Documente Academic

Documente Profesional

Documente Cultură

Paper 294204

Încărcat de

userscribd20110 evaluări0% au considerat acest document util (0 voturi)

25 vizualizări10 paginiloss

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentloss

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

25 vizualizări10 paginiPaper 294204

Încărcat de

userscribd2011loss

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 10

GCPS 2013 __________________________________________________________________________

Management of Safety Critical Elements as a Base for Risk

Management of Major Accident Hazards

Mariana Bahadian Bardy

Det Norske Veritas

Rua Sete de Setembro 111/12

th

floor

mariana.bardy@dnv.com

Flvio Luiz Barros Diniz

Det Norske Veritas

flavio.diniz@dnv.com

Paula Silveira

Det Norske Veritas

paula.silveira@dnv.com

Prepared for Presentation at

American Institute of Chemical Engineers

2013 Spring Meeting

9th Global Congress on Process Safety

San Antonio, Texas

April 28 May 1, 2013

GCPS 2013 __________________________________________________________________________

UNPUBLISHED

AIChE shall not be responsible for statements or opinions contained

in papers or printed in its publications

GCPS 2013 __________________________________________________________________________

Management of Safety Critical Elements as a Base for Risk

Management of Major Accident Hazards

Mariana Bahadian Bardy

Det Norske Veritas

Rua Sete de Setembro 111/12

th

floor

mariana.bardy@dnv.com

Flvio Luiz Barros Diniz

Det Norske Veritas

flavio.diniz@dnv.com

Paula Silveira

Det Norske Veritas

paula.silveira@dnv.com

Keywords: safety critical element, barrier, major accident hazard

Abstract

Considering the already established relevance of barriers to avoid Major Accidents, the objective

of this paper is to present a methodology for management of Safety Critical Elements (SCE),

from the identification of them, definition of relevant importance to each activity performed by

the installation and establishing alternatives and contingencies for the failure or absence of the

SCE. The proposed methodology, adapted from common use methodologies from Offshore

Industry to Process Industries, is developed in 5 steps, being Step 1 the use of a Hazard

Identification technique and indication of Major Accident Hazards. Following on Step 2 bowtie

diagrams are developed for the MAH and SCE are identified. The SOOB Summary of

Operational Boundaries on Step 3 identifies the activities that may or may not proceed or caution

is applied in the case the SCE is defeat and on Step 4 a Contingency Plan is develop to maintain

operation for the cases indicated on the SOOB that operation may not proceed or proceed with

caution. Finally, on Step 5, definition of prioritization of maintenance and inspection activities

shall be in place for each SCE, including preventive maintenance routines, inspections routines

and definition of spares, where applicable. This methodology can help on the identification of

gaps and management of critical elements and consequently improving the performance of safety

systems increasing their availability.

1. Introduction and background

Recent accidents have indicated the importance of safety barriers on management of major

accidents, reducing its likelihood or minimizing consequence. Buncefield, Texas City and

Macondo, just to indicate some, have stated in their accident investigation reports the failure of

safety barriers or non-existence of adequate ones as potential causes for the major accident

occurrence.

GCPS 2013 __________________________________________________________________________

This paper presents a methodology for management of Safety Critical Elements (SCE), adapted

from common use methodologies from Offshore Industry to Process Industries, from the

identification of them, definition of relevant importance to each activity performed by the

installation and establishing alternatives and contingencies for the failure or absence of the SCE.

Several reference have definitions of SCE and how they must be managed, as NORSOK[1], that

indicated that Safety Critical Equipment is equipment that shall be in operation to ensure escape,

evacuation and /or to prevent escalation.

According to HSE UK[2] any structure, plant, equipment, system (including computer

software) or component part whose failure could cause or contribute substantially to a major

accident is safety critical, as is any which is intended to prevent or limit the effect of a major

accident.

For this paper, SCE is defined as indicated by HSE UK, as being the Barriers that can avoid or

mitigate Major Accident Hazards.

2. Description of Methodology

For the objective of systematic management of Safety Critical Elements, the methodology

outlined in Figure 1 is proposed, covering the 5 steps described below.

Figure 1 Methodology for SCE Management

2.1 Step 1 Hazard Identification

The first step is to identify the accidental scenarios from the specific process under analysis. For

that purpose, it is proposed to perform a Process Hazard Analysis (PHA) for identification of

accidental scenarios and classification according to a Risk Matrix, defined by each company

according to its risk management process. Figure 2 represents an example of spreadsheet to be

applied for the PHA.

GCPS 2013 __________________________________________________________________________

Process Hazard Analysis (PHA)

System: Hazard/Event Group:

1.Hazard 2.Causes 3.Effects 4.Freq 5.Sev 6.Risk 7.Safeguards

8.Final

Freq

9.Final

Sev

10.Final

Risk

11.Recommendations 12.#

1

2

3

Figure 2 Example of PHA Spreadsheet

The spreadsheet has 12 columns, and two classification of the risk for each scenario. Columns 4,

5 and 6 have the classification without considering existing safety barriers for the scenario. The

barriers are listed on Column 7 and Columns 8, 9 and 10 indicate the classification of the risk,

considering the existence of the barriers and these are operating or ready to operate when needed.

For the classification of severity, likelihood/frequency and risk, a risk matrix shall be used,

representing the risk tolerability of the company. An example of risk matrix is on Figure 3,

extract from ISO 17776:2000 [3].

Figure 3 Example of Risk Matrix

GCPS 2013 __________________________________________________________________________

Note that this matrix has 5 different severity ratings and analyze four different effects: people,

assets, environment and reputation. A common approach to define Major Accidental Hazards

(MAH) is to consider whose with highest consequence classification, as the ones classified with

Severity Category 5, from the matrix indicated on Figure 3, that represents multiple fatalities as

impact on people, extensive damage for environment, massive effect to assets and major

international impact on reputation.

The main advantage to select the MAH to go to Bowtie, as described above, is that the barriers

related to those events can be clearly identified and consequently be managed properly and in a

focused way. On the other hand, when there is no distinction between MAH and other scenarios,

with lower damage potential, the number of barriers to be managed increase reducing the focus

on the major impact scenarios MAH.

Note that some safety barriers are normally identified on this PHA and shall be reviewed and

detailed on the next steps.

2.1 Step 2 Development of Bowties

The following step of this methodology is to develop bowtie diagrams for each of the MAH, or

combination of MAH, if applicable, as exemplified in Figure 4. The BowTie methodology is

designed to give a picture of the risks, to help people understand the relationship between the

risks and organizational events and to identify where barriers in place can act, on the prevention

or on the mitigation and consequently give a better overview if those are enough to mitigate the

risks related to the MAH.

Figure 4 Example of Bowtie

With the use of multidisciplinary team from the company, starting from a Top Event, localized in

the center of the diagram, causes, preventive barriers, consequences and mitigating barriers are

identified. Following, each barrier, preventive or mitigating, is classified as:

Critical: essential barrier to avoid the causes or associated consequences.

Non-critical: barrier that reduces likelihood or minimize consequence, but does not avoid

the occurrence of the top event or associated effects.

GCPS 2013 __________________________________________________________________________

Third Party: barriers, critical or not, that are not under the company responsibility for

management.

Also responsible person or function can be indicated on the bowtie for each barrier. The list of

SCE are composed by those barriers classified as critical for each bowtie.

The Safety Critical Elements (SCE) can be an Equipment, System or Procedure. In the example

presented in Figure 4, for Top Event Large Release of Flammable Gas, from Compression

System, the following barriers were classified as Safety Critical Equipment or System:

Safety interlocks

PSVs

Filter Pressure Drop Indication

Injection of Corrosion Inhibitor

Gas and Fire Detection System

Fire Fighting System

CFTV

The other critical barriers such as Mechanical Integrity Program and Emergency Planning are

considered as Safety Critical Procedure.

All of those critical elements, equipment, systems and procedures, shall be managed but

specially for the equipment and systems contingency procedures shall apply considering they are

operating under degraded conditions or out of operation. As part of this scope a Summary of

Operations Boundaries (SOOB) analysis is carried out as stated below.

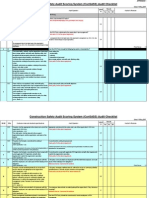

2.3 Step 3 Development of SOOB

The Step 3 of this methodology consists in developing the Summary of Operations Boundaries -

SOOB analysis. This is based on a matrix which crosses main operations and activities with the

Operational Risk Factors. Operational Risk Factors includes controls, identified in the BowTie

analysis, under reduced effectiveness and risk factors such as severe weather/sea conditions. The

matrix is completed row by row by reviewing all combinations.

The main objective is to examine if operations can be permitted or prohibited when certain

controls have been defeated or running under reduced effectiveness and examine if operations

can proceed in the case of occurrence of external factors that can potentially influence the risk of

doing these operations e.g. severe weather conditions.

This will distinguish when a stop work is applied or if that shall be a proceed with caution

condition, as indicated by IADC[4]. A traffic light system may be applied, indicating:

Red: stop the work or do not proceed;

Yellow: evaluate conditions, perform risk analysis or implement additional protection;

Green: continuous normal operation.

GCPS 2013 __________________________________________________________________________

Note that the activities will vary depending on the type of installation. Some examples are:

loading or unloading of trucks or railcars;

operation above normal conditions;

increase of capacity;

confined space entry;

working at height.

An example of analysis is for Gas Detection System failure, it is allowed to proceed with works

at heights and confined space entry; with caution, requiring additional evaluation normal

operation and loading/unloading; and not permitted operation above normal condition, increase

of capacity and hot work.

Operations vs.

Operational Risk Factors

N

o

r

m

a

l

P

r

o

d

u

c

t

i

o

n

O

p

e

r

a

t

i

o

n

A

b

o

v

e

N

o

r

m

a

l

C

o

n

d

i

t

i

o

n

s

I

n

c

r

e

a

s

e

o

f

C

a

p

a

c

i

t

y

L

o

a

d

i

n

g

/

U

n

l

o

a

d

i

n

g

T

r

u

c

k

L

o

a

d

i

n

g

/

U

n

l

o

a

d

i

n

g

R

a

i

l

c

a

r

C

o

n

f

i

n

e

d

S

p

a

c

e

E

n

t

r

y

H

o

t

W

o

r

k

W

o

r

k

i

n

g

a

t

H

e

i

g

h

t

s

Safety interlocks RA X X RA RA P RA RA

PSVs RA X X RA RA P P RA

Filter Pressure Drop Indication RA RA RA NA NA NA NA NA

Injection of Corrosion Inhibitor RA RA RA NA NA NA NA NA

Gas and Fire Detection System RA X X RA RA P X P

CFTV

P RA RA RA RA P P P

P- Permitted

RA Perform Risk Analysis

X- Do not Proceed

Figure 5 Example of SOOB Matrix

2.4 Step 4 Definition of Contingency Plan

The Step 4 of this methodology consists on the definition of Contingency Plan for each SCE.

The immediate response action that will normally be applied are:

to stop or limit operations to within the limits of remaining barriers; or

GCPS 2013 __________________________________________________________________________

identify and assess any temporary substituted safety system barrier that may be

implemented to support continued operation.

The company shall establish and document contingency procedures and a system of approval and

control of SCE to be used when those are under degraded conditions or out of operation.

The following items shall be considered:

Implementation of alternative controls equivalent;

Limitation and reduction of production;

Isolation and stopping of equipment, systems, installations;

Deadline for the temporary procedure to be allowed until corrective measures are taken.

A specific contingency plan is then developed for each SCE, using, for instance, the example

indicated in Figure 6.

SCE Permitted Acitivities

Activities with

Restriction

Prohibited Activities

Gas Detecti on

System

Confi ned Space Entry

Worki ng at hei ghts

Normal Producti on

Loadi ng/Unl oadi ng

Hot work

Operati on above

normal condi ti ons

Increase of capaci ty

Permitted Activities:

Activities with

Restriction:

Prohibited Activities:

Deadline Responsible

One month Operati on Manager

- Operati on Manager

One month Operati on Manager

SCE Resposible

If SCE not returned to ful l operati on after

fi rst deadl i ne, reduce producti on and safe

stop producti on

Performed l oadi ng/unl oadi ng acti vi ti es

wi th one extra fi el operator

Mai ntenance Manager

Activity

No limitation for the development or continuation of activity, event with

loss of the SCE

No limitation for the development or continuation of activity, event with

loss of the SCE

Not allowed to perform the activity and must be interrupted, even with

Alternative Procedures for Activities with Resctriction

Normal producti on to conti nuous wi th one

extra Operati on Supervi sor per shi ft, wi th

focus on Control Room supervi si on

Figure 6 Example of Contingency Plan for SCE

GCPS 2013 __________________________________________________________________________

2.4 Step 5 Definition of Maintenance and Inspection Prioritization

The final step for implementation of this methodology of Management of SCE is to incorporate

on maintenance and inspection routines and procedures prioritizations that will consider the

findings of the analysis of the SCE. Some important points shall be considered:

Guarantee that all SCE are classified as high priority for maintenance routines;

Guarantee no delays for inspection routines for the elements associated with MAH and

classified as SCE;

Evaluate the need of spares of SCE, where applicable.

3. Conclusion

As initially indicated, this paper presents a 5-step methodology for management of SCEs, being

those defined here as safety barriers that can avoid or mitigate Major Accident Hazards. The

objective of each step as well as practical approach and examples are presented, adapting

common use methodologies from Offshore Industry to Process Industries.

As extension of this work, considering all aspects for the presented, some improvements can be

implemented. The inclusion of procedures as part of the analysis, after the identification of the

critical procedures, with guarantee of correct training or certification of operators, is one of these

points. One additional relevant aspect is to incorporate a 6

th

step on the above methodology of

management of SCE, with the audit of process of management of the critical barriers.

Finally, it is importance to note that, this methodology was developed with the intention of

giving support for companies to systemic manage Safety Critical Elements and comply with

relevant regulation and best practices.

4. References

[1] Norsok S-001, Edition 4, February 2008, item 3.1.11. Norway. 2008

[2] Health and Safety Executive, A guide to the Offshore Installations (Safety Case)

Regulations 2005, item 83. London. 3

rd

Edition. 2006.

[3] ISO 17776:2000, Petroleum and natural gas industries Offshore production

Installations Guidelines on tools and techniques for hazard identification and risk

assessment, Table A.1. Geneva. 2006.

[4] IADC, HSE Case Guidelines for Mobile Offshore Drilling Units, Issue 3.2.1, 2009.

S-ar putea să vă placă și

- Risk Based MaintenanceDocument27 paginiRisk Based MaintenanceJoseÎncă nu există evaluări

- Connecting The Dots - Managing The Little Things That Lead To Big AccidentsDocument15 paginiConnecting The Dots - Managing The Little Things That Lead To Big Accidentsuserscribd2011Încă nu există evaluări

- Risk Assessment Methodology To Support Shutdown Plant DecisionDocument9 paginiRisk Assessment Methodology To Support Shutdown Plant DecisionDiovinyl KartilÎncă nu există evaluări

- QuestionDocument6 paginiQuestionAnosha AslamÎncă nu există evaluări

- Risk Assessment Process Safety Management TechniquesDocument3 paginiRisk Assessment Process Safety Management TechniquesGhanta Ranjith KumarÎncă nu există evaluări

- Sauf SIL Paper 4-99 (Public)Document13 paginiSauf SIL Paper 4-99 (Public)Ahmad AzabÎncă nu există evaluări

- Hazard IdentificationDocument8 paginiHazard Identificationmah_rizalÎncă nu există evaluări

- Hazard Identification at A Major Hazard Facility: Guidance NoteDocument25 paginiHazard Identification at A Major Hazard Facility: Guidance NotetemterÎncă nu există evaluări

- Risk Based Approach Risk Reduction Basics 2017Document19 paginiRisk Based Approach Risk Reduction Basics 2017kokykarkarÎncă nu există evaluări

- Iec 61508Document14 paginiIec 61508Pandhu DewantoÎncă nu există evaluări

- Asset Integrity - The Key To Managing Major Incident Risks (Ogp)Document20 paginiAsset Integrity - The Key To Managing Major Incident Risks (Ogp)Martín Diego MastandreaÎncă nu există evaluări

- Semi-Quantitative Risk Analysis For Underground Development ProjectsDocument5 paginiSemi-Quantitative Risk Analysis For Underground Development ProjectsHarold TaylorÎncă nu există evaluări

- Ecm 756 Risk Management For Construction ProjectDocument50 paginiEcm 756 Risk Management For Construction ProjectainulyaqhinÎncă nu există evaluări

- En 1050 Risk - AssessmentDocument22 paginiEn 1050 Risk - AssessmentWillian Siqueira SartoriÎncă nu există evaluări

- The Risk Reduction Process Utilizing A Hierarchy of ControlsDocument11 paginiThe Risk Reduction Process Utilizing A Hierarchy of ControlsZélia OrnelasÎncă nu există evaluări

- Bow-Tie - An Elegant SolutionDocument3 paginiBow-Tie - An Elegant SolutionRoberto BurgosÎncă nu există evaluări

- Safety AssessmentDocument44 paginiSafety AssessmentIgiegie OgheneguekeÎncă nu există evaluări

- XIV Paper 38Document11 paginiXIV Paper 38Zenon KociubaÎncă nu există evaluări

- SICK White Paper Part 3 - Risk AssessmentDocument11 paginiSICK White Paper Part 3 - Risk Assessmentrettore84Încă nu există evaluări

- Preliminary Hazard Analysis (PHA)Document8 paginiPreliminary Hazard Analysis (PHA)dÎncă nu există evaluări

- Abouessouror and Benhida (2020)Document6 paginiAbouessouror and Benhida (2020)Andi WijayaÎncă nu există evaluări

- Process Safety Performance IndicatorsDocument30 paginiProcess Safety Performance Indicatorskanakarao1100% (2)

- Enterprise Risk Management in The Airline IndustryDocument16 paginiEnterprise Risk Management in The Airline IndustryAbdurrhmanÎncă nu există evaluări

- TixierDocument13 paginiTixierAnaKarolinaMunizÎncă nu există evaluări

- Semi Quantitative ExampleDocument7 paginiSemi Quantitative ExampleEra SutrajayaÎncă nu există evaluări

- Safety in Design Paper A Live Picture of Organisational Risk by Linking Risk Management and Control AssuranceDocument12 paginiSafety in Design Paper A Live Picture of Organisational Risk by Linking Risk Management and Control Assurancemeercat_alexÎncă nu există evaluări

- Rbi RBMDocument12 paginiRbi RBMn73686861Încă nu există evaluări

- Prevent Fall HazardsDocument18 paginiPrevent Fall HazardskaimanwatsoNÎncă nu există evaluări

- Study Notes Video 4 580 Scope Basic Risk Assessment ConceptsDocument6 paginiStudy Notes Video 4 580 Scope Basic Risk Assessment ConceptsmajidÎncă nu există evaluări

- Reliability Centered Maintenance RCM Implementation and BenefitsDocument4 paginiReliability Centered Maintenance RCM Implementation and BenefitsNguyễn Duy KhangÎncă nu există evaluări

- Best Practice Guidelines For Safe Un Loading of Road Freight VehiclesDocument66 paginiBest Practice Guidelines For Safe Un Loading of Road Freight VehiclesJUAN ANTONIO MOLINAÎncă nu există evaluări

- Davis REST Paper1Document28 paginiDavis REST Paper1Rmz ExeÎncă nu există evaluări

- Tips For The Creation and Application of Effective Operating ProceduresDocument13 paginiTips For The Creation and Application of Effective Operating Procedureskirandevi1981Încă nu există evaluări

- Oisd GDN 232Document69 paginiOisd GDN 232Nilesh JogalÎncă nu există evaluări

- Kertas Penerangan - 2 Modul 6Document17 paginiKertas Penerangan - 2 Modul 6Siti fatimahÎncă nu există evaluări

- How to Identify and Analyze Hospital RisksDocument12 paginiHow to Identify and Analyze Hospital Risksver_at_workÎncă nu există evaluări

- Risk assessment techniques and toolsDocument8 paginiRisk assessment techniques and toolsAnkit KumarÎncă nu există evaluări

- Safeguard Maintenance Prioritization and PHA Data - Ron MukherjeeDocument27 paginiSafeguard Maintenance Prioritization and PHA Data - Ron Mukherjeeusman379Încă nu există evaluări

- (Elearnica - Ir) - Risk-Based Maintenance of Ethylene Oxide Production FacilitiesDocument13 pagini(Elearnica - Ir) - Risk-Based Maintenance of Ethylene Oxide Production Facilitiesamirlove206100% (1)

- RBIDocument19 paginiRBIseth_007Încă nu există evaluări

- Risk and OpportunityDocument5 paginiRisk and OpportunityQualityproÎncă nu există evaluări

- SRA Guide - Oct 2015 V5Document17 paginiSRA Guide - Oct 2015 V5fadhl alwanÎncă nu există evaluări

- Guidance On Hazard IdentificationDocument20 paginiGuidance On Hazard Identificationmath62210Încă nu există evaluări

- Equipment Criticality TutorialDocument7 paginiEquipment Criticality TutorialmailboxofmurliÎncă nu există evaluări

- Equipment Autoclave Risk Assesment - EXCELLENTDocument28 paginiEquipment Autoclave Risk Assesment - EXCELLENTASHOK KUMAR LENKA67% (3)

- N 04300 GN0107 Hazard IdentificationDocument32 paginiN 04300 GN0107 Hazard IdentificationNasrulhudaÎncă nu există evaluări

- Aircraft System Safety: Assessments for Initial Airworthiness CertificationDe la EverandAircraft System Safety: Assessments for Initial Airworthiness CertificationÎncă nu există evaluări

- Business Continuity State of the Industry ReportDe la EverandBusiness Continuity State of the Industry ReportÎncă nu există evaluări

- Mastering Opportunities and Risks in IT Projects: Identifying, anticipating and controlling opportunities and risks: A model for effective management in IT development and operationDe la EverandMastering Opportunities and Risks in IT Projects: Identifying, anticipating and controlling opportunities and risks: A model for effective management in IT development and operationÎncă nu există evaluări

- The Definitive Handbook of Business Continuity ManagementDe la EverandThe Definitive Handbook of Business Continuity ManagementÎncă nu există evaluări

- Food Control System Assessment Tool: Dimension D – Science/Knowledge Base and Continuous ImprovementDe la EverandFood Control System Assessment Tool: Dimension D – Science/Knowledge Base and Continuous ImprovementÎncă nu există evaluări

- Risk Management Using Failure Mode and Effect Analysis (FMEA)De la EverandRisk Management Using Failure Mode and Effect Analysis (FMEA)Încă nu există evaluări

- Strategies to the Prediction, Mitigation and Management of Product ObsolescenceDe la EverandStrategies to the Prediction, Mitigation and Management of Product ObsolescenceÎncă nu există evaluări

- Security Controls Evaluation, Testing, and Assessment HandbookDe la EverandSecurity Controls Evaluation, Testing, and Assessment HandbookEvaluare: 5 din 5 stele5/5 (2)

- Guidelines for the Management of Change for Process SafetyDe la EverandGuidelines for the Management of Change for Process SafetyÎncă nu există evaluări

- The Practice of Lending: A Guide to Credit Analysis and Credit RiskDe la EverandThe Practice of Lending: A Guide to Credit Analysis and Credit RiskÎncă nu există evaluări

- The Asia–Pacific Road Safety Observatory’s Indicators for Member CountriesDe la EverandThe Asia–Pacific Road Safety Observatory’s Indicators for Member CountriesÎncă nu există evaluări

- Guidelines for Defining Process Safety Competency RequirementsDe la EverandGuidelines for Defining Process Safety Competency RequirementsEvaluare: 3 din 5 stele3/5 (1)

- Challenging The She' Culture in The Russian Federation: Symposium Series No. 54 © 2008 IchemeDocument11 paginiChallenging The She' Culture in The Russian Federation: Symposium Series No. 54 © 2008 Ichemeuserscribd2011Încă nu există evaluări

- The Navigator - Issue 23 PDFDocument19 paginiThe Navigator - Issue 23 PDFuserscribd2011Încă nu există evaluări

- Xxii Paper 05Document8 paginiXxii Paper 05userscribd2011Încă nu există evaluări

- WilkinsonDocument38 paginiWilkinsonuserscribd2011Încă nu există evaluări

- Buncefield Legal ImpactsDocument13 paginiBuncefield Legal Impactschetan_7927Încă nu există evaluări

- Xxiii Paper 43Document12 paginiXxiii Paper 43userscribd2011Încă nu există evaluări

- Deepwater Horizon - Lessons Learned For The Norwegian Petroleum Industry With Focus On Technical AspectsDocument6 paginiDeepwater Horizon - Lessons Learned For The Norwegian Petroleum Industry With Focus On Technical Aspectsamal118Încă nu există evaluări

- BP OMAR Case Study WebDocument2 paginiBP OMAR Case Study Webuserscribd2011Încă nu există evaluări

- 1383Document80 pagini1383userscribd2011Încă nu există evaluări

- ErgoDocument1 paginăErgouserscribd2011Încă nu există evaluări

- Ageing InstallationsDocument28 paginiAgeing Installationsuserscribd2011Încă nu există evaluări

- 1299Document51 pagini1299userscribd2011100% (2)

- The 1D Iterative Model For Predicting Thermal Radiation From A Jet FireDocument11 paginiThe 1D Iterative Model For Predicting Thermal Radiation From A Jet Fireuserscribd2011Încă nu există evaluări

- 1230 - Ewan - Study of Pressure Safety Valve Response Times Under Transient OverpressuresDocument26 pagini1230 - Ewan - Study of Pressure Safety Valve Response Times Under Transient Overpressuresuserscribd2011Încă nu există evaluări

- Ods2010 KK BrodieDocument17 paginiOds2010 KK Brodieuserscribd2011Încă nu există evaluări

- 1400 - Isimite - Dynamic Simulation of Texas City Refinery Explosion For Safety StudiesDocument17 pagini1400 - Isimite - Dynamic Simulation of Texas City Refinery Explosion For Safety Studiesuserscribd2011Încă nu există evaluări

- 1600 - Brocklebank - CDOIF Environmental Risk Tolerability For COMAH EstablishmentsDocument17 pagini1600 - Brocklebank - CDOIF Environmental Risk Tolerability For COMAH Establishmentsuserscribd2011Încă nu există evaluări

- Review of The Robustness of Epoxy Passive Fire Protection Tech PaperDocument19 paginiReview of The Robustness of Epoxy Passive Fire Protection Tech Paperuserscribd2011100% (1)

- 1200 - Brazier - Linking Task Analysis With Other Process Safety ActivitiesDocument15 pagini1200 - Brazier - Linking Task Analysis With Other Process Safety Activitiesuserscribd2011Încă nu există evaluări

- 1100 - Oshiro - Decision Making Using Human Reliability AnalysisDocument34 pagini1100 - Oshiro - Decision Making Using Human Reliability Analysisuserscribd2011Încă nu există evaluări

- BMTWBM OilGas CFD Consequence 2013 WebsiteDocument2 paginiBMTWBM OilGas CFD Consequence 2013 Websiteuserscribd2011Încă nu există evaluări

- 1100 - Forbes - Safety Case On A PageDocument11 pagini1100 - Forbes - Safety Case On A Pageuserscribd2011Încă nu există evaluări

- NeDocument5 paginiNeuserscribd2011Încă nu există evaluări

- 1130 - Allford - Process Safety AuditingDocument15 pagini1130 - Allford - Process Safety Auditinguserscribd2011Încă nu există evaluări

- 1500 - Evans - Corporate Memory Collective IntelligenceDocument17 pagini1500 - Evans - Corporate Memory Collective Intelligenceuserscribd2011Încă nu există evaluări

- 1100 - Amyotte - No Such Thing As A Black Swan Process IncidentDocument24 pagini1100 - Amyotte - No Such Thing As A Black Swan Process Incidentuserscribd2011Încă nu există evaluări

- Risk Criteria - When Is Low Enough Good Enough - SaudiDocument8 paginiRisk Criteria - When Is Low Enough Good Enough - Saudiuserscribd2011Încă nu există evaluări

- ASFP Talk June 2005 - Copy For ASFPDocument18 paginiASFP Talk June 2005 - Copy For ASFPuserscribd2011Încă nu există evaluări

- DNV Position Paper On Key Aspects of An Effective U S Offshore Safety Regime 22 July 2010Document14 paginiDNV Position Paper On Key Aspects of An Effective U S Offshore Safety Regime 22 July 2010userscribd2011Încă nu există evaluări

- ConSASS Audit ChecklistDocument40 paginiConSASS Audit ChecklistGEEKaBITEÎncă nu există evaluări

- Risk Assessment With Risk Matrix Excel TemplateDocument10 paginiRisk Assessment With Risk Matrix Excel TemplateAurora Marie AlberbaÎncă nu există evaluări

- FMEA 2016-Penyuluhan SingkatDocument97 paginiFMEA 2016-Penyuluhan Singkatsari rezekiÎncă nu există evaluări

- Dairy HACCP Plans GuideDocument23 paginiDairy HACCP Plans GuideNaveen Kumar100% (3)

- Hazard IdentificationDocument24 paginiHazard IdentificationAmi Osh100% (2)

- ABC PTE LTD Activity-Based Risk AssessmentDocument6 paginiABC PTE LTD Activity-Based Risk Assessmentnandha gopalÎncă nu există evaluări

- Systems Assurance Management in Railway Through The Project Life CycleDocument6 paginiSystems Assurance Management in Railway Through The Project Life CycleJasmine TsoÎncă nu există evaluări

- Risk Management GuideDocument69 paginiRisk Management GuideVJ Geo100% (1)

- Implementing an Effective Safety Management SystemDocument20 paginiImplementing an Effective Safety Management SystemSherief ArafatÎncă nu există evaluări

- Medical Product Software Development and FDA Regulations4008Document85 paginiMedical Product Software Development and FDA Regulations4008ankitp_8Încă nu există evaluări

- Leveson HUG 07Document47 paginiLeveson HUG 07KristinaÎncă nu există evaluări

- Hiradc-12 LabDocument5 paginiHiradc-12 LabizzahÎncă nu există evaluări

- Safety & Health Officer: Introductory Course: GLRT0060Document23 paginiSafety & Health Officer: Introductory Course: GLRT0060Ling ShingÎncă nu există evaluări

- OHSAS 18001-2007 Gap Analysis ChecklistDocument16 paginiOHSAS 18001-2007 Gap Analysis Checklistmilou88100% (1)

- Army System Safety Management GuideDocument70 paginiArmy System Safety Management GuideJinwon ParkÎncă nu există evaluări

- QraDocument10 paginiQrauserscribd2011Încă nu există evaluări

- Absen HACCP 6 MaretDocument1 paginăAbsen HACCP 6 MaretVhee TilukayÎncă nu există evaluări

- Risk Management WFPDocument132 paginiRisk Management WFPBibek BaralÎncă nu există evaluări

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument9 paginiIjesrt: International Journal of Engineering Sciences & Research TechnologyFadi BoustanyÎncă nu există evaluări

- SHE Manual GuideDocument109 paginiSHE Manual GuidekuldeeoÎncă nu există evaluări

- Common Safety Method Guidance 2Document34 paginiCommon Safety Method Guidance 2AadiShaikhÎncă nu există evaluări

- DGCA Form 120-90 Evaluation and Approval of SMS Manual Air Operator - June 2019 PDFDocument5 paginiDGCA Form 120-90 Evaluation and Approval of SMS Manual Air Operator - June 2019 PDFdidik prihanantoÎncă nu există evaluări

- Hazard Identification and Risk Control-TemplateDocument2 paginiHazard Identification and Risk Control-TemplateShristika Pradhan100% (1)

- HACCP Principles Comparison TableDocument27 paginiHACCP Principles Comparison TablefushiersÎncă nu există evaluări

- Air Based Hazards PDFDocument17 paginiAir Based Hazards PDFRiyan SyedÎncă nu există evaluări

- HSE Front End Loading ProcedureDocument11 paginiHSE Front End Loading ProcedureVasilica BarbarasaÎncă nu există evaluări

- W22 - Chapter 11 Hazard IdentificationDocument66 paginiW22 - Chapter 11 Hazard Identificationiamayesha725Încă nu există evaluări

- Sno G D&C f001 HiradcDocument5 paginiSno G D&C f001 HiradcTri SubaktiÎncă nu există evaluări

- Hazid Lecture Part - 1Document21 paginiHazid Lecture Part - 1MohamedÎncă nu există evaluări

- STPA Handbook PDFDocument188 paginiSTPA Handbook PDFFellipe Rey0% (1)