Documente Academic

Documente Profesional

Documente Cultură

Cooling With Dehumidification PDF

Încărcat de

Kevin TsuiDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cooling With Dehumidification PDF

Încărcat de

Kevin TsuiDrepturi de autor:

Formate disponibile

The following article was taken from a larger work on psychrometrics by

Norm Christopherson

COOLING WITH DEHUMIDIFICATION

Cooling is a sensible heat process. Cooling with dehumidification is a

sensible and latent heat combination. Strictly cooling air raises the relative

humidity. This may require that some dehumidification be accomplished to

reduce the humidity to comfortable levels. The chart in figure 8-1 shows a

typical process line for cooling with dehumidification.

Figure 8- 1

The state point on the right is warmer and lower in relative humidity than

the point on the left. Moving to the left on the chart indicates a reduction in

temperature as well as an increase in relative humidity.

Also notice that the state point on the right is higher on the chart than that

on the left. As this air was cooled it moved to the left but, it also dropped to

a lower specific humidity (grains) line. This indicates that the air was not

only cooled but, some actual grains of moisture were removed. The number

of grains removed per pound of air can be determined by finding the

difference between the number of grains at each state point.

The following example of a typical cooling with dehumidification process

illustrates how the process works.

COOLING WITH DEHUMIDIFICATION

Figure 8- 2

The cooling system in figure 8-2 is cooling and dehumidifying the air

simultaneously. This is the most common air conditioning process. This

system is moving 2000 CFM of air. Dry bulb and wet bulb temperatures are

taken of the supply and return air and found to be as follows:

RETURN AIR SUPPLY AIR

DB 80 degrees DB 60 degrees

WB 65 degrees WB 55 degrees

The state points for each of these conditions are located on a psychrometric

chart. (See figure 8-3) From the chart the following additional conditions

are read and recorded.

%RH about 46% %RH about 73%

Grains about 68.5 gr Grains about 57 gr

Notice as the air was cooled the relative humidity increased. This is due to

the contraction of the air. The moisture is contained in a smaller volume of

air thus the relative humidity is higher.

Also notice that the actual humidity in grains decreased. The cooling coil

removed grains (68.5 - 57) 11.5 grains of moisture removed for each pound

of air treated by the coil. The moisture removed attached itself to the coil

and fins, ran down the fins and into the condensate pan where it is drained

off.

THE SYSTEM COOLING CAPACITY

Since this system is removing both sensible and latent heat the total heat

formula must be used to determine the operating capacity.

Using the wet bulb temperatures for the supply and return air conditions,

look up the matching enthalpy for each on the wet bulb to enthalpy

conversion chart found on page xxx. The enthalpy values from the chart are

found to be as follows:

RETURN AIR SUPPLY AIR

WB 65 = an enthalpy of 30.06 btu\lb WB 55 = an enthalpy of 23.22 btu\lb

Find the difference in enthalpy by subtracting. 30.06 - 23.22 = 6.84 btu\lb

Now we know that 6.84 btu of heat was removed from each pound of air

that passed over the evaporator coil. Some of this heat was sensible heat

because the air was cooled, and some was latent heat because grains of

moisture were removed. Now the total cooling capacity of the coil can be

determined.

The Total Heat Formula

APPARATUS DEW POINT OR EFFECTIVE COIL TEMPERATURE

The ADP (apparatus dew point) or ETC (effective coil temperature) is the

temperature of the evaporator coil for this system operating under these

conditions. The temperature is determined by drawing a straight line

between the two state points and extending this line to the saturation

(100%) line on the chart as in figure 8-4.

The coil temp, apparatus dew point or effective coil temperature is read at

the saturation curve.

Figure 8- 4

You should be able to read this temperature as somewhere between 47 and

48 degrees on a psychrometric chart. A very careful evaluation will show

the reading to be 47.5 degrees. The coil temperature is useful in

determining the coil bypass factor.

COIL BYPASS FACTOR

The bypass factor is the percentage of air passing over the coil that is not

affected by the coil. This is air that passes between the coil tubes and fins

without making physical contact thus is untreated by the evaporator.

The leaving air dry bulb (LA DB) is the dry bulb temperature of the air

leaving the coil. This is the supply air dry bulb of 60 degrees. The entering

air dry bulb temperature is the dry bulb temperature of the air entering the

coil. This is the return air dry bulb temperature of 80 degrees. The ECT is

the temperature of 47.5 degrees.

The bypass factor of .384 means that 38.4% of the air moving over the coil

is unaffected by the coil.

Typical bypass factors for normally operating coils vary from .1 to .35, or

from 10% to 35%. A high bypass factor may indicate the air flow in cfm is

too high or it may simply indicate that the system air flow is adjusted to

prevent over dehumidifying the space. High sensible heat applications of air

conditioning may be so adjusted. An example is a computer room.

A knowledge of psychrometrics and airflow integrated with the fan laws is a

great service tool for the technician. This article just begins to illustrate the

fundamental cooling and dehumidification process. Many practical uses of

psychrometrics abound.

S-ar putea să vă placă și

- Exp 1 - Refrigeration UnitDocument33 paginiExp 1 - Refrigeration UnitastigeÎncă nu există evaluări

- CH 3 Gas Refrigeration CycleDocument20 paginiCH 3 Gas Refrigeration CycleMeleseÎncă nu există evaluări

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963De la EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Încă nu există evaluări

- BDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemDocument18 paginiBDA 37201 Engineering Lab V: Thermodynamics Air Conditioning SystemMuhd I-dilÎncă nu există evaluări

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4De la EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Evaluare: 5 din 5 stele5/5 (1)

- Cooling & Dehumidification Coil PDFDocument30 paginiCooling & Dehumidification Coil PDFonkarratheeÎncă nu există evaluări

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationDe la EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationÎncă nu există evaluări

- Experiment 1 RefrigerationDocument4 paginiExperiment 1 RefrigerationErlangga Sulaiman Razak100% (1)

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86De la EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Încă nu există evaluări

- Gas Refrigeration System (Air Refrigeration)Document30 paginiGas Refrigeration System (Air Refrigeration)Ruturaj UmaranikarÎncă nu există evaluări

- Cooling and Dehumidifying AirDocument5 paginiCooling and Dehumidifying AirFaquruddin AliÎncă nu există evaluări

- Thermo Exp Refrigeration Cycle ReportDocument11 paginiThermo Exp Refrigeration Cycle Reportbaemaejor100% (1)

- Assignment 2Document28 paginiAssignment 2ahsan aliÎncă nu există evaluări

- Cooling TowerDocument12 paginiCooling TowerLillianLinÎncă nu există evaluări

- MEC551 Assignment - Design June2017Document6 paginiMEC551 Assignment - Design June2017Muhd Syafiq OthmanÎncă nu există evaluări

- Design and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingDocument16 paginiDesign and Analysis of Central Air-Conditioning System With Air Cooled Chiller of Multi-Storey Office BuildingSajjad HasanÎncă nu există evaluări

- Refrigeration Test RigDocument7 paginiRefrigeration Test Rigshibin874141100% (1)

- Effect of Capillary Tube Length On The Vcrs Performance: Experiment No. (1) Mechanical LabDocument15 paginiEffect of Capillary Tube Length On The Vcrs Performance: Experiment No. (1) Mechanical LabDilshad S FaisalÎncă nu există evaluări

- Full ReportDocument16 paginiFull ReportafiqahanuwarÎncă nu există evaluări

- Lecture 30 Thermal Engineering II (22.09.2020)Document36 paginiLecture 30 Thermal Engineering II (22.09.2020)Dr. BIBIN CHIDAMBARANATHANÎncă nu există evaluări

- Performance Analysis of Domestic RefrigeratorDocument10 paginiPerformance Analysis of Domestic RefrigeratorsyooloveÎncă nu există evaluări

- Supersonic Flow Over A Double Circular AirfoilDocument33 paginiSupersonic Flow Over A Double Circular AirfoilDragomirescu Andrei100% (1)

- Heat Pump and RefrigertorDocument10 paginiHeat Pump and RefrigertordohlalaÎncă nu există evaluări

- CH 7 PowerCyclesDocument12 paginiCH 7 PowerCyclescarleston thurgoodÎncă nu există evaluări

- Lecture-17: Multi-Stage Vapour Compression Refrigeration SystemsDocument13 paginiLecture-17: Multi-Stage Vapour Compression Refrigeration SystemsMuhaamad TiloÎncă nu există evaluări

- Heat ExchangerDocument14 paginiHeat ExchangerKlinsmannJanujajJurgenÎncă nu există evaluări

- Tube Wire Vs Wall Condenser PDFDocument15 paginiTube Wire Vs Wall Condenser PDFHimanshu100% (1)

- Mech3005 Lab1112 Fancoil PDFDocument5 paginiMech3005 Lab1112 Fancoil PDFbilal almelegy100% (1)

- Performance Test of A Vapor Compression Refrigeration CycleDocument11 paginiPerformance Test of A Vapor Compression Refrigeration CycleA-ar FebreÎncă nu există evaluări

- Practice Set 19 (Fins)Document2 paginiPractice Set 19 (Fins)Nibir SahaÎncă nu există evaluări

- Investigation of The Effect of Cooling Load On Cooling Tower Performance Thermodynamic Exp 6Document14 paginiInvestigation of The Effect of Cooling Load On Cooling Tower Performance Thermodynamic Exp 6hayder alaliÎncă nu există evaluări

- RAC Assignments 24062016 091508AMDocument37 paginiRAC Assignments 24062016 091508AMsakalidhasavasanÎncă nu există evaluări

- Internal Heat ExchangerDocument39 paginiInternal Heat ExchangerNeal Christian ParatoÎncă nu există evaluări

- Lecture-5: Typical Air-Conditioning ProcessesDocument10 paginiLecture-5: Typical Air-Conditioning Processesabrar alhadadÎncă nu există evaluări

- Heat Exchanger Sample Report 2018Document55 paginiHeat Exchanger Sample Report 2018RahulSrivastava100% (1)

- Carnot Refrigeration CycleDocument11 paginiCarnot Refrigeration CycleZaimÎncă nu există evaluări

- Me152l - Experiment 7 - AmahmudDocument20 paginiMe152l - Experiment 7 - AmahmudAli Requiso MahmudÎncă nu există evaluări

- Introduction To Microscale Heat TransferDocument14 paginiIntroduction To Microscale Heat TransferManoj Kumar MoharanaÎncă nu există evaluări

- Air Refrigeration SystemDocument29 paginiAir Refrigeration SystemSumit KumarÎncă nu există evaluări

- Test On Vapor Compression Refrigeration FINALDocument8 paginiTest On Vapor Compression Refrigeration FINALUdara ManawaduÎncă nu există evaluări

- Heat ConvectionDocument15 paginiHeat ConvectionNasri JamaludinÎncă nu există evaluări

- Exp.1 - Steady - State Thermal ConductionDocument5 paginiExp.1 - Steady - State Thermal Conductionنزار الدهاميÎncă nu există evaluări

- Smoke TunnelDocument55 paginiSmoke TunnelABHIMANYU KHADGAÎncă nu există evaluări

- Lab Note 10 Lab Manual-Heat PumpDocument11 paginiLab Note 10 Lab Manual-Heat Pumpfarah nabila100% (1)

- Heat Transfer and Mass Sheets FinalDocument22 paginiHeat Transfer and Mass Sheets FinalMahmuod Abdalrahman100% (1)

- Double Pipe Heat Exchanger ExperimentDocument7 paginiDouble Pipe Heat Exchanger ExperimentBenedicta Monis100% (1)

- RAC 32 Important QuestionDocument10 paginiRAC 32 Important QuestionBalvinderÎncă nu există evaluări

- Double Pipe Heat Exchanger Final ReportDocument14 paginiDouble Pipe Heat Exchanger Final Reportapi-445625885Încă nu există evaluări

- HT304 - Draft Report PDFDocument7 paginiHT304 - Draft Report PDFshashiÎncă nu există evaluări

- Assignment 12Document7 paginiAssignment 12Anonymous mqIqN5zÎncă nu există evaluări

- Compression RatiosDocument14 paginiCompression RatiosDirkMyburghÎncă nu există evaluări

- University of Zakho College of Engineering Mechanical DepartmentDocument22 paginiUniversity of Zakho College of Engineering Mechanical DepartmentDilshad S FaisalÎncă nu există evaluări

- Effect of Flash Gas Bypass On Performance of VCR SystemDocument4 paginiEffect of Flash Gas Bypass On Performance of VCR SystemesatjournalsÎncă nu există evaluări

- Practica CDocument2 paginiPractica CAlejandroCalleRuizÎncă nu există evaluări

- Innovative Vapor CompressionDocument13 paginiInnovative Vapor CompressionCj MoLanoÎncă nu există evaluări

- Heat ExchangerDocument32 paginiHeat ExchangerRaj Khasnobish100% (1)

- Heat Pump Experiment: Real Time COP Measurement MEE 443Document12 paginiHeat Pump Experiment: Real Time COP Measurement MEE 443Nova AprilÎncă nu există evaluări

- Unit-3, Adiabatic Saturation Temp, Psychrometric ChartDocument7 paginiUnit-3, Adiabatic Saturation Temp, Psychrometric Chartgayakwad12_ramÎncă nu există evaluări

- Acta Biomaterialia: Jess G. Snedeker, Jasper FoolenDocument19 paginiActa Biomaterialia: Jess G. Snedeker, Jasper FoolenKevin TsuiÎncă nu există evaluări

- BR Cat Cafs Ie2 Eng r00 0Document542 paginiBR Cat Cafs Ie2 Eng r00 0Kevin TsuiÎncă nu există evaluări

- Fracture and Crack Propagation in WeldmentsDocument66 paginiFracture and Crack Propagation in WeldmentsKhin Aung ShweÎncă nu există evaluări

- Complex Stress Condition CAE FatigueDocument77 paginiComplex Stress Condition CAE FatigueN.g. NagarajÎncă nu există evaluări

- Fracture and Crack Propagation in WeldmentsDocument66 paginiFracture and Crack Propagation in WeldmentsKhin Aung ShweÎncă nu există evaluări

- Vibration MeasurementDocument42 paginiVibration MeasurementChockkalingam Subramanian100% (2)

- AC 43-4aDocument131 paginiAC 43-4aKevin TsuiÎncă nu există evaluări

- Introduction To ANSYS MechanicalDocument31 paginiIntroduction To ANSYS MechanicalKevin TsuiÎncă nu există evaluări

- The Art of Instrumentation & Vibration AnalysisDocument64 paginiThe Art of Instrumentation & Vibration AnalysisfrajaprÎncă nu există evaluări

- Effect of Enhanced Mechanical Properties of Weld Metal and Heat Affected Zone On The Strength of The Welded JointDocument5 paginiEffect of Enhanced Mechanical Properties of Weld Metal and Heat Affected Zone On The Strength of The Welded JointKevin TsuiÎncă nu există evaluări

- Tribology BasicsDocument70 paginiTribology Basicsfeni4kaÎncă nu există evaluări

- AirDistributionGuide March15Document75 paginiAirDistributionGuide March15Kevin TsuiÎncă nu există evaluări

- SolidWorks Simulation - Avoiding SingularitiesDocument6 paginiSolidWorks Simulation - Avoiding SingularitiesAnonymous P8Bt46mk5IÎncă nu există evaluări

- Vehicle AerodynamicsDocument31 paginiVehicle AerodynamicsNimisha Singh100% (1)

- Technical Reference Guide Fastenal K Factor and MoreDocument62 paginiTechnical Reference Guide Fastenal K Factor and Moredlight0Încă nu există evaluări

- FM 200 - Product Brochure PDFDocument4 paginiFM 200 - Product Brochure PDFKevin TsuiÎncă nu există evaluări

- Low and High Cycle FatigueDocument85 paginiLow and High Cycle FatigueKevin TsuiÎncă nu există evaluări

- Trane 4 Chiller Plant ControlsDocument28 paginiTrane 4 Chiller Plant ControlsEdward Siu100% (3)

- 39 Space Air DistributionDocument25 pagini39 Space Air DistributionPRASAD326100% (3)

- Presentation Chilled WaterDocument40 paginiPresentation Chilled WaterMurad AliÎncă nu există evaluări

- ISOVERDocument35 paginiISOVERMadhu RaghuÎncă nu există evaluări

- Ducts and Diffusers DesignDocument106 paginiDucts and Diffusers DesignFrancis Paul100% (1)

- Alarm Valve SprinklerDocument20 paginiAlarm Valve SprinklerKevin TsuiÎncă nu există evaluări

- Pyro-Chem Manual PDFDocument109 paginiPyro-Chem Manual PDFKevin Tsui100% (4)

- Explicit Formulas For The Calculation of Regenerated Noise in DuctsDocument5 paginiExplicit Formulas For The Calculation of Regenerated Noise in DuctsKevin TsuiÎncă nu există evaluări

- Cylinder Data Sheet (FM200 Gas Bottle) PDFDocument4 paginiCylinder Data Sheet (FM200 Gas Bottle) PDFKevin TsuiÎncă nu există evaluări

- ,DanaInfo .AgAjnk1ki8-Jrx1pp1Qs-C-VzA.+FM200 UL-FM Manual Thorn (14A-07 Issue 2)Document120 pagini,DanaInfo .AgAjnk1ki8-Jrx1pp1Qs-C-VzA.+FM200 UL-FM Manual Thorn (14A-07 Issue 2)Kevin TsuiÎncă nu există evaluări

- Sprinkler 001Document66 paginiSprinkler 001Kevin Tsui100% (1)

- Brecsu Avoid AcDocument38 paginiBrecsu Avoid AcKevin TsuiÎncă nu există evaluări

- Brochures & Gadgets CatalogDocument9 paginiBrochures & Gadgets CatalogSinergroup Water Filters Water Purifiers Water SoftenersÎncă nu există evaluări

- 11AK30 - Tech Bulletins PDFDocument11 pagini11AK30 - Tech Bulletins PDFStefanvnvÎncă nu există evaluări

- Cummins QuickServe OnlineDocument2 paginiCummins QuickServe Onlineram_scribd_economicsÎncă nu există evaluări

- 1296 Stock Report 26-01-2020 PDFDocument20 pagini1296 Stock Report 26-01-2020 PDFSANJAY KUMAR SINGHÎncă nu există evaluări

- Hydraulics QuestionsDocument2 paginiHydraulics QuestionspvrkusbbÎncă nu există evaluări

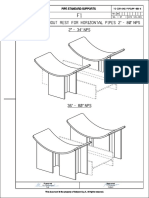

- Axial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsDocument4 paginiAxial Stop Without Rest For Horizontal Pipes 2" - 80" NPS: Pipe Standard SupportsMainuddin AliÎncă nu există evaluări

- Biocleaner Presentation SewageDocument10 paginiBiocleaner Presentation SewageLTE002Încă nu există evaluări

- Commercial Cooling Load CalculationDocument6 paginiCommercial Cooling Load CalculationMuhammad Kamran MalikÎncă nu există evaluări

- Laminar Vertical Cabinet: Basic CharacteristicsDocument2 paginiLaminar Vertical Cabinet: Basic CharacteristicsBoris KozjanÎncă nu există evaluări

- INTERFLEX Catalogue (Conduits and Fittings)Document8 paginiINTERFLEX Catalogue (Conduits and Fittings)cherif yahyaouiÎncă nu există evaluări

- Classification of Crystal Growth MethodsDocument2 paginiClassification of Crystal Growth MethodsBefzz0% (1)

- Gear RatiosDocument10 paginiGear RatiosYouMineÎncă nu există evaluări

- 009 Propulsion Azimuth Thruster - SDocument504 pagini009 Propulsion Azimuth Thruster - SSuchindran Varadaraj100% (1)

- Semiconductor MaterialDocument55 paginiSemiconductor MaterialAiman NabihahÎncă nu există evaluări

- ParkerDocument196 paginiParkerj3r007Încă nu există evaluări

- FR-F700 Instruction Manual (Basic) - IB-0600176ENG-HDocument165 paginiFR-F700 Instruction Manual (Basic) - IB-0600176ENG-Hduybac-spkhcmÎncă nu există evaluări

- Hyundai Steel Products GuideDocument40 paginiHyundai Steel Products GuidecarloÎncă nu există evaluări

- 2nd YearDocument24 pagini2nd YearAlxalx Alex50% (2)

- Catalogo MartinDocument208 paginiCatalogo MartinFrancisco Garibaldi MarquezÎncă nu există evaluări

- Electrical BOQ FinalDocument45 paginiElectrical BOQ FinalmahasubbuÎncă nu există evaluări

- Sihi LPG Solutions e 072011Document6 paginiSihi LPG Solutions e 072011Renato FinatiÎncă nu există evaluări

- Daikin PA Catalogue Revised Low ResDocument32 paginiDaikin PA Catalogue Revised Low ResKartik PrabhakarÎncă nu există evaluări

- Nonlinear Finite Element Anlaysis of Elastomers PDFDocument52 paginiNonlinear Finite Element Anlaysis of Elastomers PDFRaju63Încă nu există evaluări

- 2015jones CopperDocument6 pagini2015jones CopperRunkitoÎncă nu există evaluări

- Chapter 4 Jobbing and BatchDocument39 paginiChapter 4 Jobbing and BatchDavid HồÎncă nu există evaluări

- Pinza Scully - 67206 - Desc PDFDocument2 paginiPinza Scully - 67206 - Desc PDFYilhennys RegaladoÎncă nu există evaluări

- Sensors Pt100 TF Datasheet e ZIEHL-1Document4 paginiSensors Pt100 TF Datasheet e ZIEHL-1Anom HarimurtiÎncă nu există evaluări

- Tensile PropertiesDocument2 paginiTensile PropertiesSh.nasirpurÎncă nu există evaluări

- Manual SwitchgearDocument48 paginiManual SwitchgearVinícius MartinsÎncă nu există evaluări

- Department of Mechanical Engineering: List of Experiments Hvac LabDocument3 paginiDepartment of Mechanical Engineering: List of Experiments Hvac LabHamid MasoodÎncă nu există evaluări

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessDe la EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessÎncă nu există evaluări

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseDe la EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseEvaluare: 3.5 din 5 stele3.5/5 (69)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDe la EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingEvaluare: 5 din 5 stele5/5 (5)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionDe la EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionEvaluare: 4 din 5 stele4/5 (811)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldDe la EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldEvaluare: 4.5 din 5 stele4.5/5 (18)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingDe la EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingEvaluare: 3.5 din 5 stele3.5/5 (33)

- Fire Season: Field Notes from a Wilderness LookoutDe la EverandFire Season: Field Notes from a Wilderness LookoutEvaluare: 4 din 5 stele4/5 (142)

- The Other End of the Leash: Why We Do What We Do Around DogsDe la EverandThe Other End of the Leash: Why We Do What We Do Around DogsEvaluare: 5 din 5 stele5/5 (65)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsDe la EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsEvaluare: 4 din 5 stele4/5 (223)

- When the Sahara Was Green: How Our Greatest Desert Came to BeDe la EverandWhen the Sahara Was Green: How Our Greatest Desert Came to BeEvaluare: 4.5 din 5 stele4.5/5 (6)

- Spoiled Rotten America: Outrages of Everyday LifeDe la EverandSpoiled Rotten America: Outrages of Everyday LifeEvaluare: 3 din 5 stele3/5 (19)

- Come Back, Como: Winning the Heart of a Reluctant DogDe la EverandCome Back, Como: Winning the Heart of a Reluctant DogEvaluare: 3.5 din 5 stele3.5/5 (10)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsDe la EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsEvaluare: 3.5 din 5 stele3.5/5 (13)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeDe la EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeEvaluare: 4.5 din 5 stele4.5/5 (699)

- The Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanDe la EverandThe Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanÎncă nu există evaluări

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldDe la EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldEvaluare: 4 din 5 stele4/5 (593)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildDe la EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildEvaluare: 4.5 din 5 stele4.5/5 (44)

- The Hidden Life of Trees: What They Feel, How They CommunicateDe la EverandThe Hidden Life of Trees: What They Feel, How They CommunicateEvaluare: 4 din 5 stele4/5 (1002)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorDe la EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorEvaluare: 4.5 din 5 stele4.5/5 (137)