Documente Academic

Documente Profesional

Documente Cultură

Lithopone Is A White Pigment Composed of A Mixture of Barium Sulfate

Încărcat de

Benjamin PangihutanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Lithopone Is A White Pigment Composed of A Mixture of Barium Sulfate

Încărcat de

Benjamin PangihutanDrepturi de autor:

Formate disponibile

Lithopone is a white pigment composed of a mixture of barium sulfate (28 - 30%) and zinc sulfide (68 -

70%) with trace amounts of zinc oxide. It is produced by precipitation through filtering, heating and

quenching works. Lithopone has mostly been replaced by titanium dioxide which is more durable, but it is

much cheaper. It is used as a base for lake pigment and used as a inert pigment for paint, ink and

cosmetics as well as in a large range of applications in plastic industry. It is used as a filler in paper,

leather, and linoleum

Litopon adalah suatu pigmen yang putih yang terdiri atas suatu campuran dari sulfat barium ( 28 -30%)

dan sulfida seng ( 68 -70%) dengan sejumlah jejak dari oksida seng. Itu dihasilkan oleh hujan/timbulnya

melalui penyaringan, memanaskan dan memuaskan bekerja. Litopon mempunyai kebanyakan digantikan

oleh dioksid-titan yang lebih tahan lama, tetapi itu adalah banyak lebih murah. Itu digunakan sebagai

suatu dasar untuk pigmen danau dan menggunakan sebagai suatu pigmen yang tanpa daya untuk cat,

tinta dan kosmetika seperti juga di suatu cakupan yang besar aplikasi-aplikasi di dalam industri plastik. Itu

digunakan sebagai suatu pengisi di dalam kertas, kulit, dan linoleum

The product

LITHOPONE 30% DS is an organically coated white pigment based on a coprecipitated zinc sulfide / barium

sulfate.

Typical properties

Low binder requirement

Excellent dispersibility

Neutral hue

Low abrasiveness, thanks to low

Mohs hardness

Applications

Paints and coatings

Suitable for use in matt and semimatt powdercoating

systems, thanks to its favorable

rheological properties and excellent compatibility

with coloured pigments.

Paper

Achieves high dry opacity in the pulp.

Its good retention permits use in pigment size

preparations. Bimodal particle distribution

improves the porosity of the paper.

Plastics and rubber

TiO2 can be partially replaced with

LITHOPONE 30% DS in thermoplastic master

batches.

This products low binder requirement

compared to TiO2 permits higher pigment

concentrations.

The use of LITHOPONE 30% DS makes it

possible to reduce friction and abrasion in

production of master batches and films.

The extremely low absorption which

LITHOPONE 30% DS possesses in the near UV

range significantly improves the effects of optical

brighteners and polymerization initiators.

LITHOPONE 30% DS produces good rheology

in duroplastic moulding compounds without

causing abrasion.

Produk

LITOPON 30% DS adalah satu secara organis melapisi pigmen putih berdasar pada a

co?precipitatedsulfida seng / sulfat barium.

Kekayaan khas

Persyaratan binder rendah

Dispersibilas sempurna

Roda/warna netral

Abrasive rendah, karena yang rendah

Mohs kekerasan

Aplikasi-aplikasi

Cat-Cat dan salutan-salutan

Pantas untuk penggunaan di dalam alas dan semi?matt powder?coating

sistem, karena yang baik nya yang

kecocokan sifat reologi dan sempurna

dengan pigmen-pigmen yang diwarnai.

Kertas

Mencapai ketinggian mengeringkan sifat taktembus cahaya di dalam bubur kayu.

Ingatan nya yang baik mengizinkan penggunaan di dalam ukuran pigmen

persiapan-persiapan. Distribusi partikel bimodal

perbaiki merembes kertas.

Plastik dan karet

TiO2 dapat secara parsial digantikan dengan

LITOPON 30% DS di dalam master termo-plastik

batch-batch.

persyaratan binder Hal ini produk yang rendah

yang dibandingkan dengan TiO2 mengizinkan pigmen yang lebih tinggi

konsentrasi-konsentrasi.

Pemakaian LITHOPONE 30% DS membuat nya

mungkin untuk mengurangi friksi dan lecet/pengausan di dalam

produksi guru mengelompokkan dan memfilmkan.

Penyerapan sangat rendah yang

LITOPON 30% DS menguasai di dalam dekat UV

cakupan dengan mantap memperbaiki barang kepunyaan dari yang berhubung dengan mata

pemrakarsa-pemrakarsa bahan pencerah dan polimerisasi.

LITOPON 30% DS menghasilkan reologi baik

di dalam senyawaan cetak yang duroplastic tanpa

menyebabkan lecet/pengausan.

Efficiency is a vital factor in market survival and one of the many factors that decide efficiency is correct materials

selection, which must balance the need for quality, on the one hand, with the need for the lowest possible costs, on

the other. Titanium dioxide is one of the main raw material in the production of emulsion paints. LITHOPONE can

play a key role as an alternative, with no loss of quality. Increasingly large quantities of LITHOPONE are being

incorporated into emulsion paints for this reason. The following article examines the benefits offered by LITHOPONE

in emulsion paints and describes in detail the procedure for adjusting paint formulations for the use of LITHOPONE

Efisiensi adalah suatu faktor yang penting di dalam survival pasar dan salah satu [dari] banyak faktor

bahwa memutuskan efisiensi benar pemilihan bahan-bahan, yang harus menyeimbangkan kebutuhan

akan mutu, pada suatu pihak, dengan kebutuhan akan biaya-biaya yang mungkin paling rendah, di yang

lain. Dioksid-titan adalah salah satu [dari] bahan baku utama di dalam produksi emulsi mengecat.

LITOPON dapat memainkan suatu peran kunci sebagai satu alternatif, tanpa adanya hilangnya mutu.

Jumlah yang besar yang terus meningkat dari LITHOPONE sedang disatukan ke dalam emulsi mengecat

untuk alasan ini. Artikel yang berikut menguji manfaatnya yang ditawarkan oleh LITHOPONE di dalam

emulsi mengecat dan menguraikan secara detil prosedur untuk menyesuaikan perumusan-perumusan

cat untuk pemakaian LITHOPONE

Lithopone, C.I. Pigment White 5, is an mixture of inorganic compounds, is a widely used as a white

pigment powder. It is composed of a mixture of barium sulfate and zinc sulfide. These insoluble

compounds blend well with organic compounds and confer opacity. It was made popular by the cheap

production costs, greater coverage. Related white pigments include titanium dioxide, zinc oxide ("zinc

white"), and zinc sulfide

History

Lithipone was discovered in the 1870s by DuPont. It was manufactured by Krebs Pigments and

Chemical Company and other companies.

[3]

The material came in different "seals", which varied

in the content of zinc sulfide. Gold seal and Bronze seals contain 40-50% zinc sulfide, offering

more hiding power and strength.

[4][5]

Although its popularity peaked around 1920, approximately

220,000 tons were produced in 1990. It is mainly used in paints, putty, and in plastics.

[1]

Stability and darkening

Although barium sulfate is almost completely inert, zinc sulfide degrades upon exposure to UV

light, leading to darkening of the pigment. The severity of this UV reaction is dependent on a

combination of two factors; how much zinc sulfide makes up the pigments formulation, and its

total accumulated UV exposure. Depending on these factors the pigment itself can vary in shade

over time, ranging from pure white all the way to grey or even black. To suppress this effect, a

dopant may be used, such as a small amount of cobalt salts, which would be added to the

formulation. This process creates cobalt-doped zinc sulfide. The cobalt salts help to stabilize zinc

sulfide so it will not have as severe a reaction to UV exposure.

Production

Lithopone is produced by coprecipitation of barium sulfate and zinc sulfide. Most commonly

coprecipitation is effected by combining equimolar amounts of zinc sulfate and barium sulfide:

BaS + ZnSO

4

ZnS BaSO

4

This route affords a product that is 29.4 wt % ZnS and 70.6 wt % BaSO

4

. Variations exist, for

example, more ZnS-rich materials are produced when zinc chloride is added to the mixture of

zinc sulfate and barium sulfide.

[1]

Barium sulfide is produced by carbothermic reduction of barium sulfate. Zinc sulfate is obtained

from a variety of zinc products, often waste, by treatment with sulfuric acid.

Safety

Lithopone is not highly poisonous, reflecting the insolubility of the components. Barium sulfate

is used widely in medicine as a radiocontrast agent. Lithopone is allowed to be in contact with

foodstuffs in the US and Europe.

[1]

S-ar putea să vă placă și

- Worksheet 8.3 (Ionic Equation Step by Step) SolutionsDocument3 paginiWorksheet 8.3 (Ionic Equation Step by Step) SolutionsChantoni50% (2)

- Chemistry Investigatory Project XIIDocument24 paginiChemistry Investigatory Project XIISamaditya Jatar100% (11)

- Project Report On Pigment Colour For PlasticsDocument14 paginiProject Report On Pigment Colour For PlasticsEIRI Board of Consultants and PublishersÎncă nu există evaluări

- 2017-06 Refratechnik - Bricks CF SeriesDocument12 pagini2017-06 Refratechnik - Bricks CF SeriesSyed Kazam Raza100% (1)

- रासायनिक सूत्र (Chemical Formula) - Padhobeta.com Blog PDFDocument3 paginiरासायनिक सूत्र (Chemical Formula) - Padhobeta.com Blog PDFRAKISHO WORLDÎncă nu există evaluări

- Calculations-In-Unit-1 SDocument9 paginiCalculations-In-Unit-1 SabdiÎncă nu există evaluări

- Solutions For Masterbatches: Great Solutions With Small ParticlesDocument8 paginiSolutions For Masterbatches: Great Solutions With Small Particleshuy.dicÎncă nu există evaluări

- WUHAN DICT TECH Sodium LignosulfonateDocument3 paginiWUHAN DICT TECH Sodium LignosulfonatejimmyÎncă nu există evaluări

- Paints and Pigments ReportDocument7 paginiPaints and Pigments Reportnica roseÎncă nu există evaluări

- Thiele Polyester Additives Longversion 2007Document5 paginiThiele Polyester Additives Longversion 2007Tahir Mahmood0% (1)

- Water Based Surface Coatings FormulationDocument34 paginiWater Based Surface Coatings Formulationchayanun82% (11)

- Lithopone (B301 / B311 / DS) : Lithopone, C.I. Pigment White 5, Is A Mixture ofDocument1 paginăLithopone (B301 / B311 / DS) : Lithopone, C.I. Pigment White 5, Is A Mixture offrilymarinaÎncă nu există evaluări

- Variação Da Cor Da LigninaDocument45 paginiVariação Da Cor Da LigninaDouglas SantosÎncă nu există evaluări

- Colorants PlasticDocument14 paginiColorants PlasticPisit JantarasuwanÎncă nu există evaluări

- Mowital: Technical Data SheetDocument4 paginiMowital: Technical Data SheetIsidro CM100% (1)

- 125 Architectural CoatingDocument16 pagini125 Architectural CoatingwinsonecÎncă nu există evaluări

- Final LiteratureDocument17 paginiFinal Literatureak9922Încă nu există evaluări

- Inks For Printing On Plastic FilmsDocument8 paginiInks For Printing On Plastic FilmsLucas Del PretteÎncă nu există evaluări

- 3M - New-Approaches-To-The-Processing-Of-Rutile-Filled-PolyolefinsDocument32 pagini3M - New-Approaches-To-The-Processing-Of-Rutile-Filled-PolyolefinscwqccqÎncă nu există evaluări

- PigmentsDocument6 paginiPigmentsrashed141_tx100% (1)

- Fluorinated Surfactant and RepellentDocument16 paginiFluorinated Surfactant and RepellentHadi FauziÎncă nu există evaluări

- EDM - 012 Additives For Wood and Furniture Coatings PDFDocument8 paginiEDM - 012 Additives For Wood and Furniture Coatings PDFEugene PaiÎncă nu există evaluări

- Coatings: Self-Cleaning Mineral Paint For Application in Architectural HeritageDocument10 paginiCoatings: Self-Cleaning Mineral Paint For Application in Architectural HeritageMohan KumarÎncă nu există evaluări

- Hybrid Polymer PDFDocument8 paginiHybrid Polymer PDFPranshu JainÎncă nu există evaluări

- Sodium LignosulphonateDocument1 paginăSodium LignosulphonateUrvashi ModiÎncă nu există evaluări

- Pollution-Free Printing InksDocument2 paginiPollution-Free Printing InksKashif JavedÎncă nu există evaluări

- Slip AdditivesDocument2 paginiSlip AdditivesSdkmega Hh0% (1)

- Chemoxy International LTD Coalescing RangeDocument8 paginiChemoxy International LTD Coalescing RangeIliass MeskiÎncă nu există evaluări

- Presentation of Titanium DioxideDocument4 paginiPresentation of Titanium Dioxidem_turabÎncă nu există evaluări

- Polybutadiene Report PDFDocument9 paginiPolybutadiene Report PDFHamzah A. LaftaÎncă nu există evaluări

- Adsorption - Adsorption Is Defined As The Adhesion of Atoms, Ions, or Molecules To A Surface Which CreatesDocument1 paginăAdsorption - Adsorption Is Defined As The Adhesion of Atoms, Ions, or Molecules To A Surface Which CreatesSarah SanchezÎncă nu există evaluări

- Butadiene Rubber-BRDocument20 paginiButadiene Rubber-BRreilyshawnÎncă nu există evaluări

- Metal Carboxylates For Coatings - Driers / Siccatives: Carboxylate Acid TypesDocument10 paginiMetal Carboxylates For Coatings - Driers / Siccatives: Carboxylate Acid TypesRICHARD ODINDOÎncă nu există evaluări

- BU IGA Pigments For Printing InksDocument20 paginiBU IGA Pigments For Printing InkshatemÎncă nu există evaluări

- 5.3.5 Reactive Dyes: Fabric PretreatmentDocument14 pagini5.3.5 Reactive Dyes: Fabric PretreatmentRhoiieCbdxbadgerÎncă nu există evaluări

- Feature Article Stretch Tio2: Click HereDocument3 paginiFeature Article Stretch Tio2: Click HereBAYVIEW7Încă nu există evaluări

- Leucophor BMF Liq - e 101147Document11 paginiLeucophor BMF Liq - e 101147titus riadi chandraÎncă nu există evaluări

- OMG Americas - Additives BrochureDocument8 paginiOMG Americas - Additives BrochureUsama AwadÎncă nu există evaluări

- A2-BASF Lead Chromate ReplacementDocument29 paginiA2-BASF Lead Chromate ReplacementPablo Mariño MuñizÎncă nu există evaluări

- Polymers 12 02706Document17 paginiPolymers 12 02706markkkkkÎncă nu există evaluări

- Lyoprint Atp 30Document5 paginiLyoprint Atp 30Lambo SunÎncă nu există evaluări

- Flame RetardantsDocument4 paginiFlame Retardants1985krÎncă nu există evaluări

- Disperse DyesDocument8 paginiDisperse Dyessyed asim najamÎncă nu există evaluări

- Towards An Efficient and Durable Self-Cleaning Acrylic Paint Containing Mesoporous TiO2 MicrospheresDocument9 paginiTowards An Efficient and Durable Self-Cleaning Acrylic Paint Containing Mesoporous TiO2 MicrospheresSuélen Maria de AmorimÎncă nu există evaluări

- Lignosulfonate Used in Construction - GREEN AGROCHEM PDFDocument2 paginiLignosulfonate Used in Construction - GREEN AGROCHEM PDFSayyad AmirliÎncă nu există evaluări

- Use of Bituminous Material in Flexible Pavement: Laminate Building MaterialsDocument6 paginiUse of Bituminous Material in Flexible Pavement: Laminate Building MaterialsSriram DiwanaÎncă nu există evaluări

- Abstract:: Phenolic YellowingDocument8 paginiAbstract:: Phenolic YellowingMd.oaliur RahamanÎncă nu există evaluări

- Temporary Filling Materials PDFDocument6 paginiTemporary Filling Materials PDFIsak Isak IsakÎncă nu există evaluări

- LABSA ProposalDocument10 paginiLABSA ProposalMichelle MendozaÎncă nu există evaluări

- Luting CementsDocument13 paginiLuting CementsPanah SalahiÎncă nu există evaluări

- Luwax AF TypesDocument10 paginiLuwax AF TypesSunil GaikwadÎncă nu există evaluări

- Hao 2000Document58 paginiHao 2000Gerson JoelÎncă nu există evaluări

- Butyl Rubber IIRDocument3 paginiButyl Rubber IIRbentmoltheringerÎncă nu există evaluări

- Bleach & Enzyme Wet ProcessingDocument40 paginiBleach & Enzyme Wet ProcessingTasbir HasanÎncă nu există evaluări

- Toning of Black and White PaperDocument4 paginiToning of Black and White PaperShubhankar SoniÎncă nu există evaluări

- Additves For Non Aqueos OcatingsDocument4 paginiAdditves For Non Aqueos OcatingsImranAhmadÎncă nu există evaluări

- New Raw Materials For Cationic UvebDocument8 paginiNew Raw Materials For Cationic UvebArturo RamirezÎncă nu există evaluări

- Functions of Dyeing AuxiliariesDocument4 paginiFunctions of Dyeing AuxiliariesMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Pigmentos PerlescentesDocument20 paginiPigmentos PerlescentesMiguelAlegriaÎncă nu există evaluări

- Hipol 18 LV TDSDocument2 paginiHipol 18 LV TDSAbhineet ShrivastavaÎncă nu există evaluări

- La 2802-La 5000 (Revised - June 19)Document2 paginiLa 2802-La 5000 (Revised - June 19)Ivan TedjaÎncă nu există evaluări

- Basic DyesDocument4 paginiBasic DyesPiyadasa PanagodaÎncă nu există evaluări

- Environmentally Benign Approaches for Pulp BleachingDe la EverandEnvironmentally Benign Approaches for Pulp BleachingÎncă nu există evaluări

- Synthetic resins and their raw materialsDe la EverandSynthetic resins and their raw materialsÎncă nu există evaluări

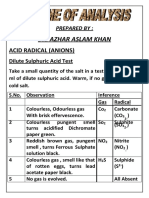

- Chemistry Salt Analysis CheatsheetDocument4 paginiChemistry Salt Analysis CheatsheetSumit Dhall74% (50)

- Process Flow DiagramDocument1 paginăProcess Flow DiagramMadhumita KumarÎncă nu există evaluări

- Balancing EqDocument6 paginiBalancing EqPol Marasigan BanzonÎncă nu există evaluări

- Unit 8 - Ionic Compound Name Triangle PuzzleDocument3 paginiUnit 8 - Ionic Compound Name Triangle PuzzleJoe SallsÎncă nu există evaluări

- Chapter 9 Review AnswersDocument4 paginiChapter 9 Review AnswersHarrison LeeÎncă nu există evaluări

- Salt Analysis-Vi Aluminum SulphateDocument3 paginiSalt Analysis-Vi Aluminum SulphateNANÎncă nu există evaluări

- Alchemists ConcordanceDocument108 paginiAlchemists Concordanceroger santosÎncă nu există evaluări

- Ionic Compound Formula Writing WorksheetDocument6 paginiIonic Compound Formula Writing WorksheetIngrid ElizabethÎncă nu există evaluări

- Excel Meracik Nutrisi-TEMPLATEDocument50 paginiExcel Meracik Nutrisi-TEMPLATELiamelvinaÎncă nu există evaluări

- N (A) Science (Chem) CHP 13b Preparation of SaltsDocument4 paginiN (A) Science (Chem) CHP 13b Preparation of SaltshamsterishÎncă nu există evaluări

- Chemistry: Solubility Rules WorksheetDocument4 paginiChemistry: Solubility Rules WorksheetAlvin AiauÎncă nu există evaluări

- Chemistry: Form 4-Chapter 8Document7 paginiChemistry: Form 4-Chapter 8Azrel YusoffÎncă nu există evaluări

- Chemicals - Formulas and Trading Names: Common Name/Trade Name Chemical Name Chemical FormulaDocument3 paginiChemicals - Formulas and Trading Names: Common Name/Trade Name Chemical Name Chemical FormulaFrendick Legaspi100% (1)

- Chemical Names and FormulasDocument8 paginiChemical Names and Formulasalbenis_batistaÎncă nu există evaluări

- Nickel SulphateDocument4 paginiNickel SulphateParvani PatankarÎncă nu există evaluări

- Recyclers GujaratDocument6 paginiRecyclers GujaratNitin KumarÎncă nu există evaluări

- Solubility Curve Practice Problems Worksheet 1Document2 paginiSolubility Curve Practice Problems Worksheet 1Unexpected TheoryÎncă nu există evaluări

- Experiment No. 7 Naming of CompoundsDocument4 paginiExperiment No. 7 Naming of CompoundsKent Kylle Andreas SaraososÎncă nu există evaluări

- Detail Cable Ladder Wall Mounting: Sedimentation TankDocument1 paginăDetail Cable Ladder Wall Mounting: Sedimentation TankjackÎncă nu există evaluări

- G10 Revised Acids, Bases and SaltsDocument81 paginiG10 Revised Acids, Bases and Saltsandrew.mooreÎncă nu există evaluări

- Ammonium CarbonateDocument3 paginiAmmonium CarbonategumtammÎncă nu există evaluări

- Formate Brine TableDocument12 paginiFormate Brine Tables v poyil100% (1)

- Solubility-Equilibria Problem Set BCM626Document10 paginiSolubility-Equilibria Problem Set BCM626Appols AlmarioÎncă nu există evaluări

- Salt AnalysisDocument20 paginiSalt AnalysisPriyansh VermaÎncă nu există evaluări

- 05-10-2012 - Reactions in Solution IntroDocument2 pagini05-10-2012 - Reactions in Solution Introamj1981Încă nu există evaluări