Documente Academic

Documente Profesional

Documente Cultură

Stair Case Design - at Design Office

Încărcat de

Shamen Amarasekara0 evaluări0% au considerat acest document util (0 voturi)

320 vizualizări14 paginiTitlu original

Stair Case Design- @ Design Office

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLSX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

320 vizualizări14 paginiStair Case Design - at Design Office

Încărcat de

Shamen AmarasekaraDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 14

Reference

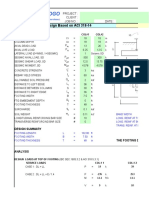

Staircase between two beams

Choose of Layout

Assume,

No of Stairs = 12 Nos

Then, rise ( R ) = 166.7 mm 150 min for Public , 175 Max for privet

going ( G ) = 250 mm

Also Check 2R+G = 583.3 mm Closer to 600, Ok

Use nosing = 25 mm Input

Then, Tread (T) = 275 mm

Waist Thickness

Assume,

Trial span/E.Depth ratio = 30

3.10.2.2 incrasing Factor = 15%

Then, Span/E.Depth = 34.5

Effective Depth ( d ) = 87.0 mm

Cover,

Table-1 Exposure Condition = Mild

Fire resistance = 1.50 hr

Aggrgate size = 20 mm

Hense, Cover = 20 mm

Assume Bar Dia. = 12 mm

Hense, Min. Height = 113.0 mm

Provide (h) = 120 mm Ok

Then, prvide ( d ) = 94 mm

Loading (for 1m wide strip)

Factor for slope = (R

2

+G

2

)

G

= 1.20

Factor for Overlap = T/G

= 1.1

Dead,

Design of Staircase - Connected to Beams at Ends

Waist = 3.46 kN/m

Steps = 2.20 kN/m

Top finishes = 0.55 kN/m

Sofft Plaster = 0.30 kN/m

Total Dead = 6.51 kN/m

Impose,

Impose = 5.00 kN/m

Design load ( n ) = 17.12 kN/m

Design for Bending

M (Span & Support) = 15.40 kNm

M = 1.74

bd

2

BS 8110-3 100A

s

= 0.48 Input from chart

Chart-2 bd

A

s,req

= 451.2 mm

2

Use T 12 Spacing @ 250

A

s,pro

= 452.6 mm

2

Satisfied

BS 8110-1

3.12.11.2.7 Allowable Spacing = 282 mm Ok

Table-3.25 Minimum r/f %

100A

s

= 0.13

A

c

Provide r/f %

100A

s

= 0.38 Satisfied

A

c

Deflection Check

M = 1.74

bd

2

BS 8110-1 f

s

= 5 f

y

A

s,req

x 1

Equation-8 8 A

s,pro

b

= 286.63 N/mm

2

BS 8110-1 Hence,

Equation-7 F

1

= 0.55 + (477-f

s

)

(Table-11,10)

120*(0.9+M/bd

2

)

1.15

8110-1 Hense, Allowable span / depth ratio, (with out stringer beam and occupied mpre than 50% of span)

3.10.2.2 =

3.4.6.3 = 26 Input

= 34.4

Actual Span / depth = 31.9

Hense deflection check is OK

Check for Shear

Gra.E. Dias Shear acting,

Note-9 V = 0.6 * F kN/m (1m width strip)

= 30.81 kN/m

v = 0.328 N/mm

2

Shear capacity,

100 A

s

/bd = 0.48

8110-1:1985 Hense, v

c

= 0.659 Input from table

Table- 3.9

0.328 < 0.659

v < vc Hense, shear R/F not required

Distribution Steel

8110-1:1985

Table-3.27 100A

s

/A

c

= 0.24 Input for Mild

Note-10 = 0.13 Input for Tor

Dias, Provided Steel = Mild (Mild or Tor)

Then, 100A

s

/A

c

= 0.24

A

s

= 288.0 mm

2

/m

Use R 8 @ 175

Then, A

s,Provided

= 288.00 mm

2

Steel is OK

Height = 2000

150 min for Public , 175 Max for privet R =

G =

Span = 3000

Closer to 600, Ok Density of Concete = 24 input

Soffite Plaster = 0.25 input

Top finishes load = 0.5 input

Impose Load = 5.0 input

f

y

= 460 N/mm

2

c =

d =

Design of Staircase - Connected to Beams at Ends

Results

n =

Input from chart

Hense, Allowable span / depth ratio, (with out stringer beam and occupied mpre than 50% of span)

Increased by = 15% Input

Hense deflection check is OK

(1m width strip)

Input from table

Hense, shear R/F not required

(c.Rectangular section-in slid slab this minimum should be provided in both direction)

167

250

20

94

Results

17.12

Reference

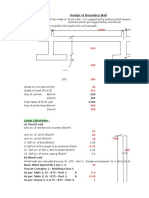

Staircase between two beams

l

b,1 l

a

l

b,2

l

b,1

=

1200

1200

Stair span and Waist thickness

8110-1 Effe.Span = l

a

+(0.5)(l

b,1

+l

b,2

)

Equation-47 = 3.50 m

Dias, Note 3

Length of Stairs = l

a

/ Effe.Span m

3.10.2.2 Length of Stairs % = 57.14 %

<60, Hense span depth enhancement not possible

Dias, Note 4 Assume,

Trial Span/Depth ratio = 32 Input for a continous 1-Way spaning stair case

Hense, Efe.Dep.(d) = 109.4 mm

Assume,

Cover = 20 mm Input Mild exposure condition and concrete protected by 10mm 1:3 cement sand rendering

Bar dia = 12 mm Input

Hense, h

Req

= 135.4 mm

Provide, h

Pro

= 140 mm Input Ok

then, Efe.Dep.(d) = 114 mm Ok

Loading for 1.2 m wide staircase

Dias, Note 5 Factor for slope = (R

2

+G

2

)

G

= 1.22

Factor for Overlap = T/G

= 1.1

Width of Staircase = 1.2 mm Input

Dead,

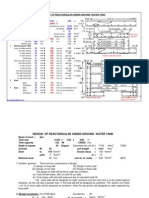

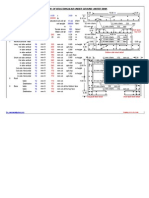

Design of Staircase - Connected with slabs

Waist = 4.92 kN/m

Steps = 2.77 kN/m

Top finishes = 0.66 kN/m

Sofft Plaster = 0.37 kN/m

Total Dead = 8.72 kN/m

Impose,

Impose = 3.60 kN/m

Design load ( n ) = 17.97 kN/m

Design for Bending

Dias, Note 6 The staircase can be idealised as follows:

Dias, Note 3

x n= 17.97

A B

0.6 2.0 0.9

B: R

A

= 19.51 kN

Hense, R

B

= 16.43 kN

Then,

M

x

= R

A

.x - n(x-0.6)

2

/2

When M

x

max dM

x

/dx = 0

dM

x

/dx = R

A

- n(x-0.6)

@ x = R

A

/ n + .6

x = 1.69 m

Then,

M

x

= 22.29 kNm

BS 8110-3 Hense, M/bd

2

= 1.43 N/mm

2

Chart 2 100A

s

/bd = 0.39

Hense, A

s

= 534 mm

2

Use T 12 Nos 5

A

s,pro

= 565.7 mm

2

Satisfied

Deflection Check

M = 1.43

bd

2

BS 8110-1 f

s

= 5 f

y

A

s,req

x 1

Equation-8 8 A

s,pro

b

= 271.38 N/mm

2

BS 8110-1 Hence,

Equation-7 F

1

= 0.55 + (477-f

s

)

(Table-11,10)

120*(0.9+M/bd

2

)

1.29

8110-1 Hense, Allowable span / depth ratio, (with out stringer beam and occupied mpre than 50% of span)

3.10.2.2 =

3.4.6.3 = 26 Input

= 33.4

Actual Span / depth = 30.7 < 33.4

Hense deflection check is OK

Check for Shear

Gra.E. Dias Shear acting,

Note-9 V = 0.6 * F kN/m (1m width strip)

= 0.00 kN/m

v = 0.000 N/mm

2

Shear capacity,

100 A

s

/bd = 1.86

8110-1:1985 Hense, v

c

= 0.659 Input from table

Table- 3.9

0.000 < 0.659

v < vc Hense, shear R/F not required

Distribution Steel

8110-1:1985

Table-3.27 100A

s

/A

c

= 0.24 Input for Mild (c.Rectangular section-in slid slab this minimum should be provided in both direction)

Note-10 = 0.13 Input for Tor

Dias, Provided Steel = Mild (Mild or Tor) Input

Then, 100A

s

/A

c

= 0.24

A

s

= 336.0 mm

2

/m

Use R 8 @ 150

Then, A

s,Provided

= 336.00 mm

2

Steel is OK

1200 l

a

= 8 250 = 2000 l

b,2

= 2000

l

a

= 2000 mm

l

b,1

= 1200 mm

l

b,2

= 1800 mm

Rise = 175 mm

Going = 250 mm Efe.Span = 3.5

Tread = 275 mm

<60, Hense span depth enhancement not possible

for a continous 1-Way spaning stair case

Mild exposure condition and concrete protected by 10mm 1:3 cement sand rendering

h = 140

d = 114

Density of Concete = 24

Soffite Plaster = 0.25 kN/m

2

Top finishes load = 0.5 kN/m

2

Impose Load = 3.0 kN/m

2

f

y

= 460 N/mm

2

Design of Staircase - Connected with slabs

Results

Inputs

Inputs

n = 17.97

Hense, Allowable span / depth ratio, (with out stringer beam and occupied mpre than 50% of span)

(c.Rectangular section-in slid slab this minimum should be provided in both direction)

S-ar putea să vă placă și

- Beam Design - at Design OfficeDocument59 paginiBeam Design - at Design OfficeShamen AmarasekaraÎncă nu există evaluări

- Column Design - at Design OfficeDocument56 paginiColumn Design - at Design OfficeShamen AmarasekaraÎncă nu există evaluări

- Retaining Wall Design - 1Document23 paginiRetaining Wall Design - 1abhijithaval100% (3)

- 6.2 Beam DesignDocument12 pagini6.2 Beam DesignShamen Amarasekara100% (2)

- Slab Design-@ Design OfficeDocument40 paginiSlab Design-@ Design OfficeShamen AmarasekaraÎncă nu există evaluări

- Hetauda Raft DesignDocument92 paginiHetauda Raft DesignSurendra MaharjanÎncă nu există evaluări

- Loading (For 1m Wide Staire Case) : Beams Provided at The Ends of Landings & Span at Right AngleDocument3 paginiLoading (For 1m Wide Staire Case) : Beams Provided at The Ends of Landings & Span at Right AnglePita KymÎncă nu există evaluări

- Hidden BeamDocument2 paginiHidden BeammagdyamdbÎncă nu există evaluări

- Column DesignDocument11 paginiColumn DesignShamen Amarasekara100% (2)

- Design of Two Way Slab: 2nd/3rd Floor Slab S1Document14 paginiDesign of Two Way Slab: 2nd/3rd Floor Slab S1John Paul Hilary EspejoÎncă nu există evaluări

- Spreadsheets To BS 8110: The Concrete CentreDocument14 paginiSpreadsheets To BS 8110: The Concrete CentreCioabla BogdanÎncă nu există evaluări

- TCC71 Stair Flight & Landing - SingleDocument7 paginiTCC71 Stair Flight & Landing - Singlehala_azhariÎncă nu există evaluări

- R C Beam DesignDocument6 paginiR C Beam Designdaddakoli007Încă nu există evaluări

- Continue One Way SlabDocument31 paginiContinue One Way Slabanon_601117903Încă nu există evaluări

- 2-WAY SLAB OPTIMIZATIONDocument120 pagini2-WAY SLAB OPTIMIZATIONSambhav PoddarÎncă nu există evaluări

- StaircaseDocument2 paginiStaircaseMAGED MOHMMED AHMED QASEMÎncă nu există evaluări

- Name of Work:-Design of Circular Beam: DegreeDocument25 paginiName of Work:-Design of Circular Beam: DegreeAnirban DeyÎncă nu există evaluări

- BASEPLT9Document5 paginiBASEPLT9Bunkun15Încă nu există evaluări

- 2way Slab DesignDocument10 pagini2way Slab DesignHari Amudhan IlanchezhianÎncă nu există evaluări

- Beam DesignDocument1 paginăBeam Designzeal86Încă nu există evaluări

- Beam DesignDocument37 paginiBeam DesignYinka Akinkunmi100% (1)

- Web Tapered Frame Design Based On AISC-ASD 9th, Appendix F Input Data & Design SummaryDocument3 paginiWeb Tapered Frame Design Based On AISC-ASD 9th, Appendix F Input Data & Design SummaryLivian TeddyÎncă nu există evaluări

- Design of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsDocument3 paginiDesign of Rectangular Combined Footing Supporting Two Axially Loaded ColumnsThirdie LerajeÎncă nu există evaluări

- Column design details for rectangular columnDocument27 paginiColumn design details for rectangular columnnsureshbabu0% (1)

- Circular beam designDocument34 paginiCircular beam designHasanuzzaman PalashÎncă nu există evaluări

- Design of Rectangular Footing Col at Edge - 3Document27 paginiDesign of Rectangular Footing Col at Edge - 3Glenn SarneÎncă nu există evaluări

- Design of Square Footing F2Document18 paginiDesign of Square Footing F2Mohammed Sumer100% (1)

- RC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Document5 paginiRC Beam Analysis & Design (En1992-1) : TEDDS Calculation Version 2.0.03Natasha WyneÎncă nu există evaluări

- Design BeamDocument50 paginiDesign BeammonirithneangÎncă nu există evaluări

- Pad Footing Design Overturning MTDocument8 paginiPad Footing Design Overturning MTAUNGÎncă nu există evaluări

- Beam Load Calculation Fill The Highlighted Cells OnlyDocument14 paginiBeam Load Calculation Fill The Highlighted Cells Onlyhary9100Încă nu există evaluări

- Structural analysis & design of roof beam, column and footingDocument7 paginiStructural analysis & design of roof beam, column and footingAntonio EstradaÎncă nu există evaluări

- Title: Slab Design PDI Block-Hetauda Input ParametersDocument13 paginiTitle: Slab Design PDI Block-Hetauda Input ParametersAnimras TamrakarÎncă nu există evaluări

- FOUNDATION ANALYSIS TITLEDocument7 paginiFOUNDATION ANALYSIS TITLERoberto Catalani100% (1)

- G12E Column capacity and design checksDocument10 paginiG12E Column capacity and design checksSumedha MayadunnaÎncă nu există evaluări

- Combined FootingDocument18 paginiCombined Footingjklo12Încă nu există evaluări

- Rcc Lintel Beam, Column, Slab and Wall Design CalculationDocument9 paginiRcc Lintel Beam, Column, Slab and Wall Design CalculationwaquarshaiÎncă nu există evaluări

- RCCe11 Element DesignDocument8 paginiRCCe11 Element DesignZayyan RomjonÎncă nu există evaluări

- Two-Cell Box Culvert Design at Islamabad AirportDocument16 paginiTwo-Cell Box Culvert Design at Islamabad AirportLa Ode Muhammad HardinÎncă nu există evaluări

- RC Roof Beam DesignDocument5 paginiRC Roof Beam DesignSujay SantraÎncă nu există evaluări

- Eurocode example ex3.1.4 connection designDocument4 paginiEurocode example ex3.1.4 connection designРостислав Василев100% (2)

- Design of RCC SlabDocument8 paginiDesign of RCC Slabrajseema_n2180% (5)

- Column DesignDocument10 paginiColumn Designmhel_almo100% (1)

- Pile Cap Design - ColumnsDocument6 paginiPile Cap Design - Columnssssmou100% (1)

- Strap FootingDocument18 paginiStrap Footinghemantkle2uÎncă nu există evaluări

- Cantilever CanopyDocument2 paginiCantilever Canopyapi-19753598Încă nu există evaluări

- Boundray Wall Design Data Ganj BasodaDocument6 paginiBoundray Wall Design Data Ganj BasodaShubham KhareÎncă nu există evaluări

- Conc Short ColDocument13 paginiConc Short ColEngDbtÎncă nu există evaluări

- 16 PoleDocument2 pagini16 PoleMario Sajulga Dela CuadraÎncă nu există evaluări

- Design of PurlinsDocument8 paginiDesign of PurlinsLa BeamÎncă nu există evaluări

- Slab design calculations and steel requirementsDocument2 paginiSlab design calculations and steel requirementsvidudalaraviÎncă nu există evaluări

- AbutmentDocument31 paginiAbutmenthrpinfra100% (1)

- Ractangular Under Ground Water Tank1Document28 paginiRactangular Under Ground Water Tank1Ali Khan100% (1)

- Design of Rectangular Water Tank with Dimensions 6m x 4m x 3.5mDocument268 paginiDesign of Rectangular Water Tank with Dimensions 6m x 4m x 3.5mchetanmale89% (28)

- UG TankDocument29 paginiUG TankImranSohailÎncă nu există evaluări

- Circular Water Tank With Domcal Top and Flat BaseDocument20 paginiCircular Water Tank With Domcal Top and Flat BaseIrshad Khan100% (2)

- Structural AnalysisDocument5 paginiStructural AnalysishampshireiiiÎncă nu există evaluări

- Footing DesignDocument30 paginiFooting DesignShaikh Muhammad Ateeq100% (1)

- Water Tank ExclusiveDocument28 paginiWater Tank Exclusivesumonrangpuri40% (5)

- Footing and beam design for column layoutDocument65 paginiFooting and beam design for column layoutarif_rubinÎncă nu există evaluări

- EM 1110-2-1416 River HydraulicsDocument176 paginiEM 1110-2-1416 River Hydraulicsdyc123100% (1)

- Design LimitationsDocument2 paginiDesign LimitationsShamen AmarasekaraÎncă nu există evaluări

- Greater Colombo Water Rehabilitation Project Pipe: Measurement Sheet ForDocument1 paginăGreater Colombo Water Rehabilitation Project Pipe: Measurement Sheet ForShamen AmarasekaraÎncă nu există evaluări

- 16 - Hazarous Waste of LandfillsDocument70 pagini16 - Hazarous Waste of LandfillsShamen AmarasekaraÎncă nu există evaluări

- Pipe Filling VolumeDocument9 paginiPipe Filling VolumeShamen AmarasekaraÎncă nu există evaluări

- Beam Design Formulas With Shear and MomentDocument20 paginiBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- EM 1110-2-1909 - Calibration of Laboratory Soils Testing EquipmentDocument45 paginiEM 1110-2-1909 - Calibration of Laboratory Soils Testing EquipmentPDHLibraryÎncă nu există evaluări

- EM 1110-2-1419 - Hydro Logic Engineering Requirements For Flood Damage Reduction Studies-WebDocument68 paginiEM 1110-2-1419 - Hydro Logic Engineering Requirements For Flood Damage Reduction Studies-WebPDHLibraryÎncă nu există evaluări

- Plain Concrete Wal Design - at Design OfficeDocument7 paginiPlain Concrete Wal Design - at Design OfficeShamen AmarasekaraÎncă nu există evaluări

- Treatment Plant HeaderDocument3 paginiTreatment Plant HeaderShamen AmarasekaraÎncă nu există evaluări

- Staircase Free StandingDocument48 paginiStaircase Free StandingShamen Amarasekara100% (1)

- Column DesignDocument11 paginiColumn DesignShamen Amarasekara100% (2)

- National Structural Concrete Specification For Building Construction - Edition 3 PDFDocument78 paginiNational Structural Concrete Specification For Building Construction - Edition 3 PDFfade2black11100% (2)

- Dbbackup ReadMeDocument3 paginiDbbackup ReadMeShamen AmarasekaraÎncă nu există evaluări

- Pile - M07Document1 paginăPile - M07Shamen AmarasekaraÎncă nu există evaluări

- EtabsconDocument204 paginiEtabsconShamen AmarasekaraÎncă nu există evaluări

- Dbsetup ReadMeDocument3 paginiDbsetup ReadMeShamen AmarasekaraÎncă nu există evaluări

- Dieng Plateau: Description of Arjuna TempleDocument3 paginiDieng Plateau: Description of Arjuna TempleRizky Nur FadilahÎncă nu există evaluări

- SOR BLDG 01-05-2018 GST-compressed PDFDocument303 paginiSOR BLDG 01-05-2018 GST-compressed PDFadhnan_rasheedÎncă nu există evaluări

- Azure Security Incident ManagementDocument14 paginiAzure Security Incident ManagementNikos PaganosÎncă nu există evaluări

- Land DevelopmentDocument130 paginiLand Developmentnirmal9583% (6)

- DG33BU SpecUpdate04 PDFDocument6 paginiDG33BU SpecUpdate04 PDFycabreragÎncă nu există evaluări

- A Design Guide For Standing Seam Roof PanelsDocument44 paginiA Design Guide For Standing Seam Roof Panelskkozak99100% (1)

- Samridhi SharmaDocument10 paginiSamridhi SharmaSamridhi SharmaÎncă nu există evaluări

- Properties of Papercrete Concrete: Building Material: Mr. Yogesh D. Shermale, Dr. Mahaveer B. VarmaDocument6 paginiProperties of Papercrete Concrete: Building Material: Mr. Yogesh D. Shermale, Dr. Mahaveer B. VarmaMadan Mohan ReddyÎncă nu există evaluări

- IntelliSense in Visual FoxPro 7Document14 paginiIntelliSense in Visual FoxPro 7jvreferencia100% (1)

- WP 3D BrandingDocument6 paginiWP 3D BrandingI Kadek Dwi NoorwathaÎncă nu există evaluări

- Asia Pacific Shopping Center Definition Standard Proposal PDFDocument18 paginiAsia Pacific Shopping Center Definition Standard Proposal PDFRina AndrianiÎncă nu există evaluări

- 5 Min Guide HiPath 3800 - 15 - 07 - 11Document2 pagini5 Min Guide HiPath 3800 - 15 - 07 - 11CheickOumarDiabyÎncă nu există evaluări

- C-5 One Way Two Way SlabDocument34 paginiC-5 One Way Two Way SlabBoopathi Yoganathan100% (2)

- JJ450-45-K Mast User ManualDocument30 paginiJJ450-45-K Mast User ManualAnupam Thakuria100% (1)

- Cradlepoint Ibr350 Spec Sheet 5Document7 paginiCradlepoint Ibr350 Spec Sheet 5blue 1234Încă nu există evaluări

- SPECIMEN EXAM TCC 102 AnswerDocument17 paginiSPECIMEN EXAM TCC 102 Answerapi-26781128Încă nu există evaluări

- AirFiber X UGDocument76 paginiAirFiber X UGJuan Carlos RodriguezÎncă nu există evaluări

- LAN Switching and Wireless Final Exam AnswersDocument16 paginiLAN Switching and Wireless Final Exam AnswersMoacir MoraesÎncă nu există evaluări

- 04,1 ZXUR 9000 GSM (V6.50.202) TroubleshootingDocument23 pagini04,1 ZXUR 9000 GSM (V6.50.202) TroubleshootingmelisachewÎncă nu există evaluări

- The Melbourne Design GuideDocument90 paginiThe Melbourne Design Guidedroessaert_stijnÎncă nu există evaluări

- Atmel Apps Journal 6Document42 paginiAtmel Apps Journal 6Rebekah PowellÎncă nu există evaluări

- Reasoning Class AssignmentDocument21 paginiReasoning Class AssignmentBindu SairaÎncă nu există evaluări

- What Are The Events in Alvs and Which Events Not Used in Alvs?Document4 paginiWhat Are The Events in Alvs and Which Events Not Used in Alvs?farooqÎncă nu există evaluări

- Bill of Quantities for Column FootingDocument3 paginiBill of Quantities for Column FootingJay BhavsarÎncă nu există evaluări

- CTSDocument66 paginiCTSLe Tan0% (1)

- Elemental Paving Construction and Maintenance GuideDocument22 paginiElemental Paving Construction and Maintenance GuideDiyoke HenryÎncă nu există evaluări

- Comparison Between Cementitious Vs Epoxy Tile Joint GroutDocument14 paginiComparison Between Cementitious Vs Epoxy Tile Joint Groutannayya.chandrashekar Civil EngineerÎncă nu există evaluări

- Marcus Vitruvius PollioDocument4 paginiMarcus Vitruvius PollioKurimaw SyÎncă nu există evaluări

- IT 205 Chapter 1: Introduction to Integrative Programming and TechnologiesDocument42 paginiIT 205 Chapter 1: Introduction to Integrative Programming and TechnologiesAaron Jude Pael100% (2)

- Assembly MnemonicsDocument3 paginiAssembly MnemonicsDonald WorthumÎncă nu există evaluări