Documente Academic

Documente Profesional

Documente Cultură

Scope of Works

Încărcat de

Victor BiacoloDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Scope of Works

Încărcat de

Victor BiacoloDrepturi de autor:

Formate disponibile

SECTION

SCOPE OF WORK

SCOPE OF WORK

TABLE OF CONTENTS

1.0 GENERAL ............................................................................................................................... 1

2.0 CONTRACTUAL MOBILIZATION .............................................................................................. 4

3.0 THE SCOPE ............................................................................................................................. 5

4.0 THE WORK ............................................................................................................................. 6

5.0 MOBILIZATION OF MARINE VESSEL ........................................................................................ 8

6.0 DEMOBILIZATION OF MARINE VESSEL .................................................................................... 8

7.0 NOTICE OF MOBILIZATION / DEMOBILIZATION ..................................................................... 8

8.0 ONSHORE FACILITIES ............................................................................................................. 9

9.0 PROJECT MANAGEMENT ..................................................................................................... 10

10.0 WORKPACK AND MINOR ENGINEERING ............................................................................. 16

11.0 ONSHORE MINOR FABRICATION ......................................................................................... 21

12.0 OPERATIONS AND CONSTRUCTIONS .................................................................................. 24

13.0 COMMISSIONING SUPPORT SERVICES ................................................................................. 28

14.0 MARINE MANAGEMENT ...................................................................................................... 29

15.0 MATERIALS, PROCUREMENT AND CONSUMABLES ............................................................... 37

16.0 HYDROPACK AND SPADING MATERIALS .............................................................................. 39

17.0 SALVAGE OF MATERIALS ...................................................................................................... 39

18.0 VENDOR DEVELOPMENT PROGRAMME (VDP) ....................................................................... 39

19.0 LOGISTIC YARD IN LABUAN ................................................................................................. 40

20.0 PROVISION OF MIRI JETTY .................................................................................................... 40

21.0 TRANSPORTATION OF MATERIALS ....................................................................................... 40

22.0 LOAD-OUT AND SEA-FASTENING ........................................................................................ 41

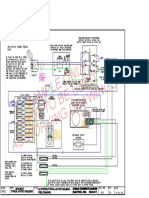

23.0 COMMUNICATION SYSTEM ................................................................................................. 42

24.0 WASTES MANAGEMENT ...................................................................................................... 43

25.0 OPTIONAL SCOPE - LIVING QUARTER BASED TOPSIDE MAINTENANCE ................................ 45

APPENDIX 1 PROVISION BY CONTRACTOR ................................................................................... 46

APPENDIX 2 ROLES AND RESPONSIBILITIES .................................................................................... 69

APPENDIX 3 CONTRACTOR PROJECT MANAGEMENT TEAM ORGANISATION CHART ................. 120

APPENDIX 4 CONSTRUCTION NORMS ........................................................................................ 121

APPENDIX 5 LIST OF APPOINTED VENDOR DEVELOPMENT PROGRAMME (VDP) VENDORS .......... 136

TABLE OF FIGURES

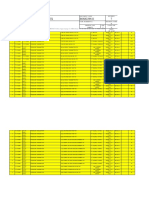

TABLE 4/01 TABLE FOR ONSHORE FACILITIES ................................................................................ 47

TABLE 4/02 TABLE FOR MARINE AND SUPPORT VESSELS............................................................... 48

TABLE 4/03 TABLE FOR DOCUMENTS ............................................................................................ 49

TABLE 4/04 TABLE FOR QA/QC DOCUMENT ................................................................................ 51

TABLE 4/05 TABLE FOR PMT TEAM ................................................................................................ 52

TABLE 4/06 TABLE FOR ADDITIONAL SUPPORT TEAM (NOTE 2) .................................................... 54

TABLE 4/07 TABLE FOR TRANSPORTATION CONTAINER ............................................................... 60

TABLE 4/08 TABLE FOR OFFSHORE CONSTRUCTION PERSONNEL ON EACH WORKBARGE AND

WORKBOAT ............................................................................................................................. 61

TABLE 4/09 TABLE FOR MARINE PERSONNEL MANNING .............................................................. 64

TABLE 4/10 TABLE FOR CATERING PERSONNEL MANNING .......................................................... 65

TABLE 4/11 HARD COPY AND SOFY COPY OF APPROVED WORKPACK ........................................ 66

TABLE 4/12 TABLE FOR COMMUNICATION EQUIPMENT ............................................................... 67

TABLE 4/13 TABLE FOR CARS ........................................................................................................ 68

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 1

1.0 GENERAL

1.1 This Section is to provide CONTRACTOR a general description of the WORK and to outline

CONTRACTORs responsibilities for performing the WORK efficiently, safely and no harm to

people.

1.2 The CONTRACTOR shall be deemed to have agreed to comply with all technical requirements

and specifications as detailed in this CONTRACT and relevant COMPANY Manual, Guideline

and Procedures.

1.3 The CONTRACTOR shall provide all the Marine VESSEL, MANPOWER and EQUIPMENT,

consumables, resources, MATERIALS, facilities and additional support services for execution of

the WORK.

1.4 As for base case, CONTRACTOR shall provide all requirements as stipulated in Appendix 1 -

Provision By CONTRACTOR and Section VII - TECHNICAL INFORMATION and/or in relevant

part of this CONTRACT.

1.5 The CONTRACTOR shall be responsible to administer the MANPOWER, Marine VESSEL,

WORKSITE, facilities, EQUIPMENT, other resources and either owned, rented or chartered by

CONTRACTOR and its SUBCONTRACTOR in relation to this CONTRACT.

1.6 The CONTRACTOR is expected to work as a team, proactive, create proper working

environment, optimize the resources and plan effectively within CONTRACTOR organization

and with COMPANY.

1.7 COMPANY has established a base load WORKBARGE and WORKBOAT utilization for FIRM

COMMITMENT and Call-Out basis as follows;

a. FIRM COMMITMENT - COMPANY guarantees cumulative utilization of one (1)

WORKBARGE 3A and one (1) WORKBARGE 3B for 270 days a calendar year for 2013

until 2015. For FIRM COMMITMENT WORKBARGE from 2016 and 2017, a notice will be

given six (6) months prior to commencement of the 2016s WORK. Provisions of FIRM

COMMITMENT WORKBARGE for this CONTRACT are as stipulated in Appendix 1

Provision By CONTRACTOR.

In the event that the award of the contract is delay until 2013, the number of COMPANY

guarantee utilization per calendar year for 2013 shall be reduce accordingly, counting

from the date the WORKBARGE is ON-HIRED until 1

st

November 2013 e.g. if the contract

is awarded on 31

st

Jan 2013, WORKBARGE is ON-HIRED on 1

st

April 2013, period of

COMPANY guarantee utilization per calendar year will be 215 days only (i.e. counting

from 1

st

April 2013 until 1

st

November 2013).

b. Call-Out The base load for WORKBARGE and WORKBOAT on Call-Out Basis is three (3)

WORKBARGE 3B, two (2) WORKBOAT 4A and two (2) WORKBOAT 4B.

COMPANY will not guarantee any utilization days or guarantee continuity of WORK for

Call-Out VESSEL, it will be on as and when required basis depending on operational

requirements. Call-Out VESSEL for this CONTRACT are as stipulated in Appendix 1

Provision By CONTRACTOR.

1.8 The CONTRACTOR shall mobilize a team of Project Management Team (PMT) member for the

CONTRACT. The PMT comprises team of personnel for HSSE Team, Marine Team, Workpack

Team, Operation Team and QA/QC Team. COMPANY reserves the right to interview the

proposed personnel prior to their mobilization.

1.9 Not Used.

1.10 Other personnel or team member not included in PMT member are deemed workforce required

by CONTRACTOR to complement the PMT and their cost shall be under CONTRACTORs own

account.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 2

1.11 COMPANY has established Firm and Call-Out Personnel enable the CONTRACTOR to execute

the CONTRACT as follows;

a. Firm Personnel CONTRACTOR personnel to be mobilized and maintained throughout the

CONTRACT period.

b. Call-Out Personnel Additional personnel deem necessary to enhance CONTRACTOR

performance or as and when basis depending on operational requirement or as requested

by COMPANY.

1.12 Provisions of Firm and Call-Out Personnel for this CONTRACT are as stipulated in Appendix 1

Provision By CONTRACTOR.

1.13 COMPANY reserves the right at its sole discretion to review the requirement, add or delete the

Firm position stated in the PMT by giving one (1) month advance notice in writing.

CONTRACTOR is responsible to act to the requirement as stated in the letter.

1.14 The CONTRACTOR can only mobilize Call-Out Personnel upon giving explanation of it

requirement and COMPANY reserves the right to reject the request from CONTRACTOR if

deemed not necessary.

1.15 The CONTRACTOR shall be responsible to make available the Onshore Facilities to domicile the

PMT, other personnel as well as to support operation and construction for performance of the

WORK.

1.16 Provision of Onshore Facilities and it associated services which required for CONTRACT as

stipulated in Appendix 1 - Provision By CONTRACTOR and shall be deemed included in Section

III - SCHEDULE OF PRICES.

1.17 CONTRACTOR and SUBCONTRACTOR personnel shall be required to work in the onshore or

offshore WORKSITE as and when required.

1.18 Any deviations to the technical requirements and specifications shall only be accepted if the

COMPANY has given its express written approval for the particular deviation.

1.19 Unless expressly stated otherwise, all costs for the fulfillment of the requirements of this Section

and Section VII - TECHNICAL INFORMATION and other relevant Section in this CONTRACT

hereinafter shall be included in Section III - SCHEDULE OF PRICES.

1.20 The rate in Section III - SCHEDULE OF PRICES shall be deemed inclusive of provisions including

but not limited to all services, facilities, equipment, transportations, documentations,

communications, personnel tools, inspection, testing, accommodation and report as required to

perform the WORK.

1.21 The CONTRACTOR shall be fully responsible for the supervision of the WORK and must take all

reasonable measures to ensure WORK is carried out expeditiously, safely and quality to the

COMPANY standard.

1.22 The CONTRACTOR shall provide qualified engineering personnel, construction personnel and

supporting personnel inclusive their tools and equipment for identifying the scope of WORK,

prepare the work plan and completing all the WORKS including commissioning and start up of

the systems within the agreed cost and schedule.

1.23 All CONTRACTOR and SUBCONTRACTORs personnel curriculum vitae (CV) have to be

approved by COMPANY prior to mobilization and be given a unique number. It is mandatory

for CONTRACTOR to mobilize personnel meeting minimum specifications defined in Section VII

- TECHNICAL INFORMATION.

1.24 CONTRACTOR is responsible to evaluate all the CV against Section VII - TECHNICAL

INFORMATION and submit evaluations together with training matrix and all necessary

certificates for COMPANY approval. COMPANY reserves the rights to reject any CV without

assigning any reason if deem that the personnel does not meet COMPANYs requirement.

1.25 If at any time the COMPANY is of the opinion the one or more of the CONTRACTORs

personnel is incompetent, misconduct, misbehaviour, inefficient or is negligent in the discharge

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 3

of the duty or is otherwise working or behaving is such ways as to make his presence or

employment under the CONTRACT undesirable, the COMPANY may notify the CONTRACTOR

in writing to that effect and CONTRACTOR shall promptly replace such personnel at no cost to

COMPANY.

1.26 The CONTRACTOR shall ensure that all its personnel have undergone the relevant Mandatory

Training as listed in Section VII TECHNICAL INFORMATION prior to deploying them in PMT

or deploying them to the WORKSITE. The requirement to attend the Mandatory Training is

compulsory and deemed inclusive in Section III - SCHEDULE OF PRICES.

1.27 CONTRACTOR shall provide all logistic arrangements and transportation for the

CONTRACTORs and SUBCONTRACTORs personnel to report and deliver to the COMPANY

WORKSITE.

1.28 The COMPANY reserves the right to utilize Marine VESSEL, SUPPORT VESSELS and

EQUIPMENT and its facilities onboard that are on hired from CONTRACTOR for other activities

or to be used by COMPANYs third (3rd) parties.

1.29 If COMPANY decides to mobilize the CONTRACTORs WORKBARGE or WORKBOAT, even

though documents stipulated in Appendix 1 - Provision By CONTRACTOR are not acceptable,

COMPANY reserve the rights to withold 5% of all invoices until all documents are acceptable

and approved.

1.30 There is no exclusiveness of WORK in the CONTRACT. The COMPANY reserves the rights and

shall be at liberty to call other contractors/third parties to carry out the WORK as and when

necessary.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 4

2.0 CONTRACTUAL MOBILIZATION

2.1 Upon award of the CONTRACT, CONTRACTOR shall mobilise the resources within the

stipulated time frame as stated hereinafter.

2.2 The CONTRACTOR shall confirm their Project Management Team (PMT) as submitted during the

tender stage. CONTRACTOR shall justify any changes and mobilisation is subjected to

COMPANYs approval.

2.3 The CONTRACTOR to submit CONTRACTORs Organisation Chart of PMT integrated with

CONTRACTORs other team such as Contract, Human Resources, Administration, Minor

Fabrication, Logistic Yard, Marine Maintenance, Logistic and Procurement to COMPANY within

one (1) week from award of the CONTRACT. The PMT position shall be filled up within thirty

(30) days after award of the CONTRACT.

2.4 The CONTRACTOR shall within thirty (30) days after award of the CONTRACT arrange with

COMPANY for pre-mobilization inspection of FIRM COMMITMENT WORKBARGE and Call-

Out VESSEL.

2.5 The CONTRACTOR shall arrange with COMPANY for pre-mobilization inspection of the Miri

Project Office (MPO) within thirty (30) days after award of the CONTRACT. The MPO shall be

ready to accommodate the PMT personnel within sixty days (60) days after award of the

CONTRACT.

2.6 The CONTRACTOR shall arrange with COMPANY for pre-mobilization inspection of the Foods

Supply facilities inclusive of the food containers, chillers and freezers within sixty (60) days after

award of the CONTRACT.

2.7 The CONTRACTOR shall arrange with COMPANY for pre-mobilization inspection of the

Positive Pressure Habitat and Non-Destructive Test (NDT) SUBCONTRACTOR and its facilities

and ready for mobilization within sixty (60) days after award of the CONTRACT.

2.8 The CONTRACTOR shall arrange with COMPANY for pre-mobilization inspections of Minor

Fabrication Yard and Logistic Yard within thirty (30) days after award of the CONTRACT. Both

yards shall be ready for mobilization within sixty (60) days after award of the CONTRACT.

2.9 CONTRACTOR shall close out all the finding or observation of pre-mobilisation inspections

prior to mobilisation or commencement of WORK.

2.10 The CONTRACTOR shall submit the Documents and QA/QC document as stated in Appendix 1

- Provision By CONTRACTOR within sixty (60) days after award of the CONTRACT. If in the

sole opinion of the COMPANY the Documents are not acceptable, COMPANY reserves the right

not to mobilise CONTRACTOR WORKBARGE or WORKBOAT or SUPPORT VESSELS.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 5

3.0 THE SCOPE

3.1 The COMPANY is engaged in oil and gas exploration and production in Malaysia. The

WORKSITE include offshore and onshore of Sarawak, Sabah and Labuan which comprises a

range of the following types of facilities;

a. Drilling Platforms

b. Production Platforms

c. Production Station

d. Mini production station with combine drilling and production stations

e. Gas Compression Platforms

f. Riser Platforms

g. Living Quarters

h. Vent and Flare Platforms and Tripods

i. Bridges and Bridge Platforms

j. Bintulu Integrated Facilities

k. Asian (Labuan) Supply Base

l. Labuan Anchorage

m. Any COMPANY onshore facilities

n. Third (3

rd

) party facilities chartered by COMPANY including Drilling Rigs, any other VESSEL.

3.2 The CONTRACTOR may require to work outside Malaysia waters in which case the rates and

prices under this CONTRACT will be applied where possible. Otherwise the rates and prices will

be re-negotiated

3.3 The CONTRACTOR shall give all necessary notices and obtain necessary permits before starting

any WORK.

3.4 Permits for the CONTRACTOR's EQUIPMENT and MANPOWER to enter a WORKSITE shall be

obtained from COMPANY.

3.5 Typical scope covers under the CONTRACT include;

a. Brown Field activities (activities performed on existing facilities);

i. Predrill preparation for rig entry and Postdrill after rig depature

ii. Well tie in

iii. Rejuvenation work

iv. Facilities upgrades and modifications

v. Decommissioning of the platforms

vi. Major and minor maintenance which include blasting, painting and major or

minor change out or replacement work

vii. Testing and commissioning of all upgrades, hook-up and tie-in work

viii. General cleaning and house keeping

ix. Clearing any punchlist from previous project phase

b. Green Field activities (activities performed on new facilities);

i. Host tie-in to existing facilities; this scope shall include riser tie-in above the hanger

flanges

ii. Hook-up of ship loose items

iii. Pre-drill preparations for Rig entries

iv. Post-drill hook-up

v. Well tie-in

vi. Testing and commissioning of all upgrades, hook-up and tie-in work

vii. Clearing any punchlist items from the fabrication yards, offshore installation

contractor and drilling scopes

c. Other activities;

i. Single Buoy Mooring (SBM) repair and change out

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 6

ii. Acidization and Well services activities

iii. Precommissisoning and commissioning assistance

iv. Provision of Marine VESSEL as offshore accommodations and support vessel

v. Minor fabrications and minor modification work

vi. Cleaning of offshore scrap materials

vii. Manpower assistance to engineering and operation

viii. Technical support service for COMPANY

ix. Provision of manpower to Asset Team

x. Transportation of COMPANY material and equipment

xi. Provision of bare WORKBARGE and WORKBOAT for COMPANYs third (3rd)

party activities

3.6 The WORK may be performed on platforms in a shutdown mode or on live platforms under

Simultaneous Production and Operation (SIMOPS) or any other governing procedures that may

be applicable at the time.

3.7 CONTRACTOR shall perform remote WORK at COMPANYs WORKSITE locations base on

Living Quarters (LQ), daily tripping or from any offshore third (3

rd

) party provided

accommodations vessel.

4.0 THE WORK

4.1 The CONTRACTOR shall fully responsible for the supervision of the WORK and its

SUBCONTRACTOR and shall take reasonable measures to ensure the WORK is carried out

safely, expeditiously and to perform the WORK or part of the WORK in accordance to the best

industry standard, compliance to relevant laws and regulations and will always safeguard and

protect COMPANYs interest and business.

4.2 The activities shall include but not limited to the followings;

a. Management of resources, HSSE, QAQC, Construction, Marine, Procurement, Logistic and

SUBCONTRACTOR.

b. Workscoping, workpack preparation, minor engineering, minor fabrication, hook up,

replace, change out, blasting, painting and testing of structural, piping, mechanical,

electrical and instrument.

c. Planning, scheduling, reporting and close out reporting.

d. Procurement, expediting, material handling, material inspection, coordination, storage and

preservation.

e. Estimate cost of WORK or portion of WORK, prepare payment certificate and submit claim.

f. Report progress of WORK or part of WORK and resolve any issue or concern that may

impact the WORK or portion of the WORK.

g. Accelerate the progress if necessary.

h. Perform heavy lifts according to approved heavy lift procedure.

i. Rigging, slinging, abseiling, insulation, scaffolding, Hot and Cold Work, vessel cleaning,

bolt tensioning, cold cutting, hot tapping, hot bolting, servicing, wrapping, spading and

isolation, cable pulling, termination, glanding, dressing and TENORM management.

j. None destructive test, hydrotest, reinstatement test, calibration, load test, loop test, megger

test, system test, precommissioning and commissioning.

k. Transportation, loading, backloading and storage include but not limited to project

COMPANY MATERIALS, project left over material, scheduled waste, none scheduled waste,

surplus, off cut material, COMPANY and CONTRACTOR waste generated material.

l. Disposal of CONTRACTOR generated scheduled and non-scheduled waste.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 7

4.3 The CONTRACTOR shall provide EQUIPMENT in accordance with COMPANYs instructions. All

EQUIPMENT shall be certified, calibrated, tested, pre-commissioned and commissioned onshore

shall again be calibrated, tested pre-commissioned and commissioned offshore, unless

stipulated or specified otherwise and/or shall be issued with certificate of fitness by third (3rd)

party.

4.4 The CONTRACTOR shall be responsible for off loading, receiving, un-crating, custody, quantity

accountability and placing all MATERIALS into their either temporary or final positions.

4.5 The CONTRACTOR shall perform receiving inspection of the MATERIALS, prepare report and

advise COMPANY if the is any damage or discrepancies within forty eight (48) hours after the

arrival of the item.

4.6 Upon completion of the installation of the MATERIALS and other appurtenances in their final

position, the CONTRACTOR shall perform a thorough inspection of the MATERIALS for any

damages and report the findings to COMPANY within twenty (24) hours the inspection has

been completed.

4.7 In the event that the MATERIALS were damaged due to CONTRACTORs negligence, the

CONTRACTOR is liable to make good of any damage at their own costs prior to handover to

COMPANY.

4.8 CONTRACTOR may make use of the COMPANYs equipment on the WORKSITE subjected to

COMPANY'S approval. The CONTRACTOR shall return COMPANYs equipment in their

original operational conditions. In the event that the equipment was damaged by

CONTRACTOR due to negligence, the CONTRACTOR is liable to make good any damage at

their own costs prior to handover to COMPANY.

4.9 Prior to commencement of the WORK, the CONTRACTOR shall be responsible for providing

and setting up onshore and offshore facilities including site offices, enclosed and secured stores

onshore or on the vessels for project materials , construction equipment, scaffolding and

weather protection as deemed necessary to complete the WORK

4.10 The CONTRACTOR shall be responsible for the removal of all temporary tie-down points, sea

fastenings, water proof wrapping and temporary blinds on the MATERIALS and its

appurtenances. Loose ends of cables, openings in piping/tubing must be adequately protected

until the MATERIALS are installed.

4.11 The CONTRACTOR shall reinstall all minor equipment/fixtures that were removed in order to

facilitate transportation of the MATERIALS or to complete the WORK.

4.12 The CONTRACTOR is responsible to provide Transportation Container as stipulated in

Appendix 1 - Provision By CONTRACTOR for transportation of the CONTRACTORs and

COMPANYs material and equipment.

4.13 The maximum period of offshore duty for all levels of personnel shall be in accordance to

COMPANYs Offshore Health Management Guideline: HSE.XXX.6003 Rev 1 and/or any

revisions or updates to the mentioned document.

4.14 All construction personnel shall be equipped with their respective personal trade toolkits and

consumables. The Personal toolkit contents for all trades are defined in Section VII - TECHNICAL

INFORMATION. The cost of personnel tool kits and its consumable are deem to be part

personnel daily rate.

4.15 All CONTRACTORs MANPOWER shall be equipped with adequate personal protective

clothing (inclusive of fire retardant coverall) and equipment relevant to the type of work being

performed. These clothing and equipment shall be as approved by COMPANY. The cost of

personal protective clothing and equipment, and its consumables (if any), are deemed to be

part of personnel daily or monthly rate. However, if any personnel are required to work at

special designated area such as H2S designated area or mercury area, the personnel shall be

equipped with the right equipment and such equipment shall be reimbursed to CONTRACTOR

in accordance to Section III SCHEDULES OF PRICES. CONTRACTOR shall also ensure that the

quantity provided is sufficient to cover for all COMPANY personnel as required.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 8

4.16 For any personnel who are tasked to perform work that requires the usage of impact resistant

gloves, then CONTRACTOR shall provides such COMPANY approved gloves to the personnel.

The cost shall be reimbursed to CONTRACTOR in accordance to Section III SCHEDULES OF

PRICES.

5.0 MOBILIZATION OF MARINE VESSEL

5.1 CONTRACTOR shall conduct in-house inspection of the VESSEL, prepare an inspection report,

and highlight any deviations for company review prior to inviting COMPANY for official

inspection of the VESSEL.

5.2 COMPANY reserves the right to reject the invitation for pre-mobilization inspection if

contractors inspection report is incomplete or the contractors inspection is poorly done.

5.3 In the event that the CONTRACTOR is unable to mobilize the marine vessel as specified in the

contract, then the CONTRACTOR shall mobilize a replacement vessel, subject to approval of

COMPANY. The replacement vessel shall be equal to or better than the vessel to be provided

under the CONTRACT.

5.4 Mobilization of marine vessel shall consider as complete and ON-HIRE upon;

a. Marine VESSEL to be alongside Asian Supply Base Jetty or Labuan Anchorage or Miri

Roads Anchorage or any other place within Sarawak/Sabah/Labuan Waters as advised

by COMPANY.

b. Complete pre-mobilisation inspection and accepted by COMPANY where all Priority 1 (P1)

punchlist items have been cleared.

c. Complete bunker survey by third party appointed by CONTRACTOR and witness by

COMPANYs Representative.

d. Complete mobilisation of Marine, Catering and Construction Personnel as per the

Workpack.

e. Complete mobilisation of tools and EQUIPMENT as per the Workpack.

f. Potable water tanks fully bunkered.

g. Pilot boat ready to move WORKBARGE into berth.

6.0 DEMOBILIZATION OF MARINE VESSEL

6.1 Demobilization of Marine VESSEL shall be considered as complete and considered OFF-HIRE

upon;

a. Marine VESSEL to be alongside Asian Supply Base Jetty or Labuan Anchorage or Miri

Roads Anchorage or any other place within Sarawak/Sabah/Labuan Waters as advised

by COMPANY.

b. Complete bunker survey by third (3rd) party and witnessed by COMPANYs Representative.

c. Returned all COMPANYs materials inclusive of documentations, telecommunication

equipment, IT equipments and Cost-Plus items to COMPANY.

7.0 NOTICE OF MOBILIZATION / DEMOBILIZATION

7.1 The COMPANY shall give the CONTRACTOR a prior written notice of sixty (60) days for the

mobilization of the FIRM COMMITMENT WORKBARGE and/or WORKBOAT (if any).

7.2 The COMPANY shall give the CONTRACTOR a prior written notice of thirty (30) days for the

demobilization of the FIRM COMMITMENT WORKBARGE and/or WORKBOAT (if any).

7.3 The COMPANY shall give the CONTRACTOR a prior written notice of sixty (60) days for any

mobilization of the Call-Out WORKBARGE or WORKBOAT and thirty (30) days for any

demobilisation of the Call-Out WORKBARGE or WORKBOAT.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 9

7.4 The COMPANY shall give the CONTRACTOR a prior written notice of thirty (30) days for

interim demobilization /mobilization of the FIRM COMMITMENT and Call-Out WORKBARGE

or WORKBOAT.

7.5 The COMPANY shall give the CONTRACTOR a prior written notice of thirty (30) days for any

mobilization of the Call-Out SUPPORT VESSELS and fourteen (14) days for any demobilization

of Call-Out SUPPORT VESSELS.

8.0 ONSHORE FACILITIES

8.1 CONTRACTOR shall provide Onshore Facilities to accommodate their resources, carry out

minor fabrication and provide support facilities for performance of the WORK throughout the

CONTRACT. The Onshore Facilities are as stipulated in Appendix 1 - Provision By

CONTRACTOR. All the cost for provision of Onshore Facilities and it associated with shall be

deemed included in Section III - SCHEDULE OF PRICES.

8.2 The Miri Project Office (MPO) shall be as per Section VII - TECHNICAL INFORMATION to

accommodate all of CONTRACTORs PMT and overhead personnel. The MPO shall not be

further than fifteen (15) km away from COMPANYs Office in Lutong.

8.3 The Minor Fabrication Yard and Logistic Yard shall be as per Section VII - TECHNICAL

INFORMATION and located at Labuan.

8.4 The CONTRACTOR may choose to accommodate the overhead personnel together with the PMT

with condition such arrangement does not make the office too congested and has no more

room for future expansion. COMPANY shall not compensate the portion of office and facilities

occupied by their overhead personnel.

8.5 The CONTRACTOR shall provide a radio facility in the MPO in accordance to Section VII -

TECHNICAL INFORMATION. The radio shall be able to reach all COMPANY offshore facilities

and the CONTRACTORs Marine VESSEL at all times. All costs for this provision inclusive of

radio facility and Radio Operators shall deem included in the Section III - SCHEDULE OF

PRICES.

8.6 In addition, the CONTRACTOR shall allocate offices for five (5) COMPANY representatives in

MPO office. CONTRACTOR shall provide six (6) parking spaces for the COMPANY

representatives at the MPO Facilities.

8.7 The CONTRACTOR shall provide IT Equipment for all Onshore Facilities as per Section VII -

TECHNICAL INFORMATION.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 10

9.0 PROJECT MANAGEMENT

9.1 GENERAL

9.1.1 The CONTRACTORs PMT are responsible for the CONTRACT. They shall be

accountable for the execution of the WORK, including but not limited implement and

maintain HSSE and QA/QC systems, preparing work planning, supplying

MANPOWER, EQUIPMENT and VESSEL, purchasing and expediting the EQUIPMENT

and MATERIALS, operating Minor Fabrication Yard and Logistic Yard complete with

logistic supports.

9.1.2 The PMT members shall be dedicated for this CONTRACT and shall be based in Miri.

Key PMT members shall be provided with mobile phone and shall be standby for any

emergency contact on twenty four (24) hours basis.

9.1.3 Replacement of Firm PMT are to be approved by COMPANY and all cost incurred

associated with the replacement shall be fully borne by CONTRACTOR.

9.1.4 The roles and responsibility of the PMT is as stipulated in Appendix 2 - Roles and

Responsibilities. The CONTRACTOR is strictly to observe the minimum requirement of

the roles and responsibilities.

9.1.5 Without exception, the PMT shall follow COMPANY onshore working hours throughout

the CONTRACT duration.

9.1.6 CONTRACTORs PMT may be required to work outside the normal COMPANY working

hours depending on operational requirements if required.

9.1.7 In the event that CONTRACTOR failed to fill any of the Firm positions of the PMT,

COMPANY have the right to deduct relevant amount in accordance to Section III -

SCHEDULE OF PRICES.

9.1.8 Monthly Rate for PMT shall be compensated to CONTRACTOR for such provision by

rate quoted in Section III - SCHEDULE OF PRICES after all the above requirements had

been fulfilled to the satisfaction of COMPANY.

9.1.9 The COMPANY reserves the right to increase or decrease the number of PMT personnel

in Appendix 1 - Provision By CONTTRACTOR and applicable rates shall be in

accordance to Section III - SCHEDULE OF PRICES.

9.1.10 The COMPANY reserves the rights to deduct from the timesheets of any PMT manhours

spent not related to this CONTRACT.

9.1.11 In the event any PMT member is absent for more than two (2) working days including

taking leave, CONTRACTOR shall notify and seek COMPANYs approval and provide

suitable relief personnel.

9.1.12 If the CONTRACTOR is unable to provide suitable relief personnel, COMPANY shall

deduct the monthly rate in accordance to Section III - SCHEDULE OF PRICES.

9.1.13 The CONTRACTOR shall provide a dedicated Operation Engineer for each

WORKBARGE and WORKBOAT to oversee the day to day operation of WORKBARGE

and WORKBOAT and the assigned project.

9.1.14 CONTRACTOR shall mobilise one (1) pax of Operation Engineer for each

WORKBARGE or WORKBOAT. CONTRACTOR is to note that the number of Operation

Engineer shall depend on the quantity of WORKBARGE and WORKBOAT mobilized.

The cost of the Operation Engineer is deemed to be part of VESSEL Daily Charter Rate.

9.1.15 If the CONTRACTOR plans to change its Firm Personnel from any Firm Position, then

the CONTRACTOR shall inform the COMPANY one (1) month in advance and seek

COMPANY approval for such change. The CONTRACTOR shall ensure minimum one

(1) month handover period between incoming candidate and outgoing incumbent. Any

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 11

costs incurred in connection with such replacement of CONTRACTORs personnel shall

be at CONTRACTORs own cost.

9.1.16 The CONTRACTOR shall at all time take all necessary precaution and measures to

prevent any unlawful, riots or disorderly conduct amongst its employee.

9.1.17 The CONTRACTOR team member is required to participate in COMPANY audits, site

visits, meetings, reviews and conference. CONTRATOR personnel attending meetings

shall follow proper meeting etiquette and to show professionalism at all time.

9.2 PROJECT MANAGER

9.2.1 The CONTRACTOR shall provide a Project Manager that meets Section VII -

TECHNICAL INFORMATION, who shall be designated as CONTRACTOR

REPRESENTATIVE with the authority to make decisions related to the performance of the

WORK.

9.2.2 The Project Manager plays vital role for successfulness of the WORK. The Project

Manager shall be professional and capable to administer the CONTRACT as required

by the COMPANY and reasonably carry out his duties as;

a. Lead and manage CONTRACTORs organisation efficiently.

b. Responsible for ensuring all resources are sufficient to execute the WORK and to

identify potential constraint or problem both during and in between WORK,

resolve or provide effective mitigation to COMPANY.

c. Expeditiously resolve the operational issues.

d. Timely delivery of contractual deliverables.

9.2.3 The COMPANY requires that the Project Manager be available for consultation with the

COMPANY REPRESENTATIVE at all times both during and in between WORK.

9.2.4 The Project Manager shall be dedicated to the CONTRACT and shall not be involved in

any other CONTRACTOR activities that are not related to this CONTRACT.

9.2.5 Should the COMPANY be of the opinion that the Project Manager is not performing as

required under the CONTRACT, the CONTRACTOR will be notified in writing. If the

non-performance continues, the CONTRACTOR shall replace the Project Manager by

another qualified person who is approved by COMPANY. Any costs incurred in

connection with such replacement of CONTRACTORs Project Manager shall be at

CONTRACTORs own cost.

9.3 CONTRACT MANAGEMENT

9.3.1 CONTRACTORs PMT comprising of senior management personnel shall be responsible

and efficiently managed the CONTRACT to meet COMPANYs business objectives and

goal.

9.3.2 The PMT shall attend meeting with COMPANY weekly or any meeting as required by

the COMPANYs representatives.

9.3.3 As minimum, COMPANY will organize meeting such as Weekly Progress Meeting,

Daily Progress Meeting, HSSE Monthly Meeting, Procurement Meeting, Workpack

Meeting throughout the CONTRACT.

9.3.4 The PMT shall manage all SUBCONTRACTORs, it employee, servants and agents

engaged in this CONTRACT.

9.3.5 The CONTRACTOR is responsible to notify the COMPANY when the VESSEL is under

Downtime, Mechanical Downtime and Major Equipment breakdown, Minor

Equipment breakdown and provide resolution or mitigation for COMPANY

consideration.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 12

9.3.6 The CONTRACTOR shall submit to the COMPANY a written record of such periods,

including a list of WORKBARGE or WORKBOAT, SUPPORT VESSELS involved, within

twenty-four (24) hours of occurrence of each such incident.

9.3.7 The CONTRACTOR shall incorporate the duration of all Standby, Waiting On

Weather, Downtimes, Breakdowns, Un-seaworthiness and as such that affect the

operation of the VESSEL and precisely reflect the conditions in Daily Status Report.

9.3.8 The CONTRACTOR shall submit all reports to COMPANY as stipulated in Section V -

ADMINISTRATION INSTRUCTIONS and/or required by COMPANYs representatives.

9.3.9 All CONTRACTORs report shall be signed by both CONTRACTOR and COMPANY

representatives.

9.3.10 The CONTRACTOR shall be responsible to provide supporting documents as a backup

for payment certificate such as signed timesheets, Daily /Weekly Progress Report, travel

request and all relevant supporting documents.

9.3.11 The COMPANY reserves the right to reject the payment certificates or invoices if

supporting document are incomplete, incorrect or missing.

9.3.12 The CONTRACTOR shall be responsible to ensure that all the invoices submitted to the

COMPANY are accurate and supported by relevant document, so as to reduce process

period of payment certificate or invoices.

9.4 MULTI SKILL MANPOWER

9.4.1 The CONTRACTOR shall provide multi skill offshore construction personnel as stipulated

in Appendix 1 - Provision By CONTRACTOR and retain them throughout the

CONTRACT.

9.4.2 The CONTRACTOR shall be responsible to systematically train and coach their multi

skill offshore construction personnel to meet CONTRACT requirement and to deploy

them to WORKSITE.

9.4.3 The CONTRACTOR offshore construction personnel are considered to be multi skill

when the offshore construction personnel posses two (2) or more skills such as

scaffolding and rigging, etc.

9.4.4 The multi skill personnel shall be able to execute the dual skill activities that he or she

has been approved for by the COMPANY.

9.4.5 The rate of multi skill personnel in Section III - SCHEDULE OF PRICES shall include all

mandatory training and courses needed to qualify them as multi skill.

9.4.6 COMPANY reserves the right to instruct CONTRACTOR to upgrade CONTRACTORs

offshore construction personnel from single trades to multi skills /dual trades.

9.5 INCENTIVE AND PERFORMANCE SCHEME FOR WORK COMPLETION

9.5.1 Once having started any part of the WORK, the CONTRACTOR shall work

continuously until that part of the WORK is complete, unless otherwise instructed by

COMPANY.

9.5.2 The CONTRACTOR shall be responsible to update the progress of WORK and to inform

the COMPANY of any issue or constraint the may slow down the WORK.

9.5.3 Any change in the planning during implementation shall be challenged and approved

by COMPANY

9.5.4 The CONTRACTOR is responsible to execute the WORK or part of the WORK, use all

resources within CONTRACTOR control and endeavour to complete the WORK or part

of the WORK within the period(s) as specified the approved Workpack and in the

relevant Purchase Order approved by the COMPANY.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 13

9.5.5 The CONTRACTOR shall be responsible to control and minimise all downtimes either

attributed by CONTRACTOR or COMPANY, similarly additional work that involve in

completing the base scope.

9.5.6 Upon completion of the WORK or part of the WORK, the CONTRACTOR will be

reimbursed for the following circumstances;

a. In the event that the CONTRACTOR complete the WORK ahead of approved

Workpack duration, CONTRACTOR shall be given incentive for the day saved

based on the early completion percentages in accordance with Section III -

SCHEDULE OF PRICES.

b. In the event that the CONTRACTOR complete the WORK beyond the approved

Workpack duration, the Daily Charter Rate of the WORKBARGE and/or

WORKBOAT will be reduced based on the percentages in accordance with Section

III - SCHEDULE OF PRICES.

c. Item (a) and (b) above shall be measure based on the scope in the approved

Workpack or base scope and exclude additional WORK or site instruction.

9.5.7 For the WORK or part of the WORK delay due to CONTRACTOR's not being able to

mobilise the resources or fail to comply with safety procedures, the lost in productivity

due to this shall be counted as CONTRACTOR's delay and shall be measure as part of

the base scope WORK duration.

9.5.8 Any delays due to waiting on weather, waiting on COMPANY's supplied materials

which are on the critical path of the WORK or operation constraint shall be excluded

from the based scope WORK duration measurement.

9.6 KEY PERFORMANCE INDICATOR (KPI) FOR THE WORK

9.6.1 CONTRACTOR is responsible for monitoring the performance of the WORK in

accordance to the approved Workpack.

9.6.2 The CONTRACTOR shall develop and submit to COMPANY for approval the

Performance Monitoring Procedure. The document shall be in accordance to

COMPANYs guidelines.

9.6.3 The Performance Monitoring Procedure shall identify the Key Performance Indicators

(KPI) for the Workpack and the WORK.

9.6.4 The KPI shall be jointly discussed and agreed by COMPANY within one (1) month after

the award of CONTRACT. The KPIs shall be reviewed, revised and agreed with

COMPANY on a yearly basis.

9.6.5 The CONTRACTOR shall provide dedicated KPI Coordinator as defined in Section VII -

TECHNICAL INFORMATION to coordinate all activities relating to tracking, analyzing

and reporting of KPIs and project performances.

9.6.6 Daily offshore performance KPI shall include Manhour Utilization, Jobcard Performance,

Productive Hour and Resource Availability.

9.6.7 The KPI Coordinator shall hold Weekly KPI performance Review Meeting with

COMPANY every Thursday of the week and CONTRACTORs Operation Engineers

(OE) shall participate in the meeting.

9.6.8 The CONTRACTOR shall arrange for the Quarterly Leadership Performance Review

presentation to COMPANY where the CONTRACTOR shall summarize the Performance

of the Workpack executed over the period.

9.6.9 It is the responsibility of CONTRACTOR to ensure that KPIs are constantly meeting

targets. The CONTRACTOR shall identify and implement corrective actions for KPIs that

have not been achieved.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 14

9.6.10 The CONTRACTOR shall assist the COMPANYs Representatives throughout the

CONTRACT duration to derive improvement initiatives for contract management.

9.6.11 The CONTRACTOR shall execute any approved initiatives by COMPANY where

CONTRACTOR actions are required.

9.6.12 The COMPANY shall carry-out six (6) monthly Business Performance Reviews (BPR) for

the CONTRACT in which the CONTRACTOR shall provide all necessary information

pertaining to project performances and KPIs.

9.6.13 The COMPANY reserves the right to implement any initiatives as to enhance the

productivity and performance of the WORK.

9.7 PURCHASE ORDER (PO)

9.7.1 The COMPANY shall issue PO for firm commitment and CONTRACTOR shall mobilize

the resources as per the CONTRACT.

9.7.2 For Call-Out commitment, the COMPANY shall issue to the CONTRACTOR a Purchase

Order Proposal Request (POPR) as defined in Section V - ADMINISTRATION

INSTRUCTIONS

9.7.3 The POPR shall state clearly nature of service, timeline, resource for the WORK or part

of the WORK or services to be executed.

9.7.4 Upon receiving the POPR, the CONTRACTOR shall immediately prepared an accurate

Purchase Order Proposal (POP) using the rates in Section III SCHEDULE OF PRICES

and submit in accordance with Section V - ADMINISTRATION INSTRUCTIONS.

9.7.5 Any approval of CONTRACTORs POPR shall not in anyway exonerate the

CONTRACTORs duty to comply with the CONTRACT requirements or specifications.

9.7.6 Whenever required, the COMPANY may initiate the WORK or part of the WORK by

issuing a Project Material and Equipment Request (PMESR) for MATERIAL, EQUIPMENT

and services as cost plus basis.

9.7.7 For the cost plus procurement, the CONTRACTOR shall prepare tender plan, technical

and commercial evaluation criteria for cost plus MATERIAL, EQUIPMENT and services.

9.7.8 COMPANYs approval given to technical and commercial evaluation shall not relief

CONTRACTOR of its obligation to the CONTRACT.

9.8 PROCEDURES AND DELIVERABLES

9.8.1 CONTRACTOR shall prepare and submit procedures and other documents as listed in

Appendix 1 - Provision By CONTRACTOR and/or as identified in the relevant section

of this CONTRACT or as requested by COMPANYs Representative for execution of the

WORK.

9.9 REPORTS

9.9.1 CONTRACTOR shall prepare and submit reports as detailed in Section V -

ADMINISTRATION INSTRUCTIONS.

9.9.2 Post Project Critique shall be issued immediately after the WORK is executed. The

minimum content of the Post Project Critique is detailed in Section V -

ADMINISTRATION INSTRUCTIONS.

9.10 PROJECT PLANNING AND CONTROL

9.10.1 The CONTRACTOR shall provide Project Planning and Control Procedures and facilities

to ensure the following;

a. Timely Completion of the WORK within budget

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 15

b. Allow early identification of slippages, their consequential impact and possible

corrective actions.

c. Automated input to weekly/fortnightly/monthly progress report as per required

format.

d. Preparation of proposals in the required format.

e. Smooth and efficient operation of its office with auditable record of all items

invoiced.

f. Software Project Planning Tools is required to prepare Cost Planning Network

(CPN), bar chart, activity network.

9.10.2 The CONTRACTOR shall take all reasonable measures to ensure that the WORK are

completed within the milestone period(s) specified in the purchase order.

9.10.3 The CONTRACTOR shall keep the COMPANY fully informed in writing of the progress

the WORK at a frequency required by the COMPANY.

9.10.4 If the WORK fall behind any agreed milestones defined in the project schedule or if it

becomes evidence that the progress has been too slow to ensure completion of the

WORK, or any part thereof in the prescribed time, then the CONTRACTOR shall take

immediate steps to expedite the progress of such WORK.

9.10.5 The quality of WORK shall be deemed to be satisfactory if the WORK delivered by the

CONTRACTOR meet the requirement in accordance with the specifications and quality

stipulated under the CONTRACT.

9.10.6 The WORK shall be deemed as poor quality if for any reason the deliverables are

found to be, but not limited to, the following;

a. Inconsistencies with the WORK provided by the CONTRACTOR and the

COMPANYs specification and/or documentation.

b. Failure by the CONTRACTOR to fully implement COMPANY instructions.

c. Non-conformance between the WORK and the COMPANYs specifications, except

where these non-conformances have been approved by the COMPANY.

d. Specifications, document and requisitioned quantities provided by CONTRACTOR

inadequate to meet specified service conditions and needs of the WORK.

e. Inconsistent, inaccurate, incomplete or contradictory deliverables.

9.10.7 If the COMPANY considers the CONTRACTOR to be in default of the above, the

CONTRACTOR shall at the CONTRACTORs cost investigate the complaint, assess the

deficiency against the CONTRACTORs approved Quality System and submit a report

to the COMPANY within seven (7) days of the notification. The report shall contain full

details as to the cause, reasons and responsibility for the deficiency together with the

recommended remedial procedures to be taken.

9.10.8 On completion of the remedial procedures and rectification of the deficiency the

CONTRACTOR shall execute an audit in order to confirm compliance to the COMPANY

satisfaction. The audit report shall be submitted to the COMPANY for approval within

seven (7) days of completion of the remedial procedures.

9.10.9 The COMPANY, at its sole discretion, may elect to rectify the poor quality deliverables,

either by employing another CONTRACTOR to carry out the remedial WORK or by

carrying out the remedial WORK in-house. The costs incurred by the COMPANY in

rectifying the poor quality deliverables shall be deducted from any payment due to the

CONTRACTOR.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 16

10.0 WORKPACK AND MINOR ENGINEERING

10.1 GENERAL

10.1.1 The CONTRACTOR shall prepare Workpack Development and Project Close Out

Procedure and submit for COMPANY approval. The procedure shall detail out all

activities, process, method, usage of construction norms from attaining the scope of

work until Workpack approval and final close out report.

10.1.2 COMPANY will provide Approved For Construction (AFC) packages, Inspection Report,

Plant Change Proposal (PCP). These are the basis for CONTRACTOR to develop the

Workpack.

10.1.3 The CONTRACTOR shall be responsible to ensure the Workpack is perfectly done by

thoroughly checking, fully scope the activities, carry out work scoping offshore and

meeting with COMPANY to resolve technical issue, correctly used the construction

norms and sequence the activities. CONTRACTOR shall verify line by line of the scope

and endeavour to minimize additional works during the execution phase.

10.1.4 The CONTRACTOR shall be responsible to carry out minor engineering work which

include but not limited to review of the AFC drawings, clash check, shop drawings,

detail drawings, lifting calculation, identify rigging aids, proposed suitable method or

special equipment to COMPANY.

10.1.5 All minor engineering work done by CONTRACTOR shall be approved by COMPANY

prior to implementation at WORKSITE.

10.1.6 When preparing the Lifting Procedure, CONTRACTOR shall comply with COMPANYs

SMEP Lifting and Hoisting Manual SMEP. EP200802258279.

10.1.7 The CONTRACTOR shall indicate any discrepancies and ambiguities in the AFC

packages to COMPANY in Site Technical Queries (STQ).

10.1.8 The CONTRACTOR shall assess all risks for the critical activities and details Controls

and Recovery Measures required during executions. Critical activities shall include

heavy lifts, vessel entry, electrical power tie-in, hot-works in potential hydrocarbon

environment, working with high pressure, working at height, working in marginal sea

state and working in potential toxic gas environment.

10.1.9 The CONTRACTOR shall prepare the Positive Isolations Plan to render the WORKSITE is

safe for construction activities. The CONTRACTOR shall be responsible for obtaining

approval from the COMPANYs Offshore Installation Manager (OIM) on Positive

Isolation prior to commencement of construction activities.

10.1.10 The CONTRACTOR shall be responsible to convert AFC drawing (only certain drawings)

into Issue For Construction (IFC) drawing and submitted to COMPANY for approval.

The approved IFC drawing shall be used for minor fabrication as well as to be included

in the Workpack for offshore construction.

10.1.11 The CONTRACTOR shall emphasize on health and safety of the personnel and

equipment during WORK planning, shall highlight all concerns to COMPANY and

include it in the relevant section of the Workpack.

10.1.12 CONTRACTORs Workpack team member shall be required to participate in

COMPANY construction review and meeting, such as Implementation Project On Paper

(IPOP), HAZID and constructability review sessions.

10.1.13 CONTRACTOR shall provide hardcopies (min. 8 sets) and a soft copy (in PDF format

and planning package in Primavera, P3 file format) of the approved Workpack and

distribute it to relevant parties as stated in Appendix 1 - Provision By CONTRACTOR.

10.1.14 All cost for producing and distribution of the Workpack to relevant parties is deemed to

be included in Section III - SCHEDULE OF PRICES.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 17

10.2 WOKRPACK DEVELOPMENT

10.2.1 The CONTRACTOR shall prepare fit for purpose Workpack that integrate effective

strategy and optimise the usage of MANPOWER (including multi skill personnel) and

EQUIPMENT to achieve project milestones.

10.2.2 The CONTRACTOR shall utilise Primavera planning software (latest revision at

CONTRACT award date) to demonstrate logical sequence of the planning.

10.2.3 The CONTRACTORs Workpack shall include the followings as minimum;

a. Project summary information and detail scope

b. Barchart, histogram, project or activity network and Critical Path Network (CPN)

c. Manpower, tools, equipment and consumables list

d. Jobcards and jobcards summary

e. Calculation sheets detailing the quantity, construction norms and trades used in

computing the jobcards manhour.

f. Material Take-Off (MTO)

g. Drawing and relevant sketches

h. Procedures, spading and isolation plan

i. Commissioning Section, refer item 10.2.11 below

j. Approval and distribution section

10.2.4 The CONTRACTOR shall prepare jobcard using Construction Norms provided in

Appendix 4 Construction Norms herein. The jobcard shall detail out all

works/activities construction, pre-commissioning and commissioning, trades and

manhours to complete all task and shall be linked to the relevant drawings and MTO.

10.2.5 The CONTRACTORs activity network must show logical construction sequence of all

activities, durations and milestone. In addition, CONTRACTOR shall produce CPN to

demonstrate the activities that are critical for the WORK or part of the WORK.

10.2.6 A copy on final activity network and Critical Path Network (CPN) shall be copied to

COMPANY for all the work undertaken by the CONTRACTOR.

10.2.7 The CONTRACTOR shall identify and categorise all MATERIALS required to complete

the WORK in the Workpack. The CONTRACTOR shall verify the accuracy and

availability of the MATERIALS as identified in COMPANYs AFC or Inspection Report in

both offshore and Minor Fabrication Yard.

10.2.8 It is CONTRACTOR responsibility to notify COMPANY if there are any discrepancies

between AFC, inspection report or upon site visit verification by CONTRACTOR at

WORKSITE.

10.2.9 During development of Workpack, CONTRACTOR shall use a Positive Pressure Habitats

for all hotwork in Zone 2 or as identified Hazardous Area Classification Drawing(s) or

in HAZID, SSP and SIMOPS.

10.2.10 In case the Positive Pressure Habitat is erected at congested area, CONTRACTOR shall

prepare a risk assessment to ensure that the person in the habitat can be evacuated

safely.

10.2.11 The CONTRACTOR shall prepare the commissioning section in each Workpack. The

commissioning section shall include;

a. Pre-commissioning and commissioning procedures.

b. List of commissioning tools and equipment.

c. System/subsystem boundary drawings.

d. Pre-commissioning and commissioning activities jobcards and network.

e. Pre-commissioning and commissioning sequence in-line with the project milestones

and handover milestones.

f. Reinstatement, dewatering, nitrogen purging, chemical cleaning, lube oil flushing.

g. Level 4 commissioning plan with system priority base on the input provided by

COMPANY Lead Commissioning Engineer (LCE).

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 18

10.2.12 CONTRACTOR shall liaise with COMPANY Lead Commissioning Engineer (LCE) for

preparing above deliverables.

10.2.13 Each Workpack planning shall be aimed and aligned with COMPANY commissioning

system priority and strategy. Construction network shall be linked to commissioning

priorities. Project is only considered complete upon completion of commissioning.

10.2.14 CONTRACTOR shall prepare Workpack in most efficient construction methods and

processes incorporating hazards involved with precautions and recovery measures

inplace with the objective of no harm to People, Assets and Environment. In addition,

CONTRACTOR shall optimize usage of multi skill personnel in Workpack preparation.

10.2.15 The CONTRACTOR shall prepare the draft Workpack for challenges session with

COMPANYs relevant project team or department. The CONTRACTOR shall actively

participate and present their strategies and planning during the challenge session.

10.2.16 CONTRACTOR shall be responsible for the final planning Workpack. Any change to

the approved Workpack shall be challenged and approved by COMPANY.

10.2.17 The approved Workpack may require to be revised and re-approved due to milestones

change, activities or resource optimization, activities clash with others and/or to meet

COMPANYs business priority, in this circumstances the CONTRACTOR shall revise the

Workpack and resubmit for approval.

10.2.18 The CONTRACTOR shall explain clearly on all the factors that affected the change of

the Workpack planning in the Post Project Critique (PPC) and Project Close-Out Report.

10.2.19 COMPANY shall recognize the Workpack as approved after COMPANYs

Representatives and/or Project Engineer have signed off the document.

10.2.20 COMPANY reserves the rights to specify additional or reduction of Offshore

Construction Personnel and EQUIPMENT via Workpack challenge session or as and

when required by COMPANY.

10.2.21 The CONTRACTOR shall prepare Workpack progress report and to submit to

COMPANY on weekly basis. Format of the report as per Section V - ADMINISTRATION

INSTRUCTIONS.

10.2.22 CONTRACTOR shall provide Workpack Preparation Aids as specified in Section VII

TECHNICAL INFORMATION.

10.3 CONSTRUCTION NORMS

10.3.1 The CONTRACTOR shall use the Construction Norms provided in Appendix 4 -

Construction Norms for Workpack planning. The Construction Norms provide by

COMPANY covers for offshore construction activities and it is inclusive of factored for

offshore constraint.

10.3.2 The CONTRACTOR shall use the Construction Norms provided to estimate manhours

for each offshore activities and to estimate total duration of the WORK.

10.3.3 The CONTRACTOR shall officially notify COMPANY during the course of Workpack

preparation, if there are any offshore activities that are currently not cover in

COMPANY provided Construction Norms. For such offshore activities without

COMPANYs Construction Norms, COMPANY shall allow CONTRACTOR to propose

their own norms.

10.3.4 When proposing the CONTRACTORs Norms, the CONTRACTOR shall propose an

established Norms which is proven or widely used in the Oil and Gas industries.

COMPANYs approval shall be required prior to utilizing the CONTRACTORs Norm in

the Workpack planning.

10.3.5 Construction Norms shall be controlled by COMPANY; it shall not be changed unless

with prior written approval from COMPANY REPRESENTATIVE.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 19

New Labour Rates = O.L.R + (O.L.R*0.85) * [(N.C.P.I/O.C.P.I)-1] + 0.05

Extra 5% in addition to the standard CPI rate adjustment

10.3.6 Continuous Expansion of Construction Norms

a. CONTRACTOR shall continuously develop and expand on the Construction Norms

provided by COMPANY. On a six (6) monthly basis, CONTRACTOR and

COMPANY shall jointly go through the table in Appendix 4 - Construction Norms

and incorporate new norms that have been approved by COMPANY over the six

(6) months period into the relevant norms table. The revised Construction Norms

Tables with the new norms will be contractual binding, subsequently shall be used

by CONTRACTOR for future Workpack planning.

10.3.7 Continuous Improvement of Construction Norms

a. CONTRACTOR shall continuously improve on the Construction Norms. On an

annual basis, CONTRACTOR and COMPANY shall jointly go through and agreed

on CONTRACTORs Workpack performance over the one (1) year period i.e. plan

Workpack duration against actual Workpack execution duration.

10.3.8 If over the one (1) year period CONTRACTOR shows average improvement of more

than five percent (5%), then COMPANY reserve the right to revise the Construction

Norms downward for the following year to take into account the improvement achieved.

However, such downward revision in Construction Norms shall be limited to 50% of the

actual improvement, as per example below:

Average Workpack Performance in % Reduction in Construction Norm in %

6% 3%

10% 5%

5% Not applicable

-3% Not applicable

10.3.9 In order to encourage CONTRACTOR to continuously improve on offshore workpack

execution performance and Construction Norms, if CONTRACTOR is able to achieve

and provide evidence of such offshore Workpack execution improvement of average

more than five percent (5%) per year, then COMPANY shall reward CONTRACTORs

Offshore Construction Personnel based on the following improved Labour Rates

Adjustment CPI plus additional five percent (5%), such reward shall be at COMPANYs

discretion:

Example of Improved Labour Rate Adjustment (i.e. Standard CPI adjustment + extra 5%)

Where,

O.L.R The Original Labour Rate in SCHEDULE 5F of Section III

SCHEDULE OF PRICES (Daily Rate and OT Hourly Rate).

N.C.P.I The Consumer Price Index (C.P.I) for Service Group for the

State of Sarawak published by the Department of Statistics,

Kuala Lumpur, Malaysia applicable for December 2013.

O.C.P.I The C.P.I applicable on December 2012.

Standard Labour Rates Adjustment, as per Section III SCHEDULE OF PRICES

(Standard CPI Adjustment)

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 20

10.4 CONSTRUCTION AND COMMISSIONING EXPERTISE

10.4.1 CONTRACTOR shall provide experience construction personnel to generate Workpack

with detailed construction methods, sequences and procedures to ensure the WORK is

carried out safely with optimized planning.

10.4.2 CONTRACTOR shall provide Construction Advisor to assist Workpack team to provide

effective construction sequence or methodology for effective Workpack planning.

10.4.3 The Construction Advisor shall be responsible to carry out offshore workscoping

together with Workpack Field Engineer and as well as to participate in COMPANY

constructability review as and when required by COMPANY.

10.4.4 Workpack Field Engineer and/or Construction Advisor shall be required to work at the

WORKSITE as and when required by COMPANY. He or she shall provide technical

guidance and solutions to the Construction Superintendent or Supervisors and other

crew during the execution phase.

10.4.5 COMPANY may require advice from CONTRACTOR on offshore construction

methodology for certain activities such as installation or lifting of complex or awkward

skid or panel. In this case, CONTRACTOR is required to propose effective methodology

or lifting plan for COMPANY review.

10.4.6 CONTRACTOR shall use COMPANY Certification and Completion Management

System (GoCCMS) to record and track on all mechanical completion, pre-

commissioning and commissioning activities.

10.4.7 The CONTRACTOR is responsible to use the GoCCMS system and to report to

COMPANY the activities using the system provided by the COMPANY throughout the

CONTRACT.

10.4.8 The COMPANY shall train CONTRACTOR personnel to be familiar with the GoCCMS

system and CONTRACTOR is required to apply it when reporting the mechanical

completion, pre-commissioning and commissioning activities.

10.4.9 The CONTRACTOR shall upload all inspection {both Inspection Test Record A (ITRA)

mechanical completion, Inspection Test Record B (ITRB) - pre-

commissioning/commissioning} checks sheets and test reports e.g. mechanical

completion certificate, pre-commissioning certificate, system acceptance certificate etc.,

in the COMPANYs GoCCMS for project progress tracking, reporting and as final

project hand over.

10.4.10 CONTRACTOR is responsible to train the graduate engineers during the CONTRACT

duration to bring them up to the next level of competencies.

10.4.11 CONTRACTOR shall provide commissioning expertise to assist the Workpack engineers

in generating the relevant commissioning document.

10.5 LUMP SUM PURCHASE ORDER PROPOSALS

10.5.1 COMPANY reserves the rights to request the CONTRACTOR to propose purchase

orders base on Lump Sum basis. Basis of such proposals shall be base on the rates

quoted in Section III - SCHEDULE OF PRICES and the Construction Norms provided

herein under Appendix 4.

10.5.2 When a purchase order is on a lump sum basis, all associated costs for any and all

additional MANPOWER, EQUIPMENT, MATERIALS, services and consumables that

become required but were insufficient or were not included in the CONTRACTORs

purchase order proposal, shall be borne by the CONTRACTOR unless these are the

result of changes in the scope of WORK instructed by the COMPANY.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 21

10.5.3 For work delayed due to waiting of weather, COMPANY supplied materials which are

on the critical path of the WORK or operation constraint, these delay shall be excluded

from the firmed duration agreed by the COMPANY.

10.5.4 Any changes in Workpack Planning during implementation shall be controlled and

approved by COMPANY.

10.4 ONSHORE MINOR FABRICATION

11.1 GENERAL

11.1.1 The CONTRACTOR shall provide all EQUIPMENT, MANPOWER and service to carry

out fabrication of the WORK or part of the WORK onshore as instructed by COMPANY.

11.1.2 The CONTRACTOR shall provide a Minor Fabrication Yard and it facility in Labuan in

accordance to Section VII - TECHNICAL INFORMATION for the performance of the

WORK. The CONTRACTOR may appoint an third (3

rd

) party onshore fabricator as

their SUB-CONTRACTOR.

11.1.3 The CONTRACTOR shall manage the Minor Fabrication Yard including provision of

Supervisor, Surveyor, HSSE personnel, inspection personnel, NDT personnel, Material

Coordinator and other supporting personnel as for smooth operation of the yard.

11.1.4 CONTRACTOR is responsible to implement CONTRACTORs PQA Plan, HSSE Plan for

Minor Fabrication Yard and maintain in accordance to COMPANY Standard.

11.1.5 If CONTRACTOR opts to subcontract the Minor Fabrication Yard, the management of

the yard, HSSE and QA/QC shall be under CONTRACTOR direct control and

responsibility.

11.1.6 The fabrication scopes are defined in the AFC drawings, Workpack or COMPANY

instructions.

11.1.7 All construction aids such as shed, props, chokes and stands require to assemble the

structural and piping component in order to complete the WORK are to be supplied by

CONTRACTOR at own cost.

11.1.8 The CONTRACTOR shall provide all services such cranes, forklift, lorry, trailer,

Transportation Container, lifting appliance and tackles to move the MATERIALS inside

the fabrication yard. CONTRACTOR shall also provide similar service for

transportations of COMPANY material from or to Labuan Supply Base.

11.1.9 The CONTRACTOR shall be responsible for the accuracies and quality of all fabricated

items. All costs and time, whether incurred at the onshore, associated with remedial

works or corrective actions that are required as a result of these inaccuracies and poor

quality shall be borne by the CONTRACTOR.

11.1.10 If the faults have to be repaired at offshore, COMPANY reserves the rights to deduct

from the timesheets of the CONTRACTOR s personnel and EQUIPMENT utilised for the

repair.

11.1.11 No fixed quantity or continuity of Minor Fabrication WORK is guaranteed by the

COMPANY throughout the CONTRACT period.

11.1.12 The CONTRACTOR shall design and provide all temporary supports and timber chokes

to aid the fabrication of Structural Steelwork and pipework. The CONTRACTOR shall

ensure the structures are stable and suitably elevated during the fabrication.

11.1.13 The CONTRACTOR shall provide a hardened or concreted storage area for storing of

all fabricated items in the Minor Fabrication Yard.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 22

11.1.14 The CONTRACTOR shall inform COMPANY of any discrepancies and ambiguities in

the AFC drawing via Site Technical Queries (STQ). STQs on each project are to be

compiled and issue to offshore together with the Workpack and Inspection reports

11.1.15 The CONTRACTOR shall produce As-Fabricated Drawings or Yard Redline Marked-Up

Drawings. The As-Fabricated Drawings shall mark-up with Redline to identify

modifications or revisions during the pre-fabrication stage.

11.1.16 The CONTRACTOR shall issue three (3) sets of As-Fabricated Drawings to COMPANY

within one (1) week after the completion of pre-fabrication together with the closeout

report for each project.

11.1.17 Provision of Minor Fabrication Yard and all personnel, construction

tools/aids/equipment, mobile or fix machinery, material, consumables, services,

telephone/fax line, email service, monthly expenses and all associated cost shall be

deemed included in fabrication unit rates as per Section III - SCHEDULE OF PRICES.

11.1.18 The CONTRACTOR to prepare Material Take Off (MTO) for the WORK or part of the

WORK and submit to COMPANY Site Representative together with Weekly Progress

Report on weekly basis.

11.1.19 The CONTRACTOR shall provide cars for COMPANY personnel usage. The cars

provided shall comply with Section VII - TECHNICAL INFORMATION.

11.1.20 The COMPANY reserves the right to request for Minor Fabrication service in Kota

Kinabalu or Miri. The rate for the fabrication work shall be in accordance with Section

III - SCHEDULE OF PRICES.

11.2 FABRICATION WORK

11.2.1 The CONTRACTOR shall properly handle and to provide protections and sufficient

preservations to COMPANY supplied MATERIALS while in the custody of the

CONTRACTOR.

11.2.2 The CONTRACTOR shall flush all pipeworks prior to cap off at the bare ends and install

plywood blinds at the flange ends.

11.2.3 Fabrication scope shall include the following;

a. Review AFC drawings and prepare pre-fabrication Materials Take-Off (MTO)

b. Provide cutting plans to optimise the usage of the MATERIALS.

c. Provide detailed shop drawings, weld map and detailed fabrication sequence as

required, trial fit procedure.

d. Mark, cut, fit up and weld Structural, Piping, Electrical and Instrument support in

accordance to the AFC Drawings or COMPANY specification.

e. Blast and Paint in accordance to Codes, Specifications, DEP and SES quality

requirements.

f. Perform all required Non-Destructive Tests and document all inspections as per the

approved Inspection and Test Plan.

g. Perform heavy lifts with approved heavy lift procedure meeting SMEP lifting and

hoisting standard.

h. Packing, crating, bundling and provide marking and tags for each ship-loose items.

i. Pack ship-loose and pre-slung large items that cannot fit into container/open trays

in accordance to COMPANY requirements.

j. Issue Consignment of Cargo (COG) and transport ship-loose items to COMPANY

Designated Jetty in Labuan Supply Base.

k. Compile and issue all relevant drawings and test reports to offshore.

l. Document and return all scrap MATERIALS to COMPANYs scrap yard.

CONTRACT NO. MY110000280 SECTION IV - SCOPE OF WORK

Section IV / Page 23

11.3 FABRICATION SPECIAL REQUIREMENT

11.3.1 The CONTRACTOR shall pre-fabricate Corrosion Resistant Alloy (CRA) materials such

as Stainless Steel, Duplex Stainless Steel, Super Duplex Stainless Steel and Inconel

materials strictly in accordance to Codes and Specifications and meeting COMPANY

requirements

11.3.2 The following precautions shall be followed;

a. Protected from contaminations such as carbon steel and chloride during fabrication

and storage of raw materials and fabricated items.

b. Tools and equipment shall be segregated and isolated.

c. Weld joints shall be cleaned with approved cleaning agent.

d. Controlled welding processes.

e. Hardness, ferrite and Positive Material Identification (PMI) where required.

f. Pre-fabricated spools shall be cleaned with acid pickling and apply with acid

pickling paste and comply with approved procedure.

g. Pre-fabricated spools shall be wrapped with plastic sheets prior to transport to

offshore.

11.3.3 Spools are to be clearly marked with warning that handling with carbon steel tools are

not allowed.

11.4 STORAGE OF THE SURPLUS AND PREFABRICATED MATERIAL