Documente Academic

Documente Profesional

Documente Cultură

Hanson G209 (SW Valves)

Încărcat de

AKSHEYMEHTADrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hanson G209 (SW Valves)

Încărcat de

AKSHEYMEHTADrepturi de autor:

Formate disponibile

1

G209h

MAY 2000

Specifications, Applications,

Service Instructions & Parts

Pump Guardian

PUMP CONTROLLER

for Refrigerant Recirculator

Packages, Accumulators,

Receivers, and Intercoolers

Bulletin G209h

MAY 2003

Specifications, Applications,

Service Instructions & Parts

" through 2"*

(13 mm through 65 mm)

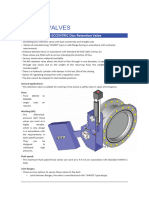

Globe and Angle

for Refrigerants

SOCKET WELD

SHUT-OFF VALVES

The advanced desi gn and mat eri al s of t he Hansen

St eel Body Socket Wel d Ref ri gerant Val ves make

t hem st ronger and f ar superi or t o ot her commonl y

avai l abl e product s. Thi s i s especi al l y t rue i n regard

t o l eakage f rom seat s, st ems, bonnet s, and pi pi ng

connect i ons. Socket wel d st eel bodi es permi t t hese

val ves t o be qui ckl y and easi l y wel ded di rect l y i nt o

pi pi ng wi t hout t he i nconveni ence of pi pe t hreadi ng

or usi ng bul ki er i ron-f l anged val ves wi t h socket wel d

st eel f l anges requi ri ng bol t s, nut s, and gasket s.

Compared t o but t wel d val ves, t he Hansen socket

wel d bodi es al l ow qui cker wel di ng, easi er pi pe

al i gnment , and cl eaner pi pe and val ve i nt eri ors.

APPLICATIONS

Typi cal uses i ncl ude:

Ammoni a r ef r i ger at i on syst em suct i on, l i qui d,

di scharge, reci rcul at i ng l i qui d, hot gas, and oi l l i nes

usi ng handwheel or seal cap model s.

St eel pi pe por t i ons of hal ocar bon commer ci al ,

i ndust ri al , and ai r condi t i oni ng syst ems usi ng seal

cap model s.

Compressor suct i on and di scharge connect i ons and

c ondens er and ev apor at or i nl et and out l et

connect i ons f or ammoni a, R22, R134a, and ot her

Hansen-approved ref ri gerant s.

KEY FEATURES

ADDITIONAL FEATURES

Sui t abl e f or ammoni a, R22, R134a, and ot her

Hansen-approved ref ri gerant s

Gl obe and angl e avai l abl e

Tef l on seat di sc (no l ead)

Avai l abl e al so as an expansi on val ve

Handwheel s or seal caps are i nt erchangeabl e

400 psi g (27 bar) saf e worki ng pressure

Temperat ure range: 60F to +240F (50C to +115C)

Bel ow 60F (50C) at l ower pressures

Nonasbest os gasket s

Made ent i rel y i n t he USA

2" Gl obe Val ve: GS200H

*2" (50 mm) t o 16" (400 mm) avai l abl e as but t wel d

INTRODUCTION

2

G209h

MAY 2000

The D di mensi on represent s t he socket dept h. See

pages 4, 6, 8, and 10.

INSTALLATION

Al l Hansen wel d val ves can be i nstal l ed i n hori zontal

or verti cal pi pe l i nes. Stems are normal l y i nstal l ed

hori zontal l y, but, dependi ng on the appl i cati on, stems

may be i nstal l ed verti cal l y. Gl obe val ves i n hori zontal

sucti on l i nes, l i qui d overfeed return l i nes, condenser

drai n l i nes, purge l i nes, oi l pot drai n l i nes, or l evel

control col umn i sol ati on val ves shoul d have stems

hori zontal to avoi d l i qui d or vapor bei ng trapped at

the val ve seat ori fi ce. Inl et pressure or di recti on of

fl ow for al l val ve si zes shoul d normal l y be under val ve

seat di sc. However, to avoi d i nstal l i ng an angl e val ve

wi th the stem down, i t i s better to i nstal l the val ve

wi th the normal fl ow opposi te the di recti on of the

arrow.

The val ve stem shoul d be opened several turns duri ng

wel di ng to prevent heat damage to the seat di sc.

Normal l y, i t i s not necessary to di sassembl e these

socket wel d val ves for i nstal l ati on wel di ng. However,

i f wel di ng i s prol onged enough to overheat the val ve

body, a wet rag shoul d be wrapped around the val ve

bonnet and upper body whi l e wel di ng. Socket wel d

fitting and valve codes require that the pipe be inserted

unti l bottomed agai nst the stop, then backed out

approxi matel y

1

/16" (1.5 mm) before wel di ng.

Welds should be annealed as necessary in accordance

wi th good practi ce. Pai nti ng val ves and wel ds i s

recommended for corrosi on protecti on. Pi pe coveri ng,

where appl i ed, shoul d have a proper moi sture barri er.

Bef ore put t i ng val ves i nt o servi ce, al l pi pe wel d

connections, valve seats, bonnet seals, and stem seals

shoul d be tested for l eaks at pressure l evel s cal l ed

for i n appropri ate codes. If necessary, reti ghten at 75

f t -l bs (100 Nm) t he t hr eaded bonnet on "

(13 mm) through 1" (32 mm) val ves. These may have

a l oosened secondary kni fe-edge seal after i nstal l ati on

due to excessi ve heati ng of val ve body.

Shut-off val ves l eadi ng to the atmosphere must not

be l eft unsupervi sed and must be pl ugged or capped

to prevent corrosion inside the valve as well as leakage

due to seat expansi on, vi brati on, pressure shock, or

i mproper openi ng. The val ve seat shoul d be cracked

open to prevent hydrostati c expansi on between the

val ve and the cap. Val ves shoul d never di rectl y feed a

water tank because of potenti al i nternal corrosi on or

seat openi ng caused by vi brati on.

INSULATION

Readi l y avai l abl e, val ve shaped bl ock i nsul ati on can

be used for both angl e and gl obe val ves. Exteri or

val ve di mensi ons for i nsul ati on are shown on pages

4, 6, 8, and 10. The W di mensi on on pages 6, 8, and 10

represents the wi dth of the rei nforcement web.

SERVICE AND MAINTENANCE

Hansen Steel Body Socket Weld Shut-Off Valves require

practi cal l y no servi ce or mai ntenance. Stem l eakage,

a common problem of shut-off valves, is almost entirely

el i mi nated by the combi nati on of pol i shed stai nl ess

steel stems and rel i abl e, conventi onal , adj ustabl e

packi ng suppl ementi ng fl ui d-ti ght o-ri ng stem seal s.

For opti mum mai ntenance, occasi onal cl eani ng of the

val ve stem wi th a soft rag and refri gerant oi l i s hel pful .

The patented o-ri ng stem seal desi gn permi ts l ow

torque operati on to open and cl ose the val ve.

ADVANTAGES

Compared t o t hreaded val ves, Hansen Socket Wel d

Val ves el i mi nat e t he chance of f ut ure l eaks at pi pe

t hreads. In addi t i on, a socket wel ded pi pe-t o-body

j oi nt el i mi nat es t he i nher ent weak nes s and

vul ner abi l i t y of t he t hr eaded por t i on of pi pe

i mmedi at el y adj acent t o a screwed val ve body or

flange.

Socket wel di ng i s easi er t han but t wel di ng f or

al i gnment. It al so provi des cl eaner i nteri or wel d j oi nts.

Compared t o f l anged val ves, Hansen Socket Wel d

Val ves el i mi nat e t he l eak pot ent i al at t he gasket

j oi nt . In addi t i on, nearl y al l ref ri gerat i on f l anged

val ves are made of cast i ron or semi -st eel , a t ype

of cast i ron. Hansen s steel val ves have much greater

tensi l e strength, ducti l i ty, and i mpact resi stance than

cast i ron.

Compared to pressed-sheet-steel wel d val ves, Hansen

val ves have heavi er cast st eel wal l t hi ckness f or

great er ri gi di t y and a corrosi on saf et y margi n.

Al l Hansen socket wel d val ves have ri si ng st ems.

Thi s al l ows t he operat or t o know at a gl ance whet her

t he val ve i s open or cl osed.

CONNECTION DIMENSIONS

The body socket s accommodat e US St andard Pi pe

Schedul e 40 or Ext ra Heavy Pi pe Schedul e 80.

MATERIAL SPECIFICATION

Body: " and " , ASTM A108 (connect i ons

ASTM A513)

1" t hrough 2" , cast st eel , ASTM A352,

grade LCB

St em: st ai nl ess st eel

Di sc Hol der: st eel

Seat Di sc: PTFE Tef l on, ret ai ned

Bal l Beari ngs: st ai nl ess st eel

Packi ng Nut : " t hrough 1" , corrosi on resi st ant

coated steel

1" t hrough 2" , el ect rol ess ni ckel

pl ated steel

St em Packi ng: graphi t e composi t e pl us

neoprene o-ri ng

Handwheel : " t hrough 1" , zi nc-pl at ed

Zamak al l oy

1" through 2" , zi nc-pl ated i ron al l oy

Bonnet: " through 1" , zi nc-chromat e pl at ed st eel

1" t hrough 2" , duct i l e i ron ASTM A536

Seal Cap: " t hrough 1" , gl ass-f i l l ed pol ymer,

safety vented

1" t hrough 2" , zi nc-pl at ed st eel

3

G209h

MAY 2000

*Schedul e 80 pi pe under 2" si ze

FLOW CAPACITIES

PIPING AND VALVE SIZING GUIDE FOR AMMONIA

FLOW COEFFICIENTS

SIZING GUIDE

These capaci t y recommendat i ons are not af f ect ed

by t he l engt h of t he pi pe l i ne. These are approxi mat e

opt i mum si zes based on power cost s versus t he

i nvest ment cost of pi pi ng and i t s t ot al i nst al l ed cost .

Pi pi ng si zed t o t hese capaci t i es wi l l have 1F (0.6C)

pressure drop f or t he f ol l owi ng equi val ent l engt hs:

Sucti on l i nes ............................ 700 di amet ers

Di scharge l i nes ........................ 1400 di amet ers

Li qui d l i nes ............................... 2400 di amet ers

Exampl e: Hansen angl e socket wel d val ves have

about 145 di amet ers of equi val ent f l ow resi st ance,

or 145/700 = 0.2F (0.1C) of equi val ent pressure

drop at t he suct i on l i ne capaci t i es shown f or a val ve

i n a suct i on l i ne. Gl obe val ves equal about 225

di ameters.

The rat i onal f or t he vapor l i ne si zi ng was devel oped

by Wi l l i am V. Ri chards i n t wo papers: Ref ri gerant

Vapor Li ne Si zi ng Not Dependent on Lengt h, 16

t h

Int ernat i onal Congress of Ref ri gerat i on, IIR, Pari s,

1983, and Practi cal Pi pe Si zi ng for Refri gerant Vapor

Li nes, Si xt h Annual Meet i ng, IIAR, San Franci sco,

1984.

E C V R E S

S H D T D H D C S E T C A P A C

. p m e T

F ] C {

E R U S S E R P

G S P ] R A B {

" ) m m 3 1 (

S H D T ] W k {

" ) m m 0 2 (

S H D T ] W k {

" 1 m m 5 2 ( )

S H D T ] W k {

" 1 ) m m 2 3 (

S H D T ] W k {

" 1 ) m m 0 4 (

S H D T ] W k {

" 2 ) m m 0 5 (

S H D T ] W k {

" 2 5 6 ( ) m m

S H D T ] W k {

s e n i L n o i t c u S

e g a t S e l g n i S

r o s s e r p m o C

0 2 +

0

( ) 7 . 6

(17 8 . )

5 . 3 3

7 . 5 1

( ) 3 . 2

( ) 1 . 1

6 . 8

7 . 5

( ) 0 3

) 0 2 (

8 . 5 1

4 . 0 1

) 6 5 (

) 7 3 (

3 . 1 2

9 . 3 1

) 5 7 (

) 9 4 (

7 . 5 3

7 . 2 2

6 2 1 ( )

) 0 8 (

1 . 1 5

0 . 4 3

) 0 8 1 (

) 0 2 1 (

s e n i L n o i t c u S

r e t s o o B

0 2

0 4

( ) 9 . 8 2

( ) 0 4

6 . 3

" 7 . 8

( ) 2 . 0

( 3 . 0 )

2 . 4

( ) 5 1

4 . 7

4 . 4

( ) 6 2

) 5 1 (

3 . 0 1

3 . 6

6 3 ( )

) 2 2 (

8 . 6 1

9 . 9

9 5 ( )

) 5 3 (

8 . 4 2

4 . 4 1

) 7 8 (

) 1 5 (

d e e f r e v O d i u q i L

) X 4 ( s e n i L n r u t e R

0 2 +

0

0 2

0 4

( ) 7 . 6

( ) 8 . 7 1

( ) 9 . 8 2

( ) 0 4

5 . 3 3

7 . 5 1

6 . 3

" 7 . 8

( ) 3 . 2

) 1 . 1 (

) 2 . 0 (

( ) 3 . 0

0 . 5

4 . 3

2 . 2

) 8 1 (

) 2 1 (

) 8 (

1 . 9

3 . 6

0 . 4

4 . 2

) 2 3 (

) 2 2 (

) 4 1 (

) 8 (

3 . 2 1

5 . 8

5 . 5

4 . 3

) 3 4 (

) 0 3 (

) 9 1 (

) 2 1 (

6 . 0 2

6 . 3 1

9 . 8

4 . 5

3 7 ( )

) 8 4 (

) 1 3 (

) 9 1 (

4 . 9 2

5 . 0 2

1 . 3 1

9 . 7

) 3 0 1 (

) 2 7 (

) 6 4 (

) 8 2 (

d e e F s a G t o H

n i a M s a G t o H

0 7 +

0 7 +

( ) 1 . 1 2 +

) 1 . 1 2 + (

1 . 4 1 1

1 . 4 1 1

9 . 7 ( )

) 9 . 7 (

2 . 2

4 . 4

) 8 (

) 5 1 (

3 . 4

6 . 8

( ) 5 1

) 0 3 (

3 . 7

7 . 4 1

) 6 2 (

) 2 5 (

1 . 4 1

1 . 8 2

) 0 5 (

) 9 9 (

6 . 9 1

2 . 9 3

( ) 9 6

) 8 3 1 (

5 . 6 3

0 . 3 7

8 2 1 ( )

) 7 5 2 (

3 5

6 0 1

) 7 8 1 (

) 3 7 3 (

r o s s e r p m o C

e g r a h c s i D

6 8 + ( ) 0 3 + 5 . 4 5 1 ) 7 . 0 1 ( 6 . 2 1 ) 4 4 ( 1 . 4 2 ) 5 8 ( 6 . 3 3 ) 8 1 1 ( 6 . 2 6 0 2 2 ( ) 3 . 0 9 ) 8 1 3 (

s n i a r D r e s n e d n o C 6 8 + ) 0 3 + ( 0 . 6 ) 1 2 ( 5 . 4 1 ) 1 5 ( 0 . 4 2 ) 4 8 ( 0 . 0 5 ) 6 7 1 ( 0 . 7 7 ) 1 7 2 ( 0 4 1 ( 3 9 4 ) 0 2 2 ) 4 7 7 (

s n i a M d i u q i L 6 8 + ) 0 3 + ( 3 . 8 2 ) 0 0 1 ( 1 . 3 5 ( ) 7 8 1 8 . 0 9 ) 0 2 3 ( 3 4 1 ) 3 0 5 ( 2 0 2 ) 1 1 7 ( 4 5 4 8 9 5 1 ( ) 7 5 6 ) 3 1 3 2 (

d e e F d i u q i L

h c n a r B

6 8 + 0 3 + ( ) 9 . 4 5 ) 3 9 1 ( 3 0 1 3 6 3 ( ) 6 7 1 ) 0 2 6 ( 7 7 2 ) 5 7 9 ( 2 9 3 ) 0 8 3 1 ( 1 8 8 ) 1 0 1 3 ( 3 7 2 1 1 8 4 4 ( )

d e e f r e v O d i u q i L

) X 4 ( y l p p u S

0 1 + ( ) 2 . 2 1 0 . 9 ) 2 3 ( 0 . 7 1 ( ) 0 6 0 . 9 2 ) 2 0 1 ( 0 . 6 4 ) 2 6 1 ( 0 . 5 6 ) 9 2 2 ( 4 4 1 ( ) 7 0 5 8 0 2 ) 2 3 7 (

E Z S L A H M D H

] M M { H C H

E L G H A E B D L G

W D L F T H E C F F E D C

] v K { v C

* H T G H E L T H E L A V U Q E

] S R E T E M { T E E F

W D L F T H E C F F E D C

] v K { v C

* H T G H E L T H E L A V U Q E

] S R E T E M { T E E F

1

/2 ) 3 1 ( 6 ) 2 . 5 ( 5 ) 5 . 1 ( 4 ) 5 . 3 ( 9 ) 7 . 2 (

3

/4 ) 0 2 ( 9 ) 8 . 7 ( 8 ) 4 . 2 ( 8 ) 9 . 6 ( 8 ) 4 . 2 (

1 ) 5 2 ( 6 2 ) 2 2 ( 5 ) 5 . 1 ( 8 1 ) 6 1 ( 8 ) 4 . 2 (

1

1

/4 ) 2 3 ( 0 3 ) 6 2 ( 4 1 ) 3 . 4 ( 1 2 ) 8 1 ( 1 2 ) 4 . 6 (

1

1

/2 ) 0 4 ( 3 5 ) 6 4 ( 1 1 ) 4 . 3 ( 1 4 ) 5 3 ( 4 1 ) 3 . 4 (

2 ) 0 5 ( 0 8 ) 9 6 ( 7 2 ) 2 . 8 ( 7 6 ) 8 5 ( 4 3 ) 4 . 0 1 (

2

1

/2 ) 5 6 ( 3 7 1 ) 0 5 1 ( 8 1 ) 5 . 5 ( 3 6 1 ) 1 4 1 ( 0 2 ) 1 . 6 (

4

G209h

MAY 2000

INSTALLATION DIMENSIONS INSULATION DIMENSIONS

INCHES (MM) INCHES (MM)

" (13 MM) AND " (20 MM) SOCKET WELD VALVE

E Z I S B

1

/2 ) 3 1 ( ) 2 3 ( 5 2 . 1

3

/4 ) 0 2 ( ) 1 5 ( 0 5 . 1

E Z I S B

1

/2 ) 3 1 ( ) 2 3 ( 5 2 . 1

3

/4 ) 0 2 ( ) 1 5 ( 0 5 . 1

5

G209h

MAY 2000

PARTS LIST

*Pri or t o 1989, " and " socket wel d val ves had cast

st eel bodi es. Repl acement part s and numbers f or t hese

val ves are t he same as t he 1" and 1" val ves l i st ed on

page 7. A pl at ed st eel seal cap i s avai l abl e. To order

speci f y part number 50-1064.

M E T H D T P R C S E D Y T Q * D H T R A P

t i K t e k s a G : f o t s i s n o c 0 4 0 1 - 0 5

1 x x g n i k c a P m e t S 1 5 4 0 0 - 0 5

2 x x r e h s a W m e t S 1 6 4 0 0 - 0 5

3 x x g n i r - O m e t S 1 9 7 1 0 - 0 5

4 x x g n i r - O t e n n o B 1 3 5 4 0 - 0 5

5 x x g n i r - O p a C l a e S 1 2 3 4 0 - 0 5

1 1 x x t u n g n i k c a P 1 3 3 9 0 - 0 5

t i K y l b m e s s A t e n n o B

1 4 0 1 - 0 5

: f o s t s i s n o c t i K e v o b A

6 x x t e n n o B 1 2 2 4 0 - 0 5

7 x x m e t S 1 2 1 0 0 - 0 5

8 x x y l b m e s s A c s i D 1 3 0 8 0 - 0 5

9 x x r e n i a t e R l l a B 1 9 3 4 0 - 0 5

0 1 x x s l l a B 0 1 6 1 0 0 - 0 5

x x t i K t e k s a G 1 0 4 0 1 - 0 5

t i K y l b m e s s A c s i D : f o s t s i s n o c

2 4 0 1 - 0 5

8 x x y l b m e s s A c s i D 1 3 0 8 0 - 0 5

9 x x r e n i a t e R l l a B 1 9 3 4 0 - 0 5

0 1 x x s l l a B 0 1 6 1 0 0 - 0 5

4 x x g n i r - O t e n n o B 1 3 5 4 0 - 0 5

" (13 MM) AND " (20 MM) SOCKET WELD VALVE

ITEM DESCRIPTION QTY PART NO.*

Handwheel Kit consists of: 50-1005

12 Handwheel 1 50-0953

13 Screw 1 50-0479

14 Name Plate 1 50-0094

15 Bonnet Thread Cap 1 50-0434

Seal Cap Kit consists of: 50-1036

16 Seal Cap 1 50-0423

5 Seal Cap O-ring 1 50-0432

17 Body, Globe 1/2" SW 1 50-0449

Body, Globe 3/4" SW 1 50-0451

Body, Angle 1/2" SW 1 50-0450

Body, Angle 3/4" SW 1 50-0452

6

G209h

MAY 2000

INSTALLATION DIMENSIONS INSULATION DIMENSIONS

W=1.00 (25), WEB THICKNESS

INCHES (MM) INCHES (MM)

1" (25 MM) AND 1" (32 MM) SOCKET WELD VALVE

W=1.00 (25), WEB THICKNESS

E Z I S D

) 5 2 ( 1 ) 3 1 ( 0 5 . 0

1

1

/4 ) 2 3 ( ) 6 1 ( 2 6 . 0

E Z I S D

) 5 2 ( 1 ) 3 1 ( 0 5 . 0

1

1

/4 ) 2 3 ( ) 6 1 ( 2 6 . 0

7

G209h

MAY 2000

PARTS LIST

*Pl at ed st eel seal cap ki t s are avai l abl e (p/n 50-1064).

1" (25 MM) AND 1" (32 MM) SOCKET WELD VALVE

M E T H D T P R C S E D Y T Q . D H T R A P

t i K t e k s a G : f o s t s i s n o c 0 4 0 1 - 0 5

1 x x g n i k c a P m e t S 1 5 4 0 0 - 0 5

2 x x r e h s a W m e t S 1 6 4 0 0 - 0 5

3 x x g n i r - O m e t S 1 9 7 1 0 - 0 5

4 x x g n i r - O t e n n o B 1 7 1 0 0 - 0 5

5 x x g n i r - O p a C l a e S 1 2 3 4 0 - 0 5

1 1 x x t u n g n i k c a P 1 3 3 9 0 - 0 5

t i K y l b m e s s A t e n n o B

: f o s t s i s n o c t i k e v o b A

1 2 0 1 - 0 5

6 x x t e n n o B 1 9 2 4 0 - 0 5

7 x x m e t S 1 2 1 0 0 - 0 5

8 x x y l b m e s s A c s i D 1 4 0 8 0 - 0 5

9 x x r e n i a t e R l l a B 1 6 2 0 0 - 0 5

0 1 x x s l l a B 0 1 6 1 0 0 - 0 5

x x t i K t e k s a G 1 0 4 0 1 - 0 5

c t i K y l b m e s s A c s i D : f o s t s i s n o

4 0 0 1 - 0 5

8 x x y l b m e s s A c s i D 1 4 0 8 0 - 0 5

9 x x r e n i a t e R l l a B 1 6 2 0 0 - 0 5

0 1 x x s l l a B 0 1 6 1 0 0 - 0 5

4 x x g n i r - O t e n n o B 1 7 1 0 0 - 0 5

M E T H D T P R C S E D Y T Q . D H T R A P

t i K l e e h w d n a H : f o s t s i s n o c 5 0 0 1 - 0 5

2 1 x x l e e h w d n a H 1 3 5 9 0 - 0 5

3 1 x x w e r c S 1 9 7 4 0 - 0 5

4 1 x x e t a l P e m a N 1 4 9 0 0 - 0 5

5 1 x x p a C d a e r h T t e n n o B 1 4 3 4 0 - 0 5

t i K p a C l a e S : f o s t s i s n o c S S 0 1 - 0 5

6 1 x x p a C l a e S 1 3 2 4 0 - 0 5

5 x x g n i r - O p a C l a e S 1 2 3 4 0 - 0 5

a 7 1 . W . S " 1 e b o l G , y d o B 1 6 8 3 0 - 0 5

b 7 1 1 e b o l G , y d o B " . W . S 1 7 8 3 0 - 0 5

c 7 1 . W . S " 1 e l g n A , y d o B 1 9 8 3 0 - 0 5

d 7 1 1 e l g n A , y d o B " . W . S 1 0 9 3 0 - 0 5

8

G209h

MAY 2000

INSTALLATION DIMENSIONS INSULATION DIMENSIONS

W=1.00 (25), WEB THICKNESS

INCHES (MM) INCHES (MM)

1" (40 MM) AND 2" (50 MM) SOCKET WELD VALVE

W=1.00 (25), WEB THICKNESS

E Z I S D

1

1

/2 ) 0 4 ( ) 6 1 ( 2 6 .

) 0 5 ( 2 ) 2 2 ( 8 8 .

E Z I S D

1

1

/2 ) 0 4 ( ) 6 1 ( 2 6 .

) 0 5 ( 2 ) 2 2 ( 8 8 .

9

G209h

MAY 2000

PARTS LIST

M E T H D T P R C S E D Y T Q . D H T R A P

t i K t e k s a G : f o s t s i s n o c

S 2 0 1 - 0 5

1 x x g n i k c a P m e t S 1 8 4 2 0 - 0 5

2 x x r e h s a W m e t S 1 7 4 2 0 - 0 5

3 x x g n i r - O m e t S 1 3 5 2 0 - 0 5

4 x x r e h s a W p U - k c a B 1 1 5 3 0 - 0 5

5 x x t e k s a G t e n n o B 1 9 5 2 0 - 0 5

6 x x t e k s a G p a C l a e S 1 0 7 2 0 - 0 5

2 1 x x t u n g n i k c a P 1 1 5 2 0 - 0 5

t i K y l b m e s s A t e n n o B

: f o s t s i s n o c t i k e v o b A

4 2 0 1 - 0 5

7 x x t e n n o B 1 9 3 2 0 - 0 5

8 x x m e t S 1 2 4 2 0 - 0 5

9 x x y l b m e s s A c s i D 1 3 6 3 0 - 0 5

0 1 x x r e n i a t e R l l a B 1 7 5 2 0 - 0 5

1 1 x x s l l a B 6 1 6 1 0 0 - 0 5

3 1 x x s t l o B t e n n o B 4 3 7 4 0 - 0 5

x x t i K t e k s a G 1 3 2 0 1 - 0 5

M E T N O T P R C S E D Y T Q . O N T R A P

t i K y l b m e s s A c s i D : f o s t s i s n o c

5 2 0 1 - 0 5

9 x x y l b m e s s A c s i D 1 3 6 3 0 - 0 5

0 1 x x r e n i a t e R l l a B 1 7 5 2 0 - 0 5

1 1 x x s l l a B 6 1 6 1 0 0 - 0 5

5 x x t e k s a G t e n n o B 1 9 5 2 0 - 0 5

t i K l e e h w d n a H : f o s t s i s n o c

6 2 0 1 - 0 5

4 1 x x l e e h w d n a H 1 1 2 3 0 - 0 5

5 1 x x e t a l P e m a N 1 4 9 0 0 - 0 5

6 1 x x w e r c S 1 4 5 2 0 - 0 5

7 1 x x p a C d a e r h T t e n n o B 1 3 6 2 0 - 0 5

t i K p a C l a e S : f o s t s i s n o c 7 2 0 1 - 0 5

8 1 x x p a C l a e S 1 0 6 2 0 - 0 5

6 x x t e k s a G p a C l a e S 1 0 7 2 0 - 0 5

a 9 1 1 e b o l G , y d o B " . W . S 1 2 3 2 0 - 0 5

b 9 1 . W . S " 2 e b o l G , y d o B 1 3 3 2 0 - 0 5

c 9 1 1 e l g n A , y d o B " . W . S 1 8 6 2 0 - 0 5

d 9 1 . W . S " 2 e l g n A , y d o B 1 9 6 2 0 - 0 5

1" (40 MM) AND 2" (50 MM) SOCKET WELD VALVE

10

G209h

MAY 2000

INSTALLATION DIMENSIONS INSULATION DIMENSIONS

W=1.75 (44), WEB THICKNESS

INCHES (MM) INCHES (MM)

2" (65 MM) SOCKET WELD VALVE

W=1.75 (44), WEB THICKNESS

11

G209h

MAY 2000

PARTS LIST

M E T H D T P R C S E D Y T Q . D H T R A P

t i K t e k s a G : f o s t s i s n o c

S 4 0 1 - 0 5

1 x x g n i k c a P m e t S 1 0 9 2 0 - 0 5

2 x x r e h s a W m e t S 1 9 9 2 0 - 0 5

3 x x g n i r - O m e t S 1 3 9 2 0 - 0 5

4 x x r e h s a W p U - k c a B 1 4 2 3 0 - 0 5

5 x x t e k s a G t e n n o B 1 0 1 3 0 - 0 5

6 x x t e k s a G p a C l a e S 1 5 1 3 0 - 0 5

2 1 x x t u n g n i k c a P 1 2 9 2 0 - 0 5

t i K y l b m e s s A t e n n o B

: f o s t s i s n o c t i k e v o b A

4 4 0 1 - 0 5

7 x x t e n n o B 1 6 8 2 0 - 0 5

8 x x m e t S 1 7 8 2 0 - 0 5

9 x x y l b m e s s A c s i D 1 4 7 3 0 - 0 5

0 1 x x r e n i a t e R l l a B 1 7 9 2 0 - 0 5

1 1 x x s l l a B 5 1 5 0 3 0 - 0 5

3 1 x x s t l o B t e n n o B 4 4 9 2 0 - 0 5

x x t i K t e k s a G 1 3 4 0 1 - 0 5

M E T N O T P R C S E D Y T Q . O N T R A P

t i K y l b m e s s A c s i D : f o s t s i s n o c 5 4 0 1 - 0 5

9 x x y l b m e s s A c s i D 1 4 7 3 0 - 0 5

0 1 x x r e n i a t e R l l a B 1 7 9 2 0 - 0 5

1 1 x x s l l a B 5 1 5 0 3 0 - 0 5

5 x x t e k s a G t e n n o B 1 0 1 3 0 - 0 5

t i K l e e h w d n a H : f o s t s i s n o c 7 S 0 1 - 0 5

4 1 x x l e e h w d n a H 1 9 1 3 0 - 0 5

5 1 x x e t a l P e m a N 1 8 1 3 0 - 0 5

6 1 x x w e r c S 1 5 9 2 0 - 0 5

7 1 x x r e h s a W t r o p p u S 1 0 8 4 0 - 0 5

t i K p a C l a e S : f o s t s i s n o c 8 S 0 1 - 0 5

8 1 x x p a C l a e S 1 4 0 3 0 - 0 5

6 x x t e k s a G p a C l a e S 1 5 1 3 0 - 0 5

a 9 1 2 e b o l G , y d o B " . W . S 1 6 5 4 0 - 0 5

b 9 1 2 e l g n A , y d o B " . W . S 1 7 5 4 0 - 0 5

2" (65 MM) SOCKET WELD VALVE

12

G209h

MAY 2000

L A H M D H

E Z S

H D T P R C S E D . D H . T A C

"

) m m 3 1 (

X X l e e h w d n a H , e b o l G H 1 5 0 S G

X X l e e h w d n a H , e l g n A H 1 5 0 S A

X X p a C l a e S , e b o l G C 1 5 0 S G

X X p a C l a e S , e l g n A C 1 5 0 S A

!

""

) m m 0 2 (

X X l e e h w d n a H , e b o l G H 6 7 0 S G

X X l e e h w d n a H , e l g n A H 6 7 0 S A

X X p a C l a e S , e b o l G C 6 7 0 S G

X X p a C l a e S , e l g n A C 6 7 0 S A

" 1

) m m 5 2 (

X X l e e h w d n a H , e b o l G H 0 0 1 S G

X X l e e h w d n a H , e l g n A H 0 0 1 S A

X X p a C l a e S , e b o l G C 0 0 1 S G

X X p a C l a e S , e l g n A C 0 0 1 S A

1

""

) m m 2 3 (

X X l e e h w d n a H , e b o l G H 5 2 1 S G

X X l e e h w d n a H , e l g n A H 5 2 1 S A

X X p a C l a e S , e b o l G C 5 2 1 S G

X X p a C l a e S , e l g n A C 5 2 1 S A

1

"

) m m 0 4 (

X X l e e h w d n a H , e b o l G H 0 5 1 S G

X X l e e h w d n a H , e l g n A H 0 5 1 S A

X X p a C l a e S , e b o l G C 0 5 1 S G

X X p a C l a e S , e l g n A C 0 5 1 S A

" 2

) m m 0 5 (

X X l e e h w d n a H , e b o l G H 0 0 2 S G

X X l e e h w d n a H , e l g n A H 0 0 2 S A

X X p a C l a e S , e b o l G C 0 0 2 S G

X X p a C l a e S , e l g n A C 0 0 2 S A

2

"

) m m 5 6 (

X X l e e h w d n a H , e b o l G H 1 5 2 S G

X X l e e h w d n a H , e l g n A H 1 5 2 S A

X X p a C l a e S , e b o l G C 1 5 2 S G

X X p a C l a e S , e l g n A C 1 5 2 S A

Al l of t he above val ves are al so avai l abl e as expansi on

val ves except t he 2" .

ORDERING INFORMATION,

SOCKET WELD SHUT-OFF VALVES

WARRANTY

Hansen val ves are guarant eed agai nst def ect i ve

mat eri al s and workmanshi p f or one year F.O.B. our

pl ant . No consequent i al damages or f i el d l abor i s

i ncl uded.

STEM PACKING

When veri fyi ng the ti ghtness of the packi ng nut, use an

8" adj ustabl e wrench. Extrusi on of some bl ack graphi te

packi ng materi al al ong the stem i s normal . If the o-ri ng

or the adj ustabl e packi ng ever needs repl acement as

evi denced by refri gerant or oi l l eakage at the stem,

open the val ve stem fi rml y to the back-seat posi ti on.

Thi s separates the o-ri ng and packi ng from the system

refri gerant. See the CAUTION secti on. Remove the

packi ng nut careful l y and then use a wi re hook or a

smal l bl ade screwdri ver to remove the packi ng and

o-ri ng. Take care not to scratch the stem or bonnet

seal i ng surfaces. Careful l y i nstal l a backup washer,

new l ubri cated stem o-ri ng, stem washer, and stem

packi ng. Ti ghten the packi ng nut onl y enough to gi ve

the handwheel sl i ght turni ng fri cti on.

CAUTION

Hansen val ves are f or ref ri gerat i on syst ems onl y.

Read t hese i nst ruct i ons compl et el y bef ore sel ect i ng,

usi ng, or servi ci ng these val ves. Onl y knowl edgeabl e,

t r ai ned r ef r i ger at i on t echni ci ans shoul d i nst al l ,

operat e, or servi ce t hese val ves. St at ed t emperat ure

and pressure l i mi ts shoul d never be exceeded. Bonnets

shoul d not be removed f rom t he val ves unl ess t he

syst em has been evacuat ed t o zero pressure. See

al so Saf et y Precaut i ons i n t he current Li st Pri ce

Bul l et i n and t he Saf et y Precaut i ons Sheet suppl i ed

wi t h t he product . Escapi ng ref ri gerant may cause

i nj ury, part i cul arl y t o t he eyes and l ungs.

TYPICAL SPECIFICATIONS

Refri gerant shut-off val ves from " (13 mm) through

2" (65 mm) si zes shal l have st eel bodi es machi ned

f or socket wel d connect i ons, st ai nl ess st eel st ems,

back-seati ng desi gn for packi ng repl acement, bonnet

t hreads f or i nst al l at i on of st em seal caps, and

sui t abi l i t y f or a saf e worki ng pressure of 400 psi g

(27 bar), as manuf act ured by Hansen Technol ogi es

Corporat i on or approved equal .

VALVE SEAT

To i nspect or repl ace the val ve seat di sc, i sol ate the

valve from the system and safely pump out all refrigerant

to zero pressure. Wi th the stem open several t urns,

careful l y remove the bonnet assembl y. Proceed sl owl y

and cautiously since some refrigerant may still be inside

the val ve body. The " (13 mm) through 1" (32 mm)

val ves have a uni que safety vent to warn of i nternal

pressure when removi ng the threaded bonnet. The 1"

(40 mm) and l arger val ves have bol ted bonnets. Evenl y

l oosen al l bol ts one to two turns. Usi ng a screwdri ver,

break t he seal bet ween t he bonnet and val ve body,

proceedi ng caut i ousl y t o avoi d any ref ri gerant whi ch

may st i l l remai n i nsi de t he val ve body. Remove t he

bonnet bol t s and bonnet assembl y, bei ng caref ul not

t o damage t he Tef l on seat di sc surf ace.

If the conical seat surface in the body is marred, remove

the marks wi th emery paper by hand or wi th a power

dri l l . If the seat di sc i s damaged, repl ace the enti re

di sc assembl y by fi rst removi ng the bal l retai ner ri ng

and ball bearings. Install a new disc assembly, including

new beari ngs and retai ner ri ng. Pri or to 1998, seat

di scs i n " (13 mm) to 1" (32 mm) socket wel d shut-

off val ves were made wi th l ead. Al l seat di scs are now

made wi th Tefl on. The new seat di sc assembl i es and

replacement kits are interchangeable with the old. Install

new stem packi ng, stem o-ri ng, stem washers, and

bonnet o-ri ng or gasket, i f necessary. Reassembl e the

bonnet i nto the val ve body wi th the stem sti l l open

several turns. Tighten the threaded bonnet to a minimum

torque of 75 ft-l bs (100 Nm). Bonnet bol ts for the 1"

(40 mm) and 2" (50 mm) val ves requi re a torque of 40

ft-l bs (55 Nm), and 2" (65 mm) val ves requi re 60 ft-l bs

(80 Nm).

6827 Hi gh Grove Boul evard

Burr Ri dge, Il l i noi s 60527 USA

Tel : (630) 325-1565 Fax: (630) 325-1572

Tol l : (800) 426-7368 ht t p: //www.hant ech.com

2004 Hansen Technol ogi es Corporat i on

S-ar putea să vă placă și

- TC1045Document6 paginiTC1045Boris ZaslichkoÎncă nu există evaluări

- BFL Chanju - 13846 SPV o & M Manual PDFDocument64 paginiBFL Chanju - 13846 SPV o & M Manual PDFजितेन्द्र कुमार शर्माÎncă nu există evaluări

- Lesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-ObjectiveDocument8 paginiLesson Diaphragm Valves, Pinch Valves and Instrument Valves: Sub-Objectivemister pogiÎncă nu există evaluări

- Mankenberg Float ValvesDocument28 paginiMankenberg Float ValvescartarÎncă nu există evaluări

- HansenDocument4 paginiHansenBruna MacedoÎncă nu există evaluări

- STASTO RT Series enDocument10 paginiSTASTO RT Series envinston.s1949Încă nu există evaluări

- Valve Maintenance1Document11 paginiValve Maintenance1mister pogiÎncă nu există evaluări

- Crane Engineering Data 1Document56 paginiCrane Engineering Data 1jerry666aÎncă nu există evaluări

- G209 IDocument8 paginiG209 IJaider CamachoÎncă nu există evaluări

- Lesson Plug, Ball and Butterfly Valves: Sub-ObjectiveDocument13 paginiLesson Plug, Ball and Butterfly Valves: Sub-Objectivemister pogiÎncă nu există evaluări

- Installation, Operation and Maintenance Manual For AIL Cast Steel Gate, Globe and Gheck ValvesDocument17 paginiInstallation, Operation and Maintenance Manual For AIL Cast Steel Gate, Globe and Gheck ValvesKarthigeyan R Rkg100% (1)

- TC0869 PDFDocument6 paginiTC0869 PDFBoris ZaslichkoÎncă nu există evaluări

- Proc - Ess System:S & Equipment: Tanks by LeeDocument6 paginiProc - Ess System:S & Equipment: Tanks by LeeNisadiyah Faridatus ShahihÎncă nu există evaluări

- Holophane Outdoor Substation Series Brochure 8-79Document2 paginiHolophane Outdoor Substation Series Brochure 8-79Alan MastersÎncă nu există evaluări

- D 500203 X 012Document20 paginiD 500203 X 012Aarthi PadmanabhanÎncă nu există evaluări

- Valvula de Solenoide HS6 BulletinDocument4 paginiValvula de Solenoide HS6 BulletinJoséMarcanoÎncă nu există evaluări

- FisherDocument20 paginiFishermanmohansingh1999Încă nu există evaluări

- Control Valves Sizing & SelectionDocument76 paginiControl Valves Sizing & SelectionABVSAI100% (6)

- Manual Zetkama Fig.215 - 216Document8 paginiManual Zetkama Fig.215 - 216George_Wabag_2014Încă nu există evaluări

- Valves: Section 7Document11 paginiValves: Section 7Emad SaadÎncă nu există evaluări

- CV 1144 Us MNSD U CopesDocument8 paginiCV 1144 Us MNSD U CopesphaindikaÎncă nu există evaluări

- Walworth Check ValvesDocument24 paginiWalworth Check ValvesFahad RockingÎncă nu există evaluări

- Metal Seated Sampling ValvesDocument4 paginiMetal Seated Sampling ValvesGiovanni TrinidadÎncă nu există evaluări

- TDS Gate Valve Range OverviewDocument32 paginiTDS Gate Valve Range Overviewسمير البسيونىÎncă nu există evaluări

- Pipeline Prover SpheresDocument2 paginiPipeline Prover SpheresandraÎncă nu există evaluări

- Valves Gate DamperDocument54 paginiValves Gate DamperLalit MeenaÎncă nu există evaluări

- Oil Well ConstructionDocument35 paginiOil Well ConstructionMustafa AlrikabiÎncă nu există evaluări

- 2500 Valve BrochureDocument12 pagini2500 Valve BrochureJurie_sk3608Încă nu există evaluări

- Zurn Aquaflush z6000 ManualDocument8 paginiZurn Aquaflush z6000 ManualrosaearlÎncă nu există evaluări

- X-Tree & WellheadDocument35 paginiX-Tree & WellheadSaqib ShahabÎncă nu există evaluări

- 4 Guidance On Valve Type SelectionDocument86 pagini4 Guidance On Valve Type SelectionKrista OneillÎncă nu există evaluări

- ValvesDocument82 paginiValvespuru55980Încă nu există evaluări

- 2, 5 Inch Side Door Stripper PDFDocument16 pagini2, 5 Inch Side Door Stripper PDFOvRrj AhmedÎncă nu există evaluări

- Cable HoistDocument4 paginiCable HoistUrip S. SetyadjiÎncă nu există evaluări

- Design Application HairpinDocument23 paginiDesign Application Hairpinkinjalpatel12345Încă nu există evaluări

- Normally Closed Solenoid Valves PDFDocument55 paginiNormally Closed Solenoid Valves PDFrahulÎncă nu există evaluări

- Alkon Valves CatalogDocument88 paginiAlkon Valves CatalogZoran JankovÎncă nu există evaluări

- Pneumatic Setcell DatasheetDocument2 paginiPneumatic Setcell DatasheetAlex20202Încă nu există evaluări

- ValvesDocument44 paginiValvesأحمد محمد قدريÎncă nu există evaluări

- IOM Manual For Air Cylinder Operated ValvesDocument21 paginiIOM Manual For Air Cylinder Operated Valvesjhon riosÎncă nu există evaluări

- Needles Restrictor Hk66k102Document16 paginiNeedles Restrictor Hk66k102seaqu3stÎncă nu există evaluări

- Valve & Type of ValesDocument82 paginiValve & Type of Valesvipinct83% (6)

- Series 600: Globe Style Sizes 3 Through 42 InchesDocument8 paginiSeries 600: Globe Style Sizes 3 Through 42 Inchesrizviabbas2012Încă nu există evaluări

- 873 400 Regulator Operation and Maintenance ManualDocument2 pagini873 400 Regulator Operation and Maintenance ManualHassan KhattabÎncă nu există evaluări

- CV1Document47 paginiCV1Sridhar GudapatiÎncă nu există evaluări

- Trade Theory 2 Electronics MechanicDocument439 paginiTrade Theory 2 Electronics MechanicChittaranjan SethiÎncă nu există evaluări

- 10 ValvesDocument23 pagini10 ValvesPower PlantÎncă nu există evaluări

- Installation, Maintenance and Operating Instructions Cast Iron, Malleable Iron and Bronze Globe ValvesDocument4 paginiInstallation, Maintenance and Operating Instructions Cast Iron, Malleable Iron and Bronze Globe ValvesmahmadwasiÎncă nu există evaluări

- Versacount ManualDocument33 paginiVersacount Manualluis_iq18006100% (1)

- Id 07945 - Power Wirewound ResistorsDocument0 paginiId 07945 - Power Wirewound ResistorsSURJIT SINGHÎncă nu există evaluări

- ERHARD Needle Valve BrochureDocument20 paginiERHARD Needle Valve BrochurephanishankarÎncă nu există evaluări

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDe la EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- The Weir Direct-Acting Feed Pump - Working InstructionsDe la EverandThe Weir Direct-Acting Feed Pump - Working InstructionsÎncă nu există evaluări

- Prevention of Actuator Emissions in the Oil and Gas IndustryDe la EverandPrevention of Actuator Emissions in the Oil and Gas IndustryÎncă nu există evaluări

- Pocket Guide to Flanges, Fittings, and Piping DataDe la EverandPocket Guide to Flanges, Fittings, and Piping DataEvaluare: 3.5 din 5 stele3.5/5 (22)

- Geotextiles and Geomembranes HandbookDe la EverandGeotextiles and Geomembranes HandbookT.S. IngoldEvaluare: 5 din 5 stele5/5 (1)

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingDe la EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingÎncă nu există evaluări

- Simple Plumbing Repairs for the Home and FarmsteadDe la EverandSimple Plumbing Repairs for the Home and FarmsteadÎncă nu există evaluări

- Final Report - Solar Cold StorageDocument75 paginiFinal Report - Solar Cold StorageAKSHEYMEHTAÎncă nu există evaluări

- Project Standards and Specifications Flare and Blowdown Systems Rev01Document12 paginiProject Standards and Specifications Flare and Blowdown Systems Rev01Venkat Rangan100% (1)

- Tech Note - Gas PhaseDocument1 paginăTech Note - Gas PhaseЗоран ХајдуковићÎncă nu există evaluări

- Selection of Material Nace - H2S - Technical Paper PDFDocument21 paginiSelection of Material Nace - H2S - Technical Paper PDFajaysharma_1009Încă nu există evaluări

- Dean PumpDocument50 paginiDean PumpAKSHEYMEHTAÎncă nu există evaluări

- Fisher 67cfr Description Part NumbersDocument1 paginăFisher 67cfr Description Part NumbersAKSHEYMEHTAÎncă nu există evaluări

- An 01 013 Ctrls & Process ValvingDocument2 paginiAn 01 013 Ctrls & Process ValvingAKSHEYMEHTAÎncă nu există evaluări

- Q A - Firetube Boiler Design Construction and Engineering Outline and Summary - July 29, 2015Document10 paginiQ A - Firetube Boiler Design Construction and Engineering Outline and Summary - July 29, 2015AKSHEYMEHTAÎncă nu există evaluări

- Fire Prevention Chemical Processing MagDocument3 paginiFire Prevention Chemical Processing MagLeeLee LeeÎncă nu există evaluări

- 2010 Amine Training SessionDocument81 pagini2010 Amine Training SessionAKSHEYMEHTA100% (4)

- Depressuring Do N DonsDocument3 paginiDepressuring Do N DonsAKSHEYMEHTAÎncă nu există evaluări

- Insulation SpecificationDocument18 paginiInsulation SpecificationAKSHEYMEHTAÎncă nu există evaluări

- Glycol Dehydrator Design Manual - 1976Document36 paginiGlycol Dehydrator Design Manual - 1976lutfi awn100% (3)

- Gas-Liquid Separators SizingrDocument3 paginiGas-Liquid Separators SizingrAKSHEYMEHTAÎncă nu există evaluări

- Strainer GuideDocument26 paginiStrainer Guidemudrijasm100% (1)

- Fisher Flashing and OutgassingDocument4 paginiFisher Flashing and OutgassingAKSHEYMEHTAÎncă nu există evaluări

- Material Stream: 1: ConditionsDocument6 paginiMaterial Stream: 1: ConditionsAKSHEYMEHTAÎncă nu există evaluări

- Is 6669 2001Document15 paginiIs 6669 2001AKSHEYMEHTAÎncă nu există evaluări

- FinFan Technical InfoDocument25 paginiFinFan Technical InfoAKSHEYMEHTAÎncă nu există evaluări

- 02 Laboratories - Fume Hood Exhaust GuidelinesDocument5 pagini02 Laboratories - Fume Hood Exhaust GuidelinesAKSHEYMEHTAÎncă nu există evaluări

- Mac Weld ThreadedDocument1 paginăMac Weld ThreadedAKSHEYMEHTAÎncă nu există evaluări

- Mac Weld ThreadedDocument1 paginăMac Weld ThreadedAKSHEYMEHTAÎncă nu există evaluări

- Design of Lifting and Tailing LugsNetsc001Document30 paginiDesign of Lifting and Tailing LugsNetsc001AKSHEYMEHTAÎncă nu există evaluări

- Steel BookDocument472 paginiSteel BookAKSHEYMEHTAÎncă nu există evaluări

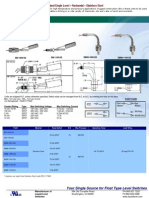

- Your Single Source For Float Type Level Switches: SM-1000-SS SM-1100-SS SM90-1000-SS SM90-1100-SSDocument1 paginăYour Single Source For Float Type Level Switches: SM-1000-SS SM-1100-SS SM90-1000-SS SM90-1100-SSAKSHEYMEHTAÎncă nu există evaluări

- Strainer GuideDocument26 paginiStrainer Guidemudrijasm100% (1)

- Steel BookDocument477 paginiSteel BookAKSHEYMEHTAÎncă nu există evaluări

- Su3321e Rev 1 (As Built)Document14 paginiSu3321e Rev 1 (As Built)AKSHEYMEHTAÎncă nu există evaluări

- Basic Calculations Piping System Design PDFDocument14 paginiBasic Calculations Piping System Design PDFjeff_shawÎncă nu există evaluări

- 01-1 V-Series Installation InstructionsDocument18 pagini01-1 V-Series Installation InstructionsAKSHEYMEHTAÎncă nu există evaluări

- D 000 Rev0Document14 paginiD 000 Rev0wlater06Încă nu există evaluări

- Transmission Angle: ME 310 (Mechanics of Machines)Document5 paginiTransmission Angle: ME 310 (Mechanics of Machines)omarÎncă nu există evaluări

- Case CX210C Tier 4Document2.298 paginiCase CX210C Tier 4Shawn StevensÎncă nu există evaluări

- PLTW AR IntroToMechanismsPowerPointDocument39 paginiPLTW AR IntroToMechanismsPowerPointAbdulsalam OmotoshoÎncă nu există evaluări

- Símbolos HidráulicosDocument21 paginiSímbolos HidráulicosAlvaro MendizabalÎncă nu există evaluări

- Diagrama Elétrico 777f Jrpuenr1744uenr1744 - SisDocument4 paginiDiagrama Elétrico 777f Jrpuenr1744uenr1744 - SisfernandoÎncă nu există evaluări

- Runner 180 FXR 2TDocument86 paginiRunner 180 FXR 2TJorge Vale PuesÎncă nu există evaluări

- 1100 Series: 1104C-44TAG2Document5 pagini1100 Series: 1104C-44TAG2ahmed hargaÎncă nu există evaluări

- Determination of A Machine's TIER LevelDocument8 paginiDetermination of A Machine's TIER LevelMahmmod Al-QawasmehÎncă nu există evaluări

- CJ TN - : Deluge Valve, External ResettingDocument16 paginiCJ TN - : Deluge Valve, External ResettingLeinner RamirezÎncă nu există evaluări

- 101101002Document6 pagini101101002Ahmed shawkyÎncă nu există evaluări

- New List of Equipments of Public Health LabDocument3 paginiNew List of Equipments of Public Health LabYasir Ali DharejoÎncă nu există evaluări

- 30 - Methods of Taper TurningDocument4 pagini30 - Methods of Taper Turningbhagirath360100% (2)

- Husqvarna LT 100Document20 paginiHusqvarna LT 100Vytautas Abromaitis100% (2)

- Realignment of ShipDocument23 paginiRealignment of ShipAlfredo Ortiz BocanegraÎncă nu există evaluări

- Product Catalogue: BeckerDocument26 paginiProduct Catalogue: BeckerLitraYudaPrahaÎncă nu există evaluări

- IPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ADocument3 paginiIPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ANikhil KarkeraÎncă nu există evaluări

- Brushless DC MotorsDocument132 paginiBrushless DC Motorsbedreddi100% (4)

- Working Principle of Hydraulic LiftDocument3 paginiWorking Principle of Hydraulic LiftNoaman Mehmood0% (1)

- Testing and Commissioning of Starter Panels Variable Frequency Drives VFDsDocument3 paginiTesting and Commissioning of Starter Panels Variable Frequency Drives VFDsHumaid ShaikhÎncă nu există evaluări

- 9-15ton WebDocument44 pagini9-15ton WebRoderick GuerraÎncă nu există evaluări

- Product Data: 16LJ Single-Effect, Low Temperature Hot Water Hermetic Absorption Liquid ChillerDocument32 paginiProduct Data: 16LJ Single-Effect, Low Temperature Hot Water Hermetic Absorption Liquid ChillersulphurdioxideÎncă nu există evaluări

- Lovejoy / Sier-Bath: "FSL" Slide Type Coupling Size FSL 2 Thru FSL 7Document3 paginiLovejoy / Sier-Bath: "FSL" Slide Type Coupling Size FSL 2 Thru FSL 7josueÎncă nu există evaluări

- Stackup ExcelDocument4 paginiStackup Excelytt5wrc9qqÎncă nu există evaluări

- Maxxforce 7Document2 paginiMaxxforce 7FERNANDO FERRUSCA86% (14)

- 4000 Cyl BlockDocument14 pagini4000 Cyl BlockAHMED MAHMOUDÎncă nu există evaluări

- NC8 Series AC Contactor06 - 500A SampleDocument35 paginiNC8 Series AC Contactor06 - 500A SamplesrushtiÎncă nu există evaluări

- Housing (Front) - Remove: Disassembly and AssemblyDocument4 paginiHousing (Front) - Remove: Disassembly and AssemblyMbahdiro KolenxÎncă nu există evaluări

- Parts Catalog PDS185S 6A1Document48 paginiParts Catalog PDS185S 6A1Khowchae Kunapat0% (1)

- Tabel Pemilihan Bahan Dan ProsesDocument2 paginiTabel Pemilihan Bahan Dan Prosesrahmid fareziÎncă nu există evaluări