Documente Academic

Documente Profesional

Documente Cultură

Engineering Manual: Conveyor Belts

Încărcat de

mseif1980Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Engineering Manual: Conveyor Belts

Încărcat de

mseif1980Drepturi de autor:

Formate disponibile

SIG Societ Italiana Gomma SpA

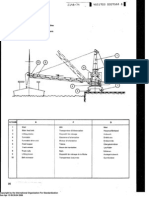

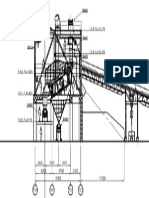

CONVEYOR BELTS

Engineering manual

Errata corrige

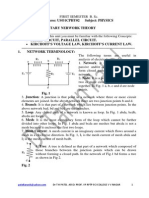

SECTION 2

Pag. 12 - Symbol error in the comment of equation 2.6:

Considering the mechanical efficiency coefficient for the transmission (Tab. 8) .

Pag.13 and 14 - Erron in equantion 2.14, 2.19, 2.21 (cos absent)

B

q ''

B

Tv1 T2 n L1 q

cos r f L1q

sen

a' '

1000

1000

Tv

Fv

B

q ''

B

L1 q

cos r f L1q

sen Ft K

2

a' '

1000

1000

Tva

Fv

B

q ''

B

L1 q

cos r f L1q

sen Ft Kw

2

a' '

1000

1000

(2.14)

(2.19)

Pag. 16 - Errors in some equation of the resumptive scheme (cos absent)

Counterweight calculation

qB

q ''

qB

cos r f L1

sen

a' '

1000

1000

Tv1 T2 n L1

Effective tension calculation

add to T1n and T2 n the term

Fv

q ''

qB

qB

L1

cos r f L1

sen T2 n

2

a' '

1000

1000

Check according to installed power N

Fv

q ''

qB

qB

L1

cos r f L1

sen Ft K

a' '

1000

1000

2

T1max Ft K 1

Fv

q ''

qB

qB

L1

cos r f L1

sen Ft Kw

a' '

1000

1000

2

Ta Ft K 1 w

SECTION 3

Page 1 of 4

(2.21)

SIG Societ Italiana Gomma SpA

Pag. 26 and 27 Radius of curvature is worked out in meters

Error in equation 3.2

Tc

w

Q

Wb

cos

3,6v

(3.2)

(Tc instead of T*)

Error in equation 3.4, 3.5 (inversion of 9 with 4,5 between equations)

sen CR A B 1000

CR

T

9

10 c

B

fs

(3.4)

sen CR A B 1000

CR

T

4,5

10 c

B

fs

(3.5)

SECTION 5

Pag. 30 In equantion 5.4 D is the lower pulley diameter expressed in meters

Pag. 30 and 31 Error in equation 5.7 and 5.15

P3calc Q

p

3,6vn

(5.7)

T3 T4 a 102 N

v

(cos is a non sense)

(5.15) (efficiency forgotten)

SECTION 6

Pag. 32 Error in equation 6.1

Recommended Maximum Belt Tension CL

CR

fs

(6.1)

(slash absent)

SECTION 7

Pag. 37 Error in equation 7.8

l2

l

cos 90

(7.8)

( instead of )

TABLES (error in underlined values)

Friction coefficient between belt and idlers

Working conditions

Page 2 of 4

Tab. 9

f

SIG Societ Italiana Gomma SpA

Good belt allignement, carrying idlers very sliding,

low friction

material, speed up to 5 m/sec.

Standard

Dusty atmosphere, low temperature, high friction

material,

overloading, speed over 5 m/sec

Very low temperature but well running installations

Regenerative conveyor with standard running

conditions

Regenerative conveyors with bad running conditions

Sliding belt without bottom cover on steel surface

0,017

0,020-0,022

0,025

0,035

0,012

0,016

0,4

Sliding belt with bottom cover on steel surface

0,7

Pipex belts for tubular conveyor systems

0,030-0,037

Belt modulus

Tab. 16

Unitary modulus

A

Ply breaking load

125

160

200

250/315

400/630

SIDERFLEX ID

SIDEFLEX IW, HE, ST

EP

13

12

11

10

9,5

NN or PP

6,6

6,8

7,5

8

8,5

60

30

To obtain the belt modulus (tension that must

be applied to the belt in order to obtain 100% of

elongation), multiply the unitary modulus A for

related tensile strength. For example:

EP 630/3 11 * 200 * 3 = 6600 KN/m

IW 1250

650*1250 = 37500 KN/m

Indicative Flexobord cleat characteristics

Cleat

type Useful height l

and

[mm]

height

D110

100

N50

45

N70

70

N105

100

C70

70

C110

105

C145

135

C180

175

C220

220

C280

270

C330

320

Tab. 17

Thichness h

[mm]

Cleat section

[dm2]

Weight

[Kg/m]

---30

40

65

40

65

85

90

100

100

100

---0,03

0,05

0,18

0,12

0,32

0,43

0,92

1,29

1,65

2,25

3,0

1,1

0,6

1,4

1,9

3,5

5,2

7,2

11,7

13,7

16,2

Indicative Flexobord

edges characteristics Tab. 18

Page 3 of 4

SIG Societ Italiana Gomma SpA

Edge

height

Width

[mm]

Weight

[Kg/m]

Wave pitch

[mm]

60

80

120

160

200

240

300

400

50

50

50

75

80

95

95

95

1,3

1,5

2,0

3,6

5,7

8,0

9,5

12,6

40

50

50

58

65

65

65

65

Characteristics of Siderflex steel cord belts Tab. 21

KN/m

350

500

630

800

mm

Kg/mq

mm

mm

-------------

-------------

5,0

3,45

14,00

3,00

5,6

4,35

15,00

3,60

N

mm

mm

N

-------------

-------------

9700

14,0

2,00

2900

13500

14,0

2,00

2900

1000 1250 1400

1600

1800

2000

2500

3150

Regular warp steel cords and high elongation weft steel cords

5,6

6,4

6,4

5,20 6,40

6,90

12,00 14,00 13,00

3,60 4,40

4,40

1980

13500

0

19800

14,0 14,0

14,0

2,00 2,00

2,00

2900 2900 2900

7,2

7,90

15,00

5,20

7,2

9,10

13,00

5,20

7,2

9,80

12,00

5,20

8,9

11,65

14,00

6,90

9,6

13,76

15,00

7,60

26700

14,0

2,00

2900

26700

14,0

2,00

2900

26700

14,0

2,00

2900

41200

14,0

2,00

2900

52000

14,0

2,00

2900

-------------------------

-------------------------

7,1

9,25

4,65

3,90

9600

12,5

2,02

2900

-------------------------

-------------------------

-------------------------

-------------------------

-------------------------

Elongation warp steel cords and high elongation weft steel cords

mm

Kg/mq

mm

mm

N

mm

mm

N

3,2

1,85

8,33

2,00

3075

17,5

1,52

1720

3,2

2,45

5,81

2,00

3075

17,5

1,52

1720

3,2

2,95

4,63

2,00

3075

17,5

1,52

1720

mm

Kg/mq

mm

mm

N

mm

mm

N

2,4

2,00

8,33

2,00

3075

12,5

1,52

1720

4,7

2,60

5,81

2,00

3075

12,5

1,52

1720

4,7

3,15

4,63

2,00

3075

12,5

1,52

1720

mm

Kg/mq

mm

mm

N

mm

mm

N

3,2

1,50

8,33

2,00

3075

15,0

1,2

800

3,2

2,15

5,81

2,00

3075

15,0

1,2

800

3,2

2,65

4,63

2,00

3075

15,0

1,2

800

4,5

4,15

6,67

2,85

5600

20,0

2,02

2900

4,5

6,0

5,00 6,35

5,38 7,04

2,85 3,90

5600 9600

20,0 20,0

2,02 2,40

2900 3775

6,0

7,05

6,25

3,90

9600

20,0

2,40

3775

6,0

7,90

5,50

3,90

9600

20,0

2,40

3775

-------------------------

-------------------------

Elongation warp steel cords and double high elongation weft steel cords

5,4

4,10

6,67

2,85

5600

12,5

1,52

1720

5,4

7,1

4,95 6,30

5,38 7,04

2,85 3,90

5600 9600

12,5 15,0

1,52 2,02

1720 2900

7,1

7,00

6,25

3,90

9600

15,0

2,02

2900

7,1

7,85

5,50

3,90

9600

15,0

2,02

2900

7,1

8,70

5,00

3,90

9600

12,5

2,02

2900

Elongation warp steel cords and nylon weft cords

4,1

3,60

6,67

2,85

5600

15,0

1,2

800

4,1

4,9

4,45 5,60

5,38 7,04

2,85 3,90

5600 9600

15,0 15,0

1,2

1,20

800

800

Page 4 of 4

4,9

6,30

6,25

3,90

9600

15,0

1,20

800

4,9

7,15

5,50

3,90

9600

15,0

1,20

800

-------------------------

S-ar putea să vă placă și

- Power System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)De la EverandPower System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)Încă nu există evaluări

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkDe la EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkÎncă nu există evaluări

- Code of Practice For Electric Overhead Travelling Cranes and Gantry Cranes Other Than Steel Work CranesDocument67 paginiCode of Practice For Electric Overhead Travelling Cranes and Gantry Cranes Other Than Steel Work CranesDeepak RaturiÎncă nu există evaluări

- NAD 3020 ServiceManualDocument6 paginiNAD 3020 ServiceManualmartin-d-johnsonÎncă nu există evaluări

- Curtain Wall With HZ & VL Louvers Structural Calculation For Building a-PART (6) at AXIS (34-42) - A'Document59 paginiCurtain Wall With HZ & VL Louvers Structural Calculation For Building a-PART (6) at AXIS (34-42) - A'نصر عبدالسلامÎncă nu există evaluări

- CFEM4th Errata January 21 2013 UpdateDocument8 paginiCFEM4th Errata January 21 2013 UpdatejoshephwanciÎncă nu există evaluări

- Summation CTDocument13 paginiSummation CTjakes87100% (1)

- Mil HDBK 217fn1Document37 paginiMil HDBK 217fn1Pradeep BhagwatÎncă nu există evaluări

- CU EU Cylinders Pistones NeumaticosDocument80 paginiCU EU Cylinders Pistones NeumaticosbloggusbloggusÎncă nu există evaluări

- Rcc95 Continuous Beams (Tables)Document8 paginiRcc95 Continuous Beams (Tables)Steve JsobÎncă nu există evaluări

- Continuous Concrete Beam Design To Bs 81101997 Table 3.5Document8 paginiContinuous Concrete Beam Design To Bs 81101997 Table 3.5sarv_kishoreÎncă nu există evaluări

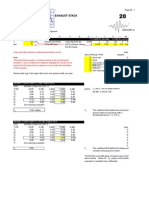

- Exhaust Stack: Engineering With The SpreadsheetDocument8 paginiExhaust Stack: Engineering With The SpreadsheetZain Saeed0% (1)

- Rotating Electrical MachinesDocument33 paginiRotating Electrical Machinesgurunathan14Încă nu există evaluări

- Shihlin Catalog 2Document23 paginiShihlin Catalog 2alvinÎncă nu există evaluări

- Designing Bevel Gears for a Speed ReducerDocument17 paginiDesigning Bevel Gears for a Speed ReducerherrerafaridÎncă nu există evaluări

- Ta38107 1 PDFDocument20 paginiTa38107 1 PDFVyasaraj KumarÎncă nu există evaluări

- Induction Motor DrivesDocument30 paginiInduction Motor DrivesAmit KumarÎncă nu există evaluări

- TM 11-5820-398-35Document201 paginiTM 11-5820-398-35Alexander J RokowetzÎncă nu există evaluări

- Document 1Document13 paginiDocument 1Prince SharmaÎncă nu există evaluări

- Aw-01-07 ColumnDocument14 paginiAw-01-07 ColumnalexanderÎncă nu există evaluări

- MD Handb2 Belt CalcDocument5 paginiMD Handb2 Belt Calcoana2507Încă nu există evaluări

- Wiring Diagram Schema Electrique: 30RA 100 B0921 PEE 0000269480Document13 paginiWiring Diagram Schema Electrique: 30RA 100 B0921 PEE 0000269480Dinu Muralidharan MÎncă nu există evaluări

- AS 3600 Concrete AmendmentDocument4 paginiAS 3600 Concrete AmendmentMohammad Hajy Aghababaei100% (1)

- Exhaust Stack: Engineering With The SpreadsheetDocument16 paginiExhaust Stack: Engineering With The SpreadsheetMakanjuola Ronald OlaitanÎncă nu există evaluări

- SMC MPC Multi Position Cylinder RodDocument14 paginiSMC MPC Multi Position Cylinder RodNut KhaopatumthipÎncă nu există evaluări

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pagini2 and 3 Genesis Series PD Meter SpecificationsMechanicalMarwanÎncă nu există evaluări

- DLM142EDocument28 paginiDLM142Eseaqu3stÎncă nu există evaluări

- Fast Cert Test CasesDocument38 paginiFast Cert Test CaseskometmayorÎncă nu există evaluări

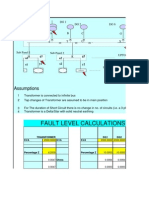

- Fault CalculationDocument15 paginiFault CalculationZIPDASHÎncă nu există evaluări

- Raft Slab DesignDocument5 paginiRaft Slab DesignLekins Sefiu Yekini100% (2)

- Hydraulic cylinders, lines, and fittings explainedDocument8 paginiHydraulic cylinders, lines, and fittings explainedYudha PrastyaÎncă nu există evaluări

- API 11AX 13th Edition Addendum 1 20190513Document16 paginiAPI 11AX 13th Edition Addendum 1 20190513john_progecoÎncă nu există evaluări

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pagini2 and 3 Genesis Series PD Meter Specificationsjimbo2032Încă nu există evaluări

- AISC 360 VerificationBeamDesign PDFDocument7 paginiAISC 360 VerificationBeamDesign PDFCarl Patrick Erni RagasÎncă nu există evaluări

- Designing A 100kHz 32 Watt Push-Pull ConverterDocument13 paginiDesigning A 100kHz 32 Watt Push-Pull Converterjayduy298136100% (1)

- GFM Marking - Smcj33a TvsDocument4 paginiGFM Marking - Smcj33a TvscraponzelÎncă nu există evaluări

- Fault CalculationDocument15 paginiFault CalculationsesabcdÎncă nu există evaluări

- ISODEL Interior 36kV HIP 300 TW PDFDocument7 paginiISODEL Interior 36kV HIP 300 TW PDFAngel Moreton FernanadezÎncă nu există evaluări

- Hydro Electric Project-Basic Layout For Francis, As Per Is, USBR and Other StandardsDocument15 paginiHydro Electric Project-Basic Layout For Francis, As Per Is, USBR and Other Standardsबिपन गुलेरियाÎncă nu există evaluări

- Re 15228 Radial Piston Hydraulic Motor With A Fixed DisplacementDocument36 paginiRe 15228 Radial Piston Hydraulic Motor With A Fixed Displacementraj8378100% (1)

- Ehp-3164439xxx AssyDocument3 paginiEhp-3164439xxx Assysantos_gurrolaÎncă nu există evaluări

- 2N6027Document9 pagini2N6027mariogizziÎncă nu există evaluări

- RCC94 Two-Way Slabs (Tables)Document4 paginiRCC94 Two-Way Slabs (Tables)Zayyan RomjonÎncă nu există evaluări

- Bus Bar Truncking Design For SandwichDocument31 paginiBus Bar Truncking Design For SandwichSanjeev Dhariwal100% (1)

- The Optimized Bridge-Leg Power Switch Circuit for Increased EfficiencyDocument4 paginiThe Optimized Bridge-Leg Power Switch Circuit for Increased EfficiencyefremofeÎncă nu există evaluări

- Engineering Materials and Design: Fatigue Analysis and Gearbox DesignDocument9 paginiEngineering Materials and Design: Fatigue Analysis and Gearbox DesignOliver RubioÎncă nu există evaluări

- Valvulas 2 y 3 inDocument65 paginiValvulas 2 y 3 inGabo Montaño MendozaÎncă nu există evaluări

- CSA S16 09 Example 001Document7 paginiCSA S16 09 Example 001thanzawtun1981Încă nu există evaluări

- Features Description: FM IF SystemDocument7 paginiFeatures Description: FM IF Systemlu1agpÎncă nu există evaluări

- CHAIN CalculationDocument18 paginiCHAIN CalculationDmitrijs MuhinsÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- 110 Waveform Generator Projects for the Home ConstructorDe la Everand110 Waveform Generator Projects for the Home ConstructorEvaluare: 4 din 5 stele4/5 (1)

- Shape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationDe la EverandShape Memory Alloy Actuators: Design, Fabrication, and Experimental EvaluationÎncă nu există evaluări

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysDe la EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysÎncă nu există evaluări

- Variable Speed AC Drives with Inverter Output FiltersDe la EverandVariable Speed AC Drives with Inverter Output FiltersÎncă nu există evaluări

- Design and Analysis of Centrifugal CompressorsDe la EverandDesign and Analysis of Centrifugal CompressorsÎncă nu există evaluări

- 2-2011-0316 Final DBB Construction BIM RFPDocument28 pagini2-2011-0316 Final DBB Construction BIM RFPmseif1980Încă nu există evaluări

- C2021pe 999 47 11Document2 paginiC2021pe 999 47 11mseif1980Încă nu există evaluări

- Margaret Sample 1 of 3Document3 paginiMargaret Sample 1 of 3mseif1980Încă nu există evaluări

- 172LOESCHEIndustrial MineralsEDocument20 pagini172LOESCHEIndustrial MineralsEmseif1980Încă nu există evaluări

- Physics Undergraduate BrochureDocument4 paginiPhysics Undergraduate Brochuremseif1980100% (1)

- Apartment LivingDocument33 paginiApartment LivingstdshopÎncă nu există evaluări

- 103 en Welding of Hardox V1 2014Document20 pagini103 en Welding of Hardox V1 2014Nguyen Duc DungÎncă nu există evaluări

- E 1220 ADocument9 paginiE 1220 Amseif1980Încă nu există evaluări

- Belt Conveyor Dynamic AnalysisDocument3 paginiBelt Conveyor Dynamic AnalysisAmit BhaduriÎncă nu există evaluări

- The Specification of TXDocument2 paginiThe Specification of TXmseif1980Încă nu există evaluări

- Series: Discrete Valve: Sub-Plate Porting 5 Port Pilot Operated Pneumatic ValveDocument14 paginiSeries: Discrete Valve: Sub-Plate Porting 5 Port Pilot Operated Pneumatic Valvemseif1980Încă nu există evaluări

- Scholarships Brochure 2016 17Document76 paginiScholarships Brochure 2016 17mseif1980Încă nu există evaluări

- 03 Lect 21 TowersDocument31 pagini03 Lect 21 TowersEric ChienÎncă nu există evaluări

- Aumund Products Chain Conveyor Drag Chain ConveyorDocument1 paginăAumund Products Chain Conveyor Drag Chain Conveyormseif1980Încă nu există evaluări

- BS en 1712 (1997)Document14 paginiBS en 1712 (1997)Taesik Kim100% (1)

- Drag Chain ConveyorsDocument20 paginiDrag Chain Conveyorsmseif1980Încă nu există evaluări

- Hot Gas Generator CCS-LT: Technical Data SheetDocument2 paginiHot Gas Generator CCS-LT: Technical Data Sheetmseif1980Încă nu există evaluări

- Are You Properly Specifying MaterialsDocument7 paginiAre You Properly Specifying Materialsrslama_lecturesÎncă nu există evaluări

- Pages From ISO 2148-2Document1 paginăPages From ISO 2148-2mseif1980Încă nu există evaluări

- Taim Oxide Screen StationDocument1 paginăTaim Oxide Screen Stationmseif1980Încă nu există evaluări

- Vibration Dampers for Stacks: Pads, TLDs & TMDsDocument7 paginiVibration Dampers for Stacks: Pads, TLDs & TMDsMarco FoglieriÎncă nu există evaluări

- Discrete Element Method - Wikipedia, The Free EncyclopediaDocument7 paginiDiscrete Element Method - Wikipedia, The Free Encyclopediamseif1980Încă nu există evaluări

- 10 CriticalDocument47 pagini10 Criticalmseif1980Încă nu există evaluări

- E - Mail: Info@saetpd - It - Internet: WWW - Saetpd.it C A P I T A L e S o C I A L e 1 - 5 0 0 - 0 0 0, 0 0 I N T - V e R S A T oDocument11 paginiE - Mail: Info@saetpd - It - Internet: WWW - Saetpd.it C A P I T A L e S o C I A L e 1 - 5 0 0 - 0 0 0, 0 0 I N T - V e R S A T omseif1980Încă nu există evaluări

- Earthquake Design Equipment SupportsDocument7 paginiEarthquake Design Equipment Supportsmseif1980Încă nu există evaluări

- Comb Manual IM 106 6888QSDocument36 paginiComb Manual IM 106 6888QSsathish2829Încă nu există evaluări

- Internship Report-1Document64 paginiInternship Report-1VIJAY SPÎncă nu există evaluări

- Data Collector 2.03.00Document20 paginiData Collector 2.03.00vyaskingÎncă nu există evaluări

- Digital Logic DesignDocument4 paginiDigital Logic DesignkiranÎncă nu există evaluări

- Peanut Brittle LabDocument2 paginiPeanut Brittle LabMary Bacon HillebrandÎncă nu există evaluări

- Core 3Document2 paginiCore 3RidhiÎncă nu există evaluări

- JETL industrial wastewater treatment reportDocument6 paginiJETL industrial wastewater treatment reportPremKumarÎncă nu există evaluări

- Describe The Physical Properties of Propylene Glycols.: PrintDocument4 paginiDescribe The Physical Properties of Propylene Glycols.: PrintKaarthicNatarajanÎncă nu există evaluări

- KALEKİMDocument18 paginiKALEKİMqaisalkurdyÎncă nu există evaluări

- Hdfs Default XML ParametersDocument14 paginiHdfs Default XML ParametersVinod BihalÎncă nu există evaluări

- Checkpoint Physics Notes Chapter 1-5Document5 paginiCheckpoint Physics Notes Chapter 1-5Siddhant Srivastava50% (2)

- SLTRT Service Level Testing Reporting ToolDocument110 paginiSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- Fisher Poistioner CatalogueDocument12 paginiFisher Poistioner CatalogueUsama IqbalÎncă nu există evaluări

- Boiler MaintenanceDocument144 paginiBoiler Maintenanceaziz100% (2)

- Premium Swab Rigs Since 1925Document8 paginiPremium Swab Rigs Since 1925fabricio3fabricio-1Încă nu există evaluări

- Catalogo - CATUDocument132 paginiCatalogo - CATUxis-zeroÎncă nu există evaluări

- High Build Epoxy Coating for Hulls and Ballast TanksDocument3 paginiHigh Build Epoxy Coating for Hulls and Ballast Tankskasosei0% (1)

- Maxxi Report FinalDocument7 paginiMaxxi Report FinalDepanshu Gola100% (1)

- Contactor Cap Lc1dDocument4 paginiContactor Cap Lc1dAlfiansyah Dharma Setia DjaketraÎncă nu există evaluări

- Us01cphy02 Unit 1 2014 THPDocument18 paginiUs01cphy02 Unit 1 2014 THPapi-264723824Încă nu există evaluări

- Trigonox101 PdsDocument3 paginiTrigonox101 PdsPaula RiveraÎncă nu există evaluări

- E380b PDFDocument12 paginiE380b PDFanaÎncă nu există evaluări

- CRSP ManualDocument140 paginiCRSP ManualCarlos Andrés Buenahora BallesterosÎncă nu există evaluări

- Checklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesDocument1 paginăChecklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesoliciakimÎncă nu există evaluări

- Human-Environment InteractionDocument3 paginiHuman-Environment Interactionapi-299100358Încă nu există evaluări

- Process Level ChartDocument2 paginiProcess Level ChartzaidinÎncă nu există evaluări

- Joy Global SolutionsDocument18 paginiJoy Global Solutionsjvr001100% (1)

- Ricoh 2090Document832 paginiRicoh 2090cosmin176100% (1)

- E Voting Requirement EnggDocument7 paginiE Voting Requirement EnggDeepak KulkarniÎncă nu există evaluări

- Flyer M 10id 12 ENDocument2 paginiFlyer M 10id 12 ENTrevor SalazarÎncă nu există evaluări