Documente Academic

Documente Profesional

Documente Cultură

Plant Visit

Încărcat de

NavarroJeisan0 evaluări0% au considerat acest document util (0 voturi)

34 vizualizări5 paginiplant visitation of certain fields of plants

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentplant visitation of certain fields of plants

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

34 vizualizări5 paginiPlant Visit

Încărcat de

NavarroJeisanplant visitation of certain fields of plants

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 5

Industrial Visit of Mechanical Engineering Department to: Machine Systems Corporation, Cebu

Date: Oct.11, 2014

Group Leader: Cajanding, Marlo D.C.

Group Members: Aquino, Micko Angelo R.

Macalolot, Eric B.

Madelo, Randel G.

Manaloto, Jose Antonio M.

Introduction

A. Brief History of the Plant

Machine Systems Corporation is a family owned business currently 3 generations in the making.

B. Mission and Vision

Mission:

Our commitment is to provide a wide range of world-class metalworking products and services. We are

determined to develop innovative approaches towards excellent customer service; responsive to the

concerns of the community through environment friendly methods and to be a leading proponent of

responsible human resource management.

Vision:

A leading provider of world-class metalworking products and services operating in the highest consistent

quality standard of environmentally sensitive production and management system together with a

highly committed human resource oriented towards a harmonious working condition to meet the

progressive needs and expectations of all stakeholders.

C. Nature of Business

The Machine Systems Corp. is a manufacturing plant that specializes in metalworking and fabrication of

mechanical parts that are used in the industry.

D. Total number of Employees

The total number of Employees that are working in the Machine Systems Corp, both part time and full

time comprises of 100+ in total.

E. What are the product lines they manufacture?

There is no definite number of products or product lines that they manufacture but they constantly

manufacture all machine parts needed by the companies from Mactan Export Processing Zone. They will

accept any order as long as it is machinable.

F. Who are the primary customers?

Most of the products manufactured by Machine Systems Corp. is requested from the Mactan Export

Processing Zone. MEPZ is a group of companies that are comprised of 200+ companies.

Process

A. What are the raw materials used?

The raw materials used by Machine Systems Corp. are all kinds of machinable metals specifically cold

steels like 5020, 1025 and 4120 and plastics. The raw materials used are also dependent on the

customers specifications.

B. What are the processes involved to produce the final product?

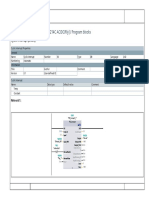

NO

YES

YES

NO

YES

Receive the Order

Sent to Office

Is the

Product

machinable?

Reject the

Order

Fabricate

a Sample

product

of the

order

Is the sample

approved by the

customer?

Reject the

Order

Machining and

Finishing of the

Product

Accept by the

Customer

C. What are the machineries used?

The Machineries used are the following:

Testing Machines:

Hardness Test

Profile Projector

Manual use:

Lathe Machines

Bore Machines

Drilling Machines

Gear Hubber

Grinding Machines

Mold Jigs

Presses

Punch and Dies

Automatic:

CNC Lathe

CNC Milling

CNC Wire Cutter

D. Quality assurance

Machine Systems Corp. has testing machines to ensure the quality of the products that they

manufacture. They test for hardness and the profile projector for small cuts and products from the wire

cutter.

E. Safety and health issues

The workers are required to put on the necessary clothing and equipment like safety glasses and masks

at all times.

The automatic machines must have their doors closed at all times for there is danger of flaking debris.

The Machine Systems Corp. is a certified company that has a ISO 9001:2008 with certificate number

01100049079.

Group Experience during the Tour and Feedback

Before the visit of the actual plant, it was required to have safety glasses on. It was due to the nature of

the business since metal shrapnel can hit the eyes.

The visit to this particular plant is informative with regards of the history of the metalworking history.

During the tour of the plant, we were told tidbits about how the metalworking business faired since the

time of Marcos. We were also told about the history of the plant, how back in the 50s and 60s the

technology in terms of metalworking was on par with Japan.

Inside the plant, the work is very systematic, with every machine working on specific parts of the

product and sometimes two or more at the same time.

The metalworking business can do more if we only had more advanced research and if only engineers

and researchers will contribute back in the Philippines and not just take a job abroad.

S-ar putea să vă placă și

- Statement of The Problem 1Document1 paginăStatement of The Problem 1NavarroJeisanÎncă nu există evaluări

- MethodologyDocument2 paginiMethodologyNavarroJeisanÎncă nu există evaluări

- IPDocument1 paginăIPNavarroJeisanÎncă nu există evaluări

- Wall Surface AreaDocument6 paginiWall Surface AreaNavarroJeisanÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Brochure HorticultureDocument46 paginiBrochure HorticulturezulfiqaralimalikÎncă nu există evaluări

- Hematology NotesDocument3 paginiHematology NotesFarisa Jane BanggoÎncă nu există evaluări

- Tender Evaluation Template GuideDocument15 paginiTender Evaluation Template GuideKhalid NaeemÎncă nu există evaluări

- Otis Brochure Gen2life 191001-BELGIUM SmallDocument20 paginiOtis Brochure Gen2life 191001-BELGIUM SmallveersainikÎncă nu există evaluări

- Mpce 24Document39 paginiMpce 24Sachin Mehla0% (1)

- ZJJ 3Document23 paginiZJJ 3jananiwimukthiÎncă nu există evaluări

- 42U System Cabinet GuideDocument68 pagini42U System Cabinet GuideGerman AndersÎncă nu există evaluări

- Exploratory Data Analysis: M. SrinathDocument19 paginiExploratory Data Analysis: M. SrinathromaÎncă nu există evaluări

- STR File Varun 3Document61 paginiSTR File Varun 3Varun mendirattaÎncă nu există evaluări

- Catalogue MinicenterDocument36 paginiCatalogue Minicentermohamed mahdiÎncă nu există evaluări

- PrognosisDocument7 paginiPrognosisprabadayoeÎncă nu există evaluări

- Haier's Performance Management in Other CulturesDocument8 paginiHaier's Performance Management in Other CulturesSubhransu SahooÎncă nu există evaluări

- Westford University College readies flagship campus with new programsDocument20 paginiWestford University College readies flagship campus with new programsSaju JanardhananÎncă nu există evaluări

- Carmina GadelicaDocument37 paginiCarmina GadelicaoniricsÎncă nu există evaluări

- ENVPEP1412003Document5 paginiENVPEP1412003south adventureÎncă nu există evaluări

- Perbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACDocument15 paginiPerbandingan Penggunaan Refrigeran R22 Dengan R407 Pada Performa ACYuli RahmawatiÎncă nu există evaluări

- Biosynthesis of FlavoursDocument9 paginiBiosynthesis of FlavoursDatta JoshiÎncă nu există evaluări

- Cost and Benefit Analysis of Outsourcing From The Perspective of Datapath LTDDocument59 paginiCost and Benefit Analysis of Outsourcing From The Perspective of Datapath LTDranzlorenzoo100% (1)

- Karan Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanDocument2 paginiKaran Chawla and Joshua Lee November 21, 2016 MEDS 3020 - Fall 2016 Dr. Rosevear, Dr. Cartwright, Dr. LiebermanJeremy DelaneyÎncă nu există evaluări

- As 2710-1984 Screw Gauges - VerificationDocument7 paginiAs 2710-1984 Screw Gauges - VerificationSAI Global - APACÎncă nu există evaluări

- 1 API 653 Exam Mar 2015 MemoryDocument12 pagini1 API 653 Exam Mar 2015 MemorymajidÎncă nu există evaluări

- Clinical behavior analysis and RFT: Conceptualizing psychopathology and its treatmentDocument28 paginiClinical behavior analysis and RFT: Conceptualizing psychopathology and its treatmentAnne de AndradeÎncă nu există evaluări

- EPM Mid Lecture 03 Chapt 1Document17 paginiEPM Mid Lecture 03 Chapt 1Partho Protim MondolÎncă nu există evaluări

- Mohammad R. Mestarihi: About Me ObjectiveDocument1 paginăMohammad R. Mestarihi: About Me ObjectiveMhmd MsttÎncă nu există evaluări

- Mathematics Specimen Papers and Mark Schemes UG013054Document102 paginiMathematics Specimen Papers and Mark Schemes UG013054minnie murphy86% (7)

- Soil Testing Lab Results SummaryDocument2 paginiSoil Testing Lab Results SummaryMd SohagÎncă nu există evaluări

- Solwezi General Mental Health TeamDocument35 paginiSolwezi General Mental Health TeamHumphreyÎncă nu există evaluări

- Escalado / PLC - 1 (CPU 1214C AC/DC/Rly) / Program BlocksDocument2 paginiEscalado / PLC - 1 (CPU 1214C AC/DC/Rly) / Program BlocksSegundo Angel Vasquez HuamanÎncă nu există evaluări

- Flight Instructor Patter Ex17Document1 paginăFlight Instructor Patter Ex17s ramanÎncă nu există evaluări

- How To Use Hyper-V Snapshot Revert, Apply, and Delete OptionsDocument15 paginiHow To Use Hyper-V Snapshot Revert, Apply, and Delete OptionsKaran MishraÎncă nu există evaluări