Documente Academic

Documente Profesional

Documente Cultură

Dynaco Dump Pump PDF

Încărcat de

nbgears0 evaluări0% au considerat acest document util (0 voturi)

272 vizualizări14 paginiDynaco (Ningbo) Hydraulic, its subsidiaries and authorized distributors provide prod uct and / or system options for further investigation by users. Products described herein, including without limitation, product features, specifications, designs, availability and pricing.

Descriere originală:

Titlu original

Dynaco Dump Pump.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDynaco (Ningbo) Hydraulic, its subsidiaries and authorized distributors provide prod uct and / or system options for further investigation by users. Products described herein, including without limitation, product features, specifications, designs, availability and pricing.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

272 vizualizări14 paginiDynaco Dump Pump PDF

Încărcat de

nbgearsDynaco (Ningbo) Hydraulic, its subsidiaries and authorized distributors provide prod uct and / or system options for further investigation by users. Products described herein, including without limitation, product features, specifications, designs, availability and pricing.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 14

Machinery Hydraulics

Product Range Information

Dynaco Hydraulic Co., Ltd.

C101/C102 Series

G101/G102 Series

Dynaco Hydraulic Publisher

Document no.

For further advanced information on the products mentioned,

http://www.dynacohydraulic.com on the Internet

please contact your pertinent marketing partner, refer to

SN091200.1.2

Date: 09.12

Email: nbgears@163.com

Web: www.dynacohydraulic.com

Typical Parts Breakdown............................................ 10

Dimensions C101/C102............................................. 9

Dimensions G101/G102............................................. 8

Typical Flow Paths...................................................... 7

Performance Curves................................................... 6

Model Features........................................................... 6

Air Shift Kits................................................................ 5

Coding: G101/G102 Series........................................ 4

Coding: C101/C102 Series......................................... 4

Description.................................................................. 3

Content

Application.................................................................. 2

2

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE DEATH, PERSONAL

INJURY AND PROPERTY DAMAGE.

having technical expertise. It is important that you analyze all aspects of your application and review the information concerning the product or system in the current product catalog. Due

to the variety of operating conditions and applications for these products or systems, the user, through its own analysis and testing, is solely responsible for making the final selection of

the products and systems and assuring that all performance, safety and warning requirements of the application are met.

WARNING

!

Copyright 2009, Dynaco (Ningbo) Hydraulic Co., Ltd, All Rights Reserved.

This document & other information from Dynaco (Ningbo) Hydraulic, its subsidiaries and authorized distributors provide prod uct and/or system options for further investigation by users

The products described herein, including without limitation, product features, specifications, designs, availability and pricing, are subject to change by Dynaco ( Ningbo) Hydraulic and

its ubsidiaries at any time without notice.

Applications:

Dump Truck

Dump Trailer

2009 Dynaco Hydraulic Co., Ltd

3

Underbody Hoist to Big Trailers -

We Have Your Pump

Pressures to 2500 psi

Speeds to 2400 rpm

Relief valve protects pump & cylinder

Air remote operators available

Choice of mountings

2- or 3-line installations

9.5, 21 & 29 gpm @ 1800 rpm

Pressures to 2500 psi

Speeds to 2400 rpm

2- or 3-line installations

Air remote operators available

Relief valve protects pump & cylinder

We design and manufacture more pump/valve combinations

for dump trucks and trailers than any other manufacturer for

39 & 48 gpm @ 1800 rpm

Choice of mountings

choice of flow ratings; these units provide the most reliable,

trouble-free control for dump trucks.

two reasons: Dynaco pump/valve family offer the widest

Dynaco dump body pump/valve products deliver the right

flow range for most applications at 1800 rpm/2000 psi.

Models with two shafts (C101/G101) can be mounted to

remote PTOs operating in either direction of rotation. Single

shaft units (C102/G102) mount directly to the vehicle drive

train. All can be connected in two- or three-line circuits to

control single-acting cylinders. All units are supplied with

factory-set 2000 psi relief valves

Pump/Valve Products

C101/C102

G101/G102

The Widest Choice

2009Dynaco Hydraulic Co., Ltd

4

Displacements

Gear in.

3

/

Width rev.

20 2.0 5.1

25 2.5 6.4

Rotation C102 Direct

Mount Only

Blank Clockwise

1 Counter Clockwise

C 1 0 D

.

Mounting

1 Remote Mount

2 Direct Mount

Spool Options

1 Detent

2 Spring Return

Displacements

Gear in.

3

/

Width rev.

0.7 0.7 1.5

1.5 1.5 3.0

2.0 2.0 3.9

Rotation G102 Only

R Clockwise

L Counter Clockwise

Mounting Flange

G102 Only

2S SAE 2 Bolt B

CS Cloverleaf Mount

4S SAE 4 Bolt B

Example:

Example:

G 1 0

Mounting Bracket Part Numbers

C101 Mounting Bracket 314-0100-005

C102 Support Bracket 391-1832-323

Mounting

1 Remote Mount

2 Direct Mount

2009 Dynaco Hydraulic Co., Ltd

Coding: C101/C102 Series

Coding: G101/G102 Series

5

C101/C102 AIR SHIFT KITS 10 Digit Part No.

ASK-6 without Toggle with Air Hose, Fittings ........................ 314-9414-006

ASK-13 with Air Metering Controller .................................... 314-9414-013

ASK-17 without Air Hose, Fittings ........................................ 314-9414-017

G101/G102 AIR SHIFT KITS 10 Digit Part No.

ASK-16 without Toggle with Air Hose, Fittings ...................... 308-9414-016

ASK-20 with Air Metering Controller .................................... 308-9414-020

C101 Air-Shift Installation Standard C101

All dump units can be shifted from the cab by cable or

by air with our Air Shift kit.

The kit consists of an air cylinder that mounts on the

valve unit, a pneumatic control valve that mounts in the

cab, 30' of air hose and all necessary connections. A

minimum of 80 psi air pressure is required, which can

be taken off the brake system or on-board compressor.

The shifter can be retro-fit easily to existing pump/valve

units by following the simple instructions with each kit.

2009Dynaco Hydraulic Co., Ltd

Air Shift Kits

6

Performance Curves

Average Pump Output @ 2000 psi

Warning

*

Model Features

A: Two- or Three-line Hookup

B: Remote Valve Actuation

C: Factory Set Rotation

D: Either Shaft Rotation

E: 1.00" diameter Keyed Shaft

F: SAE B Splined Shaft

(13 teeth, 16/32 pitch)

G101/G102

C101/C102

Model Maximum gpm@1800 rpm Maximum Available

Number psi " 1" 2" 2" Speed Features

G101 2500 9.5 21 29 2400 rpm A,B,D*,E

G102 2500 9.5 21 29 2400 rpm A,B,C*,F

C101 2500 39 48 2400 rpm A,B,D*,E

C102 2500 39 48 2400 rpm A,B,C*,F

0 500 1000 1500 2000

1800

36

27

18

9

0

1 1/2"

2"

O

u

t

p

u

t

(

g

p

m

)

Speed (rpm)

G

e

a

r

W

i

d

t

h

3/4"

0 500 1000 1500 2000

1800

48

36

24

15

0

2"

2"

O

u

t

p

u

t

(

g

p

m

)

Speed (rpm)

G

e

a

r

W

i

d

t

h

transit. Failure to provide such a lock may lead

to loss of vehicle control, accidental injury and/

or property damage.

These warnings apply to all pump/valve units.

pump/valve when in transit may allow the dump

bed to rise unintentionally. This may lead to loss

of vehicle control, accidental injury and/or

property damage.

Performance data shown are average results based on

a series of production units and are not representative

of any one unit. Tests were run with the oil reservoir

temperature at 120F, viscosity of 150 SUS at 100F.

Requests for more specific data should be directed

to our Product Support Department through your

sales representative.

Failure to disengage the PTO from driving the

device for those applications using a pull-out cable.

This device allows the pull-out cable to move the

valve spool from the raise to the neutral position only.

Since shock loading in the cable is possible, it is

essential that a spring (Part no. 391-3581-854 or

equal) be incorporated in the pull-out cable

hookup. Failure to do so could result in breakage of

the neutral stop device and could lead to injury. We

recommend that the cable be fully enclosed and

directly in line with the spool.

first securely blocking the bed to prevent its

accidental lowering.

possible. Three-line circuits consist of a pump inlet

line, a line to the cylinder and a return line to tank.

A sleeve must be installed in the pumps inlet to

allow oil to circulate through the unit and return

to tank when running in neutral. Lower operating

temperatures and the ability to install a return-line

filter are two advantages of a three-line circuit. Be

sure the return line is always below the oil level in the

reservoir. Two-line installations are for intermittent

operation only.

Never work under a raised dump bed without

If you do not understand these warnings or have

any questions about any of them, contact your

distributor or the Product Support Group at:

Phone (86-25 ) 85360418 or Fax (86-25) 89428524

dump bed to rise unintentionally while in

A device to lock the control lever in the neutral

position must be installed. Pump/valve units

without a lockable control lever may allow the

The pump/valves are equipped with a neutral stop

Three-line installations are recommended whenever

All C102/G102 units can be ordered for either direction of rotation from the factory;

All C101/G101 units can be field set for either direction of rotation.

2009 Dynaco Hydraulic Co., Ltd

7

Typical Flow Paths in C101/C102 Pump/Valve Units

Explanation of single-acting valve.

2-line Installation

3-line Installation

Spool in Neutral:

Oil recirculates internally.

Raise Position:

Oil is routed through work port to

raise the cylinder.

Lower Position:

Oil flows from the cylinder through

the relief valve to return to tank.

Spool in Neutral:

Oil circulates through the pump and

returns to tank.

Raise Position:

Oil is routed through work port to

raise the cylinder.

Lower Position:

Oil flows from the cylinder, through

the bottom port and returns to tank.

C101/C102: 2-line Installation

For intermittent operation.

C101/C102: 3-line Installation

For continuous or intermittent

operation.

CYL. LINE

INLET

CYL. LINE

TANK LINE

INLET

One line to the cylinder, one line to the reservoir.

For intermittent operation only.

One line to the cylinder, two lines to the reservoir.

For continuous or intermittent operation.

2009Dynaco Hydraulic Co., Ltd

8

G102 (CW Rotation Shown)

G101

Dimensions G101/G102

2009 Dynaco Hydraulic Co., Ltd

9

C101

C102 (CCW Rotation Shown)

Dimensions C101/C102

2009Dynaco Hydraulic Co., Ltd

10

9

8

7

6

5

4 3

2

1

17

16

18

10

11

12

4

5

6

7

15

13

14

23

22

21

20

19

24

22

25

26

27

28

29

30

31

32

3

45

46

2

42

43

1

34

33

33

35

36

37

30

38

32

42

40

41

39

2009 Dynaco Hydraulic Co., Ltd

Parts Breakdown

11

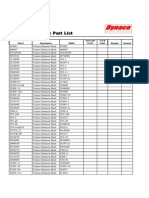

Decription Part # Qty. Series

1 Snap Ring 391-2681-493 2 C

391-2686-065 1 C2

391-2681-487 2 G

391-2686-063 1 G2

2 Lip Seal 391-2883-096 2 C

391-2883-115 1 C2

391-2883-119 2 G

391-2883-119 1 G2

3 Shaft End Cover 314-5039-201 1 C

313-5033-435 1 C2

308-5016-201 1 G

308-5030-201 1 G2

4 Ring Seal 391-2585-009 4 C

391-2585-009 3 C2

391-2585-006 4 G

391-2585-006 3 G2

5 Roller Bearing 391-0381-059 4 C,C2

391-0381-068 4 G,G2

6 Pocket Seals 391-2882-050 12 C,C2

391-2882-086 12 G,G2

7 Thrust Plate 391-2185-016 2 C

391-2185-012 2 C2

391-2185-013 2 G,G2

8 Shaft Key 391-1781-021 1 C,G

9 Gear Set

2 314-2920-640 1 C

2 1/2 314-2925-640 1 C

2 313-2920-130 1 C2

2 1/2 313-2925-130 1 C2

3/4 312-2907-842 1 G

1 1/2 312-2915-842 1 G

2 312-2920-842 1 G

3/4 312-2907-130 1 G2

1 1/2 312-2915-130 1 G2

2 312-2920-130 1 G2

10 Cap Screw

2 391-1401-111 4 C

2 1/2 391-1401-110 4 C

1 1/2 391-1401-112 4 S

3/4 391-1401-395 4 G,G2

1 1/2 391-1401-381 4 G,G2

2 391-1401-382 4 G,G2

11 Washer 391-3784-029 4 C,C2

391-3782-146 4 G,G2

12 Port End Cover (not serviceable)

KEY

C = C101 C2 = C102

G = G101 G2 = G102

Decription Part # Qty. Series

13 Gear Housing

2 314-8020-100 1 C,C2

2 1/2 314-8025-100 1 C,C2

3/4 308-8007-901 1 G,G2

1 1/2 308-8015-901 1 G,G2

2 308-8020-901 1 G,G2

14 Gasket Seal 391-2884-021 2 C,C2

391-2884-019 2 G,G2

16 Relief Valve 355-9001-067 1 C,C2

355-9001-197 1 G,G2

17 Pipe Plug 391-2282-006 1 C,C2

391-2282-003 1 G,G2

18 Optional Sleeve 391-3283-052 1 C,G,C2,G2

19 Socket Hd.

Cap Screw 391-1402-063 2 C,G,C2,G2

20 Bracket 391-0981-010 1 C,C2

391-0981-007 1 G,G2

21 Spool End Cap 391-1881-073 1 C,C2

391-1881-072 1 G,G2

22 Quad Ring Seal 391-1985-014 1 G,G2

O Ring 391-2881-103 1 C,C2

23 Valve Spool (not serviceable)

24 Spiral Pin 391-2085-009 1 C,G,C2,G2

25 Cover Plate 391-2183-124 1 G,G2

26 Retaining Ring 391-2681-486 1 G,G2

27 Spring Guide 391-1642-136 1 G,G2

28 Spring 391-3581-212 1 G,G2

29 Spring Guide 391-1642-137 1 G,G2

30 Retainer Ring 391-3782-126 1 C

31 End Cap 308-4000-100 1 G,G2

32 Cap Screw 391-1401-082 4 C,C2

391-1433-020 2 G,G2

33 Washer 391-3784-028 8 C

34 Optional Bracket 314-0100-005 1 C

35 Hex Nut 391-1451-076 4 C

391-1451-076 6 C2

36 Quad Ring Seal 391-1985-014 1 G,G2

O Ring 391-2881-103 1 C,C2

37 Detent Cap 314-0100-003 1 C,C2

308-4000-102 1 G,G2

38 Snap Ring 391-2688-003 1 C,C2

39 Detent Ball 391-0282-009 1 C,G,C2,G2

40 Detent Spring 391-3581-383 1 C,G,C2,G2

41 Lock Washer 391-3788-002 1 C,G,C2,G2

42 Detent Retainer 391-2583-079 1 C,G,C2,G2

43 Spacer 391-3383-069 1 G2

44 Seal Retainer 391-3383-087 1 C2

391-3381-040 1 G2

45 Check Assembly 391-3681-001 2 C2,G2

2 - 391-1425-433 4 C2

2 1/2 - 391-1425-432 4 C2

2009Dynaco Hydraulic Co., Ltd

Phone 86 (0) 25 8536 0418

www.dynacohydraulic.com

Dynaco Hydraulic Co., Ltd.

Dynaco Hydraulic

Sales Department

Ningbo 315000, China

Hotline 86 (0) 139 516 34086

This document, as well as the data, speci cations and other information

set forth in it, are the exclusive property of Dynaco Hydraulic . It may not be

reproduced or given to third parties without its consent.

The data speci ed above only serve to describe the product. No statements

concerning a certain condition or suitability for a certain application can be

derived from our information. The information given does not release the user

from the obligation of own judgment and veri cation. It must be remembered that

our products are subject to a natural process of wear and aging.

Subject to change.

86 (0) 25 8942 8524

2009 Dynaco Hydraulic Co., Ltd

S

N

0

9

1

2

0

0

.

1

.

2

Fax

Email: nbgears@163.com ; nbgears@aliyun.com

Huilong Street 39, Yinzhou,Ningbo,China

S-ar putea să vă placă și

- Dynaco p315 p330 p350 p365 Bushing Pump PDFDocument6 paginiDynaco p315 p330 p350 p365 Bushing Pump PDFnbgearsÎncă nu există evaluări

- Dynaco p31 p51 p76 Bearing Pump PDFDocument7 paginiDynaco p31 p51 p76 Bearing Pump PDFnbgearsÎncă nu există evaluări

- Dynaco g101 g102 Dump Pump PDFDocument6 paginiDynaco g101 g102 Dump Pump PDFnbgearsÎncă nu există evaluări

- Dynaco c101 c102 Dump Pump PDFDocument7 paginiDynaco c101 c102 Dump Pump PDFnbgearsÎncă nu există evaluări

- Dynaco Vane Pump Shafts PDFDocument3 paginiDynaco Vane Pump Shafts PDFnbgearsÎncă nu există evaluări

- Dynaco Hydraulic PDFDocument36 paginiDynaco Hydraulic PDFnbgearsÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Manual Control Acceso Ds k1201mfDocument2 paginiManual Control Acceso Ds k1201mfAlejandro FiorottoÎncă nu există evaluări

- Blow Down ValveDocument2 paginiBlow Down Valvesabi_shiÎncă nu există evaluări

- Tolerances NotesDocument14 paginiTolerances NotesAshween Royos DoutalÎncă nu există evaluări

- Ekinex® Price List (APRIL 2019)Document7 paginiEkinex® Price List (APRIL 2019)Federico Ungureanu100% (1)

- A1798504 - Chem Eng 4036 Assignment 1 ValidationDocument12 paginiA1798504 - Chem Eng 4036 Assignment 1 ValidationHoang Uyen Vy NguyenÎncă nu există evaluări

- Hytera X1pi Owners ManualDocument49 paginiHytera X1pi Owners ManualNani2220Încă nu există evaluări

- Tems Discovery Network 10.0 DatasheetDocument2 paginiTems Discovery Network 10.0 DatasheetThuan NguyenÎncă nu există evaluări

- Scapy Packet Manuplation: CE 340/S. KondakcıDocument53 paginiScapy Packet Manuplation: CE 340/S. KondakcıSamit JainÎncă nu există evaluări

- Repair Overhaul Vendor Audit ChecklistDocument15 paginiRepair Overhaul Vendor Audit ChecklisttaufeeqÎncă nu există evaluări

- KFA6-SR2-Ex1.W - RELÉ - BARREIRADocument5 paginiKFA6-SR2-Ex1.W - RELÉ - BARREIRARonaldo JuniorÎncă nu există evaluări

- Check List of SAS-Substation Automation SystemDocument5 paginiCheck List of SAS-Substation Automation SystemSanthosh Kumar VinayagamÎncă nu există evaluări

- Axxessor SSV10 Store Support VehicleDocument12 paginiAxxessor SSV10 Store Support VehicleForklift Systems IncorporatedÎncă nu există evaluări

- Offer Letter - Avinasha B LDocument2 paginiOffer Letter - Avinasha B LRajesh NayakÎncă nu există evaluări

- Uai B 0214Document4 paginiUai B 0214Jose Puc ManzanillaÎncă nu există evaluări

- HVAC Acoustic GuidelinesDocument20 paginiHVAC Acoustic Guidelinespeter_etamne100% (1)

- 2010 Transit BrochureDocument16 pagini2010 Transit BrochureHomer Skelton Ford of MillingtonÎncă nu există evaluări

- Essay Regarding Safe Use of RadiationDocument6 paginiEssay Regarding Safe Use of RadiationmaaseialÎncă nu există evaluări

- Philips Chasis l7Document39 paginiPhilips Chasis l7videosonÎncă nu există evaluări

- Verification of Antimicrobial Susceptibility TestingDocument61 paginiVerification of Antimicrobial Susceptibility Testingamare AlemuÎncă nu există evaluări

- ABAP - Advanced Debugging - Spider's Web PDFDocument4 paginiABAP - Advanced Debugging - Spider's Web PDFVineetKumarSinghÎncă nu există evaluări

- Pps Seat 163 Seat Ateca EngDocument71 paginiPps Seat 163 Seat Ateca EngManu Fran0% (2)

- APPENDIX SLB PUMP-dirotasiDocument60 paginiAPPENDIX SLB PUMP-dirotasiadhitya suzari putraÎncă nu există evaluări

- Belimo 2013 PGPLDocument419 paginiBelimo 2013 PGPLJorge Gustavo GoyecheaÎncă nu există evaluări

- PGN Fee5 Engine Hours, Revolutions Hours: Start Position Length Parameter Name SPNDocument2 paginiPGN Fee5 Engine Hours, Revolutions Hours: Start Position Length Parameter Name SPNPrashant TambeÎncă nu există evaluări

- Air BagDocument17 paginiAir BagPrabir Kumar PatiÎncă nu există evaluări

- 23xrv 4ssDocument154 pagini23xrv 4ssLouie DupayaÎncă nu există evaluări

- Air PollutuionDocument3 paginiAir PollutuionMalvikasingh93Încă nu există evaluări

- LRQA NERS Requirements Document V8.1 Final For Issue November 2021Document68 paginiLRQA NERS Requirements Document V8.1 Final For Issue November 2021David MarkidesÎncă nu există evaluări

- l200 PDFDocument369 paginil200 PDFMohammad Abu Al-ToyourÎncă nu există evaluări

- Porter's Value ChainDocument12 paginiPorter's Value ChainRatIeh DewÎncă nu există evaluări