Documente Academic

Documente Profesional

Documente Cultură

Application Story: Insulation of Commercial Walk in Freezers Checked With Thermal Imaging

Încărcat de

mariusTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Application Story: Insulation of Commercial Walk in Freezers Checked With Thermal Imaging

Încărcat de

mariusDrepturi de autor:

Formate disponibile

www.flir.

com

APPLICATION STORY

In essence inspecting walk in freezers, cold

rooms and other types of large commercial

refrigeration units is in essence very similar

to building insulation inspections, explains

Dennis van Est, thermographer at the Uden,

Netherlands, based Thermografisch en

Adviesbureau Uden. The only difference

is the direction of the heat. With building

insulation inspections we generally try to

detect heat leaking from the inside of

the building to the outside air, but with

refrigeration units we want to detect heat

leaking inwards. But the mechanism of

heat leakage is just the same.

The thermography consultant is called out

to Leeuwarden to inspect two walk in

freezers. If there is any heat leakage this

can cause a huge unnecessary expenditure

on energy bills says Van Est. Detecting

these heat leaks in an early stage allows

the owner to fix the insulation defects,

preventing soaring energy bills. With

the energy prices continually rising, the

demand for walk in refrigerator and freezer

inspections is also growing.

Heat bridges

Van Est finds insulation problems in many

of the walk in freezers and cold rooms

he is hired to inspect. This particular

freezer which Im inspecting at the

moment seems to be very well insulated,

but youd be surprised to see how often

Insulation of commercial walk in freezers

checked with thermal imaging

Enterprises that need to store large amounts of goods at temperatures well below the freezing

point of water often install large walk in freezers on their premises. These large freezers

are capable of keeping whole rooms full of these goods, usually foodstuffs, at very low

temperatures. There is just one downside: cooling requires a lot of energy. It is therefore very

important that no outside heat leaks in. To make sure that the freezers insulation is working

properly, thermographers inspect the insulation material with a thermal imaging camera.

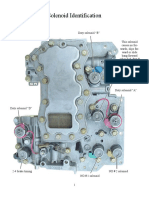

Improper welding has caused heat leakage in this sec-

tion of the freezer insulation, as shown in this thermal

image

Highly sensitive, accurate and calibrated to -40 C the

FLIR P640 thermal imaging is the perfect tool for freezer

insulation inspections.

APPLICATION STORY

For more information about thermal imaging

cameras or about this application,

please contact:

FLIR Commercial Systems B.V.

Charles Petitweg 21

4847 NW Breda - Netherlands

Phone : +31 (0) 765 79 41 94

Fax : +31 (0) 765 79 41 99

e-mail : flir@flir.com

www.flir.com

newly built refrigeration units have a

faulty construction. Sometimes the joints

between the insulation panels are not

protected properly, creating heat bridges.

This can cause a lot of unnecessary energy

consumption. In other cases older units

might develop insulation faults over time

due to wear. In both scenarios the best

way to detect these insulation defects is

by using thermal imaging cameras. Other

methods, like spot pyrometers and such,

really are not an option with this type of

inspection. It is simply too easy to miss

problems that you can relatively easily

detect using thermal imaging.

To Van Est the quality of the thermal imaging

camera is crucial for these inspections.

You need high quality thermal images to

be able to detect warmth bridges in the

freezer insulation. The thermal sensitivity

and accuracy are both very important, but

to me the image resolution is also crucial.

You need to be able to interpret what

T

8

2

0

4

4

4

{

E

N

_

u

k

}

_

A

you see in the thermal image and if you

are using a thermal imaging camera that

produces thermal images at a resolution

below the current industry standard of

640x480 pixels then you are missing a lot

of information which you need in order to

draw the right conclusions.

Excellent tool

The FLIR P640 thermal imaging camera is an

excellent tool for these inspections, according

to Van Est. With an image resolution of

640x480, a thermal sensitivity of 30 mK

(0.03 C) and an accuracy of 2 C or 2%

of the reading the thermal images produced

by the FLIR P640 thermal imaging camera

are of exceptionally high quality. This thermal

imaging camera model is also very user

friendly. Especially if you compare it with the

cameras of other manufacturers the image

quality and user friendliness of the design

are far superior. The ergonomic design is also

very important to me because you need to

prevent back aches and arm strain.

Another important thermal imaging camera

feature for this particular application is the

calibration range, says to Van Est. The FLIR

P640 thermal imaging camera is calibrated

to a minimum temperature of -40 C.

This is very important to allow accurate

temperature measurements. Most freezers

are kept at a temperature between -20 C

and -30 C. However, even at temperatures

just below the official calibration range, such

as some exceptionally cold freezers that cool

down their contents to -50 C or even -60 C,

the FLIR P640 thermal imaging camera is still

quite capable of visualizing insulation leaks.

The importance of training

A good camera is just half of the solution,

however. Although the quality of the

camera is extremely important, the

knowledge and skill of the thermographer

is just as important, says Ralf Grispen,

commercial manager at Thermografisch en

Adviesbureau Uden. We therefore make

sure that all of our inspectors have at

least a level I thermography certificate from

the FLIR Infrared Training Center (ITC) and

preferably level II as well. For us this is one

of the reasons why we chose FLIR: not only

are the thermal imaging cameras of the

highest quality; the accompanying training

offered by the ITC is also very good.

High quality thermal imaging cameras and

good training come at a price, but they are

definitely worth the money, concludes

Van Est. We have several FLIR cameras

and they are used for a wide variety of

applications, including inspections of

building insulation, industrial maintenance

inspections, HVAC systems, airplane

composite materials water ingress and

refrigeration units insulation inspections.

In fact these cameras are almost constantly

on the move from site to site."

This thermal image shows an example of improperly connected joints between insulation panels, causing heat leakage.

This thermal image shows heat leakage due to

improperly connected joints between insulation panels,

causing a lot of unnecessary energy consumption.

S-ar putea să vă placă și

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionDe la EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionEvaluare: 4.5 din 5 stele4.5/5 (3)

- Petroval EN PDFDocument4 paginiPetroval EN PDFAnonymous Wu6FDjbÎncă nu există evaluări

- Application Story: Inspecting Roof Mounted Solar Panels With Thermal ImagingDocument2 paginiApplication Story: Inspecting Roof Mounted Solar Panels With Thermal ImagingAnonymous Wu6FDjbÎncă nu există evaluări

- Digital LED Thermometer with Microcontroller AVR ATtiny13De la EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Evaluare: 5 din 5 stele5/5 (1)

- Thermal Imaging For Building Diagnostics: Discover A Wide Variety of ApplicationsDocument40 paginiThermal Imaging For Building Diagnostics: Discover A Wide Variety of ApplicationsVasile SilionÎncă nu există evaluări

- Through Flame Thermal CamerasDocument4 paginiThrough Flame Thermal CamerasAndres GmoÎncă nu există evaluări

- Thermal Imaging For Automation / Process Control: Discover A Wide Variety of ApplicationsDocument36 paginiThermal Imaging For Automation / Process Control: Discover A Wide Variety of ApplicationsQuod Erat DemonstrandumÎncă nu există evaluări

- Thermal ImagingDocument48 paginiThermal ImagingMariam RadankeÎncă nu există evaluări

- ThermoKing Transport FrigoriferDocument2 paginiThermoKing Transport FrigoriferayviwurbayviwurbÎncă nu există evaluări

- Application Story: Thermal Imaging Inspections of Roof-Mounted Solar PanelsDocument2 paginiApplication Story: Thermal Imaging Inspections of Roof-Mounted Solar PanelsAnonymous Wu6FDjbÎncă nu există evaluări

- Temperature Sensing Instrumentation For Glass ManufacturingDocument2 paginiTemperature Sensing Instrumentation For Glass ManufacturingaslamÎncă nu există evaluări

- Application Story: Solartechnik Stiens Uses FLIR Thermal Imaging Cameras To Make Sure Their Solar Panels Operate ProperlyDocument4 paginiApplication Story: Solartechnik Stiens Uses FLIR Thermal Imaging Cameras To Make Sure Their Solar Panels Operate ProperlyAnonymous Wu6FDjbÎncă nu există evaluări

- PM Brochure - 7038 Rev2 WebDocument20 paginiPM Brochure - 7038 Rev2 WebRommel LealÎncă nu există evaluări

- Orglmeister - Fire Prevention PDFDocument2 paginiOrglmeister - Fire Prevention PDFDavis CahuaÎncă nu există evaluări

- Applications For Fixed Mounted Infrared Camera SystemsDocument12 paginiApplications For Fixed Mounted Infrared Camera SystemsDhanasekaran RÎncă nu există evaluări

- Infrared Thermography at RefineriesDocument2 paginiInfrared Thermography at Refineriesayviwurbayviwurb100% (1)

- Thermal Imaging Tech ResourceDocument20 paginiThermal Imaging Tech Resourceskimav86100% (1)

- Article 7-1-2006 RobinsonDocument18 paginiArticle 7-1-2006 RobinsonAnonymous Wu6FDjbÎncă nu există evaluări

- Thermal Imaging Cameras For Optical Gas Imaging (OGI) and Furnace InspectionsDocument28 paginiThermal Imaging Cameras For Optical Gas Imaging (OGI) and Furnace Inspectionsvasile_silionÎncă nu există evaluări

- Hot Rolling Mill IndustryDocument12 paginiHot Rolling Mill IndustryJanuar Kurniawan KurniawanÎncă nu există evaluări

- Fluke AplicacionesDocument3 paginiFluke AplicacionesSergio SalÎncă nu există evaluări

- Fixed Thermal Imaging Camera Systems For Process Measurement & ControlDocument5 paginiFixed Thermal Imaging Camera Systems For Process Measurement & ControlVipul GuptaÎncă nu există evaluări

- Thermal Imaging For Building Diagnostics MraDocument39 paginiThermal Imaging For Building Diagnostics MraKerley Anderson AndradeÎncă nu există evaluări

- Technical Note: Cooled Vs Uncooled Thermal ImagingDocument4 paginiTechnical Note: Cooled Vs Uncooled Thermal ImagingGallegos MOÎncă nu există evaluări

- Thermal Camera Implementation For Crack Detection in Pressure VesselsDocument5 paginiThermal Camera Implementation For Crack Detection in Pressure VesselsVinodÎncă nu există evaluări

- Ikaros ENDocument2 paginiIkaros ENAnonymous Wu6FDjbÎncă nu există evaluări

- Thermo-Act: Automatic Fire Extinguishing SystemDocument8 paginiThermo-Act: Automatic Fire Extinguishing SystemelrajilÎncă nu există evaluări

- Electrical Inspections With Thermal Imaging: ServicesDocument8 paginiElectrical Inspections With Thermal Imaging: ServicesV.g.MohanBabuÎncă nu există evaluări

- 11609EN WHY ThermographyDocument2 pagini11609EN WHY Thermographyg_periwal_pune9635Încă nu există evaluări

- Flir 12 Things To Consider Before Buying An Infrared CameraDocument19 paginiFlir 12 Things To Consider Before Buying An Infrared Cameramanu_chatÎncă nu există evaluări

- FLIR AutomationBrochure - ENDocument16 paginiFLIR AutomationBrochure - ENimman4468Încă nu există evaluări

- Fabrication of Industrial Thermocouple PDFDocument2 paginiFabrication of Industrial Thermocouple PDFMarvinÎncă nu există evaluări

- Infrared ThermographyDocument15 paginiInfrared ThermographyreurriÎncă nu există evaluări

- Gaumer Process Heaters, Systems, and ControlsDocument43 paginiGaumer Process Heaters, Systems, and ControlskmpoulosÎncă nu există evaluări

- 12 Things To Consider Before Buying An Infrared Camera: A Guide For Investing in InfraredDocument19 pagini12 Things To Consider Before Buying An Infrared Camera: A Guide For Investing in InfraredUchuk PabbolaÎncă nu există evaluări

- 12 Things To Consider Before Buying An Infrared Camera: A Guide For Investing in InfraredDocument16 pagini12 Things To Consider Before Buying An Infrared Camera: A Guide For Investing in InfraredzilikonÎncă nu există evaluări

- FLIR - Mill Ladle Refractory MonitoringDocument2 paginiFLIR - Mill Ladle Refractory MonitoringDavis Cahua100% (1)

- One-Stop Shop For Process Automation and Solutions: Metal IndustryDocument6 paginiOne-Stop Shop For Process Automation and Solutions: Metal IndustryknchnÎncă nu există evaluări

- Alvium Cameras - Heat DissipationDocument5 paginiAlvium Cameras - Heat DissipationKarina Karmen KosaÎncă nu există evaluări

- Thermographic Testing PresentationDocument40 paginiThermographic Testing PresentationChandraSathwickÎncă nu există evaluări

- Application Story: Mill Ladle Refractory MonitoringDocument2 paginiApplication Story: Mill Ladle Refractory MonitoringAnonymous Wu6FDjbÎncă nu există evaluări

- Thermographic Imaging InspectionsDocument3 paginiThermographic Imaging InspectionsAlamÎncă nu există evaluări

- Acero TorpedoDocument1 paginăAcero TorpedoEsmeralda de MarvalÎncă nu există evaluări

- 2008-026 DenioDocument8 pagini2008-026 DenioalexanderÎncă nu există evaluări

- Pyrometer DissertationDocument4 paginiPyrometer DissertationBuyAPhilosophyPaperUK100% (1)

- Thermograpy TestDocument9 paginiThermograpy TestabcrathodÎncă nu există evaluări

- Industrial Guidebook - Camera FlirDocument48 paginiIndustrial Guidebook - Camera FlirPaulo Uchiha100% (1)

- Thermal Imaging For Science / R&D: Discover A Wide Variety of ApplicationsDocument44 paginiThermal Imaging For Science / R&D: Discover A Wide Variety of ApplicationsGallegos MOÎncă nu există evaluări

- 1551A Ex/1552A Ex Intrinsically Safe "Stik" Thermometer: The New "Gold Standard" of Industrial Temperature CalibrationDocument8 pagini1551A Ex/1552A Ex Intrinsically Safe "Stik" Thermometer: The New "Gold Standard" of Industrial Temperature CalibrationSasa MatanovicÎncă nu există evaluări

- FIAT Inprotec - Induction Bonding MonitoringDocument2 paginiFIAT Inprotec - Induction Bonding MonitoringDavis CahuaÎncă nu există evaluări

- Article 3 2004 WeigleDocument8 paginiArticle 3 2004 Weigleuamiranda3518Încă nu există evaluări

- The Expert GuidebookDocument16 paginiThe Expert Guidebookescuadrian9043Încă nu există evaluări

- An-1041 Mounting Procedures For Very High Power RF TransistorsDocument2 paginiAn-1041 Mounting Procedures For Very High Power RF TransistorsEdward YanezÎncă nu există evaluări

- Beyond The Usual Applications For Infrared ThermographyDocument4 paginiBeyond The Usual Applications For Infrared Thermographypartho143Încă nu există evaluări

- Diamond DSC ManualDocument8 paginiDiamond DSC ManualEduardo Silva Do NascimentoÎncă nu există evaluări

- Ikaros EN PDFDocument2 paginiIkaros EN PDFNiraj KulkarniÎncă nu există evaluări

- Plugin EFD CorporateDocument22 paginiPlugin EFD CorporateskluxÎncă nu există evaluări

- 2 1 2008 James RefomerDocument16 pagini2 1 2008 James RefomerVipul GuptaÎncă nu există evaluări

- Plasma TV SMPS TroubleshoutingDocument5 paginiPlasma TV SMPS TroubleshoutingmindjokerÎncă nu există evaluări

- About Indian Institute of Technology KanpurDocument54 paginiAbout Indian Institute of Technology KanpurPooja PundeerÎncă nu există evaluări

- A-Class Mark II: Print Engines For ApplicatorsDocument25 paginiA-Class Mark II: Print Engines For ApplicatorsJeffery ReynoldsÎncă nu există evaluări

- Predictive Analytics in Warranty ClaimsDocument6 paginiPredictive Analytics in Warranty ClaimsRaj SharmaÎncă nu există evaluări

- About Procurement ConsultingDocument3 paginiAbout Procurement ConsultingBiswadeep SarkarÎncă nu există evaluări

- Mba Cet 2018Document2 paginiMba Cet 2018Aarav AroraÎncă nu există evaluări

- Leading Architect and Enabler in Digital SocietyDocument31 paginiLeading Architect and Enabler in Digital SocietyRifki NugrahaÎncă nu există evaluări

- Android User GuideDocument15 paginiAndroid User GuideAnonymous 1Wb6JCkÎncă nu există evaluări

- NTS - Math Notes & Mcqs Solved Grade 8thDocument10 paginiNTS - Math Notes & Mcqs Solved Grade 8thZahid KumailÎncă nu există evaluări

- Maintenance and Repair Instructions TM 124/11: Spring-Applied Sliding Caliper Brake FSG110 With Hub CenteringDocument11 paginiMaintenance and Repair Instructions TM 124/11: Spring-Applied Sliding Caliper Brake FSG110 With Hub CenteringNik100% (1)

- FSP 851Document3 paginiFSP 851RICHIÎncă nu există evaluări

- 4 Ataxle PDFDocument22 pagini4 Ataxle PDFAnonymous XTkln6H100% (1)

- Electrical Power Systems Wadhwa 15Document1 paginăElectrical Power Systems Wadhwa 15ragupaÎncă nu există evaluări

- SP2000 COD Testkits 2014Document5 paginiSP2000 COD Testkits 2014Andres FalmacelÎncă nu există evaluări

- Director Talent Acquisition HR in Fargo ND Resume Tom FennellDocument2 paginiDirector Talent Acquisition HR in Fargo ND Resume Tom FennellTomFennellÎncă nu există evaluări

- D20S-7 Sb1159e01 PDFDocument678 paginiD20S-7 Sb1159e01 PDFGORDÎncă nu există evaluări

- ANTENASDocument10 paginiANTENASGreo HernandezÎncă nu există evaluări

- Founder-CEO Succession at Wily TechnologyDocument12 paginiFounder-CEO Succession at Wily TechnologyMayank Saini100% (1)

- Ingrid Olderock La Mujer de Los Perros by Nancy GuzmnDocument14 paginiIngrid Olderock La Mujer de Los Perros by Nancy GuzmnYuki Hotaru0% (3)

- Account Statement: Karthikeyan S 47asumugaflats, Kamarajarstreet Oragadam Ambattur, Ambattur ChennaiDocument2 paginiAccount Statement: Karthikeyan S 47asumugaflats, Kamarajarstreet Oragadam Ambattur, Ambattur ChennaiKarthikeyan MallikaÎncă nu există evaluări

- Acer Computers Aspire 9300 Aspire 9300 Aspire 7000 Service Guide Ae6e07aDocument143 paginiAcer Computers Aspire 9300 Aspire 9300 Aspire 7000 Service Guide Ae6e07acvotechnicalsÎncă nu există evaluări

- Yama Buggy 400cc Parts List and SchematicsDocument50 paginiYama Buggy 400cc Parts List and Schematicsgeorgemesfin@gmailÎncă nu există evaluări

- Chapter 1: INTRODUCTION: 1.1 BackgroundDocument5 paginiChapter 1: INTRODUCTION: 1.1 BackgroundAhsan azizÎncă nu există evaluări

- Aj 245 LTDocument1 paginăAj 245 LTHernan B.Încă nu există evaluări

- Chapter 6 PDFDocument26 paginiChapter 6 PDFDayang Azraa AfeefaaÎncă nu există evaluări

- Design of Staircase by Limit State Method UNIT-5: C.risers Minus OneDocument5 paginiDesign of Staircase by Limit State Method UNIT-5: C.risers Minus OneVAIJAYANTHI PÎncă nu există evaluări

- Installation Manual - BM-BE - 1212Document2 paginiInstallation Manual - BM-BE - 1212Lit Phen TuÎncă nu există evaluări

- Building A Gate Way Service Using A SEGW TransactionDocument10 paginiBuilding A Gate Way Service Using A SEGW Transactionswamy_yalamanchiliÎncă nu există evaluări

- Factors Affecting Beam StrengthDocument2 paginiFactors Affecting Beam StrengthkalpanaadhiÎncă nu există evaluări

- 19A Time Collection Device Integration Activity Guide PDFDocument78 pagini19A Time Collection Device Integration Activity Guide PDFAliya AmarÎncă nu există evaluări

- A Welder’s Handbook to Robotic ProgrammingDe la EverandA Welder’s Handbook to Robotic ProgrammingEvaluare: 5 din 5 stele5/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDe la EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseEvaluare: 5 din 5 stele5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDe la EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionEvaluare: 4.5 din 5 stele4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1De la EverandBuilding Construction Technology: A Useful Guide - Part 1Evaluare: 4 din 5 stele4/5 (3)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (242)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftDe la EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftEvaluare: 5 din 5 stele5/5 (5)

- Field Guide for Construction Management: Management by Walking AroundDe la EverandField Guide for Construction Management: Management by Walking AroundEvaluare: 4.5 din 5 stele4.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEDe la EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEEvaluare: 4 din 5 stele4/5 (1)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsDe la EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsÎncă nu există evaluări

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Civil Engineer's Handbook of Professional PracticeDe la EverandCivil Engineer's Handbook of Professional PracticeEvaluare: 4.5 din 5 stele4.5/5 (2)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishDe la EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishEvaluare: 4 din 5 stele4/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- How to Build a Tiny Portable House: With Plans and InstructionsDe la EverandHow to Build a Tiny Portable House: With Plans and InstructionsEvaluare: 4 din 5 stele4/5 (1)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!De la EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Evaluare: 4 din 5 stele4/5 (3)

- Markup & Profit: A Contractor's Guide, RevisitedDe la EverandMarkup & Profit: A Contractor's Guide, RevisitedEvaluare: 5 din 5 stele5/5 (11)

- Shipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!De la EverandShipping Container Homes: How to build a shipping container home, including plans, cool ideas, and more!Încă nu există evaluări

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDe la EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureEvaluare: 4.5 din 5 stele4.5/5 (2)