Documente Academic

Documente Profesional

Documente Cultură

Nanocomposite

Încărcat de

Isna NurhidayatiTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Nanocomposite

Încărcat de

Isna NurhidayatiDrepturi de autor:

Formate disponibile

Chemical

Engineering

Journal

181182 (2012) 4555

Contents

lists

available

at

ScienceDirect

Chemical Engineering Journal

journal

homepage:

www.elsevier.com/locate/cej

Nanocomposite

TiO2SiO2

gel

for

UV

absorption

Angkhana

Jaroenworaluck

a,*,

Nuchanaporn

Pijarn

a,

Nudthakarn

Kosachan

a,

Ron

Stevensb

a

National

Metal

and

Materials

Technology

Center,

114

Thailand

Science

Park,

Paholyothin

Rd.,

Klong

1,

Klong

Luang,

Pathumthani

12120,

Thailand

b

Mechanical

Engineering

Department,

University

of

Bath,

BA2

7AY

Bath,

UK

article

info

abstract

Article

history:

Received

5

April

2011

Received

in

revised

form

8

August

2011

Accepted

9

August

2011

Keywords:

TiO2SiO2

gel

TiO2fumed

SiO2

Mesoporous

SiO2

gel

UV

absorption

Energy

band

gap

Rice

husk

Nano-sized

particle

TiO2-doped

SiO2

gels

have

been

synthesized

for

use

as

composites

in

which

the

UV

absorption

efficiency,

the

major

factor

for

UV

protection,

can

be

enhanced.

SiO2

gels

having

a

mesoporous

morphology

have

been

synthesized

via

a

solgel

processing

route

using

rice

husk

as

the

starting

material

and

further

treated

using

additions

of

TiO2

from

two

sources.

The

chemical

purity

of

the

SiO2

was

measured

by

X-ray

fluorescence

analysis

(XRF).

Typical

samples

of

pure

TiO2,

SiO2

and

their

composites

were

tested

for

surface

characteristics

using

N2-sorption

(BET

surface

area).

All

the

different

compositions

processed

have

been

characterized

by

X-ray

diffraction

(XRD),

Fourier

Transform

Infrared

Spectroscopy

(FT-IR),

and

imaged

using

Scanning

and

Transmission

Electron

Microscopy

(SEM,

TEM).

The

UV

absorption

values

which

determine

the

degree

of

UV-protection,

were

measured

and

the

results

discussed.

The

concentration

of

TiO2

loading,

the

particle

size,

and

the

surface

characteristics

are

shown

to

relate

to

the

degree

of

UV

absorption

and

the

measured

energy

band

gap

of

the

composites.

2011 Elsevier B.V. All rights reserved.

1.

Introduction

Rice

husk

(RH)

has

been

long

recognized

as

one

of

the

prime

natural

sources

for

silicon

(Si).

Many

studies

describe

how

to

recycle

RH

to

produce

useful

ceramic

materials

such

as

silica

(SiO2),

silicon

carbide

(SiC),

silicon

nitride

(Si3N4),

zeolites

(alumino-silicate),

etc.

[1].

However,

when

sophisticated

technology

methods

are

used,

the

economics

of

such

processing

needs

to

be

considered

when

the

product

is

intended

for

practical

uses

in

various

industries.

Among

these

reformed

materials,

SiO2

is

considered

to

be

a

viable

material

because

of

its

cheaper

and

easier

processing.

Previous

studies

have

revealed

not

only

amorphous

SiO2

particles

having

a

size

in

the

nanoscale

range,

but

also

the

typical

characteristics

of

the

particles,

specifically

that

a

high

surface

area,

could

be

generated

by

the

final

process

of

heat

treatment

[24].

These

characteristics

are

considered

to

be

useful

for

further

processing

in

that

intimate

mixing

with

other

oxides

is

possible,

generating

higher

value

end-products

for

more

effective

applications.

Titania

(TiO2),

because

of

its

attractive

properties,

has

found

wide

ranging

applications;

it

is

non-toxic,

inexpensive,

has

good

stability,

demonstrates

superior

photocatalytic

property,

etc.

[5].

In

practice

it

can

be

used

for

anti-bacterial

applications,

water

and

air

purification,

self-cleaning

surfaces,

UV-screening

of

agriculture

films,

as

an

opacifying

agent

in

paint,

and

for

UV-absorption

in

the

form

of

sunscreen

cosmetic

products.

*

Corresponding

author.

Tel.:

+66

2

564

6500;

fax:

+66

2

564

6447.

E-mail

address:

angkhanj@mtec.or.th

(A.

Jaroenworaluck).

Modification

of

the

TiO2

involving

doping

or

coating

with

various

metal

oxides

to

enhance

properties

has

been

carried

out

in

order

to:

(i)

increase

its

efficiency,

(ii)

extend

usage

range

from

the

UV

to

the

visible

light

region,

(iii)

reduce

the

energy

band

gap

for

energy

conversion

applications,

(iv)

retard

or

accelerate

phase

transformation,

and

finally,

(v)

modify

its

surface

characteristics.

For

UV

protection,

TiO2,

as

a

fine

powder

has

been

mixed

with

organic

oils

or

suspended

in

water

in

sunscreen

cosmetics,

and

large

quantities

are

used

in

household

paints

to

enhance

brightness,

whiteness

and

preserve

stability

in

sunlight.

TiO2,

has

been

preferred

to

ZnO,

for

addition

to

sunscreens

because

it

can

absorb

a

broad-spectrum

of

both

the

UVB

(290320

nm)

and

UVA

(320400

nm,

UVA1:

320340

nm,

UVA2:

340400

nm),

whereas

ZnO

can

absorb

well

only

in

a

wide

range

of

UVA

[6].

However,

in

UV

protective

sunscreen

products,

the

absorption

characteristics

need

to

be

optimized

usually

by

employing

a

combination

of

organic

and

inorganic

UV

absorbers

to

provide

a

board-spectrum

formula

for

the

range

of

natural

UV

[69].

The

maximum

amount

of

TiO2

that

can

be

added

is

restricted

since

high

levels

of

TiO2

can

cause

irritation

of

the

skin,

it

becomes

difficult

to

remove

and

the

viscosity

becomes

excessive.

During

exposure

to

light,

the

visible

light

is

scattered,

providing

opacity

while

the

UV

components

are

absorbed

by

the

TiO2

crystal.

Here,

rutile

is

preferred

to

anatase

[5]

since

the

UV

is

absorbed

more

efficiently

and

it

is

the

more

stable

phase.

The

latest

cosmetics

use

nanosized-TiO2

in

place

of

1385-8947/$

see

front

matter

2011 Elsevier B.V. All rights reserved.

doi:10.1016/j.cej.2011.08.028

A.

Jaroenworaluck

et

al.

/

Chemical

Engineering

Journal

181182 (2012) 4555

Fig.

1.

N2

adsorptiondesorption

isotherms

of

samples:

(a)

the

synthesized

SiO2

gel

and

the

fumed

SiO2,

(b)

TiO2

(TIP)

and

TiO2

(P25),

(c)

TiO2

(TIP)SiO2

(gel)

and

(d)

TiO2

(P25)SiO2

(gel).

micron-sized

particles

in

the

sunscreen

formulations

together

with

various

other

metal

oxides

additives

such

as

CeO2,

Fe2O3,

Al2O3,

ZrO2

and

SiO2,

to

optimize

the

combined

properties

of

reflection,

absorption

and

transparency.

In

this

study,

TiO2-doped

SiO2

gels

in

the

form

of

nanocomposite

particles

have

been

prepared.

TiO2

was

doped

into

the

SiO2

gel

particles

with

the

intention

that

nanosized

TiO2

particles

would

coat

or

deposit

on

the

gel

particle

surfaces.

This

typical

microstructure

would

be

expected

to

relate

to

enhancement

of

UV

absorption.

The

SiO2

gel

used

has

been

synthesized

via

a

solgel

route

using

rice

husks

as

the

starting

material

selecting

a

process

route

designed

to

give

a

mesoporous

structure,

unlike

previous

studies

of

TiO2SiO2

or

SiO2TiO2

nanocomposites

where

commercial

chemicals

were

used

[1020].

The

energy

band

gaps

of

TiO2-doped

SiO2

gel

for

various

TiO2

loadings

in

the

SiO2

gel

has

been

measured,

and

the

use

of

different

TiO2

sources

is

reported.

UV

absorption

properties

of

the

synthesized

nanocomposites,

intended

for

use

as

the

active

ingredient

for

sunscreen,

have

been

determined.

The

experimental

results

are

discussed

in

terms

of

the

phases

present,

the

energy

band

gaps

and

the

microstructural

changes.

2.

Experimental

2.1.

Materials

Rice

husk

without

any

prior

chemical

treatment

or

washing

process

was

used

as

the

starting

source

of

the

SiO2.

The

reflux

solvent

was

sodium

hydroxide,

with

the

pH

adjusted

by

addition

of

sulfuric

acid.

Titanium

(IV)

isopropoxide

(TIP)

and

TiO2

powder

(AEROXIDE TiO2

P25,

Degussa,

Germany)

were

used

as

the

source

of

TiO2.

The

TiO2

(TIP)

was

dissolved

in

isopropyl

alcohol

whereas

ethyl

alcohol

was

used

to

dissolve

the

commercial

TiO2

(P25)

powder.

Fumed

silica

(SiO2),

AEROSIL 200,

Degussa,

Germany,

was

used

for

comparison

with

the

laboratory

produced

SiO2

gel.

2.2.

Preparation

of

SiO2

gel

The

rice

husk

was

calcined

at

650

.C

for

6

h.

A

mixture

of

rice

husk

ash

(10

g)

and

1

M

NaOH

(320

mL)

was

heated

under

a

reflux

for

5

h.

The

reaction

mixture

was

then

filtered

using

No.

5

Whatman

filter

paper,

and

the

carbon

residue

washed

with

400

mL

of

heated

DI

water,

and

then

cooled

to

room

temperature.

The

solution

was

titrated

with

1

M

H2SO4

to

pH

7.

The

solgel

aged

for

18

h

was

gently

fragmented

and

centrifuged

for

5

min

at

6000

rpm.

To

wash

out

the

impurities,

distilled

water

(400

mL)

was

added,

gently

swirled

and

the

suspension

again

centrifuged.

The

washing

process

was

repeated

6

times

to

clean

the

gel,

which

was

then

spread

on

a

glass

dish

and

dried

in

a

vacuum

oven

at

80

.C

for

24

h.

The

dried

gel

was

dry-milled

using

ZrO2

ball

media

in

a

HDPE

plastic

container

2.3.

Preparation

of

TiO2-doped

SiO2

gels

SiO2

gel

powder

prepared

as

described

in

Section

2.2

was

added

to

titanium

(IV)

isopropoxide

(TIP)

and

dissolved

in

isopropyl

alcohol

under

constant

stirring

at

room

temperature.

Water

was

then

added

to

obtain

a

molar

ratio

of

H2O:TIP

=

4:1.

The

sol

was

allowed

A.

Jaroenworaluck

et

al.

/

Chemical

Engineering

Journal

181182 (2012) 4555

Table

1

Nomenclature

for

the

powders

and

their

composites.

Samples

No.

Powders

and

its

composites

Sample

names

TiO2

SiO2

TiO2SiO2

1

Silica

gel

SiO2

(gel)

2

Fumed

silica

SiO2

(fume)

3

TIP

TiO2

(TIP)

4

TIP

Silica

gel

TiO2

(TIP)SiO2

(gel)

5

TIP

Fumed

silica

TiO2

(TIP)SiO2

(fume)

6

P25

TiO2

(P25)

7

P25

Silica

gel

TiO2

(P25)SiO2

(gel)

8

P25

Fumed

silica

TiO2

(P25)SiO2

(fume)

to

age

for

1

h

at

room

temperature.

The

samples

were

then

placed

in

an

oven

and

heated

from

30

to

110

.C

for

0.5

h

at

20

.C

intervals.

Using

a

similar

processing

route,

a

second

composite

was

made

when

SiO2

gel

was

added

to

TiO2

(P25)

and

suspended

in

ethyl

alcohol

at

room

temperature

with

constant

stirring,

followed

by

heating.

The

TiO2

loading

was

2.5,

6.5,

10.0

and

25.0

wt%,

respectively.

2.4.

Characterization

The

chemical

purity

of

SiO2

produced

from

the

synthesized

SiO2

gel

was

evaluated

by

X-ray

fluorescence

analysis

(XRF,

a

Phillips,

PW-2404,

The

Netherlands).

The

sample

for

the

XRF

analysis

was

prepared

by

pressing

5.0g

powder

with

1.0g

of

boric

acid

(H3BO3)

binder.

An

X-ray

diffractometer

(XRD,

JDX-3530,

JEOL,

Japan)

employing

Cu

K.

radiation

(

=

1.5418

A)

at

a

scanning

rate

of

0.04

2

s-1

was

used

to

measure

crystallinity

and

determine

the

phases

present

in

the

composites.

The

accelerating

voltage

and

the

applied

current

used

was

30

kV

and

40

mA,

respectively.

The

X-ray

diffraction

traces

were

acquired

in

the

2

range

1080..

The

diffraction

peaks

were

identified

with

JCPDS

data

using

Jade

7.5

software.

The

crystallite

size

of

the

powders

was

calculated

using

the

software

and

standard

formulae

based

on

the

Scherrer

equation

[21]:

K

t

=

B

cos

B

where

t

is

crystallite

size,

K

is

the

Scherrer

constant

(0.94),

is

the

wavelength

of

X-radiation

(1.5418

A),

B

is

peak

width

(FWHM),

and

B

is

the

diffraction

angle

at

which

the

half

width

is

measured.

The

surface

area,

pore

size

and

pore

volume

of

the

SiO2

gel

and

fumed

SiO2,

were

measured

using

nitrogen

(N2)

adsorption

(Quantachrome

Autosorp-1,

USA).

The

samples

were

degassed

at

250

.C

for

660

min

before

testing.

Surface

area,

pore

size

and

pore

volume

of

as-received

TiO2

(P25),

calcined

TiO2

(TIP),

TiO2

(TIP)SiO2

gel

TiO2

(P25)fumed

SiO2

including

typical

TiO2SiO2

compos-

Fig.

2.

X-ray

diffraction

patterns:

(a)

uncalcined

pure

SiO2

and

TiO2,

(b)

calcined

pure

SiO2

and

TiO2,

(c)

calcined

TiO2

(TIP)SiO2

(gel)

composites,

and

(d)

calcined

TiO2

(TIP)SiO2

(fume)

composites.

A.

Jaroenworaluck

et

al.

/

Chemical

Engineering

Journal

181182 (2012) 4555

Table

2

Surface

characteristics

of

samples

determined

by

the

N2

adsorptiondesorption

method.

Samples

BET

surface

Total

pore

Average

pore

area

(m2

g-1

)

volume

diameter

(nm)

(cm3

g-1)

SiO2

(gel)

353.04

0.6743

7.64

SiO2

(fume)

170.14

0.8685

20.42

TiO2

(TIP)

57.09

0.1664

11.66

TiO2

(P25)

55.42

0.8335

60.16

2.5

wt%

TiO2

(TIP)SiO2

(gel)

301.75

0.6394

8.48

6.5

wt%

TiO2

(TIP)SiO2

(gel)

385.52

0.6003

6.23

10.0

wt%

TiO2

(TIP)SiO2

(gel)

378.56

0.5436

5.74

25.0

wt%

TiO2

(TIP)SiO2

(gel)

349.77

0.5287

6.05

2.5

wt%

TiO2

(P25)SiO2

(gel)

211.55

0.6432

12.16

6.5

wt%

TiO2

(P25)SiO2

(gel)

230.68

0.6546

11.35

10.0

wt%

TiO2

(P25)SiO2

(gel)

154.10

0.6239

16.20

25.0

wt%

TiO2

(P25)SiO2

(gel)

238.13

0.8055

13.53

25.0

wt%

TiO2

(TIP)SiO2

(fume)

132.34

1.3090

39.57

25.0

wt%

TiO2

(P25)SiO2

(fume)

97.56

1.5080

61.83

ites

were

measured

using

the

same

methods

as

used

for

analysing

surface

characteristics

of

the

SiO2

gel

and

fumed

SiO2.

Infrared

spectra

were

collected

on

a

FT-IR

spectrometer

(System

2000,

Perkin-Elmer,

England)

at

20

.C

using

the

standard

KBr

method.

Sample

spectra

were

recorded

for

the

chemically

functional

groups

at

wavelengths

in

the

region

4000400

cm-1.

The

UV

absorption

properties

of

the

composites

were

measured

using

a

diffused

UVvis

spectrophotometer

(UV-2550,

Shimadzu,

Japan),

at

wavelengths

in

the

range

200800

nm,

at

0.1

step

scan

speed,

0.1

sampling

interval

and

1.0

slit

width.

A

scanning

electron

microscope

(SEM,

JSM-6310F,

JEOL,

Japan)

operated

at

20

kV

and

a

transmission

electron

microscope

(TEM,

JSM

2010,

JEOL,

Japan)

operated

at

200

kV

were

used

to

examine

the

morphology

and

microstructure

of

each

of

the

TiO2SiO2

composites.

Samples

for

SEM

investigation

were

dispersed

in

ethanol,

sonicated

in

an

utrasonic

bath

for

10

min,

dropped

onto

brass

stubs,

dried

in

a

vacuum

chamber

at

room

temperature

and

coated

with

sputtered

gold

prior

to

examination.

Samples

for

TEM

examination

were

dispersed

in

ethanol

and

sonicated

in

an

ultrasonic

bath

for

10

min,

and

then

fished

out

onto

carbon

films

supported

on

200

mesh

Cu

grids.

The

grids

were

dried

and

placed

in

the

microscope

for

microstructural

observation.

3.

Results

and

discussion

3.1.

Composite

characteristics

and

phases

present

A

list

of

samples

prepared

using

the

present

synthesis

route

is

shown

in

Table

1.

The

TiO2SiO2

gels

were

made

using

TiO2

from

two

sources;

TIP

and

P25.

Fumed

SiO2

was

used

as

a

standard

for

comparison

with

the

synthesized

SiO2

gel.

The

laboratory

processed

SiO2

gel

and

TiO2SiO2

gels

are

all

in

the

form

of

white

powders.

High

purity

SiO2

gel

(98.79%

SiO2

from

XRF

analysis).

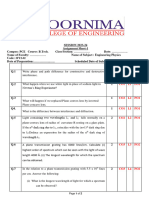

Fig.

1(a)

shows

the

N2

adsorptiondesorption

isotherms

of

the

fumed

SiO2

and

SiO2

gel.

A

characteristic

hysteresis

loop

of

mesopores

of

the

SiO2

gel

isotherm

is

seen

and

considered

to

be

the

so-called

type

IV

which

has

been

attributed

to

ink-bottle

pores

[22]

while

the

isotherm

of

the

fumed

SiO2

appears

somewhat

different.

The

SiO2

gel

isotherm

may

relate

to

localization

of

agglomerated

particles.

Unlike

pure

fumed

SiO2,

the

gel

can

adsorb

moisture

because

of

its

highly

porous

structure,

defined

by

a

BET

specific

surface

area

of

353.04

m2

g-1,

a

pore

diameter

of

7.64

nm,

and

a

mesoporous

structure.

Fumed

SiO2

has

a

lower

BET

specific

surface

area

of

170.14

m2

g-1,

with

a

larger

pore

diameter

of

20.42

nm

(see

the

inset

table

in

Fig.

1).

It

is

noted

that

the

pore

volume

of

the

synthesized

SiO2

gel

is

lower

than

that

of

the

fumed

SiO2,

which

may

be

related

to

its

agglomerated

morphology.

Fig.

3.

(a)

FT-IR

spectrograms

of

the

composites:

TiO2

(TIP)SiO2

(gel),

TiO2

(TIP)SiO2

(fume),

TiO2

(P25)SiO2

(gel)

and

TiO2

(P25)SiO2

(fume)

at

10

wt%

TiO2

loading

(a)

before

and

(b)

after

calcination

at

400

.C

for

10

h.

Pure,

white

TiO2

can

be

obtained

from

TIP,

a

colorless

liquid

that

rapidly

hydrolyses,

readily

evaporates

and

easily

forms

a

solid

(powder)

residue.

Fig.

1(b)

shows

the

N2

adsorptiondesorption

isotherms

of

the

calcined

TiO2

(TIP)

and

as-received

TiO2

(P25).

A.

Jaroenworaluck

et

al.

/

Chemical

Engineering

Journal

181182 (2012) 4555 49

Table

3

Crystal

size

of

uncalcined

and

calcined

sample

powders

based

on

XRD

analysis.

Samples

TiO2

SiO2

Anatase

Rutile

Before

After

Before

After

Before

After

SiO2

(gel)

18.10

21.60

SiO2

(fume)

18.70

19.30

TiO2

(TIP)

10.87

19.60

TiO2

(P25)

23.20

24.40

35.40

38.10

2.5

wt%

TiO2

(TIP)SiO2

(gel)

ND

ND

ND

ND

6.5

wt%

TiO2

(TIP)SiO2

(gel)

ND

ND

ND

ND

10.0

wt%

TiO2

(TIP)SiO2

(gel)

ND

11.10

ND

ND

25.0

wt%

TiO2

(TIP)SiO2

(gel)

ND

13.10

ND

ND

2.5

wt%

TiO2

(P25)SiO2

(gel)

16.00

15.80

ND

ND

ND

ND

6.5

wt%

TiO2

(P25)SiO2

(gel)

18.43

18.50

ND

ND

ND

ND

10.0

wt%

TiO2

(P25)SiO2

(gel)

19.50

19.40

22.90

22.90

ND

ND

25.0

wt%

TiO2

(P25)SiO2

(gel)

20.20

21.30

29.10

31.90

ND

ND

2.5

wt%

TiO2

(TIP)SiO2

(fume)

ND

ND

ND

ND

6.5

wt%

TiO2

(TIP)SiO2

(fume)

ND

ND

ND

ND

10.0

wt%

TiO2

(TIP)SiO2

(fume)

ND

ND

ND

ND

25.0

wt%

TiO2

(TIP)SiO2

(fume)

ND

11.20

ND

ND

2.5

wt%

TiO2

(P25)SiO2

(fume)

ND

ND

ND

ND

ND

ND

6.5

wt%

TiO2

(P25)SiO2

(fume)

ND

ND

ND

ND

ND

ND

10.0

wt%

TiO2

(P25)SiO2

(fume)

18.40

19.50

23.80

25.20

ND

ND

25.0

wt%

TiO2

(P25)SiO2

(fume)

19.70

19.90

28.20

31.10

ND

ND

Note:

:

none,

ND:

not

detectable

because

of

the

analyzed

limitation.

Fig.

4.

UVvisreflectancespectraof(a)pureSiO2

andTiO2,(b)TiO2

(TIP)SiO2

(gel),(c)TiO2

(TIP)SiO2

(fume),and(d)allcompositesdopedwith10wt%TiO2.

A.

Jaroenworaluck

et

al.

/

Chemical

Engineering

Journal

181182 (2012) 4555

Fig.

5.

The

energy

band

gap

(Eg)

of

TiO2

(TIP)SiO2

gel,

TiO2

(TIP)fumed

SiO2,

TiO2

(P25)SiO2

gel

and

TiO2

(P25)fumed

SiO2

versus

wt%

TiO2

present.

Different

profiles

can

be

observed

which

suggest

that

the

TiO2

(P25)

is

not

agglomerated

and

there

is

no

mesoporous

characteristic,

as

is

present

in

the

TiO2

(TIP)

formed

by

agglomeration

of

individual

small

particles.

Fig.

1(c)

and

(d)

show

for

comparison

profiles

of

the

N2

adsorptiondesorption

isotherms

of

the

TiO2

(TIP)SiO2

gel

and

TiO2

(P25)SiO2

gel,

respectively.

The

mesoporous

characteristics

can

be

obvious

for

each

composition.

The

isotherm

characteristics

of

the

TiO2

(TIP)SiO2

gel

is

similar

to

the

TiO2

(P25)SiO2

gel

although

the

BET

surface

area

of

both

types

composites

show

significant

differences.

The

BET

surface

area

of

TiO2

(P25)SiO2

gel

has

a

lower

value

than

the

TiO2

(TIP)SiO2

gel

composites,

as

summarized

in

Table

2,

while

the

different

values

for

BET

surface

area

of

TiO2

(P25)

and

TiO2

(TIP)

are

not

significant.

This

indicates

a

different

characteristic

which

can

imply

that

the

TiO2

(P25)

particles

covering

the

SiO2

gel

surfaces

decrease

the

overall

composites

surface

area

whereas

this

has

not

occurred

in

TiO2

(TIP)SiO2

gel.

It

is

possible

that

the

TiO2

(P25)

particles

are

not

agglomerated

and

can

distribute

readily

on

the

gel

particle

surfaces

which

could

well

reduce

the

surface

area

of

the

gel.

However,

the

TiO2

(TIP)

particles

which

are

agglomerated

can

be

distributed

locally

on

the

gel

surfaces.

It

is

possible

that

the

gel

surfaces

can

be

exposed

without

the

TiO2

being

totally

covered

by

particles.

It

is

also

interesting

that

the

TiO2SiO2

gel

composites

have

higher

BET

values

than

the

TiO2fumed

SiO2.

This

should

be

related

to

the

surface

area

of

the

SiO2

gel

which

is

higher

than

that

of

the

fumed

SiO2

itself.

The

number

of

TiO2

particles

attaching

onto

the

substrate

surfaces

is

possible

to

be

higher.

Fig.

2(a)

and

(b)

shows

a

comparison

of

phase

present

in

the

uncalcined

and

calcined

samples

from

pure

TiO2

and

the

synthesized

and

commercial

SiO2,

respectively.

The

calcined

temperature

and

holding

time

in

this

study

was

fixed

to

control

the

phase

present

in

the

TiO2SiO2

composites.

XRD

profiles

show

clearly

that

both

the

SiO2

gel

and

fumed

SiO2

have

an

amorphous

structure

with

a

diffuse

intensity

peak

at

2

~

22.

.

For

analysis

of

the

XRD

profiles

of

pure

TiO2

(P25),

JCPDS

no.

211272

and

21-1276

were

used,

the

highest

peak

intensity

of

(1

0

1)

and

for

(1

1

0)

were

measured

to

calculate

the

phases

present

and

to

determine

the

crystallite

size

of

anatase

and

rutile,

respectively.

The

XRD

results

indicate

the

presence

of

the

crystalline

phases

of

anatase

and

rutile

for

the

as-received

and

calcined

TiO2

(P25).

However

the

ratio

of

anatase:rutile

phases

changed

from

approximately

90:10

to

80:20

after

the

TiO2

(P25)

had

been

calcined.

This

is

a

clear

Fig.

6.

SEM

micrographs

of

the

pure

oxides,

(a)

SiO2

gel,

(b)

fumed

SiO2,

(c)

TiO2

(TIP),

and

(d)

TiO2

(P25).

A.

Jaroenworaluck

et

al.

/

Chemical

Engineering

Journal

181182 (2012) 4555

Fig.

7.

SEM

micrographs

of

the

calcined

composites

doped

with

10wt%

TiO2:

(a)

TiO2

(TIP)SiO2

(gel),

(b)

TiO2

(TIP)SiO2

(fume),

(c)

TiO2

(P25)SiO2

(gel),

and

(d)

TiO2

(P25)SiO2

(fume).

indication

that

the

calcination

condition

used

in

this

study

had

an

effect

on

the

phase

transformation

process.

For

the

synthesized

TiO2

(TIP),

for

both

the

uncalcined

and

calcined

powder,

characteristic

peaks

of

anatase

were

found.

In

addition

a

high

intensity

peak

at

2

~

30.8.,

the

characteristic

peak

of

the

(1

2

1)

plane

of

brookite

was

clearly

apparent.

Based

on

the

JCPDS

file

no.

29-1360,

this

peak

is

the

second

highest

intensity

peak

of

brookite.

The

first

and

the

third

are

at

2

~

25.3.

and

2

~

25.7.

,

respectively,

which

overlap

the

major

characteristic

peak

of

anatase

(2

~

25.3

of

(1

0

1)

plane).

For

the

uncalcined

powder,

this

characteristic

peak

of

anatase

appears

to

be

split

at

its

top,

all

of

which

suggests

that

a

brookite

phase

is

present

with

the

anatase.

These

particular

characteristic

peaks

could

also

be

found

in

the

calcined

powder

but

the

peaks

of

the

calcined

powder

are

noticeably

sharper.

It

may

well

be

that

the

brookite

formation

takes

place

by

a

phase

transformation

from

anatase

during

the

calcination

process.

It

is

clear

that

the

majority

of

the

crystalline

phase

in

the

TiO2

(TIP)

powder

is

anatase

and

that

for

the

calcination

condition

used,

the

rutile

phase

could

not

be

identified

in

any

of

the

samples

of

TiO2

(TIP).

Fig.

2(c)

shows

XRD

profiles

of

the

calcined

TiO2

(TIP)SiO2

gel

composites.

With

less

than

10.0

wt%

TiO2,

the

crystalline

phase

of

anatase

cannot

be

clearly

identified.

The

base

line

of

all

the

XRD

traces

includes

a

signal

due

to

the

amorphous

phase.

For

TiO2

(TIP)fumed

SiO2

composites,

the

trend

of

the

XRD

profiles

is

similar

to

that

of

the

calcined

TiO2

(TIP)SiO2

gel

composites,

as

shown

in

Fig.

2(d).

However

the

brookite

phase

could

be

seen

in

the

XRD

traces

of

the

25

wt%

TiO2

(TIP)fumed

SiO2

composites.

For

all

the

TiO2

(P25)SiO2

composites,

their

XRD

profiles

indicate

the

presence

of

crystalline

phases

of

anatase

and

rutile

before

and

after

calcination.

Table

3

summarises

the

calculated

crystal

size

of

pure

SiO2,

TiO2

and

their

composites.

The

amorphous

nature

of

SiO2

had

a

marked

effect

on

the

base

lines

of

the

XRD

profiles

which

limited

the

process

of

identifying

the

crystalline

size

by

this

technique.

However,

the

crystallite

size

of

the

calcined

SiO2

gel

and

TiO2

(TIP)

is

in

the

same

size

range

as

the

commercial

fumed

SiO2

and

TiO2

(P25).

The

estimated

size

of

the

TiO2

in

the

TiO2

(TIP)SiO2

composites

is

smaller

than

that

measured

for

the

pure

TiO2

(TIP)

or

for

the

composites

of

TiO2

(P25)SiO2.

3.2.

Chemical

functional

groups

FT-IR

spectra

of

the

composites,

10.0

wt%

TiO2

(TIP)

and

TiO2

(P25)

for

both

fumed

SiO2

and

SiO2

gel

before

and

after

calcination,

have

been

determined

and

are

compared

in

Fig.

3(a)

and

(b),

respectively.

The

spectral

peaks

near

3500

and

1640

cm-1

present

in

all

samples

are

attributed

to

the

stretching

mode

of

water

hydroxyl

bonds

[12,14,23].

There

are

strong

bands

at

470,

800

and

1100

cm-1

ascribed

to

the

bending

modes

of

SiOSi,

to

symmetric

vibration

of

SiOSi

and

to

asymmetric

stretching

of

SiOSi,

respectively

[10,12,19,20].

A

weak

band

at

~900950

cm-1

is

attributed

to

SiOH

stretching

frequency

for

the

silanol

groups

[24,25].

The

samples

exhibit

a

slightly

more

intense

broad

band

at

3500

cm-1

prior

to

calcination.

The

FT-IR

results

in

the

region

of

the

peaks

at

~3500

cm-1

demonstrate

that

the

SiO2

gel

shows

a

higher

adsorbed

water

content

than

fumed

SiO2.

The

composites

of

the

SiO2

gel

have

a

higher

intensity

peak

than

that

of

the

fumed

SiO2

around

3500

cm-1.

This

large

broad

band

is

attributed

to

the

presence

of

the

OH

stretching

frequency

of

the

silanol

groups

and

also

to

any

of

the

remaining

adsorbed

water

[26].

Thus

it

would

appear

that

the

composites

based

on

the

SiO2

gel

can

adsorb

water

rather

more

effectively

than

those

of

fumed

SiO2.

Furthermore,

the

A.

Jaroenworaluck

et

al.

/

Chemical

Engineering

Journal

181182 (2012) 4555

Fig.

8.

TEM

bright

field

images

of

pure

oxides,

(a)

SiO2

gel,

(b)

fumed

SiO2,

(c)

TiO2

(TIP),

and

(d)

TiO2

(P25).

TiO2

(TIP)SiO2

gel

shows

higher

adsorbed

water

content

than

the

calcined

sample

and

has

a

higher

adsorbed

water

content

than

the

TiO2

(P25)SiO2

gel

or

the

uncalcined

sample.

From

the

FT-IR

spectra

at

450750

cm-1,

only

one

absorption

peak

for

anatase

is

present

at

~500

cm-1

whereas

the

rutile

gives

two

peaks

at

510

cm-1

and

640

cm-1.

The

spectral

peaks

are

ascribed

to

the

stretching

vibrations

of

the

TiO

bond

[10,23].

As

the

calcined

temperature

reaches

400

.C,

a

broad

absorption

band

appears

at

500650

cm-1,

which

indicates

the

formation

of

the

rutile

phase,

probably

on

or

near

the

surface

of

anatase

crystals.

Thus

the

phase

transformation

from

anatase

to

rutile

can

be

monitored

by

the

relative

intensity

of

these

characteristic

peaks.

3.3.

UV

absorption

properties

Fig.

4(a)

shows

the

UV

absorption

spectra

of

pure

samples.

The

absorption

edge

is

absent

in

the

two

lowest

curves

corresponding

to

the

pure

fumed

SiO2

and

pure

SiO2

gel,

respectively.

It

is

clear

that

SiO2

itself

does

not

have

good

absorption

properties,

however,

the

SiO2

having

the

high

porosity

may

be

used

as

a

support

medium

for

the

TiO2

particles.

The

results

indicate

that

the

absorption

spectrum

for

pure

calcined

TiO2

(TIP)

shows

the

largest

shift

to

a

longer

wavelength

and

higher

absorption

than

TiO2

(P25).

Fig.

4(b)

and

(c)

show

for

comparison

the

absorption

spectra

of

pure

SiO2

gel,

fumed

SiO2

and

their

composites

formed

with

2.5,

6.5,

10.0

and

25.0

wt%

TiO2

(TIP)

The

degree

of

absorption

appears

to

be

increased

with

the

increase

in

wt%

TiO2

and

shift

to

longer

wavelength.

For

the

TiO2

(TIP)SiO2

(gel)

composites,

the

highest

absorption

is

found

at

6

wt%

TiO2

(TIP).

The

higher

additions

of

TiO2

may

show

a

reduced

absorption

as

a

result

of

particle

agglomeration.

It

is

apparent

that

the

absorption

edges

shift

to

a

higher

wavelength

(red

shift)

as

the

wt%

TiO2

(TIP)

increases.

The

results

indicate

a

trend

in

that

the

increasing

absorption

value

depends

on

the

wt%

TiO2

(TIP)

added.

In

Fig.

4(d),

the

TiO2

(TIP)SiO2

composites

are

seen

to

have

higher

absorption

values

when

compared

to

the

commercial

TiO2

(P25).

The

shift

of

the

absorption

edge

towards

longer

wavelength,

the

so

called

red

shift,

could

be

observed.

The

observed

red

shift

of

the

absorption

edge

for

the

TiO2fumed

SiO2

and

TiO2SiO2

gel

compared

to

pure

TiO2

(P25)

and

TiO2

(TIP)

is

suggested

to

be

due

to

size

effects

typical

of

small

particles.

UV

absorption

of

TiO2SiO2

gel

is

higher

than

for

the

TiO2fumed

SiO2

for

both

the

TiO2

from

P25

and

TIP.

This

may

well

relate

to

the

A.

Jaroenworaluck

et

al.

/

Chemical

Engineering

Journal

181182 (2012) 4555 53

Table

4

Absorption

edge

and

Eg

values

of

pure

and

composite

samples.

Sample

Absorption

edge

(nm)

Eg

(kV)

wt%

TiO2

wt%

TiO2

2.5

6.5

10.0

25.0

100.0

2.5

6.5

10.0

25.0

100.0

TiO2

(TIP)

385

3.22

TiO2

(P25)

390

3.18

TiO2

(TIP)SiO2

(gel)

350

370

370

385

3.54

3.35

3.35

3.22

TiO2

(P25)SiO2

(gel)

390

395

400

400

3.18

3.14

3.10

3.10

TiO2

(TIP)SiO2

(fume)

358

367

367

386

3.47

3.38

3.38

3.21

TiO2

(P25)SiO2

(fume)

380

385

390

402

3.26

3.22

3.18

3.09

Fig.

9.

TEM

bright

field

images

of

the

calcined

10

wt%

TiO2

composites:

(a)

TiO2

(TIP)SiO2

(gel),

(b)

TiO2

(TIP)SiO2

(fume),

(c)

TiO2

(P25)SiO2

(gel),

and

(d)

TiO2

(P25)SiO2

(fume).

mesoporous

structure

of

SiO2

gel

allowing

the

TiO2

to

deposit

on

where

E

is

the

Energy

gap,

h

is

Plancks

constant

(6.625

10-34

Js),

the

gel

surfaces

and

particularly

to

the

smaller

pore

size

of

the

gel.

c

is

the

velocity

of

light

(3.0

108

ms-1)

and

is

the

wavelength

(nm),

respectively.

The

wavelengths

were

determined

from

the

3.4.

Energy

band

gap

absorbance

curves

at

the

point

of

contact

with

the

x-axis

of

the

absorbance-wavelength

plots.

This

method

was

used

to

evaluate

The

energy

band

gap

can

be

calculated

by

substituting

the

energy

band

gaps

(Eg)

after

a

trial

and

error

calculation

for

the

appropriate

wavelength

value

()

into

the

equation

[27]:

energy

band

gap

of

TiO2

(P25).

The

energy

band

gap

of

TiO2

(P25)

obtained

using

this

method

is

closer

to

the

theoretical

value

when

hc

E

=

compared

to

the

two

methods:

A.

Jaroenworaluck

et

al.

/

Chemical

Engineering

Journal

181182 (2012) 4555

(i)

the

(F(R)

h)1/2

versus

h

plot,

in

term

of

the

KubelkaMunk

function,

where

F(R)

=

(1

-

R)2/(2R)

and

R

is

reflectance

(%)

[13]

and

(ii)

differential

reflectance

(dR/d)

versus

plot

[28].

The

relationship

between

Eg

and

wt%

TiO2

doped

in

SiO2

is

summarized

and

plotted

in

Table

4

and

Fig.

6,

respectively.

For

crystalline

TiO2,

the

theoretical

band

gap

between

the

valence

band

and

the

conduction

band

is

3.2

eV

for

anatase

[7,10,18,23]

and

3.0

eV

for

rutile

[7,8,10,18,23].

From

this

study,

the

energy

band

gap

was

determined

~3.18

eV

for

the

TiO2

(P25)

consisting

of

mixed

anatase

and

rutile

phases.

The

trend

in

values

of

Eg

for

mixed

TiO2

nano-crystals

of

both

rutile

and

anatase

phases

decreases

continuously

with

the

increase

in

rutile

content.

The

energy

gap

in

the

TiO2

(P25)SiO2

gel

and

TiO2

(TIP)SiO2

gel

is

higher

than

that

for

TiO2

(P25)fumed

SiO2

and

TiO2

(TIP)fumed

SiO2

for

all

the

different

TiO2

additions.

The

results

in

Fig.

5

show

that

the

highest

value

for

Eg

is

given

for

the

2.5

wt%

TiO2

(TIP)SiO2

gel.

The

band

gap

decreases

for

all

the

samples

with

increase

in

the

TiO2

content.

Again,

the

crystalline

form

of

the

samples

affects

the

change

in

band

gap

with

the

TiO2

(P25)SiO2

gel

giving

the

lowest

value

and

the

TiO2

(TIP)SiO2

gel

giving

the

highest

value.

The

lack

of

sensitivity

of

the

energy

band

gap

to

small

additions

of

dopant

(TiO2)

strongly

suggests

that

the

energy

change

is

due

to

small

bond

length

changes

induced

by

nearest

neighbor

crystal

chemistry.

However

for

additions

>10.0

wt%,

the

energy

band

gap

decreases.

Consequently,

it

would

appear

that

10.0

wt%

TiO2

(P25)

addition

is

the

optimum

composition

for

the

TiO2

(P25)SiO2

gel.

The

energy

band

gap

decreases

with

the

amount

of

TiO2

(TIP)

added.

At

25.0

wt%

TiO2

addition,

the

highest

absorption

and

the

lowest

value

for

the

energy

band

gap

was

found.

The

absorption

increases

with

the

wt%

TiO2

(TIP)

increase

up

to

10.0

wt%,

but

above

this

value

the

absorption

decreases,

the

10

wt%

TiO2

(TIP)SiO2

gel

having

the

highest

absorption.

Conversely,

the

energy

band

gap

increases

when

the

wt%

TiO2

(TIP)

decreases.

The

energy

band

gap

values

for

6.5

and

10.0

wt%

TiO2

(TIP)SiO2

gel

are

not

significantly

different

from

that

of

the

25.0

wt%

addition

which

has

the

lowest

energy

band

gap

in

the

series.

However

for

ease

of

preparation

of

the

TiO2

(TIP)SiO2

gels,

the

most

suitable

concentration

is

considered

to

be

~10.0

wt%

of

TiO2

(TIP).

3.5.

Microstructure

investigations

3.5.1.

SEM

observation

Fig.

6(a)(d)

are

SEM

images

showing

the

microstructures

of

Fig.

10.

HR-TEM

images

of

(a)

10

wt%

TiO2

(TIP)SiO2

gel

and

(b)

10

wt%

TiO2

calcined

SiO2

gel,

fumed

SiO2,

as-received

TiO2

(P25),

and

calcined

(TIP)fumed

SiO2

after

calcination

at

400

.C

for

10

h.

TiO2

(TIP),

respectively.

It

is

clear

that

particles

of

TiO2

(TIP)

and

SiO2

gel

have

agglomerated

while

particles

of

TiO2

(P25)

and

fumed

SiO2

are

randomly

dispersed.

The

image

revealed

that

pure

SiO2

3.5.2.

TEM

observation

gel

consists

of

both

large

and

small

agglomerated

particles.

The

Bright

field

images

of

the

pure

SiO2

and

TiO2

samples

are

shown

agglomerated

mass

has

broken

up

into

small

pieces

revealing

the

in

Fig.

8(a)(d).

The

SiO2

gel

particles

are

agglomerated

whereas

fine

individual

gel

particles

on

the

fractured

surfaces.

the

grains

of

the

fumed

SiO2

are

well

dispersed

and

have

a

fairly

The

microstructure

of

all

the

composites

observed

differs

some-narrow

size

distribution.

The

TiO2

(TIP)

particles

are

smaller

than

what.

Fig.

7(a)(d)

are

selected

as

being

representative

of

the

TiO2

(P25)

but

these

smaller

particles

tend

to

have

agglomerated.

microstructures

of

the

10.0

wt%

TiO2SiO2

composites.

The

images

The

particle

characteristics

of

the

TiO2

(P25)

and

the

fumed

SiO2

of

the

10.0

wt%

TiO2

(TIP)SiO2

gel

show

a

structure

consisting

are

similar,

as

shown

in

Fig.

8(b)

and

(d).

of

agglomerations

of

both

large

and

small

particles

which

may

Fig.

9(a)(d)

shows

the

microstructures

of

the

composites,

themselves

be

formed

of

even

smaller

agglomerates

covering

their

which

can

be

readily

compared.

For

the

composite

made

up

of

TiO2

surfaces.

However

the

images

of

the

10.0

wt%

TiO2

(TIP)fumed

(TIP)SiO2

(gel),

the

crystalline

TiO2

grains

are

agglomerated

and

SiO2

show

well

dispersed

nanoparticles

having

a

narrow

size

distri-attached

onto

the

SiO2

gel

surface

as

is

shown

in

Fig.

9(a).

However

bution.

From

examination

of

the

TiO2

(P25)fumed

SiO2,

particles

with

the

sample

of

TiO2

(TIP)fumed

SiO2,

individual

TiO2

(TIP)

of

TiO2

and

SiO2

are

observed

to

be

dispersed

uniformly

(see

particles

could

be

observed

on

the

surfaces

of

the

fumed

SiO2

(the

Fig.

7(c)).

In

the

course

of

the

SEM

observations,

it

was

not

pos-dark

spots

in

Fig.

9(b)).

In

the

TiO2

(P25)SiO2

gel

composite

it

can

sible

to

distinguish

between

the

TiO2

and

SiO2

particles

which

are

be

seen

that

the

TiO2

(P25)

particles

have

attached

to

each

other

of

a

similar

size

and

shape

and

have

similar

brightness

and

contrast.

and

some

are

completely

surrounded

on

the

gel

surface.

The

TiO2

A. Jaroenworaluck et al. / Chemical Engineering Journal 181 182 (2012) 45 55 55

(P25)fumed SiO2 composite shows different behavior in that both

types of particles are intimately mixed. Grains of the TiO2 (P25)

and the SiO2 gel particles have different structural forms, being

crystalline and amorphous respectively.

HRTEM images, Fig. 10(a) and (b) reveal agglomeration of crystalline

TiO2 (TIP) on SiO2 gel and fume SiO2. It is noted that the size

of the individual particles in the composite is smaller when measured

from calibrated micrographs than the values obtained from

XRD data and the Scherrer equation,

~7 nm (see Table 3 and the figures).

It is suggested that the TiO2 particles in the composites are

limited in their ability to grow easily since they become occluded

by the SiO2 grains and pores. A detailed investigation reveals that

individual TiO2 (TIP) particles having a crystalline structure are

attached onto the fumed SiO2 surfaces, a feature which may be

related to the larger pore diameters compared to those present in

the SiO2 gel.

The TEM images allow conclusions to be made particularly

regarding the influence of the nanostructure in that the UV absorption

properties of the TiO2SiO2 gel or TiO2fumed SiO2 depend on

the particle size of the active TiO2 phase in the composites and the

surface properties of the supporting media (SiO2 gel or fumed SiO2),

relating directly to the particle distribution of the components.

4. Conclusions

A mesoporous SiO2 gel was synthesized utilising recycled rice

husk as a precursor. The gel was doped with various amounts of

TiO2 using TIP and P25 and these were characterized and measured

for UV absorption for evaluation of their energy band gap

by comparing with TiO2fumed SiO2 composites. At the temperatures

and conditions used for calcination, the synthesized TiO2

prepared from the TIP forms a well crystallised pure anatase phase.

SiO2 gel particles are preferable to agglomerates and the TiO2 (TIP)

particles are best dispersed on the SiO2 gel with its mesoporous

structure. However, with the TiO2 (P25)SiO2 gel, the TiO2 (P25),

particles are preferable to agglomerates. The UV absorption properties

have been related to the level of TiO2 doping and the phase,

size and surface characteristics of the support media (SiO2 gel or

fumed SiO2).

Acknowledgement

This work is financially supported by the National Metal and

Materials Technology Center (MTEC) under funded no. MT-B-48-

CER-07-190-I and MT-B-51-CER-07-206-I.

References

[1] L. Sun, K. Gone, Silicon-based materials from rice husks and their applicati

ons,

Ind. Eng. Chem. Res. 40 (2001) 58615877.

[2] R. Conradt, P. Pimkhaokham, U. Leela-Adisorn, Nano-structured silica from ri

ce

husk, J. Non-Cryst. Solids 145 (1992) 7579.

[3] T.H. Liou, Preparation and characterization of nano-structured silica from r

ice

husk, Mat. Sci. Eng. A: Struct. A364 (2004) 313323.

[4] M. Estevez, S. Vargas, V.M. Castano, R. Rodriguez, Silica nano-particles prod

uced

by worms through a bio-digestion process of rice husk, J. Non-Cryst. Solids 355

(2009) 844850.

[5] A. Fujishima, X. Zhang, D.A. Tryk, TiO2 photocatalysis and related surface p

henomena,

Surf. Sci. Rep. 63 (2008) 515582.

[6] P. Kullavanijaya, H.W. Lim, Photoprotection, J. Am. Acad. Dermatol. 52 (2005

)

937958.

[7] N. Serpone, D. Dondi, A. Albini, Inorganic and organic UV filters: their rol

e

and efficacy in sunscreens and suncare products, Inorg. Chim. Acta 360 (2007)

794802.

[8] T.A. Egerton, N.J. Everall, J.A. Mattinson, L.M. Kessell, I.R. Tooley, Inter

action of

TiO2 nano-particles with organic UV absorbers, J. Photochem. Photobiol. A 193

(2008) 1017.

[9] S. Yabe, T. Sato, Cerium oxide for sunscreen cosmetics, J. Solid State Chem.

171

(2003) 711.

[10] S.I. Seok, J.H. Kim, TiO2 nanoparticles formed in silica solgel matrix, Mate

r.

Chem. Phys. 86 (2004) 176179.

[11] E. Pabn, J. Retuert, R. Quijada, A. Zarate, TiO2SiO2 mixed oxides prepared by

a combined solgel and polymer inclusion method, Microporous Mesoporous

Mater. 67 (2004) 195203.

[12] Z. Li, B. Hou, Y. Xu, D. Wu, Y. Sun, W. Hu, F. Deng, Comparative study of s

olgel

hydrothermal and solgel synthesis of titaniasilica composite nanoparticles,

J. Solid State Chem. 178 (2005) 13951405.

[13] J. Aguado, R. van Grieken, M.J. Lpez-Munoz, J. Marugn, A comprehensive

study of the synthesis, characterization and activity of TiO2 and mixed

TiO2/SiO2 photocatalysts, Appl. Catal. A: Gen. 312 (2006) 202212.

[14] A.A. Ismail, H. Matsunaga, Influence of vanadia content onto TiO2SiO2 matrix

for photocatalytic oxidation of trichloroethylene, Chem. Phys. Lett. 447 (2007)

7478.

[15] G. Calleja, D.P. Serrano, R. Sanz, P. Pizarro, Mesostructured SiO2-doped Ti

O2

with enhanced thermal stability prepared by a soft-templating solgel route,

Microporous Mesoporous Mater. 111 (2008) 429440.

[16] E. Beyers, E. Biermans, S. Ribbens, K. de Witte, M. Mertens, V. Meynen, S.

Bals,

G. van Tendeloo, E.F. Vansant, P. Cool, Combined TiO2/SiO2 mesoporous photocatal

ysts

with location and phase controllable TiO2 nanoparticles, Appl. Catal.

B: Environ. 88 (2009) 515524.

[17] H.E. Byrne, W.L. Kostedt IV, J.M. Stokke, D.W. Mazyck, Characterization of

HFcatalyzed

silica gels doped with Degussa P25 titanium dioxide, J. Non-Cryst.

Solids 355 (2009) 525530.

[18] B. Llano, G. Restrepo, J.M. Marn, J.A. Navo, M.C. Hidalgo, Characterisation a

nd

photocatalytic properties of titaniasilica mixed oxides doped with Ag and Pt,

Appl. Catal. A: Gen. 387 (2010) 135140.

[19] A. Nilchi, S. Janitabar-Darzi, A.R. Mahjoub, S. Rasouli-Garmarodi, New TiO2

/SiO2

nanocompositesphase transformations and photocatalytic studies, Colloids

Surf. A 361 (2010) 2530.

[20] J. Zou, J. Gao, H2O2-sensitized TiO2/SiO2 composites wit high photocatalyti

c

activity under visible irradiation, J. Hazard. Mater. 185 (2011) 710716.

[21] B.D. Cullity, Element of X-ray Diffraction, second ed., Addison-Wesley Publ

ishing

Company, United States of America, 1978.

[22] T. Allen, Particle Size Measurement, 5th ed., Kluwer Academic Publishers, T

he

Netherlands, 1999.

[23] W. Jun, Z. Gang, Z. Zhaohong, Z. Xiangdong, Z. Guan, M. Teng, J. Yuefeng, Z

.

Peng, L. Ying, Investigation on degradation of azo fuchsine using visible light

in the presence of heat-treated anatase TiO2 powder, Dyes Pigments 75 (2007)

335343.

[24] J.A.A. Sales, C. Airoldi, Calorimetric investigation of metal ion adsorptio

n on

3-glycidoxypropyltrimethylsiloxane + propane-1,3-diamine immobilized on

silica gel, Thermochim. Acta 427 (2005) 7783.

[25] Y.M. Wang, S.W. Liu, Z. Xiu, X.B. Jiao, X.P. Cui, J. Pan, Preparation and p

hotocatalytic

properties of silica gel-supported TiO2, Mater. Lett. 60 (2006) 974978.

[26] J. Estella, J.C. Echeverra, M. Laguna, J.J. Garrido, Effects of aging and dr

ying

conditions on the structural and textural properties of silica gels, Microporous

Mesoporous Mater. 102 (2007) 274282.

[27] V. Balzani, F. Scandola, Supramolecular Photochemistry, Ellis Horwood Limit

ed,

Chichester, 1991.

[28] M. Radecka, A. Trenczek-Zajac, K. Zakrzewska, M. Rekas, Effect of oxygen no

nstoichiometry

on photo-electrochemical properties of TiO2-x, J. Power Sources

173 (2007) 816821.

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)