Documente Academic

Documente Profesional

Documente Cultură

Brookfield Viscometer Assignment

Încărcat de

Ricardo VelozDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Brookfield Viscometer Assignment

Încărcat de

Ricardo VelozDrepturi de autor:

Formate disponibile

Brookfield Viscometer Assignment

Introduction

The Brookfield viscometer works by rotating a cylindrical spindle of known surface area

in a fluid, and finding the torque on the spindle. Viscosity is then found through the

relationship:

=

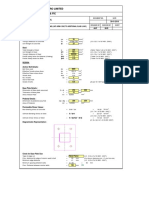

Figure 1- This is very similar design to our viscometer. The only significant difference is the speed

control. Ours is on the side and operates in stepped increments of ! 1"! #$ and $ %&'. From

Brookfield(s )*olution to *ticky &ro+lems,

Where is the viscosity in poise, is the shear stress in dynes cm!, and is the rate of

shear "sec

#$

%. The full scale torque of our &V' model viscometer is ()*.) dyne#cm+

torque is linear with the scale reading. , material requiring a shear stress of $ dyne per

cm

!

to produce a shear rate of one reciprocal second has a viscosity of $ poise "$--cp%.

Theory

.ewtonian fluids such as light oils have a viscosity that is constant with shear rate.

Bingham fluids have a constant viscosity, but require a certain /yield#stress0 "o% in order

to initiate shear "movement%:

+ =

o

1ower &aw fluids are either pseoudoplastic "shear thinning% or dilatant "shear

thickening%. These fluids obey the model:

n

k =

Where k is the /consistency inde20 and n is positive for dilatant fluids and negative for

pseudoplastics "note that for n 3 $, k reduces to the .ewtonian viscosity%.

, power law fluid that has a yield stress is also called a /4erschel Bulkley0 fluid, and

follows:

n

o

k + =

'or cylindrical spindles, the area can be computed as 5

!

&. Torque is computed as the

force acting on the outer surface of the spindle times the radius "/lever arm0%. Therefore,

the following relationships hold:

6hear

5ate "sec

#$

%

%

"

!

! ! !

! !

b c

b c

R R x

R R

6hear 6tress "dynescm

!

%

L R

M

b

!

!

=

Viscosity

=

7efinitions: 3 angular velocity of

spindle "radsec%

%c 3 radius of container

"cm%

%+ 3 radius of spindle

"cm%

- 3 radius at which

shear rate is being

measured

' 3 torque input by

instrument

. 3 effective length of

spindle

*tandard Operating &rocedure

$% &evel the viscometer using the bolts on the legs of the instrument.

!% 8nsert the spindle guard.

*% 8nsert the spindle by very carefully holding the viscometer side and screwing the

spindle in a counterclockwise direction "/left handed threads0%.

9% :arefully lower the viscometer into the solution to be measured using the

mounting nut on the viscometer handle. 8nsert up to the insertion marking on the

spindle.

;% :heck to make sure the viscometer is still level

(% Turn the viscometer on and set to the desired speed "the combination of spindle

and speed should not cause the torque reading to e2ceed $--<%.

)% Wait several rotations for the reading to stabili=e and mark the torque by pressing

down on the clutch lever.

>% Turn off the motor when the needle is in front of the view window and read the

scale.

?% :alculate torque by multiplying the factor found on the card by the unit. @se the

/&V0 and the appropriate spindle number. 6pindle numbers are stamped on the

top of the shaft.

$-% :lean up and unplug viscometer after use.

/-periments

8#Affect of Temperature on Vegetable Bil

'ollowing the 6B1 and using spindleC$, measure the viscosity of the :risco :anola Bil at

several different temperatures. 6tart at room temperature and use the water bath to hear

the solution, periodically taking measurements. Deasure the viscosity at all 9 speeds if

possible.

88#.on#.ewtonian 'luid "ketchup%

'ollowing the 6B1 and using spindleC9, measure the viscosity of the ketchup at all 9

speeds "room temperature%.

Analysis

8# Affect of Temperature on Vegatable Bil

$% ,t a given temperature, are all of the viscosity readings appro2imately the same

for each speedE What does this tell you about the nature of the fluidE

!% 1lot temperature versus viscosity. 7oes viscosity increase or decreaseE 4ow do

these values compare to accepted values for similar oilsE

*% :heck to see if the viscosity of the oil follows the temperature dependence given

in the Brookfield /6olutions to 6ticky 1roblems0 .pdf file and determine

coefficients , and B in equation $; on page !(.

9% 'or the lowest temperature, calculate the torque "scale reading$-- 2 (*).)%, the

shear stress and the shear rate. 7o this for all 9 speeds. 1lot shear rate versus

shear stress. 'ind the slope of the resultant line. 8s the slope within a ?;<

confidence interval of the values you calculated using the factors from the cardE

88# Fetchup Viscosity

$% 1lot rotational speed of the stirrer vs. viscosity. What does the data indicate about

the nature of the fluidE 6ee if a power function "insert trendline% fits the data.

!% 1lot rotational speed of the stirrer vs. viscosity on a log#log plot. What does this

"along with C$% tell you about the fluid propertiesE

*% @se linear regression of the data from C! to find the intercept at =ero 51D. This

is the dynamic yield torque.

9% Fetchup often doesnGt flow unless you bang on the bottom of the bottle. What

does this tell you about the fluidE :onstruct a plot that allows you to determine

the yield stress.

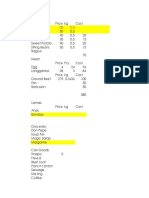

Ta+le 1*pindle 0imensions-

6pindle C$ 6pindle C9

7iameter "cm% $.>>9 (.;$

Affective &ength "cm% -.*! *.$-$

S-ar putea să vă placă și

- Ec Trak ManualDocument426 paginiEc Trak ManualAnonymous VVPsrs4Hxy100% (1)

- Oil Source Rock Correlations Limitations - Curiale 2008Document12 paginiOil Source Rock Correlations Limitations - Curiale 2008cafegrÎncă nu există evaluări

- SurgeDocument1 paginăSurgefrancisryan4519Încă nu există evaluări

- Anti CollisionDocument5 paginiAnti CollisionJaime A PolancoÎncă nu există evaluări

- 9.625 Inter-Prod 53.5 PPFDocument17 pagini9.625 Inter-Prod 53.5 PPFAnonymous XbmoAFtIÎncă nu există evaluări

- Mud Engineer Work ScopeDocument5 paginiMud Engineer Work ScopeMohamed AbozeimaÎncă nu există evaluări

- Volant Specs CRTi4-7.01 PDFDocument5 paginiVolant Specs CRTi4-7.01 PDFRaymond ChuÎncă nu există evaluări

- Ees ExampleDocument12 paginiEes ExamplesbjÎncă nu există evaluări

- Wire Co - Union Drilling LineDocument27 paginiWire Co - Union Drilling LinebeanxinhÎncă nu există evaluări

- Job Pertamina-Petrochina East Java: Wahdanadi, ErikDocument2 paginiJob Pertamina-Petrochina East Java: Wahdanadi, Erikuli ulinuhaÎncă nu există evaluări

- Heavy Hex Nuts Dimensions, Weight Imperial Metric SizesDocument5 paginiHeavy Hex Nuts Dimensions, Weight Imperial Metric SizesEnyÎncă nu există evaluări

- Chapter 2-J Positive Displacement MotorsDocument23 paginiChapter 2-J Positive Displacement MotorsFor Free Drilling Training CenterÎncă nu există evaluări

- Trex 01157Document17 paginiTrex 01157OSDocs2012Încă nu există evaluări

- SOP 829-019 Rig Out The Mud Tanks and Pumps.Document2 paginiSOP 829-019 Rig Out The Mud Tanks and Pumps.Anonymous XbmoAFtIÎncă nu există evaluări

- Underbalance PerforatingDocument4 paginiUnderbalance Perforatingfrancisryan4519Încă nu există evaluări

- Handbook For Magnaflux Y6 Electromagnetic Yoke Nov 11 English Printable VersionDocument4 paginiHandbook For Magnaflux Y6 Electromagnetic Yoke Nov 11 English Printable VersionAnonymous AlhzFE9EVNÎncă nu există evaluări

- P&a Cmt. Calcu.Document2 paginiP&a Cmt. Calcu.francisryan4519Încă nu există evaluări

- HH 83-1D SurveyDocument3 paginiHH 83-1D SurveyMahmoud Ahmed Ali AbdelrazikÎncă nu există evaluări

- SD-24P Bit Record 2Document1 paginăSD-24P Bit Record 2Them Bui XuanÎncă nu există evaluări

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredDocument16 paginiKill Sheet: Prerecorded Infromation Pump Strokes RequiredAbdul Hameed OmarÎncă nu există evaluări

- Pos North1 - Basic WCR Rev0Document874 paginiPos North1 - Basic WCR Rev0Felipe RamírezÎncă nu există evaluări

- 16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7Document1 pagină16.TDI FCR Data 9.625 43.50 PPF P110 BTC Rev.7javier monteroÎncă nu există evaluări

- SV-LX: IpoektDocument162 paginiSV-LX: IpoektThế Dũng NguyễnÎncă nu există evaluări

- Amal-18 Sta DDR#20 02-03-2020Document30 paginiAmal-18 Sta DDR#20 02-03-2020eng7mohamed7hashimÎncă nu există evaluări

- Goldenman Petroluem Equipment Co., Limited: Quotation ListDocument4 paginiGoldenman Petroluem Equipment Co., Limited: Quotation ListEstuardo AlvaradoÎncă nu există evaluări

- Khurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationDocument9 paginiKhurmala Field Field Department Drilling Deve. Oil Wells Project TU LocationAhmedÎncă nu există evaluări

- C 04.a Looking DownholeDocument6 paginiC 04.a Looking DownholeFelix Julio Céspedes SotoÎncă nu există evaluări

- Make Up TorqueDocument1 paginăMake Up TorqueNicasio AlonzoÎncă nu există evaluări

- Morning Report 19 - 24 April 2012Document3 paginiMorning Report 19 - 24 April 2012tolstoy potemkinÎncă nu există evaluări

- TCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsDocument1 paginăTCO - QE - Al Khor - MM-0030 - 7 Packer Retrieval +P and A + Section Mill ToolsrajafonsekaÎncă nu există evaluări

- Unconventional HydrocarbonsDocument3 paginiUnconventional HydrocarbonsMisael Maldonado GutierrezÎncă nu există evaluări

- Synthetic-Based Mud Report No. 39: LLOG ExplorationDocument1 paginăSynthetic-Based Mud Report No. 39: LLOG Explorationadvantage025Încă nu există evaluări

- BHA#06 10.625x12.25in RSS+MWD+LWD+PBL+RR Real R2Document1 paginăBHA#06 10.625x12.25in RSS+MWD+LWD+PBL+RR Real R2Guillermo ToledoÎncă nu există evaluări

- RIG: F28 Shock Sub: OD (Inch) ID (Inch) Length (M) Thread S950024 6-1/8" 9-1/2" 2-7/8" 7-5/8"Document16 paginiRIG: F28 Shock Sub: OD (Inch) ID (Inch) Length (M) Thread S950024 6-1/8" 9-1/2" 2-7/8" 7-5/8"berrouiÎncă nu există evaluări

- TVD & Kill Weight CalculationsDocument40 paginiTVD & Kill Weight Calculationsfrancisryan4519Încă nu există evaluări

- Master Mud TestDocument74 paginiMaster Mud TestSaravanaÎncă nu există evaluări

- Completion (Natural Flow)Document3 paginiCompletion (Natural Flow)Mohammed Ali YoussefÎncă nu există evaluări

- Repair Side Tracking DL LGDocument74 paginiRepair Side Tracking DL LGeleceron7919Încă nu există evaluări

- Daily HSE Summary Report 28-03-2018Document1 paginăDaily HSE Summary Report 28-03-2018Mahmoud Ahmed Ali AbdelrazikÎncă nu există evaluări

- Hosan 1 EWOR Final CheckDocument40 paginiHosan 1 EWOR Final CheckvengurionÎncă nu există evaluări

- String Diagram Toot Deep-1 OGDCL DST-6 - 3Document1 paginăString Diagram Toot Deep-1 OGDCL DST-6 - 3Aadil HaroonÎncă nu există evaluări

- Wafra Well Target TimelineDocument33 paginiWafra Well Target TimelineShraddhanand MoreÎncă nu există evaluări

- Serie Age Formation Top OH M DJHN-3 0 Continental IntercalaireDocument12 paginiSerie Age Formation Top OH M DJHN-3 0 Continental IntercalaireAlexander KlmÎncă nu există evaluări

- Copia de Bha de PozoDocument18 paginiCopia de Bha de PozoBertha Julieth Lopez ParraÎncă nu există evaluări

- Well #1 - Well #1 - PROFILE PDFDocument1 paginăWell #1 - Well #1 - PROFILE PDFHassan ZakeriÎncă nu există evaluări

- BHA and Running ProcedureDocument5 paginiBHA and Running ProcedureRANJITH K PÎncă nu există evaluări

- Drilling Fluid ProgramDocument434 paginiDrilling Fluid ProgramhakoubÎncă nu există evaluări

- Budgetary Quotation Summary - Sensor Update: M/D TotcoDocument8 paginiBudgetary Quotation Summary - Sensor Update: M/D Totcocmrig74Încă nu există evaluări

- By-16 Drilling Monitoring Report 05.11.2012Document3 paginiBy-16 Drilling Monitoring Report 05.11.2012shuvo134Încă nu există evaluări

- AHMSW 8 Fiche de PhaseDocument12 paginiAHMSW 8 Fiche de PhaseBOUBAKER LOGBIÎncă nu există evaluări

- PBL Hole CleaningDocument2 paginiPBL Hole CleaningOlgaLuciaÎncă nu există evaluări

- Drilling HomeworkDocument14 paginiDrilling HomeworkRaphael L Cotta MacedoÎncă nu există evaluări

- 155 Clients 0501 27718-0Document5 pagini155 Clients 0501 27718-0cmrig74Încă nu există evaluări

- ALCAD HC185P DatasheetDocument27 paginiALCAD HC185P DatasheetEn Faizul100% (1)

- Well Data Summary ProgramDocument13 paginiWell Data Summary ProgramTemitope BelloÎncă nu există evaluări

- Synthetic-Based Mud Report No.10: Ongc 20-Feb-22Document4 paginiSynthetic-Based Mud Report No.10: Ongc 20-Feb-22ongcchemist gd chitraÎncă nu există evaluări

- Drilling BHA - General AssemblyDocument3 paginiDrilling BHA - General AssemblyAdel Ahmed AlkhaligyÎncă nu există evaluări

- MudLog NEB-85 Scale 200 (130-5325 FT) - April 25th 2018Document30 paginiMudLog NEB-85 Scale 200 (130-5325 FT) - April 25th 2018parama drillingÎncă nu există evaluări

- Casing Clean Up Tools Description: Casing Scraper Junk Basket Junk SubDocument3 paginiCasing Clean Up Tools Description: Casing Scraper Junk Basket Junk Subnurwinanto01Încă nu există evaluări

- 13.Unit of dynamic viscosity µ=Ns/m or poise 14.Unit of kinematic viscosity γ= m /sec or stoke 15.Unit of discharge Q=m /sec=velocity *area 16.Discharge equation for venturimeter =Q Cd* (a a a a a aDocument9 pagini13.Unit of dynamic viscosity µ=Ns/m or poise 14.Unit of kinematic viscosity γ= m /sec or stoke 15.Unit of discharge Q=m /sec=velocity *area 16.Discharge equation for venturimeter =Q Cd* (a a a a a asirsa11Încă nu există evaluări

- ShareDocument1 paginăShareRicardo VelozÎncă nu există evaluări

- Unit 2: Learning From ApolloDocument2 paginiUnit 2: Learning From ApolloRicardo VelozÎncă nu există evaluări

- ShareDocument1 paginăShareRicardo VelozÎncă nu există evaluări

- TABLE 2-351 Saturated Water Substance-Temperature (Fps Units)Document6 paginiTABLE 2-351 Saturated Water Substance-Temperature (Fps Units)Ricardo VelozÎncă nu există evaluări

- The Apollo HoaxDocument15 paginiThe Apollo HoaxknowledgefirstÎncă nu există evaluări

- A Key Engineer From David LaithDocument3 paginiA Key Engineer From David LaithRicardo VelozÎncă nu există evaluări

- Engineering EconomyDocument4 paginiEngineering EconomyRicardo VelozÎncă nu există evaluări

- Engineering EconomyDocument4 paginiEngineering EconomyRicardo VelozÎncă nu există evaluări

- Interest: Future Worth: EffectiveDocument5 paginiInterest: Future Worth: EffectiveRicardo VelozÎncă nu există evaluări

- The Corporation Code of The PhilippinesDocument7 paginiThe Corporation Code of The PhilippinesRicardo VelozÎncă nu există evaluări

- Corporate ConstitutionDocument2 paginiCorporate ConstitutionRicardo VelozÎncă nu există evaluări

- Interest: Future Worth: EffectiveDocument5 paginiInterest: Future Worth: EffectiveRicardo VelozÎncă nu există evaluări

- How To Create Your Constitution and By-LawsDocument4 paginiHow To Create Your Constitution and By-LawsRicardo VelozÎncă nu există evaluări

- Diffusion Through A Stagnant Gas FilmDocument16 paginiDiffusion Through A Stagnant Gas FilmSuleman Tariq100% (3)

- Day 1Document60 paginiDay 1Ricardo VelozÎncă nu există evaluări

- ChE 505 Chapter 10NDocument46 paginiChE 505 Chapter 10NYassin RoslanÎncă nu există evaluări

- Scandal in Bohemia: Adventure 1Document32 paginiScandal in Bohemia: Adventure 1Ricardo VelozÎncă nu există evaluări

- Business ContractDocument5 paginiBusiness ContractRicardo Veloz100% (1)

- TomorrowDocument2 paginiTomorrowRicardo VelozÎncă nu există evaluări

- Quadratic EquationDocument1 paginăQuadratic EquationRicardo VelozÎncă nu există evaluări

- Lab Form 1Document1 paginăLab Form 1Ricardo VelozÎncă nu există evaluări

- White Paper: Dispersing Powders in Liquid For Particle Size AnalysisDocument7 paginiWhite Paper: Dispersing Powders in Liquid For Particle Size AnalysisRicardo VelozÎncă nu există evaluări

- Schedule Weekly 24 HoursDocument1 paginăSchedule Weekly 24 HourschandranegaraÎncă nu există evaluări

- Hydroxy ApatiteDocument3 paginiHydroxy ApatiteRicardo VelozÎncă nu există evaluări

- MsdsDocument5 paginiMsdsRicardo VelozÎncă nu există evaluări

- Schedule Weekly 24 HoursDocument1 paginăSchedule Weekly 24 HourschandranegaraÎncă nu există evaluări

- Daily Planner Template 03Document3 paginiDaily Planner Template 03Ricardo VelozÎncă nu există evaluări

- Mineral SeparationDocument9 paginiMineral SeparationNamwangala Rashid NatinduÎncă nu există evaluări

- (Dy - DX) (X 2+1) + (4 (Y 2) +1) + (8xy) +1 - Wolfram - AlphaDocument2 pagini(Dy - DX) (X 2+1) + (4 (Y 2) +1) + (8xy) +1 - Wolfram - AlphaRicardo VelozÎncă nu există evaluări

- DIY Knifemaker's Info Center - Heat Treatment Oven ProjectDocument34 paginiDIY Knifemaker's Info Center - Heat Treatment Oven ProjectRicardo VelozÎncă nu există evaluări

- ChE 122 Lecture Notes 03 II. Basic Concepts and The First Law (2.7-2.10)Document4 paginiChE 122 Lecture Notes 03 II. Basic Concepts and The First Law (2.7-2.10)MarkVergelBorjaÎncă nu există evaluări

- P&H 50t Ingles PDFDocument19 paginiP&H 50t Ingles PDFDanilo MarinÎncă nu există evaluări

- Design of Base Plate LKP Arm 4-F-30.01.2018Document5 paginiDesign of Base Plate LKP Arm 4-F-30.01.2018HarikrishnaÎncă nu există evaluări

- Cylinder Head - Install: Desarmado y ArmadoDocument4 paginiCylinder Head - Install: Desarmado y ArmadoDavid Apaza HurtadoÎncă nu există evaluări

- Doser Line Fuel Valve Dd1513Document7 paginiDoser Line Fuel Valve Dd1513cheolllÎncă nu există evaluări

- Taheri-Degradation and Improvement of Mechanical Properties of Rock Under Triaxial Compressive Cyclic LoadingDocument8 paginiTaheri-Degradation and Improvement of Mechanical Properties of Rock Under Triaxial Compressive Cyclic LoadingRichardson Chavez TaypeÎncă nu există evaluări

- Chapter 2 - Lubrication (Added)Document32 paginiChapter 2 - Lubrication (Added)Najip TalibinÎncă nu există evaluări

- Potter Air Relief Valve - 5401165 - PavDocument3 paginiPotter Air Relief Valve - 5401165 - PavFrancisco AlarconÎncă nu există evaluări

- Service Manual #41Document106 paginiService Manual #41GrindK0re73% (15)

- Utp 068 HHDocument1 paginăUtp 068 HHRoberto_PrrÎncă nu există evaluări

- Vibration Testing Theory and PracticeDocument31 paginiVibration Testing Theory and PracticeDilara Çınarel0% (3)

- c68700 Aluminum BrassDocument1 paginăc68700 Aluminum Brassm_f_deathÎncă nu există evaluări

- Insight NDT Equipment LTD - ..Document2 paginiInsight NDT Equipment LTD - ..aoxoxzÎncă nu există evaluări

- Assignment: - Design of Pneumatic Conveyer Dryer: SpecificationDocument4 paginiAssignment: - Design of Pneumatic Conveyer Dryer: SpecificationPraween NishadÎncă nu există evaluări

- HWP Datasheet Full-SetDocument10 paginiHWP Datasheet Full-SetPhan Công ChiếnÎncă nu există evaluări

- Checklist GD BandlockDocument3 paginiChecklist GD BandlockdeogmozyxÎncă nu există evaluări

- 1 OnlineDocument21 pagini1 OnlineBành Đức MinhÎncă nu există evaluări

- Volume 01 Principles of FlightDocument303 paginiVolume 01 Principles of FlightYousif AL AyoubiÎncă nu există evaluări

- C17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetDocument3 paginiC17058 XXXXXXXX FPSO Carioca MV30: Lthe Offshore Engineering Nozzle Evaluation SheetJ A S JASÎncă nu există evaluări

- Astm A216Document4 paginiAstm A216salazaralexi100% (1)

- DCS BeamDesign Lect3Document14 paginiDCS BeamDesign Lect3Rahul ChaudharyÎncă nu există evaluări

- MGT Turbec t100 CCDocument28 paginiMGT Turbec t100 CCDk DamoÎncă nu există evaluări

- FP IgniterDocument13 paginiFP IgniterDavid AlexanderÎncă nu există evaluări

- C Rollway PDFDocument16 paginiC Rollway PDFoxonoerÎncă nu există evaluări

- Hydraulic Jet PumpDocument3 paginiHydraulic Jet Pumpvictor javier nuñezÎncă nu există evaluări

- Final OSB PRIMA - 4038 - 4738 - 3APRIL14Document232 paginiFinal OSB PRIMA - 4038 - 4738 - 3APRIL14sengottaiyanÎncă nu există evaluări

- Hiace Techstream 1st RunDocument3 paginiHiace Techstream 1st RunStephen MasemoÎncă nu există evaluări

- Scope of Work For Various Valve ServicingDocument3 paginiScope of Work For Various Valve ServicingSreekanthMylavarapu100% (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDe la Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideEvaluare: 3.5 din 5 stele3.5/5 (7)

- The Laws of Thermodynamics: A Very Short IntroductionDe la EverandThe Laws of Thermodynamics: A Very Short IntroductionEvaluare: 4.5 din 5 stele4.5/5 (10)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDe la EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionEvaluare: 4.5 din 5 stele4.5/5 (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDe la EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisEvaluare: 4 din 5 stele4/5 (2)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDe la EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseEvaluare: 4.5 din 5 stele4.5/5 (51)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDe la EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedEvaluare: 5 din 5 stele5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDe la EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsÎncă nu există evaluări

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyDe la EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyEvaluare: 5 din 5 stele5/5 (1)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDe la EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisEvaluare: 5 din 5 stele5/5 (1)

- Handbook of Mechanical and Materials EngineeringDe la EverandHandbook of Mechanical and Materials EngineeringEvaluare: 5 din 5 stele5/5 (4)

- A Complete Guide to Safety Officer Interview Questions and AnswersDe la EverandA Complete Guide to Safety Officer Interview Questions and AnswersEvaluare: 4 din 5 stele4/5 (1)

- Mechanical Vibrations and Condition MonitoringDe la EverandMechanical Vibrations and Condition MonitoringEvaluare: 5 din 5 stele5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchDe la EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchEvaluare: 4 din 5 stele4/5 (10)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDe la EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsÎncă nu există evaluări

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CDe la EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CÎncă nu există evaluări