Documente Academic

Documente Profesional

Documente Cultură

Ep0194483a1 PDF

Încărcat de

SJ ChuaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ep0194483a1 PDF

Încărcat de

SJ ChuaDrepturi de autor:

Formate disponibile

09}

(12

Europaisches

Pat ent amt

European

Patent Office

Publication number:

0 1 9 4 4 8 3

Office

europeen

des brevets A1

EUROPEAN PATENT APPLI CATI ON

Application number: 86102208.5

Int. CI.4: B 01 D 53/ 22

^

B 01 D 13/ 00

Date of filing: 20.02.86

Priority 01.03.85 US 707299 Applicant: AIRPRODUCTS ANDCHEMICALS, INC.

01.03.85 US 707298 P.O. Box 538

Allentown, Pennsylvania 18105(US)

Date of publication of application:

@ Inventor: Pez, Guido Peter

17.09.86 Bulletin 86/38 3705 Vale View Drive

Allentown, PA18103IUS)

Designated Contracting States:

BE DE FR GB NL Inventor: Carlin, Richard Trotter

Idylwood Apts, Apt No. 666 Slate Creek Drive

Cheektowaga New York 14227(US)

Representative: Kador 8t Partner

Corneliusstrasse 15

D-8000Miinchen5(DE)

(54) Method for

gas separation.

57 A

process

for separating a gas

from a mixture of

gases

comprises passing the

gas

mixture over a membrane,

selectively permeable by the

gas being separated, owing to

one or more reversible reactions between a continuous layer

of active molten material, immobilized in a thin, rigid,

porous, inert support therefor, and the

gas being separated.

Techni cal F i e l d

This i n v e n t i o n r e l a t e s to an i mproved method of

s e p a r a t i o n of a

g a s

from

a

mi xt ur e of

gases

and to i mproved membranes f or the s e p a r a t i o n

p r o c e s s .

Background A r t

Numerous

appr oaches to the s e p a r a t i o n of

a

gas

from a mi xt ur e o f

gases by d i f f e r e n t i a l

per meat i on have been

i n v e s t i g a t e d . Robb et a l . , i n

U.S. Pat ent 3, 335, 545, have pr oposed use of

a l i qui d, e nt r a ppe d in

a

porous or pe r me a bl e s uppor t , to s e p a r a t e

mi xt ur es of

gas es .

The

use of a

s o - c a l l e d " q u a s i - l i q u i d f i l m, " f or exampl e, di e t hyl e ne g l y c o l ,

in

a

s uppor t

has p e r mi t t e d s e p a r a t i o n of car bon di oxi de from n i t r o g e n ,

hydrogen or

oxygen,

the s e l e c t i v i t y bei ng somewhat hi gher t han would be

p r e d i c t e d on the bas i s of the mol ecul ar wei ght s

of the

gases as the s o l e

f a c t o r , i n f l u e n c i n g s e p a r a t i o n . Ward, I I I , has pr opos ed, in U.S. P a t e n t

3, 503, 186, a s i mi l a r p r o c e d u r e for s e p a r a t i n g s ul f ur di oxi de from o t h e r

g a s e s .

The

use

of f a c i l i t a t e d

t r a n s p o r t l i qui d membranes has been r e vi e we d

by Way et a l . , J. Membrane Sci ence, vol . 12 (1982),

pages

239- 259.

Anot her t y p i c a l d i s c l o s u r e of ga s s e p a r a t i o n usi ng a

f a c i l i t a t e d

t r a n s p o r t i mmobi l i zed membr ane is t ha t of Bas s et t et a l . , Bi ochi mi ca e t

Bi ophys i ca Act a, vol . 211 ( 1970) ,

pages

194-215. F a c i l i t a t e d

t r a n s p o r t

of

gases t hr ough l i q u i d membranes is al s o r e c i t e d , f or

exampl e,

in t h e

f ol l owi ng U.S. P a t e n t s :

Wa r d , I I I , et al . ' 510 r e c i t e us i ng an

i mmobi l i zed

l i q u i d

f i l m as a

per meabl e membrane, wher ei n t he l i q u i d f i l m c ont a i ns at l e a s t one

s o l u b l e , n o n - v o l a t i l e , di s s ol ve d c a r r i e r s pe c i e s , which is r e v e r s i b l y

c h e mi c a l l y r e a c t i v e wi t h

a

s e l e c t e d

component

of

a gaseous

mi x t u r e .

Ki mura, et al . (U.S. Pa t e nt 4, 318, 714) have r e c i t e d us i ng a n

i on- e xc ha nge

membrane to a c c o mg l i s h f a c i l i t a t e d s e p a r a t i o n of a gas

f r o m

a mi xt ur e of

g a s e s .

Yanamot o, et al . (U.S. Pat ent 3, 155, 467) have d i s c l o s e d s e p a r a t i o n

and p u r i f i c a t i o n of

hydr ogen, usi ng a pal l adi um a l l oy as a per meabl e wa l l

s t r u c t u r e .

Sol i d and mol t en s a l t e l e c t r o l y t e s have. been d i s c l o s e d , in t he f u e l

c e l l or e l e c t r o c h e mi c a l a r t s , in t he f ol l owi ng r e p r e s e n t a t i v e p a t e n t s :

Yo s h i s a t o , et a l . , in U.S. Pa t e nt 4, 330, 633, r e c i t e us i ng a s o l i d

e l e c t r o l y t e compr i s i ng a s i n t e r e d

body

of mixed i nor ga ni c met al oxi des a s

a membrane for the r e g e n e r a t i o n of

oxygen

at r e l a t i v e l y hi gh t e mp e r a t u r e s

( about 800 C) .

Oxygen is known to

per meat e s e l e c t i v e l y t hr ough me t a l l i c s i l v e r .

However,

oxygen

f l uxe s at r eas onabl e

t e mpe r a t ur e s ( about 400C)

are l ow,

as r e p o r t e d by Gr yaznov, et a l . , Rus s i an. J. Phys. Chem., vol . 47 ( 1973) ,

pages

1517- 1519. At hi gher t e mp e r a t u r e s , me t a l l i c membranes f or t h e

s e p a r a t i o n of

oxygen

from ot her

gases are u n s t a b l e , s e e Mul ha upt , U. S.

Pat ent 3 , 3 5 9 , 7 0 5 .

A l i mi t i n g f e a t ur e in

many

of t hese d i s c l o s u r e s is t ha t

a gas

s h o u l d

not c ompl e t e l y per meat e the e l e c t r o l y t e or e l e c t r o d e , s i nce c ompl e t e

p e n e t r a t i o n coul d s hor t c i r c u i t the d e v i c e .

Bat l gne et a l . , U.S. Pat ent 4, 396, 572, r e c i t e

usi ng a por ous

c e r a mi c

b a r r i e r , havi ng a p l u r a l i t y of super i mposed l a ye r s of

pa s t e s

of

v a r y i n g

c ompos i t i on, to

s e pa r a t e

urani um h e x a f l u o r i d e i s ot opes by u l t r a f i l t r a t i o n .

I t is

a ppa r e nt

t hat p r e s e n t l y

a v a i l a b l e membranes for

s e p a r a t i o n o f

gases by d i f f u s i o n , per meat i on or

u l t r a f i l t r a t i o n

are for the most

p a r t

r e l a t i v e l y u n s e l e c t i v e or complex in s t r u c t u r e .

I t is t h e r e f o r e

an obj e c t o f t h i s i nve nt i on to pr ovi de met hods a nd

a r t i c l e s of t he s e p a r a t i o n of

gases

from mi xt ur e s , which are much

mor e

hi ghl y

s e l e c t i v e and have hi gher f l uxes of per meat i ng

gas

t han

p r e s e n t l y

a v a i l a b l e met hods and to pr ovi de membranes which

are si mpl e to c o n s t r u c t

and to u s e .

Di s c l os ur e of I n v e n t i o n

In

one a s p e c t ,

t hi s i nve nt i on r e l a t e s to a pr ocess

f or

s e p a r a t i n g a t

l eas t

one gas

from

a mi xt ur e of

gas es ,

compr i s i ng pas s i ng the

gas

mi x t u r e

over a membrane s e l e c t i v e l y per meabl e to the

gas

bei ng s e p a r a t e d as a

r e s ul t of

one or more r e v e r s i b l e r e a c t i o n s , i nc l udi ng o x i d a t i o n - r e d u c t i o n

r e a c t i o n s , bet ween the

gas bei ng s e pa r a t e d

and

an

a c t i ve ma t e r i a l in t h e

membrane; wher ei n the membrane compr i ses a t hi n,

por ous,

i ne r t

s uppor t

i n

which is i mmo b i l i z e d t h e a c t i v e ma t e r i a l and the act i ve ma t e r i a l is

a

mol t en s a l t , p r e f e r a b l y capabl e of one or more

r e v e r s i b l e r e a c t i o n s wi t h

the

gas bei ng s e p a r a t e d .

In a not he r

a s pe c t ,

t h i s i nve nt i on r e l a t e s to a

pr oces s

f o r

s e p a r a t i n g a gas

from at l e a s t

one ot her

gas

in

a

mi xt ur e

by

the

s t eps

o f

i nt r oduc i ng the mi xt ur e i nt o a module havi ng at l eas t

a feed

gas

i n l e t

and a per meat e gas

out l e t and c ont a i ni ng a membrane s e l e c t i v e l y pe r me a bl e

to the

gas

bei ng s e p a r a t e d ,

which membrane compr i ses a t hi n,

porous

i n e r t

suppor t

in which an a c t i ve ma t e r i a l is i mmobi l i zed wi t hi n the

p o r e s ,

whi ch membrane has

a

i n l e t si de and a per meat e

si de and which a c t i v e

ma t e r i a l i s a

mol t en s a l t capabl e of under goi ng one or more r e v e r s i b l e

r e a c t i o n s , wi t h

t he gas bei ng s e p a r a t e d ; pas s i ng the mi xt ur e

t hr ough t h e

f eed i n l e t and i nt o c o n t a c t wi t h t he i n l e t si de of the membrane; r emovi ng

from t he i n l e t si de of t he membrane a

gas

st ream r e j e c t e d by the membrane

and

r emovi ng

from the

per meat e gas

o u t l e t the

gas pas s i ng by

r e a c t i o n

t hr ough the membr ane.

In s t i l l a not he r a s p e c t , t h i s i n v e n t i o n r e l a t e s to a me mb r a n e f o r

gas s e p a r a t i o n p r o c e s s e s ,

c ompr i s i ng a t hi n,

por ous,

i n e r t

s uppor t

i n

whi ch is i mmobi l i zed

a

mol t en a c t i v e s a l t , capabl e of

under goi ng one o r

more

r e v e r s i b l e r e a c t i o n s , ot he r t han o x i d a t i o n - r e d u c t i o n r e a c t i o n s , wi t h

t he

gas

bei ng s e p a r a t e d .

" S a l t , " as used in t he s p e c i f i c a t i o n and cl ai ms , means a s u b s t a n c e

which i s compr i s ed of c a t i ons and ani ons and which is c h a r a c t e r i z e d

by

o v e r a l l e l e c t r i c a l n e u t r a l i t y . The c a t i ons and ani ons

may

be i n o r g a n i c ,

or ga ni c or a combi nat i on of bot h. I t wi l l be under s t ood t ha t s a l t s ha ve

a wide

range

of

mel t i ng poi nt s and t h a t , for the

pur poses

of t h i s

i n v e n t i o n , t he me l t i ng poi nt of t he s a l t used as a c t i ve ma t e r i a l is t h e

minimum

t e mp e r a t u r e , at which the membranes of t hi s i nve nt i on can be u s e d

f or s e p a r a t i o n of a

gas

from

a mi xt ur e of

g a s e s .

" I mmobi l i z e d, " as used in the s p e c i f i c a t i o n and cl ai ms , r e f e r s t o

mol t en a c t i ve ma t e r i a l , c a pt ur e d wi t hi n the

por es

or i n t e r s t i c e s of t h e

cer ami c or ot he r

s uppor t , as

wel l

as

any

ma t e r i a l in the form of

a t h i n

f i l m of s a l t mel t on t he s ur f a c e of t he s uppor t . Al t hough t he mo l t e n

s a l t need not n e c e s s a r i l y f i l l t he e n t i r e v o i d volume o f t h e

p o r o u s

s uppor t ,

i t is be l i e ve d

t ha t a t hi n cont i nuous l ayer

of mol t en s a l t in

o r

on t he

s uppor t i s n e c e s s a r y

f or the s u c c e s s f u l ope r a t i on of the membr anes.

" Re v e r s i b l e r e a c t i o n , " as used in the s p e c i f i c a t i o n and c l a i ms

e s s e n t i a l l y means a chemi cal r e a c t i o n which

can go

f or war d to the

r i g h t

or backwar ds to the l e f t , dependi ng upon

the r e l a t i v e c o n c e n t r a t i o n s o f

r e a c t a n t s and pr oduct s at a n y t i me . One

type

of r e v e r s i b l e r e a c t i o n

wi t hi n the meaning

of the i nve nt i on is f or mat i on of

a

c o o r d i n a t i o n

compl ex. A c o o r d i n a t i o n

complex or

c o o r d i n a t i o n compound c o n s i s t s of a

c e n t r a l atom or i on, s ur r ounde d by a s et of ot her at oms, i ons or s ma l l

mol e c ul e s . The at oms, ions or mol ecul es s ur r oundi ng t he c e n t r a l atom

a r e

c o n v e n t i o n a l l y c a l l e d l i ga nds . The r e s u l t i n g e n t i t y is

g e n e r a l l y a

complex and, s p e c i f i c a l l y ,

in the p r a c t i c e of t hi s i n v e n t i o n is a compl ex

i on. The

gas

bei ng s e p a r a t e d

from the mi xt ur e wi l l

a c c o r d i n g l y be a

l i ga nd in t hi s compl ex i o n .

Typi cal exampl es

of c o o r d i n a t i o n compounds

i nc l ude e n t i t i e s such a s

- +3 +3 ++

PF6. Cr(CO6), Cr(NH3)6+3, CO(NH3)6+3, CoCl4

and Zn(NH3)2++. The

compl exes

us ef ul in accor dance with t hi s i nve nt i on wi l l be t hose f or med

by an

ion of a s a l t , whet her a

cat i on or an a n i o n .

In a r e p r e s e n t a t i v e cas e,

the s e p a r a t i o n of ammonia from

ni t r oge n i n

c ont a c t wi t h a membrane compr i s i ng mol t en zinc c h l o r i d e , i t is p r o p o s e d

t hat the zi nc c h l o r i d e in t hi s ammoni a- r i ch envi r onment r e a c t s r e v e r s i b l y

to form

a

zi nc ammoni at e c o o r d i n a t i o n compound, Zn(NH3)++. The

i n i t i a l c o n d i t i o n o f a c r o s s - s e c t i o n of the membrane is

t hought to be

t hat de pi c t e d be l ow:

The zi nc ammoniate i ons t hus formed at the f eed si de wi l l d i f f u s e

t owa r d t he

per meat e s i de , where t her e is a lower c o n c e n t r a t i o n of s uc h

i ons. At the

per meat e

si de

membrane-gas i n t e r f a c e , where t her e is

a much

l ower p a r t i a l

p r e s s u r e

of ammonia, the zinc ammoniate i ons w i l l

r e v e r s i b l y d i s s o c i a t e back i nt o zi nc ions and f r ee ammonia, which i s

removed as the

per meat e s t r e a m.

The

s t eady s t a t e c o n d i t i o n of the membrane is shown in the di agr am

bel ow, wher ei n the zi nc i ons thus formed at the

per meat e

si de d i f f u s e

back to a r e g i o n o f l ower c o n c e n t r a t i o n at the feed s i de, t hus c o mp l e t i n g

the o v e r a l l cycl e, whi ch amounts to net t r a n s p o r t

of ammonia

t hr ough t he

membrane. This net t r a n s p o r t

of ammonia t hrough the membrane a r i s e s f r om

the r e v e r s i b l e r e a c t i v i t y of ammonia with zinc ions and the

mobi l i t y o f

t he z i n c i o n s and zi nc ammoni at e i ons in t he mol t en s a l t . Chl or i de a c t s ,

i n t h i s exampl e, to pr ovi de e l e c t r i c a l

n e u t r a l i t y .

The ot her f eed

gas, n i t r o g e n , does not r e a c t wi t h the mol t en s a l t .

Si nce t her e is

no mechani sm

by wh i c h n i t r o g e n can be

t r a n s p o r t e d a c t i v e l y

t h r o u g h t he membr ane, i t r emai ns l a r g e l y on t he f eed si de and a n

e x c e l l e n t o v e r a l l s e p a r a t i o n of ammonia n i t r o g e n is t hus a c h i e v e d .

Al t hough t he f o r e g o i n g gi ves a pr oposed t h e o r e t i c a l e x p l a n a t i o n o f

t he mechani sm

by

which t he

pr oc e s s

of t he p r e s e n t

i nve nt i on

o p e r a t e s , i t

wi l l b e unde r s t ood t ha t t he i n v e n t o r s do not . wi s h to be bound by s u c h

e x p l a n a t i o n

and

r e l y on t he appended

cl ai ms to def i ne the i n v e n t i o n .

In p r a c t i c e , p r e f e r r e d s e p a r a t i o n s empl oyi ng c o o r d i n a t i o n c ompl e xe s

ar e t hos e wh e r e i n :

(a) f us ed mol t en l i t h i u m n i t r a t e is used f or the s e p a r a t i o n

o f

ammonia from n i t r o g e n or hydr ogen or a mi xt ur e t h e r e o f , p r e f e r a b l y f r om

n i t r o g e n , b y t he r e v e r s i b l e f or ma t i on of

a l i t hi um ammoniate in t he me l t ;

(b) ammonia is

s e p a r a t e d

from

hydr ogen or n i t r o g e n usi ng mol t en z i n c

c h l o r i d e as

t h e a c t i v e ma t e r i a l in t he membrane and the complex

formed i n

t he mel t is

a mono or di ammoni at e; a n d

(c) wat er i s

s e p a r a t e d from

oxygen,

n i t r o g e n or ai r

by

f or ma t i on o f

one or more d i s s o l v e d

hydr a t e compl exes in a mel t of l i t hi um and s odi um

n i t r a t e s .

Anot her t ype of r e v e r s i b l e r e a c t i o n , a p p r o p r i a t e for t he p r a c t i c e o f

t h i s i n v e n t i o n is an a c i d - b a s e r e a c t i o n . This

t ype

of r e a c t i on i n c l u d e s

t h o s e of Ar r heni us a c i d s , Lowr y- Br ons t ed aci ds and Lewis aci ds a n d

b a s e s .

A

r e p r e s e n t a t i v e embodi ment of

a s e p a r a t i o n i nvol vi ng an

a c i d - b a s e

r e a c t i o n is the s e p a r a t i o n

of car bon di oxi de from

a

mi xt ur e of

g a s e s ,

usi ng as the a c t i ve membrane i n g r e d i e n t a mol t en

t e t r a a l k y l a mmo n i u m

c a r b o x y l a t e s a l t .

Al kyl can be the same or d i f f e r e n t

a l kyl

of 1 - 24

car bon atoms and is

p r e f e r a b l y of 1 - 10 car bon at oms. The c a r b o x y l a t e

can have

any

ani on r a d i c a l whi c h wi l l

give a

s a l t of t he mel t i ng p o i n t

r ange,

d e s i r e d f or o p e r a t i o n of the membrane. Tet r ahexyl ammoni um

benzoat e (THAB) is

p a r t i c u l a r l y p r e f e r r e d .

These

t e t r a a l kyl a mmoni um c a r b o x y l a t e s can

al s o be used for t h e

s e p a r a t i o n of

hydr ogen s u l f i d e from ot her

g a s e s .

A f u r t h e r r e v e r s i b l e r e a c t i o n , u t i l i z e d in the p r a c t i c e of t h i s

i n v e n t i o n , is f or ma t i on of

an or gani c chemi cal

compound, which is

c a p a b l e

of

s pont aneous f or ma t i on and d i s s o c i a t i o n at the

t e mp e r a t u r e

of

o p e r a t i o n

of the membrane. For exampl e, t et r aal kyl ammoni um s a l t s o f amino a c i d s

can r eact r e v e r s i b l y wi t h car bon di oxi de to form c a r ba ma t e s . Th i s

r e a c t i o n

can be used f or t he

s e p a r a t i o n

of carbon di oxi de from o t h e r

gases. Alkyl can be the

same or

d i f f e r e n t

al kyl of 1-24 car bon atoms. A

p r e f e r r e d embodiment is t ha t in which the amino aci d is gl yc i ne o r

s a r c os i ne and the al kyl i s of 1-10 car bon atoms. In t he

case

o f

s a r c o s i n e , the r e l e v a n t r e a c t i o n i s :

' I t is

pr oposed t hat s e p a r a t i o n

of ammonia, based on f or ma t i on o f

c o o r d i n a t i o n

compl exes wi t h zi nc c h l o r i d e ,

may

be

gover ned accor di ng t o

chemi cal

p r o p e r t i e s set f o r t h

by

Krasnov et a l . , "Tabl es and Diagrams o f

Thermodymanic Pr o p e r t i e s of Zinc Chl or i de Ammoniates in

Vapor and Li q u i d

Phas es , " Moskov.

Vsesoyuznyy Topl o- Te khni c he s ki y I n s t i t u t e . I n v e s t i y a ,

Moscow, n o . l l ( 1 9 3 5 ) ,

pages

44-49; St ar okadomskaya,

" S a t u r a t i o n P r e s s u r e

of Ammonia

During the Thermal Decompos i t i on of the Diammonium Sal t o f

Zinc Ch l o r i d e , " Zhur nal Pr i k l a d n o y Khi mi i , vol . 9 (1935 or 1936),

pa ge s

599-602; Zubakhi na, " I n v e s t i g a t i o n of Complexing in the

ZnCl2-NH3

Syst em, " Trudy Na u c h n o - l s s l e d o v a t e k ' s k o g o I n s t i t u t e Osnovnoi Khi mi i , v o l .

19 ( 1969) ,

pages

105- 110.

S o l u b i l i t y

be ha vi or of ammonia in mel t s of a l k a l i n i t r a t e a nd

p e r c h l o r a t e

is d i s c u s s e d b y Al l u l l i , J. Phys. Chem. , vol 73( 1969) ,

p a g e s

1084- 1087.

-

P r o p e r t i e s of c h l o r o a l u mi n a t e s , which

might be

germane

to the

use o f

mol t e n

cupr ous

c h l o r i d e c o o r d i n a t i o n compl exes, e . g . ,

(C2H5)3NH+ CuCl2-

or (C2H5)3 NH+CuCl 2- as

a c t i ve ma t e r i a l s f or the c o o r d i n a t i o n

of car bon monoxi de, ar e r e por t e d by Wal ker, "Sol i d and Li qui d Pha s e s

Co n t a i n i n g

CuAICI4, "

Symposium on

Advances in

Se pa r a t i on Te c hnol ogy,

p r e s e n t e d bef or e t he Di v i s i o n of Pet r ol eum Chemi s t r y, I nc . , S e a t t l e

Meet i ng, March, 1983,

pages

746-755; Kendal l , et a l . , "A St udy

of t h e

Fa c t o r s I n f l u e n c i n g Compound

For mat i on and S o l u b i l i t y

in Fused S a l t

Mi x t u r e s , " J. Am. Chem. Soc. , vol . 45 (1923)

pages

963, f f ; Hus s e y,

"Room

Te mpe r a t ur e

Mol t en Sal t Syst ems, Mamantov et a l . , ed. , Advances i n

Mol t en Sa l t Chemi s t r y 5, El s e v i e r , New York ( 1983) ,

pages

185-219;

H u s s e y

et a l . , "The El e c t r o c h e mi s t r y " o f Copper

in

a Room

Temper at ur e

Ac i d i c

Ch l o r o - a l u mi n a t e Me l t , " J. El ect r ochem. Soc. : So l i d - St a t e Sci ence a nd

Te c hnol ogy, v o l . 1 2 6 1979),

pages

1029-1034; and

Hussey, Mamantov e d . ,

Advances in Mo l t e n Sa l t Chemi s t r y 5,

pages

219- 223.

The r e a c t i o n of s i l v e r (1) compounds havi ng har d c o u n t e r i o n s ;

e . g . ,

AgBF4, AgC104,

wi t h o l e f i n s is r e c i t e d by Cot t on et a l . , "Advanced

I n o r g a n i c Chemi s t r y A Compr ehensi ve Text , " John Wiley & Sons, New Yor k

( 1980) ,

pages

9 7 1 - 9 7 2 . I t is

expect ed t hat the r e por t e d complex f o r ma t i o n

of monoval ent s i l v e r compounds

wi t h o l e f i n s coul d be e xpl oi t e d f o r

s e p a r a t i n g o l e f i n s from

a gas

mi xt ur e c o n t a i n i n g t hem.

Anot her r e v e r s i b l e r e a c t i o n is a " Re ve r s i bl e o x i d a t i o n - r e d u c t i o n

r e a c t i o n , " whi ch

as used in the

s p e c i f i c a t i o n

and cl ai ms

e s s e n t i a l l y

means an o x i d a t i o n - r e d u c t i o n r e a c t i o n which

can go

f or war d to the r i g h t

or

in

r e v e r s e to t he l e f t , dependi ng

upon

the r e l a t i v e c o n c e n t r a t i o n s o f

r e a c t a n t s a n d pr oduc t s at

any

t i me. Re p r e s e n t a t i v e r e a c t i o n s i n c l u d e

i n t e r c o n v e r s i o n bet ween n i t r a t e and n i t r i t e i o n s :

It is pr opos ed

t hat oxi des

are pr oduced by

r e a c t i ons such

a s :

and t hat the oxi des in the mel t , i nc l udi ng one or more of

0=, 02=

and

02r

c a t a l y z e the r e a c t i o n .

Anot her

t ype of o x i d a t i o n - r e d u c t i o n r e a c t i o n which can be e x p l o i t e d

in the

p r a c t i c e

of t hi s i nve nt i on i nc l ude s i n t e r c o n v e r s i o n o f

oxygen- oxi de s p e c i e s :

A

f u r t h e r e x e mp l a r y o x i d a t i o n - r e d u c t i o n r e a c t i o n is t hat i n v o l v i n g

o x i d a t i o n of

hydr ogen by hydr oxi de i o n s :

In a r e p r e s e n t a t i v e case, an a l k a l i met al n i t r a t e mol t en s a l t

membrane is f i r s t a c t i v a t e d by a l l owi ng some

of the n i t r a t e

(NO3)

ions to l ose

oxygen

and to f o r m n i t r i t e

(NO2)

i ons in the me l t

s p ont a n e o us l y, as

r e s u l t of h e a t i n g .

The worki ng mol t en s a l t membrane wi l l t hus cont ai n both an a l k a l i

met al n i t r a t e and an

a l k a l i metal n i t r i t e . The ope r a t i on

of the membrane

can be f u r t h e r v i s u a l i z e d as f o l l o w s :

At the feed si de of the membrane, ni t r oge n and

oxygen

are

in c o n t a c t

wi t h the s ur f ace of t he a l k a l i metal n i t r a t e / n i t r i t e mel t . The i n i t i a l

c o n d i t i o n i s as d e p i c t e d in t he f ol l owi ng c r o s s - s e c t i o n a l di agr am of t h e

membr ane:

The exces s

c o n c e n t r a t i o n of n i t r a t e ions at t he feed si de of t h e

membrane wi l l

promot e

t h e i r d i f f u s i o n t owar ds the

per meat e

s i de. At t h i s

i n t e r f a c e , t he r e i s

a much l ower p a r t i a l pr e s s ur e

of

oxygen,

t han at t h e

f eed i n t e r f a c e ; t h e r e f o r e , n i t r a t e i ons wi l l

r e v e r s i b l y d i s s o c i a t e i n t o

n i t r i t e i ons and l i b e r a t e

oxygen,

which is removed in the

p e r me a t e

s t r e a m. The s t e a dy s t a t e c o n d i t i o n of t he membrane is shown in t h e

di agr am bel ow, in which n i t r i t e i ons t hus formed at the

per meat e

s i d e

d i f f u s e back to a r egi on of l ower c o n c e n t r a t i o n at the feed si de t o

c o mp l e t e t h e o v e r a l l

c yc l e ,

which amount s t o n e t t r a n s p o r t

of

oxyge n

t hr ough

t he membrane. The net

t r a n s p o r t

of

oxygen

a r i s e s from r e v e r s i b l e

r e a c t i v i t y

of

oxygen

wi t h n i t r i t e i ons and mo b i l i t y of the n i t r i t e a n d

n i t r a t e i ons in t he s a l t .

The ot her feed

gas, ni t r oge n, does not r eact wi t h the mol t en s a l t .

Because t her e is

no

mechanism

by

which

n i t r o g e n can be a c t i v e l y

t r a n s p o r t e d t hr ough the mel t , i t wi l l be l a r g e l y r e j e c t e d at the f e e d

si de of the membrane., In t hi s

way,

e x c e l l e n t

s e p a r a t i o n

of n i t r o g e n and

oxygen

is a c h i e v e d .

Al t hough t he f or e goi ng gi ves an at t empt t o p r o v i d e a t h e o r e t i c a l

e x p l a n a t i o n

of the mechanism of the

pr oc e s s

of t he pr es ent i nve nt i on, i t

wi l l be under s t ood t hat the i nve nt or s do not wi sh to be bound by s u c h

e x p l a n a t i o n and r el y on the appended cl ai ms to def i ne the i n v e n t i o n .

It is

pr oposed t hat the

use

of

an

a l k a l i met al n i t r a t e mel t membrane

for s e p a r a t i o n of

oxygen

from ai r r e l i e s on the n i t r a t e - n i t r i t e

i n t e r c o n v e r s i o n . However, the r e a c t i on bet ween

oxygen

and oxi de s p e c i e s

may

al s o be o c c u r r i n g , as di s c us s e d more f u l l y by Zambonin, et a l . , J .

Am. Chem. Soc. , vol . 91 (1969),

pages

2225- 2228; Zamboni n,

E l e c t r o a n a l y t i c a l Chemi st r y and I n t e r f a c i a l El e c t r o c h e mi s t r y , vol . 45

( 1973) ,

pages

451-458 and Fl i nn et a l . , J. El e c t r o a n a l . Chem., vol 63

( 1975) ,

pages

39- 57.

It is al s o known t hat ot her mol t en s a l t syst ems

r eact r e v e r s i b l y

wi t h

oxygen

by

pr oc e s s e s i nvol vi ng e q u i l i b r i a wi t h reduced

oxygen

s p e c i e s , p a r t i c u l a r l y oxide ( O )

per oxi de

L02)

and

s u p e r o x i d e

(02).

For exampl e,

i t has been

r e por t e d

t hat

Na2O-Na2SO4

mel t s t ake

up oxygen r e v e r s i b l y at 920C, pr es umabl y by the r e a c t i o n s :

St er n et a l . , J. Phys. Chem. vol . 83 ( 1979) ,

pages

2848-2854. It is a l s o

t hought

t hat redox e q u i l i b r i a , i n v o l v i n g the decompos i t i on of s u l f a t e t o

s u l f i t e and

gaseous

s ul f ur di oxi de, are

i n v o l v e d .

It is

expect ed t hat

hydr oge n- hydr i de i n t e r c o n v e r s i o n in mo l t e n

a l k a l i met al hydr oxi de membranes of the i nve nt i on would

oper at e

i n

accor dance wi t h the behavi or r e por t e d by Bai kov, et a l . , " Ac t i va t i on o f

Mol ecul ar

Hydrogen by

Sol i d and Fused Hydr oxi des . I I I . Ki net i cs and

Mechanism of I s ot ope Exchange Between Hydrogen and Sol ut i ons of Water i n

Al kal i Mel t s" and "IV. The Role of Cat i ons in the

Ca t a l ys i s

o f

Homomol ecul ar Exchange of Hydrogen on Sol i d Hydr oxi de s , "

K i n e t i k a i

Ka t a l i z , vol . 23 ( 1982) ,

pages

573-577 and vol . 24 ( 1983) ,

p a g e s

5 0 2 - 5 0 5 .

Re v e r s i b l e

oxygen upt ake

from

Na 0-NaCl

mel t s is al s o known,

St e r n , et a l . , J. El ect r ochem. Soc. , vol . 124 ( 1977) ,

pages

641- 649.

Cupr ous

c h l o r i d e - a l k a l i me t a l h a l i d e mel t s ,

e . g . , CuCl - CuCl 2- KCl ,

are

a l s o known to r e a c t r e v e r s i b l e wi t h

oxygen, pr oba bl y by t he r e a c t i o n :

Font ana, et a l . , Ind. Eng. Chem., vol . 44 ( 1952) ,

pages

369- 378.

Because of the compl exi t y of t he redox

pr oc e s s e s t hought to occur i n

s a l t me l t s , i t is unde r s t ood t hat t he

pr oc e s s e s

of t h i s i nve nt i on i n c l u d e

t r a n s f e r of

ga s e s , capabl e of under goi ng an o x i d a t i o n - r e d u c t i o n r e a c t i o n

wi t h a mol t en s a l t , i mmobi l i zed in

a s uppor t , r e g a r d l e s s of t he mechani sm

by

whi ch t he

pr oc e s s a c t u a l l y t akes p l a c e .

I t wi l l be unde r s t ood t ha t the r e v e r s i b l e r e a c t i o n s , a p p r o p r i a t e

f o r

use

in t he p r a c t i c e of t hi s i nve nt i on, are not l i mi t e d to t hose set f o r t h

a b o v e .

The membranes of the pr e s e nt

i n v e n t i o n are r e p r e s e n t e d

ma c r o s c o p i c a l l y in

Fi g. 1, f or the s e p a r a t i o n

of

a per meabl e

gas

(A) f r om

a

mi xt ur e of

gases

A and B. The

por ous

s ol i d s uppor t

is a r i gi d, o r

s l i g h t l y f l e x i b l e , i n e r t ma t e r i a l , s e l e c t e d from me t a l l i c , pol ymer i c o r

cer ami c s u b s t r a t e s . The

s uppor t

ma t e r i a l is f i l l e d

or coat ed wi t h a t

l e a s t a c ont i nuous

l ayer

of the s e l e c t e d mol t en s a l t , or mi xt ur e t h e r e o f .

The f eed

gas pas s es over t he feed si de of the membrane, as shown

by t h e

mi xt ur e A + B on the

upper

si de of Fi g. 1. The r e a c t i v e member of t h e

gas

mi xt ur e wi l l

undergo one or more r e v e r s i b l e r e a c t i o n s wi t h ions i n

t he mol t en s a l t , as

di s c us s e d above.

Eve nt ua l l y, at s t e a dy s t a t e

c o n d i t i o n s , the r e a c t i v e

gas

(A) per meat es the membrane. In a n

e xpe r i me nt a l c ont e xt , the

r e a c t i ve or per meat e gas

(A) is removed f r om

the syst em by an i ne r t

sweep gas

and a sample of the

sweep gas

st ream i s

t r a n s f e r r e d to a gas chr omat ogr aph

f or

a n a l y s i s . In a l ar ge

s c a l e

u t i l i z a t i o n of the i nve nt i on, i t wi l l be p r e f e r r e d to exhaus t

pe r me a t e

gas

from the

syst em

with

a compr es s or

and t r a n s f e r

r e l a t i v e l y pur e

per meat e gas

to a pr ocess

r e q u i r i n g

i t or to c o n t a i n e r s .

I t is

pr opos ed t hat the

gas pr e s s ur e ,

r e qui r e d to di s pl a c e l i q u i d

t hat is i mmobi l i zed by c a p i l l a r y

f or ces from the

pores

of a porous

we t t e d

membrane, conforms to the e qua t i on ( Por t e r , "Handbook of S e p a r a t i o n

Techni ques f or Chemi cal En g i n e e r s , " S c h we i t z e r , ed. , Mc Gr a w- Hi l l ( 1979) ,

Appendi x A,

page

2- 89) :

wher ei n Y is t he s ur f ace t e n s i o n of the g a s - l i q u i d i n t e r f a c e , 0 is t h e

c ont a c t angl e bet ween the l i q u i d and the

pore

wal l and d is the

pore

s i z e .

In q u a l i t a t i v e t erms, the s a l t or mi xt ur e of s a l t s s e l e c t e d f or t h e

membrane wi l l be f l u i d at the t e mpe r a t ur e

of

use,

but the melt wi l l n o t

have an

e xc e s s i ve r at e of flow

or t endency to dry out or mi gr at e

from t h e

i ne r t

s uppor t .

The s a l t wi l l be e s s e n t i a l l y n o n - v o l a t i l e under c o n d i t i o n s

of u s e .

Al t hough membranes, c ompr i s i ng a monomol ecul ar l ayer

of a c t i v e

mol t en s a l t in t he i ner t

s uppor t

wi l l f unc t i on in accor dance wi t h t h e

i nve nt i on, i t is p r e f e r r e d to use membranes, havi ng a cont i nuous f i l m o f

mol t en a c t i ve s a l t i mmobi l i zed in and l ayer ed on

the

s uppor t , or a

combi nat i on t h e r e o f . Membranes meet i ng t hi s c r i t e r i o n wi l l have a

r e l a t i v e l y low

p e r me a b i l i t y to a

n o n - r e a c t i v e

gas

at 760 t or r at t h e

t e mpe r a t ur e of

u s e , a s

measur ed a ga i ns t

the backgr ound cont ent of i n e r t ,

n o n - r e a c t i v e

sweep gas on the

per meat e

si de of the membrane. In a

p r e f e r r e d case,

the

p e r me a b i l i t y of ni t r oge n as the i ner t

gas

is s e l e c t e d

as a s t a nda r d and is below 20 Bar r er under t hes e c o n d i t i o n s .

The

s uppor t

is s e l e c t e d from cer ami c, g l a s s ,

me t a l l i c and

o r g a n i c

pol ymer i c ma t e r i a l s , s t a bl e at the t emper at ur e

of

use,

which

are e i t h e r

r i gi d or s l i g h t l y f l e x i b l e and which do not r e a c t wi t h the a c t i ve mo l t e n

s a l t or wi t h the

gas

mi xt ur e

bei ng t r e a t e d . A p r a c t i c a l lower l i mi t f o r

the t hi c kne s s of

s e l f - s u p p o r t i n g membranes is below 0.01 c e n t i me t e r s , b u t

some

t hi nne r ma t e r i a l s

may

l ack the r i g i d i t y r e qui r e d. However,

u l t r a f i n e

porous

cer ami c f i l ms , l ess than 20 mi cr omet er s in t hi c kne s s

a r e

known, Leemaars et a l . , J. Ma t e r i a l s Sci ence, vol . 19( 1984) ,

pa ge s

1077-1088. It wi l l be unde r s t ood t hat the

s uppor t can be coat ed o r

a d h e r e d t o a n o t h e r ma t e r i a l ,

u s u a l l y

of

g r e a t e r p o r o s i t y , which wi l l

pr ovi de t he s t r u c t u r a l r i g i d i t y r e q u i r e d .

For exampl e, a " c ompos i t e " or "asymmet r i c" membrane, as de s c r i be d i n

Sc h we i t z e r , "Handbook of Se p a r a t i o n Techni ques

f or Chemi cal

En g i n e e r s , "

McGraw Hi l l ( 1 9 7 9 ) , p a g e s 2-19 to 2- 26, c ont e mpl a t e d f or

use

in t h e

p r a c t i c e

of t h i s i n v e n t i o n woul d have a

t hi n f i n e l y

por ous l a y e r ,

c o n t a i n i n g t he a c t i v e mol t en s a l t , s uppor t ed

f u r t h e r on a ma c r opor ous

s uppor t c o mp r i s i n g pol yme r i c , cer ami c or

me t a l l i c ma t e r i a l .

I t i s f u r t h e r p r e f e r r e d t ha t t he s uppor t

have a por e

s i ze of 0 . 0 0 3 -

100 mi c r o me t e r s . It wi l l be a p p r e c i a t e d t hat l ar ge

e f f e c t i v e membrane

a r e a s c a n be a t t a i n e d by us i ng a p l u r a l i t y of s mal l er membr anes,

c onne c t e d

by a ma ni f ol d

or ot he r connect i ng means, or t ha t a l a r g e

membrane can be made me c h a n i c a l l y s t r ong by the use of s uppor t i ng means ,

wel l known to t hos e s k i l l e d in the a r t .

The membrane

may

be c o n t a i n e d wi t hi n a module in t he c o n f i g u r a t i o n

of hol l ow f i b e r s , a s p i r a l wi ndi ng or a

s e r i e s of f l a t

p l a t e s . A

d e s c r i p t i o n of hol l ow f i b e r and s pi r a l l y- wound

membrane c o n f i g u r a t i o n s i s

gi ven

in Sc h we i t z e r , i b i d . ,

pages

2-61 to 2-65 and 2- 21, r e s p e c t i v e l y .

In

any s e p a r a t i o n

p r o c e s s ,

c a r r i e d out under the p r i n c i p l e s of t h i s

i n v e n t i o n where the mol t en s a l t under goes

r e v e r s i b l e r e a c t i o n s wi t h t h e

gas

bei ng s e p a r a t e d , t he maximum a c hi e va bl e f l ux of

per meat e gas p e r

c r o s s - s e c t i o n a l

ar ea

of membrane is equal to the e f f e c t i v e d i f f u s i o n

c o e f f i c i e n t of t he c a r r i e r ( a c t i v e mol t en s a l t ) , mu l t i p l i e d by t h e

c o n c e n t r a t i o n g r a d i e n t of c a r r i e r ( dr i vi ng

f or ce) bet ween the t wo

i n t e r f a c e s of t he membrane. Thus ,

In g e n e r a l , the f l ux

t hr ough a

membrane may be e xpr e s s e d as t h e

pr oduc t

of

a s t a n d a r d p e r me a b i l i t y t i mes the c r o s s - s e c t i o n a l

ar ea

of t h e

membrane, t i me s (P/l. ), wher ei n l is the

pr e s s ur e

d i f f e r e n c e

a c r os s t he membrane and l is the t hi c kne s s of the membr ane.

As in

any f a c i l i t a t e d t r a n s p o r t syst em,

the a c t ua l f l ux wi l l a l s o

depend on t he k i n e t i c s of the r e v e r s i b l e r e a c t i ons of the per meat i ng

g a s

wi t h t he mol t e n s a l t .

Pe r me a b i l i t y (Po) is expr es s ed

in Bar r er u n i t s , t hat i s ,

3 2

1 Bar r er = ( c m . cm x

1 0 ) / ( s e c . c m . cmHg)

When pol ymer i c membranes are used to

s uppor t a melt and i t i s

de s i r e d to

e xpr e s s

the g a s f l u x t hr ough the membrane in

a manner whi c h

r e f l e c t s

onl y

the

s e p a r a t i o n per f or mance

of the mel t , a c o r r e c t i o n w i l l

be made for the

p o r o s i t y

and t o r t u o s i t y of t he membr ane, so t h a t :

Flux = Po . A. (P/l) ( p o r o s i t y / t o r t u o s i t y )

S e l e c t i v i t y ( S ) f or a mi xt ur e of

gas es ,

A and B, in which A is t h e

per meat e gas,

is expr es s ed by

the r a t i o of p e r me a b i l i t i e s :

Very hi gh s e l e c t i v i t i e s are obs er ved, usi ng t ypi c a l membranes o f

t hi s i nve nt i on. For exampl e,

s e l e c t i v i t i e s of 80-145 were measured f o r

s e p a r a t i o n of ammonia from ni t r oge n, usi ng a mol t en s al t membrane o f

l i t hi um c h l o r i d e . The

same s e p a r a t i o n , u t i l i z i n g molten zinc c h l o r i d e

a s

the a c t i ve mol t en s a l t in the membrane,

gave

s e l e c t i v i t i e s above 1000 : 1.

Si mi l a r l y , the s e p a r a t i o n

of car bon di oxi de from ni t r oge n, u s i n g

mol t en

t et r aal kyl ammoni um benzoat e or s a r c o s i n a t e s a l t s in the membr anes ,

exceeded a s e l e c t i v i t y of 10. In the case

of the t e t r a l kyl a mmoni um

benzoat e membrane, i t

was s u r p r i s i n g l y f o u n d t h a t the

pr esence

of wa t e r

in the

gas

st r eam improved the s e p a r a t i o n , r a t h e r than a f f e c t i n g i t

d e l e t e r i o u s l y .

The s e l e c t i v i t y for

s e pa r a t i on

of wat er

vapor

from ni t r oge n, us i ng a

mol t en l i t hi um n i t r a t e / s o d i u m n i t r a t e membrane, was

about 200 : 1.

It is t h e r e f o r e

appar ent

t hat the membranes of the pr es ent i n v e n t i o n

give i mpr es s i ve s e l e c t i v i t i e s , compared to s e l e c t i v i t i e s of known

membranes, t y p i c a l exampl es of which

are set f o r t h in Table 1 be l ow.

For the

r e g e n e r a t i o n of

oxygen

from a i r , p r e f e r r e d

mel t s

are l i t h i u m

n i t r a t e

or sodium n i t r a t e , i mmobi l i zed in

a porous

me t a l l i c

or c e r a mi c

s uppor t . Pr e f e r r e d

ope r a t i ng t e mpe r a t ur e s are above 400C, more

p r e f e r a b l y above 450C. Mi xt ur es of n i t r a t e s , p a r t i c u l a r l y

of two

o r

more of sodium, l i t hi um and pot assi um n i t r a t e s , c ont a i ni ng a maximum o f

99%

by wei ght of

any

of the n i t r a t e s , are p a r t i c u l a r l y p r e f e r r e d .

S e l e c t i v i t i e s a ppr oa c hi ng

200 f or

oxygen

in a i r have been

a c h i e v e d ,

us i ng t he t e a c h i n g s of t hi s i n v e n t i o n . I t wi l l be a p p r e c i a t e d t h a t s uc h

s e l e c t i v i t i e s ar e much hi ghe r t han t hose obs er ved f or s e p a r a t i o n o f

o x y g e n - n i t r o g e n

mi xt ur e s usi ng c o n v e n t i o n a l

pol ymer membranes, as shown

in Tabl e 2 .

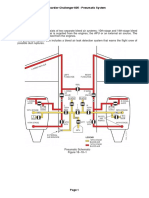

Br i e f De s c r i p t i o n of the Dr awi ngs

In Fi g.

1 i s shown a s i de vi ew of

a membrane, us e f ul f or t h e

p r a c t i c e

of t he i n v e n t i o n .

In F i g s . 2 , 3 and 4

ar e shown a t e s t

a ppa r a t us

f or

de mons t r a t i ng t h e

p r i n c i p l e s

of t h i s i n v e n t i o n , i n c l u d i n g a membrane, membrane hol der a nd

t e s t c e l l .

Best Mode for Car r yi ng Out the I n v e n t i o n

In a most p r e f e r r e d as pect

of t hi s i nve nt i on, the membrane c o mp r i s e s

an

i ne r t cerami c s uppor t

at l e a s t 0.02 cm

in t h i c k n e s s , and which has

a

pore

s i ze of 0 . 0 0 3 - 200 mi cr omet er s , is f i l l e d wi t h

a

cont i nuous f i l m o f

molten a c t i ve ma t e r i a l and has a p e r me a b i l i t y to

n i t r o g e n below 20

Bar r er s at 760 t o r r at the t e mpe r a t ur e

of

u s e .

Wi t hout f u r t h e r e l a b o r a t i o n , i t is be l i e ve d t hat

one

s k i l l e d in t h e

art can,

u s i n g t h e pr e c e di ng d e s c r i p t i o n , u t i l i z e t he

p r e s e n t

i n v e n t i o n

to i t s f u l l e s t e xt e nt . The f o l l o wi n g p r e f e r r e d s p e c i f i c embodi ment s

a r e ,

t h e r e f o r e , to be c ons t r ue d as merel y i l l u s t r a t i v e and not l i mi t a t i v e o f

the r emai nder o f t h e d i s c l o s u r e in

any way

what s oever . In the f o l l o wi n g

Exampl es, t e mpe r a t ur e s are set f or t h unc or r e c t e d in

degr ees Ce l s i u s .

Unless ot her wi s e i n d i c a t e d , al l par t s and pe r c e nt a ge s are by we i g h t .

For exper i ment s at hi gh t e mpe r a t ur e s , a membrane compr i s i ng a

t h i n

fi l m (about 0.2 mm) of

a

mol t en

s a l t s uppor t ed

in

a por ous

me t a l l i c o r

cerami c ma t e r i a l , was used. In a t y p i c a l case,

the membrane

s uppor t was

a c i r c u l a r pi ece

of #304 s t a i n l e s s s t e e l woven

wi re mesh (about 0.02 cm

in t h i c k n e s s ,

pore

si ze from 4-13 mi cr omet er s , Pal l

Cor p. , Cor t l a nd, NY),

s uppor t ed r i g i d l y

bet ween two I nconel 600 r i ngs about 10

cm

in i n n e r

di amet er . The me s h wa s l o a d e d wi t h a s al t

by me l t i ng the

dry

s a l t i n t o

i t s

por es ,

unt i l at l e a s t enough s a l t was used to pr ovi de a v i s i b l y

cont i nuous mol t en f i l m on one s ur f a c e of the wire mesh. The t h u s - c o a t e d

mesh and

suppor t assembl y was s eal ed i nt o a sample c e l l . In Fi gs. 2 and 3

are

shown a top view and a si de view, r e s p e c t i v e l y , of hol der a s s e mb l y 4

for

a wire mesh membrane s uppor t .

In Fig.

4 is shown the

sample c e l l 5,

i ncl udi ng the gol d 0- r i ng wi t h which the

suppor t as s embl y

is s e a l e d i n t o

the sample c e l l .

The sample

c e l l

or

module 5, as shown in

Fi g. 4, was pr ovi ded wi t h

means

f or i nt r oduc i ng f eed

g a s t h r o u g h

feed i n l e t 7 on the feed si de o f

the membrane 1, and for removal of a

gas

st ream r e j e c t e d by the membrane

t hr ough r e j e c t o u t l e t 8 wi t h per meat e sweep gas

i n l e t 10 on the o p p o s i t e

side of the membrane, f or pas s i ng

sweep gas

in c ont a c t wi t h the membrane

1 and

permeat e

o u t l e t means

11 for conveyi ng per meat e gases

and c a r r i e r

gas es

to an a n a l y z e r means. The a ppa r a t us was housed in

a t h e r mo s t a t t e d ,

t u b u l a r , h i g h - t e mp e r a t u r e he a t i ng mant l e and coul d

ope r a t e a t

t e mp e r a t u r e s up

to about 550C. The e xpe r i me nt a l assembl y al so i n c l u d e d

a gas

mani f ol d and was f u r t h e r pr ovi ded

wi t h e l e c t r o n i c

mass

f l ow

c o n t r o l l e r s t o per mi t p r e c i s e bl e ndi ng

of f eed

gas

mi xt ur e s . A

ga s

c hr oma t ogr a ph was used f or a n a l y s i s of the per meat e

gases

in the

sweep

s t r e a m.

A t y p i c a l l o we r - t e mp e r a t u r e membrane was pr e pa r e d by pl aci ng s e v e r a l

d r o p s o f a l ow- me l t i ng s a l t ( t et r ahexyl ammoni um be nz oa t e , Eastman Kodak

Co. ) on a c i r c u l a r pi ece

of 3501 ( Cel anese

Cor p. ) por ous pol ymer.

The

pol ymer was 27 mi c r ome t e r s t hi c k and had

pore

di mens i ons of 0.4

x

0 . 0 4

mi c r ome t e r s . The s a l t was smeared

over the s uppor t

wi t h a mi c r os c ope

s l i d e , which was

used t o remove excess

s a l t from the membrane. The

f i l l e d / c o a t e d membrane was l oaded i nt o a c e l l , ot he r wi s e as above, b u t

t h e r mo s t a t t e d i n a b a t h of e t hyl e ne g l y c o l .

In a not he r embodi ment of t he i nve nt i on

a s p e c t ,

t he method of t h i s

i n v e n t i o n wi l l be s e p a r a t i o n of

oxygen

from ot he r

gas es , usi ng mo l t e n

sodi um or l i t hi um n i t r a t e , i mmobi l i zed in

a por ous

met al s uppor t , at a

t e mp e r a t u r e above 400C.

Example 1

Se p a r a t i o n of Ammonia from Ni t r ogen us i ng a Li t hi um Ni t r a t e

I mmobi l i zed Mol t en Sa l t Membrane

S t a i n l e s s s t e e l woven

wi re mesh (# 304, about 0. 02 cm t hi ck, 4- 13

mi c r ome t e r s

pore

s i z e , ar ea about 0.8

cm2)

was coat ed wi t h f u s e d

l i t h i u m n i t r a t e

t o p r o v i d e a v i s i b l y c ont i nuous mol t en f i l m on one

s u r f a c e of t he wi re mesh, whi ch

was

mount ed i nt o the h i g h - t e mp e r a t u r e

t e s t i n g a p p a r a t u s .

The sampl e was heat ed to a f ur nace

t emper at ur e

o f

279C, us i ng a f eed fl ow of 30

cm3/min

f or f eed

gas

and a

sweep

flow on

t he

per meat e

si de of t he membrane of 30

cm3/min

of hel i um, both a t

about 1 at mos pher e p r e s s u r e

and 25C. The t o t a l

pr e s s ur e

in the c e l l

dur i ng the e xpe r i me nt s was about 760 t o r r . The c o n c e n t r a t i o n of

gases

i n

t he per meat e s t r eam was

de t e r mi ne d

by gas chr omat ogr aphy, usi ng a

305

cm

mo l e c u l a r s i eve column f or n i t r o g e n

and a

183

cm Chromosorb column f o r

ammonia, bot h ope r a t e d i s o t h e r ma l l y at 60C. Af t er the syst em ha d

s t a b i l i z e d at the o p e r a t i n g t e mp e r a t u r e ,

t her e was no l eak of

n i t r o g e n

acr os s

t he membrane, as

i n d i c a t e d by

very

low n i t r o g e n p e r me a b i l i t y .

The u t i l i t y

of the membrane in

s e p a r a t i n g

ammonia from ni t r oge n was

t e s t e d in t hr ee one- day runs. Duri ng each

run,

the c o n c e n t r a t i o n o f

ammonia in t h e a mmo n i a / n i t r o g e n

f eed

was var i ed from 0-100%. The

c o n c e n t r a t i o n s of ammonia and n i t r o g e n in the

per meat e were moni t or ed by

gas

c h r o ma t o g r a p h y .

Re s ul t s for s p e c i f i c ammonia n i t r o g e n mi xt ur e s ,

r e p r e s e n t i n g a n

aver age

of the t hr ee one- days runs we r e :

These r e s u l t s show t hat good s e p a r a t i o n of ammonia and n i t r o g e n was

a c c ompl i s he d, usi ng the i mmobi l i zed l i t hi um n i t r a t e membrane. It is a l s o

a ppa r e nt t hat p e r me a b i l i t y is

a

f u n c t i o n of the p a r t i a l

p r e s s u r e s

at t h e

feed i n t e r f a c e of t he membr ane.

Example 2

(a) Se pa r a t i on of Ammonia from Ni t r ogen usi ng a Zinc Ch l o r i d e

I mmobi l i zed Mol t en Sal t Membrane

The membrane was pr epar ed by mel t i ng zinc c h l o r i d e i nt o the

pores

o f

s t a i n l e s s s t e e l mesh (about 0. 02 cm t hi c k, area 0.8

cm2).

The membrane

was pl a c e d i n t he hi gh t e mpe r a t ur e c e l l and checked f or

c o n t i n u i t y by

meas ur i ng p e r me a b i l i t y of

pure

n i t r o g e n at 310C.

The membrane was used f or

s e p a r a t i o n o f ammonia from

n i t r o g e n over a

21-day per i od

of cont i nuous o p e r a t i o n . Gas flow on

bot h the f eed and

per meat e

si de

was

20

cm3/min

at about 1 aim and 25C. P e r me a b i l i t i e s

were c a l c u l a t e d as

t he means

of 10-15 measurement s of ammonia a nd

n i t r o g e n f l uxe s over a t wo- hour pe r i od, a f t e r t he

syst em

had r e a c h e d

e q u i l i b r i u m under a gi ven set of c o n d i t i o n s . Re s ul t s

we r e :

Ni t r oge n

f l ux t hr ough the zi nc c h l o r i d e membrane was

very

low, c l o s e

to t he backgr ound

l evel of

n i t r o g e n

in the

sweep

s t r eam. The r e f or e , t h e

s e l e c t i v i t y c o u l d n o t be de t e r mi ne d q u a n t i t a t i v e l y , but wa s e s t i ma t e d t o

be at l e a s t 1000 : 1.

(b) Se p a r a t i o n of Ammonia from Hydr oge n

Expe r i me nt s were

done

as

in

Example 2( a) , us i ng as the f eed st r eam a

mi xt ur e of ammonia and hydr ogen. Argon was

used as t he

per meat e sweep

gas

to f a c i l i t a t e d e t e c t i o n of hydr ogen by the

gas c h r o ma t o g r a p h .

At 311C, us i ng f eed of

pure

hydr ogen (800 t o r r ) , t he s t a n d a r d

hydr ogen p e r me a b i l i t y was c a l c u l a t e d t o be 9 Ba r r e r . Under the same

c o n d i t i o n s , us i ng pure

ammonia as f eed, the p e r me a b i l i t y of ammonia

was

2.9 x

104

Ba r r e r s . Th e r e f o r e , t he ammoni a/ hydr ogen s e l e c t i v i t y was

about 3 2 0 0 : 1 .

Example 3

Se p a r a t i o n of Ammonia from Ni t r oge n usi ng Zi nc Chl or i de I mmobi l i z e d

Mol t en Sa l t Suppor t ed in

a Porous Cerami c Membrane

A c i r c u l a r

sampl e

of

woven zi r coni um di oxi de c l o t h (about 0.038 cm

in t h i c k n e s s , 87% p o r o s i t y , t ype ZYW-15, Zi r c a r Cer ami cs , Fl o r i d a , N. Y. )

was soaked in mol t en zi nc c h l o r i d e . The t h u s - i mp r e g n a t e d membrane

was

s andwi ched bet ween two a nnul a r I nconel r i ngs ( out er di amet er about 1

cm,

i nner di a me t e r about 0.6 cm). The r e s u l t i n g assembl y was s eal ed i nt o t h e

hi gh t e mp e r a t u r e t e s t c e l l us i ng gol d O- r i n g s .

Pe r me a b i l i t y

measurement s were

made

as in

Example

2 at

gas p r e s s u r e s

of about 1 atm, f eed r at es of a mmoni a / ni t r oge n

or hel i um

sweep gas

of 20

cm3/min

at about 1 ai m and 25C and an

i n t e r n a l membrane t e mp e r a t u r e o f

311C.

Owing to u n c e r t a i n t i e s about the t hi c kne s s of the membr ane,

p e r me a b i l i t i e s i n Ba r r e r ,

a s i n d i c a t e d below, are u n c e r t a i n . Membrane

pe r f or ma nc e ,

de f i ne d as

Po/l

( cm / cm .

sec. cmHg) was

obt a i ne d

by

di vi di ng

s t a n d a r d p e r me a b i l i t y by the assumed t h i c k n e s s of the membrane

(l = 0. 038 cm). The ni t r oge n f l ux was a c c o r d i n g l y v e r y low, compar ed

to the backgr ound

l evel of n i t r o g e n

in the hel i um

sweep.

The e s t i ma t e d

PoNH3/PoN2 was

at l eas t 1400: 1

Example 4

Se p a r a t i o n of Carbon Di oxi de from Ni t r ogen usi ng a

Tet r ahexyl ammoni um Benzoat e I mmobi l i zed Mol t en Sal t Membrane

The membrane was pr epar ed by pl a c i ng s e ve r a l drops

o f

t e t r a he xyl a mmoni um be nz oa t e (THAB, Eastman Kodak Corp. ) on a

c i r c u l a r

pi ece

of 3501

Cel gar d" ( Cel anese Co r p . , t h i c k n e s s 0.0027

cm, ar ea 2 . 5 6

cm2,

pore

di mens i ons 0.4 x 0 . 0 4 mi c r o me t e r s , t o r t u o s i t y 1. 25, p o r o s i t y

0. 5) . The s a l t

was smeared over the pol ymer f i l m and al l owed to ent er t h e

porous

pol ymer. Excess s a l t was removed. The membrane was l oaded i n t o

the l o we r - t e mp e r a t u r e c e l l , t h e r mo s t a t t e d wi t h an et hyl ene gl ycol b a t h .

The i n i t i a l f eed flow was 11.7

cm3/min

of car bon di oxi de and 16. 9

cm3/min

of n i t r o g e n

and the per meat e

flow

was 10

cm3/min

of h e l i u m,

bot h at 1 atm. The per meat e was a na l yz e d

f or car bon di oxi de and n i t r o g e n

by gas chr omat ogr aphy, us i ng an

183 cm Por opak P col umn, run i s o t h e r ma l l y

at 60 C.

Carbon di oxi de and n i t r o g e n p e r me a b i l i t i e s were measured as a

f u n c t i o n of

t e mpe r a t ur e , t a ki ng i nt o account t he t o r t u o s i t y and

p o r o s i t y

of t he

s u p p o r t .

Re s u l t s wer e:

These r e s u l t s show t ha t car bon di oxi de p e r me a b i l i t y i nc r e a s e s wi t h

i n c r e a s i n g t e mpe r a t ur e ,

but s e l e c t i v i t y d e c r e a s e s .

Example 5

Se p a r a t i o n of Carbon Di oxi de from Ni t r oge n us i ng a

Tet r ahexyl ammoni um Sa r c o s i n a t e (THAS) I mmobi l i zed Molten S a l t

Membrane

Tet r ahexyl ammoni um hydr oxi de was pr e pa r e d by s t i r r i n g t o g e t h e r

t et r ahexyl ammoni um bromi de (2. 2

g,

East man Kodak Cor p. ) and 6.5

g.

o f

s i l v e r (I) oxi de in 25 ml of 80% met hanol : 20% wat er by volume. The

hydr oxi de was

t i t r a t e d wi t h

aqueous

s a r c o s i n e s o l u t i o n . Removal o f

s o l v e n t , us i ng a r ot a r y e v a p o r a t o r , gi ve t et r ahexyl ammoni um s a r c o s i n a t e ,

N( n- C6H11) 4 + NH(CH3)-CH2COO,

in t he form of

a yel l ow l i qui d. The

s a r c o s i n a t e

was

used to

pr e pa r e a membrane, s uppor t e d in a porous p o l y me r

f i l m as

in

Example

4. The membrane

was 0. 0027

cm in t h i c k n e s s ,

2. 56

c m

in

ar ea,

and had

a t o r t u o s i t y

of 1. 25 and p o r o s i t y of 0 . 5 .

The

pe r me a t i on exper i ment s were done at

gas p r e s s u r e s

about 760 t o r r a t

f eed f l ows of 11.7

cm3/min

f or car bon di oxi de and 16.9

cm3/min

f o r

n i t r o g e n and

sweep gas

fl ow (hel i um) of 10

cm3/ mi n.

Res ul t s wer e:

The THAS membrane was ope r a t e d

f or about four days at or below 75C

wi t hout

any

obser ved a l t e r a t i o n in i t s

p r o p e r t i e s . Af t er the membrane

was

heat ed to 95C, the car bon d i o x i d e p e r me a b i l i t y at 60C

was 218

Ba r r e r s and

PoCO2/PoN2

was 1 2 . 8 .

Al t hough the THAS membrane had l ower carbon di oxi de

p e r me a b i l i t y

t ha t the THAB membrane

of

Exampl e 4, the THAS

membrane

had

h i g h e r

s e l e c t i v i t y at e l e va t e d t e mp e r a t u r e s t han the THAB

membr ane.

Example 6

Se pa r a t i on of Water Vapor from Ni t r oge n usi ng Li t hi um Ni t r a t e / S o d i u m

Ni t r a t e I mmo b i l i z e d Mol t en Sal t Membrane

A mol t en s a l t membrane of

a

mi xt ur e of l i t hi um n i t r a t e / s o d i u m

n i t r a t e ( 0. 75: 0. 25 mol %)

was

i mmobi l i zed in

a s t a i n l e s s s t e e l wire mesh

as

in

Example 1. The membrane was pl a c e d

in the high t e mpe r a t ur e c e l l

and used to s e pa r a t e wat er

vapor

from n i t r o g e n . The d e t e c t i o n

syst em was

s i mi l a r to t hat of Example 1, except

t ha t a set of

hygr omet er s was

a t t a c h e d to each of the f eed and

per meat e

st r eams to measure dew

or f r o s t

poi nt (wat er c o n c e n t r a t i o n ) . The n i t r o g e n / wa t e r

feed mi xt ur e s

wer e

pr e pa r e d by pas s i ng n i t r o g e n t hr ough a bubbl e r , immersed in

a

wa t e r / e t h y l e n e gl ycol c ons t a nt t e mpe r a t ur e bat h. Feed mi xt ur e s of 1-3%

(by volume) of wat er were t hus o b t a i n e d .

Gas flows

were

20

CM /min

at about 1 atm. The membrane t h i c k n e s s

( s t e e l mesh) was

0.02

cm and the membrane area 0.8 cm. When t h e

membrane was heat ed to 230C,

very

low ni t r oge n p e r me a b i l i t y was

obs er ved. This i n d i c a t e s t hat the mol t en s a l t film

was c ont i nuous . The

membrane was

t e s t e d

over

f our

days

wi t h n i t r o g e n / wa t e r mi xt ur e s . Re s u l t s

we r e :

Owing to t he low l e ve l of n i t r o g e n pas s i ng t he f i l m, of t he or der o f

t he backgr ound l e ve l of n i t r o g e n , onl y a lower l i mi t f or

h y d r o g e n /

n i t r o g e n s e l e c t i v i t y

coul d be e s t i ma t e d. The t h u s - e s t i ma t e d

PoH2O/PoN2

is about 200: 1. I t is t h e r e f o r e

a ppa r e nt

t ha t t h e

s o d i u m/ l i t h i u m n i t r a t e i mmobi l i zed s a l t

membr ane per mi t s e x c e l l e n t

s e p a r a t i o n

of

wat er

from n i t r o g e n at 200 - 300C.

E x a m p l e 7

Ef f e c t of Wat er on Se p a r a t i o n of Carbon Di oxi de Usi ng an I mmobi l i z e d

Sa l t Membrane of Tet r ahexyl ammoni um Be nz oa t e

A membrane of t et r ahexyl ammoni um benzoat e, under c o n d i t i o n s

o t h e r wi s e as

in

Example 4, was used to s t u d y t h e e f f e c t of added wat er on

t he e f f i c i e n c y of

s e p a r a t i n g

car bon di oxi de from

n i t r o g e n . The wet f e e d

was pr oduced by bubbl i ng f eed t hr ough wat er at ambi ent

t e mpe r a t ur e

b e f o r e

pas s age over t he membr ane.

The f ol l owi ng r e s u l t s were o b t a i n e d :

These r e s u l t s show t hat moi st f eed had

hi gher car bon d i o x i d e

p e r me a b i l i t y

and s e l e c t i v i t y at lower

t e mpe r a t ur e s t han dry f eed. As t h e

t e mpe r a t ur e was r a i s e d, the e f f e c t of added wat er de c r e a s e d. I n

exper i ment s at 90C and above, a ddi t i on of wat er to the feed had

no

meas ur abl e e f f e c t .

Example 8

Se p a r a t i o n of

Oxygen

from Air usi ng a Li t hi um Ni t r a t e I mmobi l i z e d

Molten Sa l t Membrane

S t a i n l e s s s t e e l woven wire mesh (#304, about 0. 02

cm t hi c k, 4- 13

mi cr omet er s

pore

s i z e , area about 0.8

cm2)

was coat ed wi t h mo l t e n

l i t hi um n i t r a t e b y g r i n d i n g dry

l i t hi um n i t r a t e and p l a c i n g i t on t h e

mesh under an at mospher e

of

dry argon.

The cel l was c l os e d, connect ed t o

a gas

mani f ol d and heat ed to 285C under a feed flow of 10

cm3/min

o f

n i t r o g e n and per meat e

flow of 10

cm3/min

of hel i um at 1 atm

p r e s s u r e

for about 20 hr. At the end of t hi s time the l i t hi um n i t r a t e had we t t e d

t he s t a i n l e s s s t e e l mesh and formed

a v i s i b l y c ont i nuous mol t en f i l m

o n

one

s ur f a c e of t he wi r e mesh, and t hus

s e p a r a t e d t he feed and

p e r me a t e

s i des of t he c e l l :

The c e l l was

t hen heat ed to a f ur nace t e mp e r a t u r e of 429C, usi ng a

f eed flow of 10

cm3/min

of

zero gr ade

a i r and a

sweep

flow on t h e

p e r me a t e s i d e

of the membrane of 10

cm3/min

of hel i um, bot h at a b o u t

1 at mos pher e p r e s s u r e

and 25C. The t o t a l

p r e s s u r e

in t he cel l d u r i n g

t he e xpe r i me nt s was

about 760 t o r r .

The c o n c e n t r a t i o n of

gases

in the

per meat e

s t r eam was det er mi ned

by

gas

c hr oma t ogr a phy, us i ng a 183 cm 5A mol e c ul a r s i e ve column f or n i t r o g e n

and

oxygen,

o p e r a t e d i s o t h e r ma l l y at 60C. Af t er

t h e s y s t e m ha d

s t a b i l i z e d at t he o p e r a t i n g t e mp e r a t u r e ,

t he r e

was no l eak of

n i t r o g e n

a c r os s

t he membrane, as i n d i c a t e d by very

low n i t r o g e n p e r me a b i l i t y .

I t was obs e r ve d t ha t

oxygen

p e r me a b i l i t y i n c r e a s e d gr a dua l l y over 42

hour s of h e a t i n g .

Thi s

was

a t t r i b u t e d to an i n c r e a s e in t h e

c o n c e n t r a t i o n of oxi des (O .

O2 O2)

in the mol t en s a l t . I t

is pr opos ed t h a t t he d i s s o l v e d oxi des in t he mol t en s a l t c a t a l yz e d t h e

r e a c t i o n :

Ni t r oge n p e r me a b i l i t y was c ons t a nt ( about 12 Ba r r e r s ) . The

f o l l o wi n g r e s u l t s were o b t a i n e d :

These r e s u l t s show t hat a l i t hi um n i t r a t e i mmobi l i zed s a l t membrane

f u n c t i o n e d wel l f or a r e a s ona bl e t i me, and had good p e r me a b i l i t y a nd

s e l e c t i v i t y f or

oxyge n.

Example 9

Se p a r a t i o n

of Oxygen from Air usi ng a Sodium Ni t r a t e I mmobi l i z e d

Mol t en Sal t Membrane

A mol t en s al t membrane of

a sodium n i t r a t e

was i mmobi l i zed in

a

s t a i n l e s s s t e e l wire mesh as

in

Example

1. The sodi um n i t r a t e

was l o a d e d

ont o the s t a i n l e s s s t e e l mesh under an argon

a t mos phe r e a nd the cel l

was

a t t a c h e d to the

gas

mani f ol d. The c e l l was heat ed to 323C under a f e e d

flow of 10

cm3/min

o f n i t r o g e n and a per meat e

flow of 10

cm3/min

o f

hel i um f or about 15 h at 760 Torr. The f eed

gas was t hen changed t o

10

cm3/

min of zero grade

ai r at 760 To r r .

The c e l l

was

heat ed g r a d u a l l y to 450C, but no

oxygen was d e t e c t e d

in the per meat e st r eam, usi ng the a n a l y t i c a l method of

Example 1. At

477C,

oxygen was

obser ved in the

per meat e.

An e s s e n t i a l l y c o n s t a n t

val ue was

r eached a f t e r 4 h. The c e l l was hel d

at 477C f or 18 h and

t hen t he t e mpe r a t ur e was

va r i e d bet ween 452C and S25C t o det er mi ne t h e

e f f e c t of t e mpe r a t ur e

on

oxygen p e r me a b i l i t y . Re s ul t s

we r e :

Ni t r oge n p e r me a b i l i t y remai ned r e l a t i v e l y c o n s t a n t , at 12- 15

Ba r r e r . Thi s example shows t hat sodium n i t r a t e i mmobi l i zed mol t en s a l t

can

be used f or the s e p a r a t i o n of

oxygen

from a i r .

1. A

pr oc e s s

f or s e p a r a t i n g a

gas

from at l e a s t one ot her

gas

in

a

mi x t u r e , c ompr i s i ng pa s s i ng t he

gas

mi xt ur e

over a membrane s e l e c t i v e l y

pe r me a bl e to t he

gas bei ng s e p a r a t e d ,

which membrane compr i s es a t h i n ,

por ous

i n e r t

s uppor t

in which an a c t i v e ma t e r i a l is i mmo b i l i z e d wi t h i n

t he

por e s

and t he a c t i v e ma t e r i a l i s a mol t en s a l t .

2. The

pr oc e s s

of Cl ai m 1 wher ei n t he mol t en s a l t is

capabl e o f

u n d e r g o i n g one or more r e v e r s i b l e r e a c t i o n s , wi t h t he

gas bei ng s e p a r a t e d .

3. The

pr oces s

of Claim 2, wher ei n t he r e v e r s i b l e r e a c t i o n i s

f o r ma t i o n of a

c o o r d i n a t i o n

c ompl e x.

4. The

pr oc e s s

of Cl ai m 2, wher ei n t he r e v e r s i b l e r e a c t i o n is

a n

a c i d b a s e r e a c t i o n .

5. The

pr oc e s s

of Claim 2, wher ei n t he r e v e r s i b l e r e a c t i o n i s

f o r ma t i o n of an or ga ni c chemi cal compound.

6. The

pr oc e s s

of Claim 2 wher ei n t he r e v e r s i b l e r e a c t i o n is a n

o x i d a t i o n - r e d u c t i o n r e a c t i o n .

7. The

pr oc e s s

of Claim 1, wher ei n t he membrane i s c o n t a i n e d

wi t h i n

a module of hol l ow f i b e r s , a s p i r a l wi ndi ng or a

s e r i e s of f l a t

p l a t e s .

8. The

pr oc e s s

of Claim 1, wher ei n the r e v e r s i b l e

o x i d a t i o n - r e d u c t i o n r e a c t i o n i s n i t r a t e - n i t r i t e i n t e r c o n v e r s i o n ,

oxyge n

i s t he

gas

bei ng s e pa r a t e d and the a c t i ve ma t e r i a l in t he membrane i s

mol t e n a l k a l i met al n i t r a t e .

9. The

pr oces s

of Claim 1, wher ei n the

porous

membrane

c o n t a i n i n g

the mol t en s a l t i s s u p p o r t e d on a macr opor ous suppor t composed o f

cer ami c, g l a s s ,

me t a l l i c or pol yme r i c

ma t e r i a l .

10. The

pr oces s

of Claim 1, i nc l udi ng removing

gas pa s s i ng t h r o u g h

the membrane by. a st r eam of s weep

g a s .

11. The

pr oces s

of Cl ai m 1, i nc l udi ng removing gas pa s s i ng t h r o u g h

the membrane usi ng a c o mp r e s s o r .

S-ar putea să vă placă și

- 1 s2.0 S1385894713007869 Main PDFDocument7 pagini1 s2.0 S1385894713007869 Main PDFSJ ChuaÎncă nu există evaluări

- Nitric Acid PlantsDocument6 paginiNitric Acid Plantsabekat13Încă nu există evaluări

- Measurements of Oil-Water Separation Dynamics in Primary Separation Systems Using Distributed Capacitance SensorsDocument15 paginiMeasurements of Oil-Water Separation Dynamics in Primary Separation Systems Using Distributed Capacitance SensorsSJ ChuaÎncă nu există evaluări

- 1 s2.0 S0263876204726271 MainDocument8 pagini1 s2.0 S0263876204726271 MainSJ ChuaÎncă nu există evaluări

- Nitric Acid Manufacturing PlantDocument27 paginiNitric Acid Manufacturing Plantrasyid93Încă nu există evaluări

- Lecture 2 - Intro To HYSYSDocument40 paginiLecture 2 - Intro To HYSYSSJ Chua0% (1)

- Operational Experience of A Commercial Scale Plant of Electron Beam Puri®cation of Ue GasDocument5 paginiOperational Experience of A Commercial Scale Plant of Electron Beam Puri®cation of Ue GasSJ ChuaÎncă nu există evaluări

- 1 s2.0 S0016236107004085 MainDocument7 pagini1 s2.0 S0016236107004085 MainSJ ChuaÎncă nu există evaluări

- Radiation Physics and Chemistry: Ioan Calinescu, Diana Martin, Andrezj Chmielewski, Daniel IghigeanuDocument9 paginiRadiation Physics and Chemistry: Ioan Calinescu, Diana Martin, Andrezj Chmielewski, Daniel IghigeanuSJ ChuaÎncă nu există evaluări

- A Modification of The Demonstration of The Ostwald Process: Journal, 15 ItDocument1 paginăA Modification of The Demonstration of The Ostwald Process: Journal, 15 ItSJ ChuaÎncă nu există evaluări

- 1 s2.0 S0969806X04000921 MainDocument4 pagini1 s2.0 S0969806X04000921 MainSJ ChuaÎncă nu există evaluări

- ESP Sample Spec SheetDocument2 paginiESP Sample Spec SheetSJ ChuaÎncă nu există evaluări

- 1 s2.0 S0969806X07000941 MainDocument5 pagini1 s2.0 S0969806X07000941 MainSJ ChuaÎncă nu există evaluări

- Lecture 1 - Intro To Process SimulationDocument48 paginiLecture 1 - Intro To Process SimulationSJ ChuaÎncă nu există evaluări

- 1142 2908 1 PB PDFDocument4 pagini1142 2908 1 PB PDFIbrahim LahmidÎncă nu există evaluări

- Separation of Ammonia & WaterDocument14 paginiSeparation of Ammonia & WaterSiti Hajar JamaluddinÎncă nu există evaluări

- Fifty Years of Electrostatic PrecipitationDocument13 paginiFifty Years of Electrostatic PrecipitationSJ ChuaÎncă nu există evaluări

- Discharge ElectrodeDocument21 paginiDischarge ElectrodeSJ Chua100% (1)

- Turner Et Al 02Document13 paginiTurner Et Al 02SJ ChuaÎncă nu există evaluări

- 21st Century ESP DesignDocument12 pagini21st Century ESP DesignSJ ChuaÎncă nu există evaluări

- Krupp Nitric Acid PlantDocument16 paginiKrupp Nitric Acid PlantSJ ChuaÎncă nu există evaluări

- Turner Et Al 01Document15 paginiTurner Et Al 01SJ ChuaÎncă nu există evaluări

- Application of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaDocument24 paginiApplication of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaSJ ChuaÎncă nu există evaluări

- CEIC Data Manager Username and PasswordDocument1 paginăCEIC Data Manager Username and PasswordIsmail Jamaluddin100% (1)

- DataStream Communications ConfigurationDocument1 paginăDataStream Communications ConfigurationIsmail JamaluddinÎncă nu există evaluări

- Physical Properties of Pure MethanolDocument1 paginăPhysical Properties of Pure MethanolSJ ChuaÎncă nu există evaluări

- Safety PrecautionDocument1 paginăSafety PrecautionSJ Chua100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)