Documente Academic

Documente Profesional

Documente Cultură

G3512le PDF

Încărcat de

andrey7219Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

G3512le PDF

Încărcat de

andrey7219Drepturi de autor:

Formate disponibile

CATERPILLAR

SR4 GENERATOR

Type . . . . . . . . . . . Static regulator, brushless excited

Construction. . . . . . . . Single bearing, close coupled

Three phase . . . . . . . . . . . . . . . . . . . . . Wye connected

Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Class F

Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . Drip proof

Alignment. . . . . . . . . . . . . . . . . . Caterpillar pilot shaft

Overspeed capability . . . . . . . . . . . . . . . . . . . . . . 130%

Waveform. . . . . . . . . . . . . . . . Less than 5% deviation

Voltage regulator . . . . . . . . . . . 3-phase sensing with

..............................................................Volts-per-Hertz

Voltage regulation. . . . . . . . . . . . . . . . Less than 1%

Voltage gain. . . . . . . . Adjustable to compensate for

...............................engine speed droop and line loss

TIF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 50

THF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Less than 3%

Gas Engine

Generator

Set

V-12, 4-Stroke-Cycle Spark-Ignited

Bore mm (in). . . . . . . . . . . . . . . . . . . . . . . . . 170 (6.7)

Stroke mm (in) . . . . . . . . . . . . . . . . . . . . . . . 190 (7.5)

Displacement L (cu in) . . . . . . . . . . . . . . 51.8 (3158)

Aspiration . . . . . . . . . . . . Turbocharged-Aftercooled

Compression ratio . . . . . . . . . . . . . . . . . . . . . . 8:1, 11:1

Shipping Weight (dry) kg (lb) . . . . . . 9166 (20 190)

(includes engine, generator, and rails)

FEATURES

G3512 LE

1500 rpm

50 Hz

900-950 kVA; 720-760 kW

Continuous Power

CATERPILLAR

ENGINE SPECIFICATIONS

n CATERPILLAR

FACTORY PACKAGE

Factory designed, assembled, and tested.

Supported by Caterpillar parts and labor

warranty through your local Caterpillar

dealer.

n DIESEL STRENGTH BUILT IN

Blocks, crankshafts, liners, and connecting

rods are common with higher loaded Cat

diesel engines. Robust design provides

prolonged life at lower gas engine loads.

n ELECTRONIC IGNITION SYSTEM WITH

DETONATION SENSITIVE TIMING

The Caterpillar Electronic Ignition System

(EIS) provides optimized spark timing for all

operating conditions. Timing is automatically

controlled to maintain continuous detonation

protection.

n LOWEXHAUST EMISSIONS

2.0 gram/bhp-hr NOx. Lower emissions are

achievable for selected applications; consult

your Caterpillar dealer.

n FUEL FLEXIBILITY

Capability to burn a wide range of gaseous

fuels, including landfill gas, digester gas, coal

seam gas, and propane.

n GALLERY COOLED PISTONS

Oil passageways provide cooler piston

temperatures which prevent carbon build-up

and increase detonation margin.

n COOLING WATER TEMPERATURE

Choice of cooling water temperature

between 99 C and 127 C to match heat

recovery requirements.

Shown with

Optional Equipment

OPTIONAL EQUIPMENT

Air cleaners with

service indicator

Breather, crankcase

Cooler, lubricating oil

Filters, lubricating oil, RH

Flywheel housing,

SAE No. 00

Governor (Woodward),

magneto engine: 2301

EIS engine: 2301A

Ignition system

Altronic III or

Caterpillar EIS

Instrument panel,

RH or LH

exhaust temp.

intake manifold

pressure

intake manifold

temp.

oil pressure

oil pressure

differential

service meter

water temp.

Lifting eyes

Manifold, exhaust,

watercooled

Paint,

Caterpillar yellow

Protection devices

Pumps

gear driven

aftercooler water

lubricating oil

jacket water

Rails, mounting, 13 inch

Regulator,

gas pressure

SAE standard rotation

Thermostats

and housing

Torsional vibration

damper

Cooling systems,

high temperature

Custom generator

voltages

Exhaust fittings

Generator mounted

control panel

Governor (Woodward),

magneto engine: 2301A

Load share governor

Low BTU arrangements

Low pressure gas fuel

system (10 kPa)

Muffler

Power takeoffs

Prelube pump

Starting systems

Tachometer

G3512 LE GAS GENERATOR SET

STANDARD EQUIPMENT

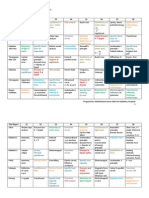

G3512 LE Low Pressure 1500 rpm 32 SCAC 54 SCAC 32 SCAC 54 SCAC

Electrical Output @ 0.8 PF without Fan kW 760 720 760 720

kVA 950 900 950 900

Engine Speed rpm 1500 1500 1500 1500

Voltage 400/3300 400/3300 400/3300 400/3300

Compression Ratio 11:1 11:1 8:1 8:1

Min Gas Pressure Required kPa 10-34 10-34 10-34 10-34

NO

x

g/bhp-hr 2.00 2.00 2.00 2.00

CO g/bhp-hr g/bhp-hr 1.93 1.92 1.78 1.83

HC (total) g/bhp-hr 3.82 3.68 2.71 2.78

HC (non-methane) g/bhp-hr 0.57 0.55 0.41 0.42

Exhaust O

2

(dry) % 7.6 7.5 7.9 8.0

Fuel Consumption (100% load) MJ/kW-hr 10.33 10.61 10.58 10.79

Fuel Consumption (75% load) MJ/kW-hr 10.95 11.09 10.69 10.98

Air Inlet Flow Rate Nm

3

/min 63.2 59.9 68.6 66.3

Exhaust Gas Flow Rate @ stack C Nm

3

/min 160.0 154.0 175.0 170.0

Heat Rejection to Jacket Water (total) kW 643.0 672.0 620.0 628.0

Heat Rejection to Exhaust (to 177 C) kW 388.0 382.0 431.0 421.0

Heat Rejection to Aftercooler kW 139.0 105.0 171.0 139.0

Heat Rejection to Atmosphere kW 80.0 80.0 80.0 80.0

Exhaust Gas Stack Temperature Deg C 456.0 467.0 465.0 468.0

TECHNICAL DATA

G3512 LE GAS GENERATOR SET

* SCAC refers to Separate Circuit Aftercooling water inlet temperature.

Ratings and data based on specified standard conditions (back page).

G3512 LE High Pressure 1500 rpm 32 SCAC 54 SCAC 32 SCAC 54 SCAC

Electrical Output @ 0.8 PF without Fan kW 760 720 760 720

kVA 950 900 950 900

Engine Speed rpm 1500 1500 1500 1500

Voltage 400/3300 400/3300 400/3300 400/3300

Compression Ratio 11:1 11:1 8:1 8:1

Min Gas Pressure Required kPa 207-278 207-278 241-278 241-278

NO

x

g/bhp-hr 2.00 2.00 2.00 2.00

CO g/bhp-hr g/bhp-hr 1.93 1.92 1.78 1.83

HC (total) g/bhp-hr 3.82 3.68 2.71 2.78

HC (non-methane) g/bhp-hr .57 .55 .41 .42

Exhaust O

2

(dry) % 7.6 7.5 7.9 8.0

Fuel Consumption (100% load) MJ/kW-hr 10.33 10.61 10.58 10.79

Fuel Consumption (75% load) MJ/kW-hr 10.95 11.09 10.69 10.98

Air Inlet Flow Rate Nm

3

/min 63.2 59.9 68.6 66.3

Exhaust Gas Flow Rate @ stack C Nm

3

/min 160.0 154.0 175.0 170.0

Heat Rejection to Jacket Water (total) kW 648.0 676.0 627.0 633.0

Heat Rejection to Exhaust (to 177 C) kW 388.0 382.0 431.0 421.0

Heat Rejection to Aftercooler kW 133.0 101.0 165.0 134.0

Heat Rejection to Atmosphere kW 80.0 80.0 80.0 80.0

Exhaust Gas Stack Temperature Deg C 456.0 467.0 465.0 468.0

G3512 LE GAS GENERATOR SET

Materials and specifications are subject to change without notice. The International System of Units (SI) is used in this publication.

LEHX6193 1996 Caterpillar Inc. Printed in U.S.A.

All rights reserved.

GAS GENERATOR SET TOP VIEW

See general dimension drawing 119-9594 for additional

Electronic Ignition System (EIS) engine detail and NA

information.

For magneto ignition system engines see general

dimension drawing 7C-4609.

Note: General configuration not to be used for

installation.

RD

0

3

2

2

0

0

.

3

(

8

6

.

6

3

)

306

103

104

201

401

402

401

521

2

9

6

.

0

(

1

1

.

6

5

)

424.2 (16.70)

446.7 (17.59)

700.0 (27.56)

1

7

8

3

.

0

(

7

0

.

2

0

)

1

1

5

6

.

4

(

4

5

.

5

3

)

1170.0 (46.06)

851.5 (33.52)

304.8 (12.00)

523.2 (77.46)

02

0

3

02

CONDITIONS AND DEFINITIONS

Ratings are based on SAE J1349 standard

conditions of 100 kPa (29.61 in Hg) and 25 C

(77 F). These ratings also apply at ISO3046/1,

DIN6271 and BS5514 standard conditions of

100 kPa (29.61 in Hg) and 27 C (81 F); and

API 7B-11C standard conditions of 99 kPa

(29.38 in Hg) and 29 C (85 F) also apply.

Ratings are based on dry natural gas having a low

heat value of 35.22 MJ/m

3

(905 btu/ft

3

). Variations

in altitude, temperature, and gas composition

from standard conditions may require a reduction

in engine horsepower.

Turbocharged-aftercooled ratings apply to

1525 m (5000 ft) and 25 C (77 F). Naturally

aspirated engines apply to 150 m (500 ft) and

29 C (85 F). For applications which exceed these

limits consult your Caterpillar dealer.

Continuous Output available without varying

load for an unlimited time. Continuous power in

accordance with ISO8528, ISO3046/1, AS2789,

DIN6271, and BS5514.

02

03

103

104

201

308

401

402

521

RD

Centerline of Engine

Rear Face of Cylinder Block

Water Inlet

Water Outlet

Fuel Inlet

Oil Filter

Air Inlet

Exhaust

Conduit Entrance

Removal Distance

S-ar putea să vă placă și

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDe la EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsEvaluare: 5 din 5 stele5/5 (2)

- Spec Sheets - Cat 3208 PropulsionDocument4 paginiSpec Sheets - Cat 3208 Propulsionap00Încă nu există evaluări

- OCTG Piping Inspection MethodsDocument26 paginiOCTG Piping Inspection MethodsAli HashimÎncă nu există evaluări

- 3412 Get Set SpecsDocument4 pagini3412 Get Set Specslatranca100% (3)

- Detroit Diesel 8063-7405Document4 paginiDetroit Diesel 8063-7405Francisco CanidoÎncă nu există evaluări

- Caterpillar-3516C HD Marine EngineDocument4 paginiCaterpillar-3516C HD Marine EngineViswanathan Damodaran100% (4)

- Caterpillar 3512BDocument4 paginiCaterpillar 3512BArunnvinthan RajendramÎncă nu există evaluări

- Dynamometer: Theory and Application to Engine TestingDe la EverandDynamometer: Theory and Application to Engine TestingÎncă nu există evaluări

- Abb Itp-Ega - PCC Extension Panel - Itp - Rev0Document12 paginiAbb Itp-Ega - PCC Extension Panel - Itp - Rev0naumanÎncă nu există evaluări

- Daikin - Air Conditioning Training MaterialDocument92 paginiDaikin - Air Conditioning Training MaterialJM ArcillaÎncă nu există evaluări

- True Charge 20 Amp 3 Stage Charger ManualDocument78 paginiTrue Charge 20 Amp 3 Stage Charger ManualElliot Capson100% (1)

- 22 G3512 C555Document4 pagini22 G3512 C555texwan_Încă nu există evaluări

- Cat G3516Document4 paginiCat G3516Nazir Hussain100% (1)

- Generador Cat 3406C 260KW PDocument2 paginiGenerador Cat 3406C 260KW PTecnologia WilconÎncă nu există evaluări

- 2206c-E13tag2&3 Tpd1688e4Document20 pagini2206c-E13tag2&3 Tpd1688e4Daniel Graterol100% (2)

- Ficha Gerador Olympian GEP550Document6 paginiFicha Gerador Olympian GEP550Geetha_jagadish30100% (1)

- Generador Cat 3512bDocument4 paginiGenerador Cat 3512bcarlucido247970Încă nu există evaluări

- Hoja Tecnica Generador A GasDocument4 paginiHoja Tecnica Generador A GasJose Alberto Zamudio BaccaÎncă nu există evaluări

- Cat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Document4 paginiCat Engine Specifications 2.0 G/BHP-HR Nox (Nte)Oghale B. E. OmuaborÎncă nu există evaluări

- Caterpillar D125-6 Spec Sheet OpenDocument8 paginiCaterpillar D125-6 Spec Sheet OpenMTU650Încă nu există evaluări

- Cat C280-8Document16 paginiCat C280-8riz506100% (2)

- G3512 SpecDocument4 paginiG3512 SpecnunkpÎncă nu există evaluări

- 3608 2938kva ContinuousDocument2 pagini3608 2938kva ContinuoustabourianÎncă nu există evaluări

- Gerador A Gas PDFDocument4 paginiGerador A Gas PDFpaulo102030Încă nu există evaluări

- Caterpillar Planta ElectricaDocument6 paginiCaterpillar Planta ElectricaguyglesiasÎncă nu există evaluări

- Standby 175 KW Prime 157.5 KW: Diesel Generator SetsDocument6 paginiStandby 175 KW Prime 157.5 KW: Diesel Generator SetsHenry ValenciaÎncă nu există evaluări

- Cartepillar C32 Diesel Oilfield Generator SetDocument4 paginiCartepillar C32 Diesel Oilfield Generator SetJesus Enrique Figueroa GilÎncă nu există evaluări

- 150RZGDocument4 pagini150RZGJorge Andre Olivera Aranibar100% (1)

- Continuous 2000 kVA at 1500 RPM: GAS Generator SetDocument4 paginiContinuous 2000 kVA at 1500 RPM: GAS Generator Setmuhammad arif100% (1)

- 3516 516de4a 50HZ 6300Document6 pagini3516 516de4a 50HZ 6300sinliongÎncă nu există evaluări

- G3306 Gas Petroleum EnginepdfDocument4 paginiG3306 Gas Petroleum EnginepdfGustavo López CarriónÎncă nu există evaluări

- 1104d-E44ta sbl@96.5kw (Tpd1575e1)Document10 pagini1104d-E44ta sbl@96.5kw (Tpd1575e1)pricopdaniel50% (2)

- Caterpillar Gas EngineDocument4 paginiCaterpillar Gas Enginecandra100% (1)

- G3406NADocument4 paginiG3406NABenjamin MewingÎncă nu există evaluări

- Eq Generacion Electrica Iluminacion Olympian GEP150Document5 paginiEq Generacion Electrica Iluminacion Olympian GEP150Gianni EscalanteÎncă nu există evaluări

- 3512B 1500RPM 1300KW BrochureDocument4 pagini3512B 1500RPM 1300KW BrochuresalembatopÎncă nu există evaluări

- Cat 3306B DITA PropulsionDocument40 paginiCat 3306B DITA PropulsionStroe VladÎncă nu există evaluări

- G3306Document4 paginiG3306carlucido247970100% (1)

- Grupos Electronicos Diesel Cat n3306 225ekw PrimeDocument4 paginiGrupos Electronicos Diesel Cat n3306 225ekw PrimejalexivanÎncă nu există evaluări

- XQ1000 Lehx0532Document6 paginiXQ1000 Lehx0532Anonymous uZJfsg819LÎncă nu există evaluări

- Diesel Generator Set - Lehe5521-01Document8 paginiDiesel Generator Set - Lehe5521-01Dayo IdowuÎncă nu există evaluări

- Caterpillar 3406Document6 paginiCaterpillar 3406api-224431410Încă nu există evaluări

- Deutz 616Document6 paginiDeutz 616sdiamanÎncă nu există evaluări

- CaterpilarDocument4 paginiCaterpilarpangestu66100Încă nu există evaluări

- Marine Propulsion Engine: Fast VesselDocument4 paginiMarine Propulsion Engine: Fast VesselaldandanalÎncă nu există evaluări

- Scania Engine Data 1588878Document20 paginiScania Engine Data 1588878Anderson Aguiar69% (16)

- (Lehw0191-00) 3512c (HD) Ataac With DGBDocument4 pagini(Lehw0191-00) 3512c (HD) Ataac With DGBvictor.ciprianiÎncă nu există evaluări

- Specifications: 3512B Marine AuxiliaryDocument2 paginiSpecifications: 3512B Marine AuxiliaryLuis Alberto LopezÎncă nu există evaluări

- Caterpillar Marine InformationDocument58 paginiCaterpillar Marine InformationTrunk DangÎncă nu există evaluări

- Cat 12Document4 paginiCat 12Surya Chala PraveenÎncă nu există evaluări

- GEP33-1 (3-Phase) : Diesel Generating SetDocument6 paginiGEP33-1 (3-Phase) : Diesel Generating SetAndres AlegriaÎncă nu există evaluări

- Manual Kholer 2000reozddDocument4 paginiManual Kholer 2000reozddVictorÎncă nu există evaluări

- G3516B-1300 KW PDFDocument6 paginiG3516B-1300 KW PDFgerrzen64Încă nu există evaluări

- TBD 616Document6 paginiTBD 616sdiamanÎncă nu există evaluări

- 2506-A E15tag1 Datos TecnicosDocument14 pagini2506-A E15tag1 Datos TecnicosValeddia Beatriz Gutierrez Nina100% (1)

- Service Literature 80Mgf Series Units: Corp. 9801 L2 Revised 08 2004Document46 paginiService Literature 80Mgf Series Units: Corp. 9801 L2 Revised 08 2004askew9103Încă nu există evaluări

- Main Engine 3516C 1920 BKW 1600 RPM SpecDocument6 paginiMain Engine 3516C 1920 BKW 1600 RPM SpecCarlos Luis Esquerdo Marcano100% (1)

- Cat 3512 1280HP A RatingDocument4 paginiCat 3512 1280HP A RatingingjoseosunaÎncă nu există evaluări

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDe la EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesÎncă nu există evaluări

- Model Predictive Control of High Power Converters and Industrial DrivesDe la EverandModel Predictive Control of High Power Converters and Industrial DrivesÎncă nu există evaluări

- E-Wave Networks (P) LTD.: (An Iso 9001:2008 Certified Telecom Company)Document8 paginiE-Wave Networks (P) LTD.: (An Iso 9001:2008 Certified Telecom Company)Mohan JhaÎncă nu există evaluări

- R11 Segment 12Document49 paginiR11 Segment 12Dæmon PhobosÎncă nu există evaluări

- Engine Oil: Operation and Maintenance ManualDocument5 paginiEngine Oil: Operation and Maintenance ManualАлександр БудзинскийÎncă nu există evaluări

- Hi-Kalibre Actuator ManualDocument13 paginiHi-Kalibre Actuator Manual柴俊卿Încă nu există evaluări

- Analisis Soalan Fizik Kertas 2 BHG A Trial SPM 2010Document3 paginiAnalisis Soalan Fizik Kertas 2 BHG A Trial SPM 2010Norhazami HashimÎncă nu există evaluări

- APD345C-6 CompressedDocument5 paginiAPD345C-6 CompressedKelvinVelasquezPascualÎncă nu există evaluări

- Max Seal Fluid Loss Control AdditiveDocument2 paginiMax Seal Fluid Loss Control AdditiveadrianitoalaÎncă nu există evaluări

- Fire Issue: BNBC 2006 and BNBC 2017 (Upcoming) PDFDocument3 paginiFire Issue: BNBC 2006 and BNBC 2017 (Upcoming) PDFSayemAbusadat100% (1)

- Aeroshell Fluid 31: Specifications U.S. British French Russian NATO Code Joint Service DesignationDocument2 paginiAeroshell Fluid 31: Specifications U.S. British French Russian NATO Code Joint Service Designationarmando.ribamarÎncă nu există evaluări

- Naman Mehta Sustainable VIIIDocument13 paginiNaman Mehta Sustainable VIIInaman mehtaÎncă nu există evaluări

- Solar Based Grass CutterDocument6 paginiSolar Based Grass CutterTTÎncă nu există evaluări

- Basic Electronic For Marine EngineersDocument45 paginiBasic Electronic For Marine EngineersŞansal DikmenerÎncă nu există evaluări

- Desigo SystemDocument9 paginiDesigo Systemcindy .(00000050761)Încă nu există evaluări

- SM 18Document16 paginiSM 18Uriel HerreraÎncă nu există evaluări

- Climate Change: Frequently Asked QuestionsDocument8 paginiClimate Change: Frequently Asked QuestionsAdriano Racho MelendresÎncă nu există evaluări

- SKF TIH 240 Heater Instruction ManualDocument134 paginiSKF TIH 240 Heater Instruction ManualWei Leng tehÎncă nu există evaluări

- 1. المضخهDocument20 pagini1. المضخهالمهندسوليدالطويلÎncă nu există evaluări

- TNB Iar 2020Document360 paginiTNB Iar 2020yerio.dwiyantoÎncă nu există evaluări

- 06 Ba Exakt 80eplus EnglischDocument154 pagini06 Ba Exakt 80eplus EnglischAya adelÎncă nu există evaluări

- Yamaha Outboard Carburetor KitsDocument4 paginiYamaha Outboard Carburetor KitsMarine Parts ChinaÎncă nu există evaluări

- 230L2M551 - Cement Mixing EquipmentDocument43 pagini230L2M551 - Cement Mixing Equipmentyao nestorÎncă nu există evaluări

- Test Report GroutDocument2 paginiTest Report GroutKuldeep ChakerwartiÎncă nu există evaluări

- IAEA Fukushima Remediation Final - Report151111Document81 paginiIAEA Fukushima Remediation Final - Report151111EnformableÎncă nu există evaluări

- Multec 3.5 PDFDocument178 paginiMultec 3.5 PDFRogério MorenoÎncă nu există evaluări

- Low-Voltage Halogen Lamps Without Reflector: Product Family DatasheetDocument13 paginiLow-Voltage Halogen Lamps Without Reflector: Product Family DatasheetparasprrmÎncă nu există evaluări

- Quasi Turbine EngineDocument18 paginiQuasi Turbine EngineKailas Sree Chandran100% (2)