Documente Academic

Documente Profesional

Documente Cultură

Universiti Teknologi Mara Fakulti Kejuruteraan Kimia Chemical Engineering Laboratory Ii CHE523

Încărcat de

Heather Jarvis100%(2)100% au considerat acest document util (2 voturi)

1K vizualizări14 paginidistillation column engineering laboratory experiment

Titlu original

distillation column

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentdistillation column engineering laboratory experiment

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

100%(2)100% au considerat acest document util (2 voturi)

1K vizualizări14 paginiUniversiti Teknologi Mara Fakulti Kejuruteraan Kimia Chemical Engineering Laboratory Ii CHE523

Încărcat de

Heather Jarvisdistillation column engineering laboratory experiment

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 14

UNIVERSITI TEKNOLOGI MARA

FAKULTI KEJURUTERAAN KIMIA

CHEMICAL ENGINEERING LABORATORY II

CHE523

NAME :

GROUP : EH2203 (GROUP 5)

EXPERIMENT : DISTILLATION COLUMN

DATE PERFORMED : 17 JUNE 2014

SEMESTER : 3

PROGRAMME / CODE : CHE523

SUBMIT TO : MADAM AZRINI

No. Title Allocated Marks (%) Marks

1 Abstract/ Summary 5

2 Introduction 5

3 Objectives 5

4 Theory 5

5 Apparatus 5

6 Methodology/ Procedure 10

7 Result 10

8 Calculations 10

9 Discussion 20

10 Conclusion 10

11 Recommendations 5

12 Reference 5

13 Appendix 5

TOTAL MARKS 100

Remarks:

Checked by:

_________________

Date :

TABLE OF CONTENTS

BIL TITTLE PAGE

1 ABSTRACT

2 INTRODUCTION

3 OBJECTIVES

4 THEORY

5 APPARATUS

6 PROCEDURES

7 RESULTS

8 CALCULATIONS

9 DISCUSSION

10 CONCLUSION

11 RECOMMENDATIONS

12 REFERENCE

13 APPENDIX

INTRODUCTION

The distillation column is a process in which a liquid or vapor mixture of two or more

substances is separated into its component fractions of desired purity, by the application and

removal of heat. The separation of a mixture of alcohol and water into its components; of liquid

air into nitrogen, oxygen, argon; and of crude petroleum into gasoline, kerosene, fuel oil, and

lubricating stock are examples of distillation. Suppose there are two components, A and B. Both

of these components are found in both phases. There are four variables: pressure, temperature,

and concentrations of component A in the liquid and vapor phases (the concentrations of

component B are unity less those concentrations of A). If the pressure is fixed, only one

variable, e.g., liquid-phase concentration, can be changed independently and temperature and

vapor-phase concentration follow. The fact about distillation column is the vapor of a boiling

mixture will be richer in the component that have lower boiling point. Therefore, when this vapor

is cooled and condensed, the condensate will contain more volatile components. At the same

time, the original mixture will contain more of the less volatile material. The separation process

requires three things. First, a second phase must be formed so that both liquid and vapor

phases are present and can contact each other on each stage within a separation column.

Secondly, the components have different volatilities so that they will partition between the two

phases to different extent. Lastly, the two phases can be separated by gravity or other

mechanical means. Distillation differs from absorption and stripping in that the second phase is

created by thermal means. In practice, distillation may be carried out either of two principal

methods. The first method is based on the production of a vapor by boiling the liquid mixture to

be separated and condensing the vapors without allowing any liquid to return to the still. There

is then no reflux, which is called batch distillation. The second method is based on the return of

part of the condensate to the still under such conditions that this returning liquid is brought into

intimate contact with the vapors on their way to the condenser. Either of these methods may be

conducted as a continuous steady-state distillation process, including single-stage partial

vaporization without reflux (flash distillation) and continuous distillation with reflux (rectification),

for systems containing only two components.

OBJECTIVES

Experiment A: to determine the pressure drop over distillation column for various boil-up rates,

in batch distillation.

Experiment B: use of refractometer for determining mixture composition.

Theory

Distillation is a process of separating two or more miscible liquids by taking advantage of

the boiling point differences between the liquids. In order to understand how the distillation

works, consider the mixture of toluene and methylcyclohexane for this distillation experiment.

Heat is added to the mixture of toluene and methylcyclohexane and eventually the most volatile

component (in this case methylcyclohexane) begins to vaporize. When the methycyclohexane

vaporizes, it takes with it molecules of toluene. The methycyclohexane-toluene vapor mixture is

then condensed and evaporated again, giving a higher mole fraction of methycyclohexane in the

vapor phase and a higher mole fraction of toluene in the liquid phase.

This process of condensation and evaporation continues in stages up the column until the

methycyclohexane rich vapor component is condensed and collected as top product and the

water rich liquid is collected as bottom product. Figure below shows the distillation column used

in the experiment.

In order to understand thoroughly the distillation process, let consider what happen when

heating a liquid. At the boiling point, the molecules of the liquid posses enough kinetic energy to

escape into the vapor phase (evaporation) and some molecule in the vapor phase return to the

liquid phase (condensation).

During the mixing, the vapor will pick up more of component methylcyclohexane from the

liquid while the liquid will be richer with component toluene. As the vapor rises further up,it

becomes richer and richer in component methylcyclohexane but poorer with component

toluene. The feed stream is introduced on some intermediate tray where the liquid has

approximately the same composition as the feed. The part of column above the feed point is

rectifying section while the lower part is stripping section.

APPARATUS

Experiment A: determine the pressure drop over the distillation column for various boil-up rates,

in batch distillation.

1. Distillation column.

2. 100mL of measuring cylinder.

3. Refractormeter.

4. 250mL measuring cylinder graduated.

5. Stop watch.

Experiment B: determining mixture compositions

1. Refractometer.

2. 100mL beaker

3. Burrete

4. Droper.

PROCEDURES

Experiment A: determine the pressure drop over the distillation column for various boil-up rates,

in batch distillation.

1. Before starting, al the valves on the equipment are closed. Then, the valve V10 on the

reflux pipe is opened.

2. The boiler is filled with 10 litres of mixtures to be distillated.

3. The filter cap on the top of the reboiler is firmly replaced.

4. Turned on the power supply to the control panel.

5. The temperature selector switch is setup to T9 which is for temperature in boiler. The

cooling water is admitting to condenser by opened the V5 at flow rate on F11 of

approximately 3 litres/min.

6. The power controller are turned on for reboiler heating element dully anti-clockwise and

switch the switch turning on the power to the heating element to power on position.

7. Red lamp is illuminate to indicate the heating element is on.

8. The power controller is turned to clockwise until reading of approximately 0.75W is

obtained on the digital wattmeter.

9. The contents of the reboiler will begin to warm up and observed through the temperature

readout meter.

10. Valves V6 and V7 is opened which connect base and top of distillation column,

respectively, to the manometer.

11. The V6 and V7 are opened.

12. First and 5

th

plates are observed.

13. Vapour is rise up in the column and observed.

14. Vapour enters the condenser and reappears as droplets into the glass walled distilled

receiver vessel.

15. V3 is partially open and drained the condensate. The sample is start to collect and timing

at the same time. Sample is collected approximately 90mL and 100mL.

16. After taking a sample, take reading of pressure drops over both the top and bottom

section. Make sure always open V6 and V7.

17. Measure the sample by using refractometer.

18. After finish read pressure drop, close V6 and V7.

19. Repeat the experiment for power 250 watt until 1.5kW after 10 minutes done taking

pressure drop reading.

Experiment B: determining mixture composition

1. The refractive index (RI) of pure methylcyclohexane and pure toluene is measured.

2. The small quantities of 25 mol %, 50 mol % and 75 mol % methylcyclohexane are

prepared is mixed respectively with 75 mol%, 50 mol% and 25 mol% toluene to measure

their RI.

3. The data are recorded.

RESULTS

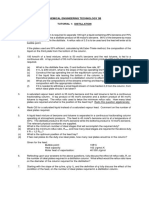

Experiment A: Determining column pressure drop

Power (kW) Boil-up Rate

( litres/hr)

Pressure drop (cm

H

2

O) Top bottom

overall

Degree of

foaming on

trays

Refractive

index

0.50 3.81 70 Gentle 1.43755

0.95 10.80 66 Gentle

localized

1.43794

1.00 14.40 223 Localized 1.43836

1.25 81.00 150 Loading 1.44688

1.50 9.53 128 Flooding 1.45339

Experiment B: Determining mixture compositions

Concentration Refractive index

100% 1.42326

75% 1.43789

50% 1.46129

25% 1.33310

0% 1.49683

Plot the curve relating pressure drop as a function of boil-up rate.

The graph of refractive index versus mol percent methylcyclohexane in

methylcyclohexane/toluene mixture.

0

50

100

150

200

250

3.812 10.8 14.4 81 9.53

P

r

e

s

s

u

r

e

d

r

o

p

,

c

m

H

2

O

Boil-up rate, L/hr

Pressure drop vs boil-up rate

1.25

1.3

1.35

1.4

1.45

1.5

1.55

0 0.25 0.5 0.75 1

R

e

f

r

a

c

t

i

v

e

i

n

d

e

x

Mole fraction of methylcyclohexane

Refractive index vs mole fraction of MCH

SAMPLE OF CALCULATION

For 100 ml of mixture, quantity required:

i) 0% methylcyclohexane : 100% toluene

V

mch

+ V

tol

= 100ml

0

+ V

tol

= 100ml

V

mch

= 0

V

tol

= 100 mL

ii) 25% methylcyclohexane : 75% toluene

V

mch

+ V

tol

= 100ml

V

mch

+ 2.51 V

mch

= 100ml

V

mch

= (100/3.51)

V

mch

= 28.49 mL

V

tol

= 71.51 ml

iii) 50% methylcyclohexane : 50% toluene

V

mch

+ V

tol

= 100ml

V

mch

+ 0.838 V

mch

= 100ml

V

mch

= (100/1.838)

V

mch

= 54.4mL

V

tol

= 45.6 mL

iv) 75 %methylcyclohexane : 25% toluene

V

mch

+ V

tol

= 100ml

V

mch

+ 0.280 V

mch

= 100ml

V

mch

= (100/1.280)

V

mch

= 78.125mL

V

tol

= 21.875 mL

v) 100% methylcyclohexane : 0% toluene

V

mch

+ V

tol

= 100ml

V

mch

+ 0 = 100ml

V

mch

= (100/1)

V

mch

= 100mL

V

tol

= 0 mL

Discussion

Based on the results of the experiment conducted, the more power input to heat the

higher the boil up rate of the mixture. Gradually the degree of foaming on trays changed from

gentle to flooding when the heat increased. This shows the mixture of methylcyclohexane are

diffused in the distillation column and separated in the Rasching ring. The process was speed

up rapidly when the heat increased per time and the mixture collected and to compare with

refractive index. The foaming on trays mostly localized and flooding where the mixture

completely separated in contact of fluid and the Rasching ring help to increase the separation

process by the surface area of fluid contact each other and diffuse more easily. But when the

process too flooding, it reflux and the remaining collected for the other batch.

The most suitable power required for this process based on the results obtained, the 1

kW power is suitable for separating the methylcyclohexane in the distillation process. 1 kW

power produces 14.4 L/hr of boil up rate and the pressure drop of 223. In addition the foaming

state was localized where the most required process for distillation column to determine the

pressure drop (top to bottom) and steady process. With this state, the process easy to handle

and most crucial was pressure drop. The pressure drop obtained was high and it reached the

equilibrium where the separation needed is in steady state. The localized foaming was not too

aggressive and the methylcyclohexane not reflux.

For the refractive index, the concentration of 50% methylcyclohexane and 50% toluene

shows the 1.46129 index where the separation was at optimum. The volume needed for the

refractive index from distillation column was almost suitable for the whole process required.

Conclusion

From the experiment, we can conclude that the objective of the experiment is achieved.

What we can see from the result, the pressure drop in the distillation column is not the function

of the power that has supplied. At power of 0.50kW, the pressure drop recorded was 70cm H

2

O.

At 0.95 kW the pressure drop was drop to 66cm H

2

O. However by increasing the power to 1kW

the pressure drop increase to 223 cm H

2

O. From the observation, the degree of foaming is

changing with the increasing power. It changes from gentle-gentle localized-localized-loading

and flooding. From the experiment, from the compare of RI value, the more power the distillation

process consumed, the more high molar composition of methylcyclohexane that collected as the

product.

Recommendations

There are several recommendations must be performed to decrease the percentage of the error

in order to increase the accuracy of the Reynolds number such as;

1. The general start-up procedures need to be performed before starting each of the

experiment. This is to ensure all the components of the unit are in good conditions and

working smoothly. It will affect the reading of the experiment and reduce the

performance of the unit if the components are not in satisfied conditions.

2. To get more accurate reading, the experiment must be repeated at least 3 times by

calculating the average reading. This will reduce the deviation from the theoretical data.

3. Make sure that our eye is the same level as the meniscus of water when we take the

reading to avoid parallax error.

REFFERENCE

1. UiTM Chemical Engineering Lab Manual 2014, Distillation Column

2. Unit Operations Of Chemical Engineering 7

th

Edition, Warren L. McCabe, Julian C.

Smith, Peter Harriott

3. Green, D.W., ed. Perrys Chemical Engineering Handbook. Sixth Edition. McGraw-Hill

Book Company, New York. 1984.

4. http://www.nt.ntnu.no/users/preisig/Repository/TKP_4110_Felles_Lab/experiment%20de

scriptions/DistInstruct.pdf

APPENDIX

S-ar putea să vă placă și

- 1939 1708 Data Link Fault TracingDocument16 pagini1939 1708 Data Link Fault TracingAyoub Ayoub100% (1)

- BMW E46 RearlightDocument4 paginiBMW E46 RearlightLiviu CasuneanuÎncă nu există evaluări

- Ultimate ESAS Data Bank CompilationDocument19 paginiUltimate ESAS Data Bank CompilationVea ValcorzaÎncă nu există evaluări

- Distillation Column Lab ReportDocument14 paginiDistillation Column Lab ReportWahida Shukori67% (3)

- LIDO Introduction PDFDocument127 paginiLIDO Introduction PDFStiliyana Bakalova100% (2)

- Distillation Column ReportDocument27 paginiDistillation Column Reportvaqif100% (1)

- Service Training BW211D-40 Eng PDFDocument150 paginiService Training BW211D-40 Eng PDFEdnilson dos Santos89% (18)

- Reboiler and VaporiserDocument56 paginiReboiler and Vaporiserjihad jamareiÎncă nu există evaluări

- Gasoline Direct InjectionDocument21 paginiGasoline Direct InjectionhoangÎncă nu există evaluări

- CH3802 Formal DistillationDocument33 paginiCH3802 Formal DistillationAldi StefanusÎncă nu există evaluări

- Distillation Column ExperimentDocument18 paginiDistillation Column ExperimentKino Tel Lok100% (1)

- Reactive Distillation: Selected PapersDocument10 paginiReactive Distillation: Selected PapersAli Naveed FarookiÎncă nu există evaluări

- Report Distillation ColumnDocument20 paginiReport Distillation ColumnAzam Najmi33% (3)

- Exp 06 - Distillation ColumnDocument11 paginiExp 06 - Distillation ColumnAli AhmadÎncă nu există evaluări

- Chemistry Laboratory EquipmentsDocument11 paginiChemistry Laboratory EquipmentsEliutario IgnacioÎncă nu există evaluări

- Batch Distillation of Water-Methanol SystemDocument78 paginiBatch Distillation of Water-Methanol Systemsatadruc50% (4)

- Continuous Stirred Tank Reactor (CSTR) in SeriesDocument15 paginiContinuous Stirred Tank Reactor (CSTR) in SeriesHaizul Radzi33% (3)

- Designing A Sieve Tray Distillation ColumnDocument24 paginiDesigning A Sieve Tray Distillation ColumnJinelleColoso80% (5)

- hsg47 - Avoiding Danger From Underground Services PDFDocument40 paginihsg47 - Avoiding Danger From Underground Services PDFAchilleas21Încă nu există evaluări

- Distillation Column - HeuristicsDocument25 paginiDistillation Column - HeuristicsTrinityRVx100% (1)

- PK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory IiiDocument21 paginiPK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory Iiibedirtupak92% (12)

- Distillation Tutorial 1Document1 paginăDistillation Tutorial 1Richardt LootsÎncă nu există evaluări

- PDF FileDocument50 paginiPDF FileHussein AyoubÎncă nu există evaluări

- CHE504 Lab Report Distillation Column Group 1Document25 paginiCHE504 Lab Report Distillation Column Group 1Jaymac0% (1)

- Single Effect EvaporatorDocument2 paginiSingle Effect Evaporatorchemant7100% (1)

- Laboratory ReportDocument31 paginiLaboratory ReportJim100% (2)

- Lab 3 Plug FlowDocument29 paginiLab 3 Plug FlowHikaru MokaÎncă nu există evaluări

- Stirred Tank Reactors in SeriesDocument25 paginiStirred Tank Reactors in SeriesChristopher Emeka Ominyi100% (1)

- Lab6-Tubular Flow ReactorDocument11 paginiLab6-Tubular Flow ReactorNurtasha Atikah100% (1)

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentDe la EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentÎncă nu există evaluări

- Principles and Case Studies of Simultaneous DesignDe la EverandPrinciples and Case Studies of Simultaneous DesignÎncă nu există evaluări

- Smart Soot Blower SystemDocument8 paginiSmart Soot Blower SystemidigitiÎncă nu există evaluări

- Solvent Extraction: Please Submit Question 4 For MarkingDocument3 paginiSolvent Extraction: Please Submit Question 4 For MarkingThembi Matebula100% (1)

- Chapter One 1.1. BackgroundDocument16 paginiChapter One 1.1. Backgroundchisom100% (1)

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDe la EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationÎncă nu există evaluări

- CSTRDocument15 paginiCSTRbilisfreak100% (3)

- Gas AbsorptionDocument24 paginiGas AbsorptionShalini Krishnan100% (1)

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringDe la EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringÎncă nu există evaluări

- Tray Distillation Column With RefluxDocument26 paginiTray Distillation Column With RefluxMelvin MoorÎncă nu există evaluări

- CSTR ReportDocument21 paginiCSTR ReportJonathon Douglas100% (1)

- Lab 2 - Distillation Column CompleteDocument18 paginiLab 2 - Distillation Column CompleteHadiChan100% (1)

- Lab 4Document18 paginiLab 4Amir Al-AimanÎncă nu există evaluări

- Cebu Institute of Technology - University: CHE501-V1 Group 2Document11 paginiCebu Institute of Technology - University: CHE501-V1 Group 2Joshua ClimacoÎncă nu există evaluări

- Exp - 2 Bubble Cap Distillation ColumnDocument13 paginiExp - 2 Bubble Cap Distillation ColumnAdawiyah Al-jufri100% (1)

- CSTRDocument20 paginiCSTRSharing Caring100% (1)

- Distillation ColumnDocument32 paginiDistillation ColumnTatiana RosarioÎncă nu există evaluări

- Liquid LiquidDocument8 paginiLiquid LiquidAnonymous b9fcR5Încă nu există evaluări

- CHE504 - Lab Report On Distillation ColuDocument27 paginiCHE504 - Lab Report On Distillation ColuMuhammad Irfan MalikÎncă nu există evaluări

- Distillation ReportDocument17 paginiDistillation ReportSebastian PinzonÎncă nu există evaluări

- CSTR SeriesDocument14 paginiCSTR SeriesElina Nes100% (1)

- Separation Processes Lab ReportDocument15 paginiSeparation Processes Lab ReportArslanQureshi0% (1)

- Experiment: Packed Distillation ColumnDocument4 paginiExperiment: Packed Distillation Columnnhalieza1067Încă nu există evaluări

- CONTINUOUS DistillationDocument5 paginiCONTINUOUS DistillationNaseer SattarÎncă nu există evaluări

- Experiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Document5 paginiExperiment: Batch Reactor Unit Operations Lab I (CHEGR3787L) Fall 2004Janice YanÎncă nu există evaluări

- Chemical Engineering Laboratory Ii: /DT Term Is Zero SinceDocument9 paginiChemical Engineering Laboratory Ii: /DT Term Is Zero SinceKayathre Raveendran100% (1)

- Title Page: The Total Mass Flow Rate of A SystemDocument35 paginiTitle Page: The Total Mass Flow Rate of A SystemJimÎncă nu există evaluări

- Batch Reactive DistillationDocument7 paginiBatch Reactive DistillationChalmer BelaroÎncă nu există evaluări

- Adverse Vapour Flow ConditionsDocument3 paginiAdverse Vapour Flow ConditionsSana HajriÎncă nu există evaluări

- Lab 1Document12 paginiLab 1JoeJeanÎncă nu există evaluări

- C4 Lab ReportDocument11 paginiC4 Lab ReportchaitanyaÎncă nu există evaluări

- Gas AbsorptionDocument19 paginiGas AbsorptionAnonymous NyvKBW100% (3)

- Azeotropic Mass BalanceDocument25 paginiAzeotropic Mass BalancesowjanyaavkÎncă nu există evaluări

- Chapter 4 - Efficiency of ColumnsDocument38 paginiChapter 4 - Efficiency of ColumnsAnonymous vRU4VlÎncă nu există evaluări

- Unit Operation Laboratory 2 (CCB 3062)Document7 paginiUnit Operation Laboratory 2 (CCB 3062)Carl Erickson100% (1)

- Distillation ColumnDocument74 paginiDistillation Columnfatengz100% (3)

- Reactive DistillationDocument13 paginiReactive DistillationUtkarsh KapoorÎncă nu există evaluări

- 64K (8Kx8) Parallel EEPROM With Page Write and Software Data Protection AT28C64BDocument18 pagini64K (8Kx8) Parallel EEPROM With Page Write and Software Data Protection AT28C64BChu Thi ThuanÎncă nu există evaluări

- SSA 716 StudentGuide 20150211Document551 paginiSSA 716 StudentGuide 20150211Ashok Kumaresan100% (1)

- S BlockDocument27 paginiS BlockAditya BansalÎncă nu există evaluări

- OBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895Document7 paginiOBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895SwapnasaritÎncă nu există evaluări

- The Cunard Building, LiverpoolDocument2 paginiThe Cunard Building, LiverpoolIbrahim FawwazÎncă nu există evaluări

- Truebluepower: Advanced Lithium-Ion Battery TB17Document2 paginiTruebluepower: Advanced Lithium-Ion Battery TB17Milad YadollahiÎncă nu există evaluări

- Chandrayan 2Document11 paginiChandrayan 2SELVALAKSHMI S VÎncă nu există evaluări

- Edgen Murray ProductsDocument20 paginiEdgen Murray Productsafiqaziz86Încă nu există evaluări

- C510WNDocument2 paginiC510WNEdgarDavidDiazCamposÎncă nu există evaluări

- MYG Varistors Data SheetDocument4 paginiMYG Varistors Data SheetPedro Giménez100% (1)

- Fruit Recognition Deep LearningDocument53 paginiFruit Recognition Deep Learningsaran20099Încă nu există evaluări

- 13 - NM Electrical Stimulation in NeurorehabilitationDocument29 pagini13 - NM Electrical Stimulation in NeurorehabilitationvladÎncă nu există evaluări

- KomdisDocument4 paginiKomdisGading cacaÎncă nu există evaluări

- Brochure Tialoc Chemical Resistant Piping Systems: Page 1 of 20Document20 paginiBrochure Tialoc Chemical Resistant Piping Systems: Page 1 of 20Fernando Cesar PérezÎncă nu există evaluări

- Fracture Toughness Evaluation of WC-Co Alloys by Indentation TestingDocument12 paginiFracture Toughness Evaluation of WC-Co Alloys by Indentation TestingFjodorSergÎncă nu există evaluări

- IPECS-eMG80 Quick Start GuideDocument11 paginiIPECS-eMG80 Quick Start GuideDjromeo EdyÎncă nu există evaluări

- Parts Catalog: This Catalog Gives The Numbers and Names of Parts On This MachineDocument39 paginiParts Catalog: This Catalog Gives The Numbers and Names of Parts On This MachinePericoÎncă nu există evaluări

- Unit 5: Extra Practice: KeyDocument1 paginăUnit 5: Extra Practice: KeyMuniz BarbosaÎncă nu există evaluări

- Design of Ms Pipe:: - (40 MM NB, Class'b'Document4 paginiDesign of Ms Pipe:: - (40 MM NB, Class'b'Kancharla Naga Ratna KumarÎncă nu există evaluări

- C Basic ExercisesDocument7 paginiC Basic ExercisesAngelo MartinÎncă nu există evaluări