Documente Academic

Documente Profesional

Documente Cultură

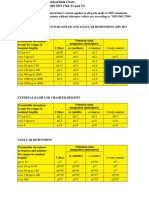

Standard Machining Tolerance

Încărcat de

Denny Ilyas AttamimiDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Standard Machining Tolerance

Încărcat de

Denny Ilyas AttamimiDrepturi de autor:

Formate disponibile

Tolerance class Standard dimension range

Symbol Description

Over 0.5

1

to

3 incl.

Over 3 to 6

incl.

Over 6 to 30

incl.

Over 30 to

120 incl.

Over 120 to

400 incl.

Over 400 to

1000 incl.

Over 1000 to

2000 incl.

Over 2000 to

4000 incl.

Tolerance

f Precision grade 0.05 0.05 0.1 0.15 0.2 0.3 0.5

m Medium class 0.1 0.1 0.2 0.3 0.5 0.8 1.2 2

c Coarse class 0.2 0.3 0.5 0.8 1.2 2 3 4

v Very coarse class 0.5 1 1.5 2.5 4 6 8

Note

1

: Tolerances for standard dimensions of less than 0.5 mm shall be specified individually.

Tolerance class Standard dimension range

Symbol Description

Over 0.5

2

to

3 incl.

Over 3 to

6 incl.

Over 6

Tolerance

f Precision grade

0.2 0.5 1

m Medium class

c Coarse class

0.4 1 2

v Very coarse class

Note

2

: Tolerances for standard dimensions of less

than 0.5 mm shall be specified individually.

Tolerance class

Nominal length on shorter side

100 or less

Over 100 to 300

incl.

Over 300 to 1000

incl.

Over 1000 to 3000

incl.

Perpendicularity tolerance

H 0.2 0.3 0.4 0.5

K 0.4 0.6 0.8 1

L 0.6 1 1.5 2

Tolerance class

Nominal length

10 or less

Over 10 to 30

incl.

Over 30 to 100

incl.

Over 100 to

300 incl.

Over 300 to

1000 incl.

Over 1000 to

3000 incl.

Straightness and fatness tolerance

H 0.02 0.05 0.1 0.2 0.3 0.4

K 0.05 0.1 0.2 0.4 0.6 0.8

L 0.1 0.2 0.4 0.8 1.2 1.6

Tolerance class

Nominal length

100 or less

Over 100 to 300

incl.

Over 300 to 1000

incl.

Over 1000 to

3000 incl.

Symmetry tolerance

H 0.5

K 0.6 0.8 1

L 0.6 1 1.5 2

Tolerance class Length of shorter side of angle

Symbol Description

Units: mm

10 or less

Over 10 to

50 incl.

Over 50 to

120 incl.

Over 120

to 400 incl.

Over 400

Tolerance

f Precision grade

1 30 20 10 5

m Medium class

c Coarse class 130 1 30 15 10

v Very coarse class 3 2 1 30 20

1265 1266

GENERAL DIMENSIONAL TOLERANCES FOR PARTS FORMED BY PRESS

Excerpts from JIS B 0408 1991

WORKING FROM SHEET METAL AND SHEAR FROM METAL PLATES

JIS B 0410 1991

TECHNICAL DATA

1. Regular cut dimension tolerance JIS B 0405 1991

Tolerances for length excluding chamfered portion Units: mm

2. Tolerance for length of chamfered portion

radius of rounding for edges and edge

chamfering dimension

4. Regular perpendicularity tolerance JIS B 0419 1991

Units: mm

5. Regular straightness and fatness tolerance JIS B 0419 1991

Units: mm

6. Regular symmetry tolerance

Units: mm

3. Angle tolerance

Units: mm

TECHNICAL DATA STANDARD MACHINING TOLERANCES

Excerpts from JIS B 0405 1991

JIS B 0419 1991

0.05

0.1

0.15

0.2

0.3

0.5

0.1

0.2

0.3

0.5

0.8

1.2

0.3

0.5

0.8

1.2

2

3 6 3 1.2

4 2 0.8

2.5 1.2 0.5

1.5 0.8 0.3

1 0.5 0.2

0.5 0.3 0.1

t 1.6 1.6t 3 3t 6 6t 12

0.1

0.2

0.3

0.5

0.8

1.2

0.3

0.5

0.8

1

1.5

2

0.3

0.4

0.5

0.8

1.2

0.5

0.8

1.2

2

2.5

0.8

1

1.5

2

3

1.2

1.5

2

3

4

1.5

2

2.5

3

4

6

4

3

2

1.5

5

3

2

1.5

0.8

3

2

1.5

0.8

0.5

2.5

1.5

1

0.5

0.3

1.2

0.8

0.5

0.3

0.2

2

1.2

0.8

0.5

0.3

0.2

1.2

0.8

0.5

0.3

0.2

0.1

t 3 3t 6 6t 12

0.3

0.8

1.5

3

6

0.5

1.2

3

6

10

0.5

1

2

4

6

0.8

1.5

3

6

10

1.5

2

3

6

10

t 1.6 1.6t 3 6t 12 3t 6

1. General dimension tolerance for parts formed by press working from sheet metal JIS B 04081991

Table 1. General dimension tolerances of punching Units: mm

Standard dimension

Grade

Grade A Grade B Grade C

More than 1000 No more than 2000

No more than 1000 More than 400

No more than 400 More than 120

No more than 120 More than 30

No more than 30 More than 6

No more than 6

Note Note

No more than 6

More than 6 No more than 30

More than 30 No more than 120

More than 120 No more than 400

More than 400 No more than 1000

No more than 2000 More than 1000

Grade C Grade B Grade A

Grade

Standard dimension

Units: mm Table 2. General dimensional tolerances of bending and drawing

Table 1. General dimensional tolerances of cut widths Units: mm

Standard dimension

No more than 30

More than 30 No more than 120

More than 120 No more than 400

More than 400 No more than 1000

No more than 2000 More than 1000

No more than 4000 More than 2000

2. General tolerances for parts formed by shear from metal plates JIS B 04101991

Grade A Grade B Grade A Grade B Grade A Grade B Grade A Grade B

Material thickness tclass

Grade

Grade

Material thickness tclass

Grade B Grade A Grade B Grade A Grade B Grade A Grade B Grade A

More than 2000 No more than 4000

More than 1000 No more than 2000

No more than 1000 More than 400

No more than 400 More than 120

No more than 120 More than 30

No more than 30

Nominal dimensionof cut length

Table 2. General tolerances of straightness Units: mm

Units: mm Table 3. General tolerances for perpendicularity

No more than 30

More than 30 No more than 120

More than 120 No more than 400

More than 400 No more than 1000

No more than 2000 More than 1000

No more than 4000 More than 2000

Grade A Grade B Grade A Grade B Grade A Grade B

Material thickness tclass

Grade

Nominal length of short

side

Grade A, B, and C are equivalent to tolerance grades f, m, and c

in JIS B 0405.

Grade A, B, and C are equivalent to tolerance grades f, m, and c

in JIS B 0405.

PD-08.indd 1265-1266 2012/10/25 17:12:13

S-ar putea să vă placă și

- Misumi Technical Data PDFDocument1 paginăMisumi Technical Data PDFtnchsg100% (1)

- General Tolerances DIN ISO 2768Document4 paginiGeneral Tolerances DIN ISO 2768NaveenRajÎncă nu există evaluări

- General Tolerances To DIN ISO 2768 T1 and T2Document2 paginiGeneral Tolerances To DIN ISO 2768 T1 and T2manageieÎncă nu există evaluări

- Standard Machining Tolerance JIS B 0405Document6 paginiStandard Machining Tolerance JIS B 0405fsijestÎncă nu există evaluări

- General Tolerances DIN ISO 2768Document2 paginiGeneral Tolerances DIN ISO 2768Vasil Gospodinov79% (24)

- General Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)Document1 paginăGeneral Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)VIVEK UPADHYAYÎncă nu există evaluări

- Tolerance For Press Work PDFDocument1 paginăTolerance For Press Work PDFmr.nguyenkÎncă nu există evaluări

- JIS B0419-1991 (Dung Sai Kich Thuoc)Document1 paginăJIS B0419-1991 (Dung Sai Kich Thuoc)Giang Nguyễn BáÎncă nu există evaluări

- Metric Tolerances and Thread PitchDocument2 paginiMetric Tolerances and Thread PitchEnDjo Ech RahardjoÎncă nu există evaluări

- General Tolerances - DIN - ISO - 2768 PDFDocument2 paginiGeneral Tolerances - DIN - ISO - 2768 PDFHenrique MarquesÎncă nu există evaluări

- Surface Roughness by Different Processing MethodsDocument1 paginăSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- SAE J1926, MS 16142 - CuttersDocument11 paginiSAE J1926, MS 16142 - CutterspbsurfÎncă nu există evaluări

- CR StandardsDocument6 paginiCR Standardsalpha_beta48Încă nu există evaluări

- GD&TDocument74 paginiGD&Tgary311098Încă nu există evaluări

- General Dimensional Tolerances For Sheet Metal Formed Parts. (Unless Otherwise Specified)Document1 paginăGeneral Dimensional Tolerances For Sheet Metal Formed Parts. (Unless Otherwise Specified)murali036Încă nu există evaluări

- JIS ToleranceDocument3 paginiJIS Tolerancef_riseÎncă nu există evaluări

- HHHHHHHHHHHDocument4 paginiHHHHHHHHHHHGuru VagaÎncă nu există evaluări

- Tolerance AnalysisDocument10 paginiTolerance Analysisdineshnexus100% (1)

- Din 7168Document1 paginăDin 7168Anderson SantosÎncă nu există evaluări

- Is 2102Document8 paginiIs 2102Sowmen Chakroborty100% (1)

- Us 12e pr1265 PDFDocument1 paginăUs 12e pr1265 PDFAzis AbdÎncă nu există evaluări

- General Tolerance - IsO 2768-mH (DIN 7168) (JIS B 0419)Document3 paginiGeneral Tolerance - IsO 2768-mH (DIN 7168) (JIS B 0419)olive_poa100% (3)

- Iso 2768-1 TolerancesDocument2 paginiIso 2768-1 TolerancesTang Bv100% (2)

- Parkers: BS EN 10258: 1997Document3 paginiParkers: BS EN 10258: 1997JagankumarÎncă nu există evaluări

- ToleranceDocument9 paginiTolerancemarkom123Încă nu există evaluări

- Tolerances To en 10051 For Continuously Rolled HotDocument4 paginiTolerances To en 10051 For Continuously Rolled HotSorin LescaiÎncă nu există evaluări

- Tolerances To en 10051Document2 paginiTolerances To en 10051Joan ReigÎncă nu există evaluări

- Din 7168Document2 paginiDin 7168Amândio Santos75% (4)

- Maryland Metrics Technical Data Chart - General Tolerances To DIN ISO 2768Document2 paginiMaryland Metrics Technical Data Chart - General Tolerances To DIN ISO 2768Faruk EkinciÎncă nu există evaluări

- Maryland Metrics Technical Data Chart: General Tolerances To DIN ISO 2768 T1 and T2Document3 paginiMaryland Metrics Technical Data Chart: General Tolerances To DIN ISO 2768 T1 and T2Nandha KumarÎncă nu există evaluări

- Tolerances FabDocument1 paginăTolerances FabAnwarÎncă nu există evaluări

- 9 Regular Machining Dimension Tolerance 01Document1 pagină9 Regular Machining Dimension Tolerance 01OllenkÎncă nu există evaluări

- Tolerance Class Designation (Description)Document2 paginiTolerance Class Designation (Description)Cristian PopescuÎncă nu există evaluări

- Worldsupport Standards14.Php ActioDocument3 paginiWorldsupport Standards14.Php ActioSteel Zevallos PitzuhaÎncă nu există evaluări

- General Tolerances DIN ISO 2768Document4 paginiGeneral Tolerances DIN ISO 2768La Hong LeÎncă nu există evaluări

- Iso 2768-1Document1 paginăIso 2768-1Roberto Mota100% (1)

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesDe la EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesEvaluare: 1 din 5 stele1/5 (1)

- Disston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderDe la EverandDisston Lumberman Handbook - Containing A Treatise Of The Construction Of Saws And How To Keep Them In OrderÎncă nu există evaluări

- Cylindrical Compression Helix Springs For Suspension SystemsDe la EverandCylindrical Compression Helix Springs For Suspension SystemsÎncă nu există evaluări

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionDe la EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionÎncă nu există evaluări

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsDe la EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsÎncă nu există evaluări

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosDe la EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosÎncă nu există evaluări

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDe la EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsÎncă nu există evaluări

- JFK - Toots Shor Restaurant - Mike ToddDocument4 paginiJFK - Toots Shor Restaurant - Mike ToddMichael SmithÎncă nu există evaluări

- Lotfp Character Creation PamphletDocument6 paginiLotfp Character Creation PamphletTifany OhanaÎncă nu există evaluări

- TombKings 2011Document13 paginiTombKings 2011Luis Aquino100% (2)

- Vector IndexDocument13 paginiVector IndexJondri Yoza0% (1)

- CV Transmission PlanningDocument5 paginiCV Transmission Planninger.pankajkeshari1784Încă nu există evaluări

- FlashArray XR2 & XR3 Cabling GuideDocument21 paginiFlashArray XR2 & XR3 Cabling GuideluckyÎncă nu există evaluări

- The Apres-Garde - A History of Avantgarde MusicDocument72 paginiThe Apres-Garde - A History of Avantgarde MusicIgor Rosa0% (1)

- Spare Parts List: Sludge Pumps CP 0077Document16 paginiSpare Parts List: Sludge Pumps CP 0077obumuyaemesiÎncă nu există evaluări

- Enrique IglesiasDocument25 paginiEnrique IglesiasNagham Bazzi0% (1)

- ListofaprovedprojectsDocument22 paginiListofaprovedprojectsMahend RanÎncă nu există evaluări

- The Abington Journal 05-25-2011Document28 paginiThe Abington Journal 05-25-2011The Times LeaderÎncă nu există evaluări

- Steps in Bituminous Road ConstructionDocument3 paginiSteps in Bituminous Road Constructionlance lancelottiÎncă nu există evaluări

- She Works A Lot Present Simple WRITING - 1Document1 paginăShe Works A Lot Present Simple WRITING - 1alex esteves mejiaÎncă nu există evaluări

- Materi Bahasa Inggris Report Text SMP/MTsDocument25 paginiMateri Bahasa Inggris Report Text SMP/MTsLuthfan0% (1)

- Pipe Culvert 1000MMDocument8 paginiPipe Culvert 1000MMgtarun22gupta86% (7)

- PE 103 DANCES Unit 5 Hip Hop DanceDocument5 paginiPE 103 DANCES Unit 5 Hip Hop DanceVictor Angelo AlejandroÎncă nu există evaluări

- Chantons La Mlodie EspagnoleDocument4 paginiChantons La Mlodie EspagnoleKristinÎncă nu există evaluări

- ENE KB9022 On LA-A342P ZIPS3Document15 paginiENE KB9022 On LA-A342P ZIPS3Hassan FakhouryÎncă nu există evaluări

- God Is Here by Darlene ZschechDocument1 paginăGod Is Here by Darlene ZschechEmanuel ScomparinÎncă nu există evaluări

- Excerpt FromDocument7 paginiExcerpt FromCathryn ValmontÎncă nu există evaluări

- Introduction To Computer NetworksDocument17 paginiIntroduction To Computer NetworkskhanpmansoorÎncă nu există evaluări

- Oneida VVS FootballDocument1 paginăOneida VVS FootballOneida Daily DispatchÎncă nu există evaluări

- Mixdown For Mastering TipsDocument12 paginiMixdown For Mastering Tipshelboy_trcÎncă nu există evaluări

- Kurt VonnegutDocument1 paginăKurt VonnegutФаридÎncă nu există evaluări

- Caught in A Mosh: Standard TuningDocument15 paginiCaught in A Mosh: Standard TuningTauno LepistöÎncă nu există evaluări

- The OXford Dictionary of Literary Terms (3 Ed)Document1 paginăThe OXford Dictionary of Literary Terms (3 Ed)yonseienglish33% (3)

- How To Build A Robot at Home - 9 Steps (With Pictures) - WikiHowDocument3 paginiHow To Build A Robot at Home - 9 Steps (With Pictures) - WikiHowPonggey YabolÎncă nu există evaluări

- The Top Five Glute ExercisesDocument19 paginiThe Top Five Glute ExercisesGilberto Solares50% (2)

- Master Your Nikon D-SLR Camera 2015 PDFDocument223 paginiMaster Your Nikon D-SLR Camera 2015 PDFFaiza Hassan100% (5)

- Jazzy PrayersDocument3 paginiJazzy PrayersTheLivingChurchdocsÎncă nu există evaluări