evaluări

- Carbon Dioxide Concentration in Mediterranean Gre-Wageningen University and Research 36304Document8 paginiCarbon Dioxide Concentration in Mediterranean Gre-Wageningen University and Research 36304dya97Încă nu există evaluări

- IJSWR - Volume 50 - Issue 5 - Pages 1111-1125Document15 paginiIJSWR - Volume 50 - Issue 5 - Pages 1111-1125dya97Încă nu există evaluări

- Spirulina:: Mass Production of The Blue-Green Alga An OverviewDocument15 paginiSpirulina:: Mass Production of The Blue-Green Alga An Overviewdya97Încă nu există evaluări

- Vatren Jurin Micronutrient Uptake and Sources 2015Document26 paginiVatren Jurin Micronutrient Uptake and Sources 2015dya97Încă nu există evaluări

- NRAES-186 LowResDocument170 paginiNRAES-186 LowResdya97Încă nu există evaluări

- B PriyankaIJCMDocument6 paginiB PriyankaIJCMdya97Încă nu există evaluări

- EMA Strain Catalogue 3rd EditionDocument163 paginiEMA Strain Catalogue 3rd Editiondya97Încă nu există evaluări

- Growth Performance of Spirulina (Arthrospira) : Platensis in A Low Cost Medium: An AssessmentDocument8 paginiGrowth Performance of Spirulina (Arthrospira) : Platensis in A Low Cost Medium: An Assessmentdya97Încă nu există evaluări

- Spirulina Cultivation A ReviewDocument15 paginiSpirulina Cultivation A Reviewdya97Încă nu există evaluări

- 2012 JITOMATE Red PDFDocument23 pagini2012 JITOMATE Red PDFdya97Încă nu există evaluări

- Xi 3 1Document1 paginăXi 3 1Krishnan KozhumamÎncă nu există evaluări

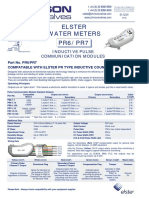

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleDocument1 paginăData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaÎncă nu există evaluări

- Congenital Flexural Deformity in CalfDocument6 paginiCongenital Flexural Deformity in CalfBibek SutradharÎncă nu există evaluări

- PEOPLE V JAURIGUE - Art 14 Aggravating CircumstancesDocument2 paginiPEOPLE V JAURIGUE - Art 14 Aggravating CircumstancesLady Diana TiangcoÎncă nu există evaluări

- Solo ParentsDocument1 paginăSolo ParentsOZ CincoÎncă nu există evaluări

- NRF Nano EthicsDocument18 paginiNRF Nano Ethicsfelipe de jesus juarez torresÎncă nu există evaluări

- Rooftop Rain Water Harvesting in An Educational CampusDocument9 paginiRooftop Rain Water Harvesting in An Educational CampusAkshay BoratiÎncă nu există evaluări

- Science and TechnologyDocument21 paginiScience and TechnologyPat MillerÎncă nu există evaluări

- Crime Data Analysis 1Document2 paginiCrime Data Analysis 1kenny laroseÎncă nu există evaluări

- ASOTDocument4 paginiASOTemperors_nestÎncă nu există evaluări

- E61 DiagramDocument79 paginiE61 Diagramthanes1027Încă nu există evaluări

- Mil STD 792fDocument13 paginiMil STD 792fdoradoanÎncă nu există evaluări

- REV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Document2 paginiREV Description Appr'D CHK'D Prep'D: Tolerances (Unless Otherwise Stated) - (In)Bacano CapoeiraÎncă nu există evaluări

- 3 Activities For Adults To Practice Modeling SELDocument10 pagini3 Activities For Adults To Practice Modeling SELDavid Garcia PerezÎncă nu există evaluări

- READING 4 UNIT 8 Crime-Nurse Jorge MonarDocument3 paginiREADING 4 UNIT 8 Crime-Nurse Jorge MonarJORGE ALEXANDER MONAR BARRAGANÎncă nu există evaluări

- Review - Practical Accounting 1Document2 paginiReview - Practical Accounting 1Kath LeynesÎncă nu există evaluări

- Updoc - Tips Dictionar Foraj e RDocument37 paginiUpdoc - Tips Dictionar Foraj e RDaniela Dandea100% (1)

- Soil SSCDocument11 paginiSoil SSCvkjha623477Încă nu există evaluări

- Leather & Polymer - Lec01.2k11Document11 paginiLeather & Polymer - Lec01.2k11Anik AlamÎncă nu există evaluări

- ArticleDocument5 paginiArticleJordi Sumoy PifarréÎncă nu există evaluări

- Model Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelDocument30 paginiModel Probabilistik: "Variable Demand and Variable Lead Time" & Konsep Service LevelVladimir Hery WijannarkoÎncă nu există evaluări

- Analysis of Pure Copper - A Comparison of Analytical MethodsDocument12 paginiAnalysis of Pure Copper - A Comparison of Analytical Methodsban bekasÎncă nu există evaluări

- Heat Transfer ExampleDocument4 paginiHeat Transfer Examplekero_the_heroÎncă nu există evaluări