Documente Academic

Documente Profesional

Documente Cultură

Asgmn 1 Concrete - Hariz

Încărcat de

Muhd Hariz0 evaluări0% au considerat acest document util (0 voturi)

21 vizualizări14 paginiblablalbla

Titlu original

Asgmn 1 Concrete -Hariz

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentblablalbla

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

21 vizualizări14 paginiAsgmn 1 Concrete - Hariz

Încărcat de

Muhd Harizblablalbla

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 14

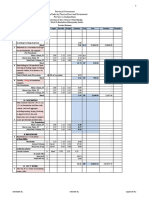

CONTENT TABLE PAGE

1.0 BASIC PROPERTIES OF CONCRETE

1

2.0 BASIC KNOWLEDGE OF CEMENT

2

3.0 STORAGE METHODS OF CEMENT

5

4.0 FINE AGGREGATE AND COARSE AGGREGATE

6

5.0 PROPERTIES OF WATER USED IN CONCRETE MIXTURE

9

6.0 BASIC CONCEPT OF CONCRETE MIX

10

7.0 FRESH CONCRETE

11

8.0 ROLE OF ADDITIVES IN CONCRETE MIXTURE

12

REFRENCES

13

1.0 Basic Properties of Concrete

Concrete is a composite construction material composed of cement and other

cementations materials such as fly ash and slag cement, aggregate (generally a coarse

aggregate made of gravels or crushed rocks such as limestone or granite, plus a fine

aggregate such as sand), water and chemical admixtures.

- Cement is a substance that produced by burning a mixture of limestone and clay.

- Fine and Coarse aggregates make up the bulk of a concrete mixture. Sand,

natural gravel and crushed stone are mainly used for this purpose

- Water used for mixing concrete should be free from substances such as silt, soil,

organic acids and other organic materials such as salt and alkali. Usually the

water used for mixing concrete is eligible drinking water or taken from approved

source

1

2.0 Basic Knowledge Of Cement

Types of cement in the market are listed below :

a) Ordinary Portland Cement @ OPC (BS 12 : 1971).

b) Rapid-Hardening Portland Cement @ RHPC (BS 12 : 1971).

c) White & Coloured Portland Cement.

d) Low Heat Portland Cement @ LHPC (BS 1370 : 1974).

e) Portland-Blast furnace Cement (BS 146 : 1973).

f) Sulphate Resisting Portland Cement (BS 4027 : 1972).

g) High Strength Portland Cement .

h) Masonry Cement (BS 5224 : 1976).

2

CHEMICAL COMPOSITION OF PORTLAND CEMENT:

Name of Compound

Chemical

Composition

Usual

Abbreviation

Tricalcium Silicate 3CaO.SiO

2

C

3

S Quick Reaction

Dicalcium Silicate 2CaO.SiO

2

C

2

S Slow Reaction

Tricalcium Aluminate 3CaO.Al

2

O

3

C

3

A

Very Quick

Reaction

Tetra-Calcium

Aluminoferrite

4CaO.Al

2

O

3

Fe

2

O

3

C

4

AF

Not Very

Important

Hydration of water in cement :

When cement, fine aggregate, coarse aggregate and water are mixed and blended,

water and cement come together through a chemical process called hydration and

produced cement paste.

This cement paste was acted as a binder/adhesive to the concrete components such

as fine (sand) or coarse aggregates.

3

Function of chemical substances in cement :

- to modify the properties of hardened concrete.

- to ensure the quality of concrete during mixing, transporting, placing, and

curing.

- to overcome certain emergencies during concrete operations.

4

3.0 Storage Methods of Cement

Storage methods in a factory

- By using silos storage method

-

Storage methods at the construction site

- In most construction projects godowns are constructed at site for storage of a

few days requirement of cement.

- cement bags should be laid on a dry platform made of wooden planks resting

over brick-masonry concrete, dry sand aggregates raised about 15 cm above

the ground level.

5

4.0 Fine and Coarse Aggregate

Criteria For Aggregates

1. Aggregate is used to describe the gravels, crushed stones & other materials

which are mixed with cement & water to make concrete.

2. Aggregate is form 75% of the volume of concrete, so chosen the suitable

materials is important & also aggregate should contain no constituent material

which might have adverse affect of the hardening of cement or the durability of

hardened cement.

Physical properties :

Normal Density Aggregate:

1. Aggregate having a specific gravity between about 2.5 and 3.0 & a bulk density

in ranges 1450 to 1750 kg/m

3

.

2. It can be classified as normal aggregate and it may be of crushed aggregate or

naturally reduced in size.

6

Light Weight Aggregate:

1. Any aggregate with a particle density of less than 200 kg/m

3

or dry loose bulk

density of less than 1200 kg/m

3

is defined as Light Weight Aggregate.

2. Subdivided into following groups:

Naturally Occurring Materials Important examples of these are pumice,

volcanic tuff, porous limestone.

Naturally Occurring Materials Which Required Further Processing Expanded

Clay, Shale & Slate and other Expanded Minerals such as Perlite & Vermiculite.

Materials Which Occur as Industrial By Products Sintered Pulverished Fuel Ash

(Fly Ash), Sintered Slate & Colliery Waste, Foamed or Expanded Blast Furnace

Slag.

Has Low Density & High Water Absorption.

Other characteristic of concrete using Light Weight Concrete are coarse surface

texture due to reduced workability, lower tensile strength, lower modulus of

elasticity (50% - 70% of the normal concrete), tendency to segregate, higher

creep and shrinkage.

High Density Aggregate:

1. Aggregate of specific gravity, that is ranging from 2.8 to 2.0 & unit weight from

2800 to 2900 kg/m

3

are used to make high density concrete.

2. Examples of aggregate: magnetite & barytes.

3. The compressive strength: 20 21 N/mm

2

.

4. The cement-aggregate ratio varies from 1:5 & 1:9 with a water-cement ratio

between 0.5 0.65. They produce dense & crack free concrete.

5. This aggregate is not suitably graded and hence, it is difficult to have adequate

workability without segregation.

Functions of aggregate in concrete.

The functions of aggregate in concrete is as a mass particle which are suitable for

resisting action of applied load, abrasion & percolation of moisture and the action of

weather.

It is also as to reduce the volume changes resulting from setting and hardening of

concrete

8

5.0 Properties of Water Used In Concrete Mixtures

QUALITY OF WATER SUITABLE FOR CONCRETE MIXTURE:

It should be free from oil.

It should be potable i.e. Fit for drinking purpose.

Free from acids or alkalis or other such organics impurities. The PH value of

water shall generally be not less than 6.

Free from iron, vegetable matter or any other substance which is likely to have

adverse effect on concrete.

Salt water is not recommended because of the present of harmful salt

FUNCTION OF WATER IN THE CONCRETE MIXTURE:

1) To enable the chemical reaction which cause setting & hardening.

2) To lubricate the mixture of gravel, sand and cement in order to facilitate placing.

3) To easy a workability for concrete mixture.

9

6.0 Basic Concept Of Concrete Mix

DEFINITION OF CONCRETE MIXTURE:

- process of selecting the appropriate constituents of concrete materials to

produce concrete mixes that can be strong, tough, has high workability and

economical.

CONCRETE MIX RATIO:

1) The use of concrete to determine the required mix ratio.

2) Normally, concrete is strong in compression stresses but weak in the tensile

stress.

3) Mix ratio usually used was 1:2:4 (cement: sand: coarse aggregate), 1:3:6 and

1:5:10 depended on its purpose and application.

4) Table below shown an example of concrete mix ratio that depends on its

purpose:

MIX RATIO USES

1:1.5:3 For Pre-Cast Concrete, Water Tank, etc

1:2:4 For Reinforced Concrete to make column, beam, wall, etc

1:3:6 For Floor, Mass Concrete, etc

1:5:10 For site wall in the trenches of hard ground and a concrete floor

under suspension

10

7.0 Fresh Concrete

Fresh concrete is a mixture of water, cement, aggregate and admixture. The

constituents materials should be uniformly distributed after mixing within the concrete

mass during handling and placing. Workability of fresh concrete, that is the ease with

which concrete is placed and consolidated

Factors influencing workability :

a) Water-Cement Ratio.

b) Aggregate-Cement Ratio.

c) Admixture/Additives Substances.

d) Shape & Fleshiness of Aggregate.

e) Time & Temperature.

11

8.0 Additives In Concrete Mixture

Types of additive :

RETARDING SUBSTANCES

ACCLERATING SUBSTANCES

SUPERPLASTICIZER SUBSTANCES

WATER REDUCING SUBSTANCES

AIR ENTRAINING SUBSTANCES

12

Refrences :

http://www.lmcc.com/concrete_news/0307/hydration_and_strength.asp

http://matse1.matse.illinois.edu/concrete/prin.html

CC 203 Chapter 1 note

13

S-ar putea să vă placă și

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Joint Waterproofing For Watertight Concrete Systems PDFDocument180 paginiJoint Waterproofing For Watertight Concrete Systems PDFasdÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Checklist For Pre-Pour ConcretingDocument1 paginăChecklist For Pre-Pour ConcretingDanish mallick100% (1)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Paraweb BBA 09-R146Document12 paginiParaweb BBA 09-R146marius1979100% (1)

- IRS Concrete Bridge Code SummaryDocument151 paginiIRS Concrete Bridge Code SummaryHimanshu Gupta0% (1)

- ADVANCED CONSTRUCTION RAFT FOUNDATIONDocument28 paginiADVANCED CONSTRUCTION RAFT FOUNDATIONAashi Gupta100% (1)

- Safety Requirements for ScaffoldsDocument16 paginiSafety Requirements for ScaffoldschassasÎncă nu există evaluări

- Explanation of One Way and Two Way Slab ActionDocument17 paginiExplanation of One Way and Two Way Slab Actionxckwzr100% (4)

- Building Survey Report SampleDocument91 paginiBuilding Survey Report SampleabcÎncă nu există evaluări

- Trinity Drainage Construction Works: S/No Item QtyDocument15 paginiTrinity Drainage Construction Works: S/No Item QtyNonsoufo ezeÎncă nu există evaluări

- Cement Combinations For Durable ConcreteDocument18 paginiCement Combinations For Durable Concretetakis.papadopoulos6672Încă nu există evaluări

- Fe Ce 511 Prestressed ConcreteDocument6 paginiFe Ce 511 Prestressed ConcreteJeana Rick GallanoÎncă nu există evaluări

- ITA-AFTES - Guideline For The Design of Shield Tunnel Lining PDFDocument29 paginiITA-AFTES - Guideline For The Design of Shield Tunnel Lining PDFAnonymous PsEz5kGVaeÎncă nu există evaluări

- Thesis Shokrollah Zare - Prediction Model and Simulation Tool For Time and Cost of Drill and Blast Tunnelling PDFDocument139 paginiThesis Shokrollah Zare - Prediction Model and Simulation Tool For Time and Cost of Drill and Blast Tunnelling PDFMinKoan Kim100% (1)

- Brochure Waterproofing Sikaproof GCC Low PDFDocument16 paginiBrochure Waterproofing Sikaproof GCC Low PDFHavietz Akbar AlfariziÎncă nu există evaluări

- PP20063 InternshipDocument22 paginiPP20063 InternshipGaurav Dhembare100% (2)

- CHTT CuoghiDocument11 paginiCHTT CuoghiArtur HoxhaÎncă nu există evaluări

- Influence of Supervision On Labour Productivity OnDocument19 paginiInfluence of Supervision On Labour Productivity OnAnonymous 94TBTBRksÎncă nu există evaluări

- Hydroflex Water Isolation ProductsDocument24 paginiHydroflex Water Isolation ProductssherzodÎncă nu există evaluări

- Bibaha Mandap 1Document3 paginiBibaha Mandap 1Anu PathakÎncă nu există evaluări

- Study On The Effect of Glass Fibre Reinforced Concrete and Concrete Tiles Reinforced ConcreteDocument8 paginiStudy On The Effect of Glass Fibre Reinforced Concrete and Concrete Tiles Reinforced ConcreteIJRASETPublicationsÎncă nu există evaluări

- Mix Design Details For 40 MPaDocument1 paginăMix Design Details For 40 MPaTaposh PaulÎncă nu există evaluări

- Fosroc Nitoflor FC550: Constructive SolutionsDocument4 paginiFosroc Nitoflor FC550: Constructive SolutionsVincent JavateÎncă nu există evaluări

- G3A Barkan S MethodDocument38 paginiG3A Barkan S MethodHsein WangÎncă nu există evaluări

- Global ConcreteDocument9 paginiGlobal ConcreteCHHABIRANI TUDUÎncă nu există evaluări

- Mrsptu Ug Open Electives-Ii 2016 Batch Onwards Updated On 17.09.2019Document25 paginiMrsptu Ug Open Electives-Ii 2016 Batch Onwards Updated On 17.09.2019jellymaniÎncă nu există evaluări

- Load DistributionDocument44 paginiLoad Distributionሽታ ዓለሜÎncă nu există evaluări

- 0.20100628 TDS - OxidePigments-GreefieldDocument2 pagini0.20100628 TDS - OxidePigments-GreefieldGreefield JasonÎncă nu există evaluări

- SikaLatex 118Document2 paginiSikaLatex 118Shaun WongÎncă nu există evaluări

- COP Certificate of Payment, MOP - Memorandum of Payment Calculation SheetDocument50 paginiCOP Certificate of Payment, MOP - Memorandum of Payment Calculation Sheetsayali pardhiÎncă nu există evaluări

- Specific Requirements & Scope of Work For RCC PilingDocument38 paginiSpecific Requirements & Scope of Work For RCC PilingTauqueerAhmadÎncă nu există evaluări