Documente Academic

Documente Profesional

Documente Cultură

LEHDER 0030SourceTesting

Încărcat de

xien_nDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

LEHDER 0030SourceTesting

Încărcat de

xien_nDrepturi de autor:

Formate disponibile

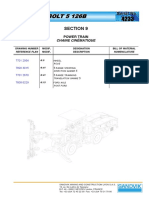

LEHDER Environmental Services Limited

704 Mara Street, Suite 210, Point Edward, Ontario, Canada N7V 1X4 Phone: (519) 336-4101 Fax: (519) 336-4311

9954 67Avenue, Edmonton, Alberta Canada T6E 0P5 Phone: (780) 462-4099 Fax: (780) 462-4392

www.lehder.com

Source Testing

Introduction

LEHDER has sophisticated state-of-the-art instrumentation and a staff of

experienced professionals available to perform source emission projects of any

size and complexity. Stack sampling at an industrial source is conducted for a

number of reasons such as:

To satisfy testing conditions described in facility permit and approvals

To develop accurate emission inventories and emission factors

To understand and adjust industrial processes

To determine pollutant impacts from specific sources

Stack

Sampling

Test Methods

Stack sampling test methods follow procedures and techniques described in

provincial, state, federal and USEPA source testing codes. There are numerous

recognized test methods for measuring industrial stack emissions. Some of the

test methods used by LEHDER to evaluate source emissions and effluent

parameters include:

Methods 1-5: Determination of particulate emissions from stationary sources

Method 5A: Determination of particulate emissions from the asphalt processing industry

Method 5E: Determination of particulate emissions from the wool fiberglass industry

Method 6: Determination of SO

2

emissions from stationary sources

Method 6C: Determination of SO

2

emissions from stationary sources (analyser method)

Method 7: Determination of NO

X

emissions from stationary sources

Method 7E: Determination of NO

X

emissions from stationary sources (analyser method)

Method 8 Determination of sulfuric acid mist and sulfur dioxide

Method 9: Determination of visible emissions

Method 10: Determination of carbon monoxide

Method 12: Determination of inorganic lead emissions from stationary sources

Method 13A: Determination of total fluoride emissions (SPADNS zirconium lake method)

Method 13B: Determination of total fluoride emissions (specific ion electrode method)

Method 17: Determination of particulate emissions (in-stack filter technique)

Method18: Measurement of gaseous organic compound emissions by GC

Method 22: Determination of visible fugitive emissions

Method 23: Determination of dioxins and furans from stationary sources

Method 25A: Determination of total gaseous organic concentration using an FID

Method 26: Determination of HCl emissions from stationary sources

Method 26A: Determination of hydrogen halide and halogen emissions

Method 29: Determination of metals emissions from stationary sources

Method 201A: Determination of PM

10

emissions

Method 202: Determination of condensable particulate emissions

Method 206: Determination of ammonia emissions

Method 316: Determination of formaldehyde emissions

CARB Methods, BAAQMD Methods, Environment Canada Methods, Ontario Odor Method

CEMS &

CISCO

Continuous Emission Monitoring Systems (CEMS) are used to collect real time

data for various parameters such as O

2

, CO

2

, CO, NO

X

, SO

2

, THC and flow.

LEHDER has broad experience with:

EPS 1/PG/7 Ensuring facilities meet requirements of the Environment

Canada Protocols and Performance Specifications for Continuous

Monitoring of Gaseous Emissions from Thermal Power Generation.

CEMS Certification Tests Performing Certification tests on CEMS.

R.A.T.A. Conducting Relative Accuracy Test Audit and Bias programs.

Audits Independent Audits of CEMS QA/QC Manuals.

Writing Creating custom CEMS QA/QC Manuals.

C.G.A. Assistance with Cylinder Gas Audits.

Extractive

FTIR

Several advantages are associated with the use of an Extractive FTIR

monitoring system. For example:

Multiple gaseous pollutants can be measured simultaneously with a single

instrument.

Pollutant/gas parameter data is acquired on a " real time" basis

Field applications using the FTIR monitoring system include:

Process (material trials, process optimization, control equipment efficiency

testing)

Environmental (source screening, compliance assurance monitoring,

emission factor development, supporting emission inventories i.e. NPRI and

SARA TRI, permit compliance testing)

Odour

Sampling and

Evaluation

LEHDER has developed a unique phased approach to odour investigations to

ensure that the problem is clearly understood and solutions are developed that

address the root cause of the odourous emissions. Part of the evaluation

consists of the collection and analysis of odour samples.

Samples are collected using the LEHDER Predilution system to maintain sample

integrity by minimizing the loss of odourants by adsorption and/or condensation,

as well as to minimize sample oxidation during transport and storage.

Odour measurements are conducted using the calibrated LEHDER Dynamic

Dilution Olfactometer and an eight-person odour panel. The Olfactometer is a

ternary port system operated in a forced choice mode as described in ASTM

679-91.

This is the only mobile olfactometer recognized by the Ontario MOE.

Related Air

Quality

Services

The Air Quality Management Services provided by LEHDER include:

Regulatory Negotiations and Strategic Planning

Applications for Permits, Licenses and Environmental Compliance Approval

Source Testing (Air)

Compliance

Engineering/Process Evaluations

Odor Evaluations

Compliance Odor Testing and modeling

Dispersion Modeling

AERMOD

ISCPRIME

SCREEN3

Ontario Appendix to Regulation 346 model

Preparing Source and Emission Inventories

Annual Emission Inventories

NPRI

GHG Reporting

For further

information

For further information please contact:

Pete Pakalnis (519) 336-4101 Ext. 227 pakalnis@lehder.com

Mike Denomme (519) 336-4101 Ext. 225 mdenomme@lehder.com

About

LEHDER

LEHDER Environmental Services is an environmental consulting company

focused on providing Excellence in Industrial Air Quality Services. Formed in

1995, LEHDER is now one of the largest Air Quality Management companies in

Canada.

All Air Quality aspects source testing, emission inventories, air dispersion

modeling, data interpretation and approval applications are managed

internally.

Visit our web site at www.lehder.com

Factsheet: 0030-6

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- BSR NH Circle Jaipur 2016Document103 paginiBSR NH Circle Jaipur 2016vikash kumar50% (4)

- SinxbyxDocument9 paginiSinxbyxGreeshmaÎncă nu există evaluări

- PACSystemsRX3i CS GFA559G (2010)Document4 paginiPACSystemsRX3i CS GFA559G (2010)Omar Alfredo Del CastilloÎncă nu există evaluări

- Sjoblom, J. - Handbook of Emulsion Technology PDFDocument731 paginiSjoblom, J. - Handbook of Emulsion Technology PDFdcharlies92% (13)

- Geotechnical Engineering 1 (RMIT) Course RevisionDocument53 paginiGeotechnical Engineering 1 (RMIT) Course RevisionSaint123Încă nu există evaluări

- Design For Manufacturing Course - by DFRDocument257 paginiDesign For Manufacturing Course - by DFRhlgc63100% (2)

- UH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math ModelDocument361 paginiUH-60A Blackhawk Eng. Simulation Program, Vol. 1, Math Modelmanitheaerialfighter100% (1)

- Internship Report May 2016Document11 paginiInternship Report May 2016Rupini RagaviahÎncă nu există evaluări

- Method StatementDocument4 paginiMethod StatementtayitbatovÎncă nu există evaluări

- S09 Power TrainDocument90 paginiS09 Power TrainPLANEAMIENTO MDRILLÎncă nu există evaluări

- Service Manual: PhilipsDocument39 paginiService Manual: PhilipsRogerio E. SantoÎncă nu există evaluări

- Stock # Carbon Weight Burn Temp Puncture StrengthDocument8 paginiStock # Carbon Weight Burn Temp Puncture StrengthMintÎncă nu există evaluări

- 2013 11 DUPLEX EasyDocument21 pagini2013 11 DUPLEX EasyAnonymous HC0tWeÎncă nu există evaluări

- An Introduction Into The Feynman Path Integral PDFDocument94 paginiAn Introduction Into The Feynman Path Integral PDFLivardy WufiantoÎncă nu există evaluări

- Report On Automatic Phase Changer: Submitted ByDocument32 paginiReport On Automatic Phase Changer: Submitted ByAndrea JohnsonÎncă nu există evaluări

- Bubbling Kun NiDocument7 paginiBubbling Kun NiBelen CRÎncă nu există evaluări

- Astm D3359Document9 paginiAstm D3359Angel GuachaminÎncă nu există evaluări

- Ism CodeDocument9 paginiIsm CodePraneel KurhadeÎncă nu există evaluări

- RT L2 General Examination PaperDocument4 paginiRT L2 General Examination PaperdaddadÎncă nu există evaluări

- KST GlueTech 44 enDocument80 paginiKST GlueTech 44 enLeandro RadamesÎncă nu există evaluări

- 03-1 Synchronous Machines 1 DNDocument25 pagini03-1 Synchronous Machines 1 DNsaif thuraonÎncă nu există evaluări

- Skytrain Avia Services: Emergency Procedures ManualDocument32 paginiSkytrain Avia Services: Emergency Procedures ManualEndro RastadiÎncă nu există evaluări

- Published Document Guidance On The Use of BS EN 13108, Bituminous Mixtures - Material SpecificationsDocument8 paginiPublished Document Guidance On The Use of BS EN 13108, Bituminous Mixtures - Material SpecificationsCristián JiménezÎncă nu există evaluări

- CH 1: Materials Used in Pipework & Plumbing FittingsDocument10 paginiCH 1: Materials Used in Pipework & Plumbing FittingsEmad BassemÎncă nu există evaluări

- Computer Networking: A Top-Down Approach Featuring The InternetDocument27 paginiComputer Networking: A Top-Down Approach Featuring The InternetmssacÎncă nu există evaluări

- Materials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilDocument5 paginiMaterials Today: Proceedings: Avula Suresh, T. Nancharaiah, Ravikumar Dumpala, B. Ratna SunilBart MaxÎncă nu există evaluări

- Restoration and Adaptive Re-Use of Queen Mary's High School: Phase-1Document4 paginiRestoration and Adaptive Re-Use of Queen Mary's High School: Phase-1Sonali GurungÎncă nu există evaluări

- Chapter 7 Notes Computer OrganizationDocument20 paginiChapter 7 Notes Computer OrganizationsriÎncă nu există evaluări

- Dogging Guide 2003 - WorkCover NSWDocument76 paginiDogging Guide 2003 - WorkCover NSWtadeumatas100% (1)