Documente Academic

Documente Profesional

Documente Cultură

Executive Summary PDF

Încărcat de

Ali YousefDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Executive Summary PDF

Încărcat de

Ali YousefDrepturi de autor:

Formate disponibile

June 2014

1

EXECUTIVE SUMMARY

June 2014

2

1. EXECUTIVE SUMMARY

NIORDC is planning to construct a gas condensate refinery Park in Southern Iran at

Asalouyeh. Initial capacity is 480,000BPD. A preliminary scheme selection has been made.

This report presents the results of the feasibility study undertaken by NIORDC to

demonstrate the economic and financial viability of the proposed refinery investment.

The refinery will process stabilized gas condensate taken from different phases of the

South Pars Oil and Gas projects. The main design objectives are to produce refined

products that meet desired specifications

2 main process configuration options were considered in this work. An overall refinery

material balance was derived using an LP based approach to determine distillate/product

cut-points that maximize the economic return from the refinery and allow all product

specifications to be met. Each option was then evaluated in terms of its CAPEX, OPEX,

utility usage and Internal Rate of Return to enable one specific configuration to be

identified. Feedstock and product prices used in this study have been provided by

NIORDC.

3.1 Description of Refinery Facilities

The proposed refinery configuration consists of the process units with their respective

capacities presented below:

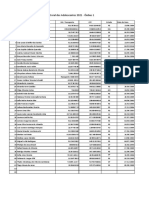

Process Units Capacities (BPSD)

Condensate Fractionation Unit (CFU) 60000

LPG recovery Unit (LRU) 3100

LPG Treatment Unit (LTU) 3100

Naphtha Hydrotreater (NHT) 34450

Kerosene Treatment Unit (KTU) 3700

Refinery products are:

LPG

Light Naphtha

Heavy Naphtha

J et A1

Diesel

June 2014

3

All utilities are assumed to be imported.

All gas used for firing will be sweet fuel gas. There is no anticipated demand for fuel oil

firing. On this basis, atmospheric emissions from the refinery are likely to be low.

Feedstock is supplied to the site via a 2 km pipeline from Asalouyeh. Refined products are

exported from site via pipelines tobe exported jetty.

3.2 Refinery Material Balance

The refinery material balance that developed by NIORDC for the refinery is as below:

Table 3.1 - Refinery Material Balance

Feed

bbls/day T/day

Condensate

60000 7131

Products

LPG

3100 294.6

Light Naphtha

16000 1718.7

Heavy Naphtha

18450 2183.2

J et Al

3700 456.5

Diesel

18739 2447.97

Fuel gas production (T/day) - 20

Sulphur production (T/day)

-

10

3.3 Product Quality

The proposed refinery configuration successfully meets required specification.

3.4 Process Licensor Considerations

To establish a basis for future technology selection for the Refinery, NIORDC contacted

potential licensors with a general inquiry to solicit their interest in, and ability to participate

June 2014

4

in, the future development of the refinery project as well as to establish the specific units in

which they might be interested. A key objective of this general inquiry was to obtain an

initial indication of the licensors that would be able to license technology to the Project

since some licensors may not be able to deal with the Project due to U.S. Government

sanctions imposed on Iran.

With the responses received, it would be possible to secure licenses for hydrotreating

licensed process unit technologies included in the proposed configuration but the concern

on CCR unit license availability will be remained.

Table 3.2 - Interested Potential Process Licensors

Process Unit Potential Licensors

Hydrotreater RIPI ,HaldorTopsoe,Axens

SRU KTI

HPU HaldorTopsoe

3.5 Project Implementation

NIORDC estimated timetable for the Projects main activities and tasks, following

completion of this Detailed Feasibility Study, the Sponsors initial approach to Lenders and

the Sponsors decision to proceed with the development of the Project, is shown in Figure

3.1. As shown, this timeline assumes that the Projects financing activities will take place in

parallel with the BED and EPC ITB activities so that Financial Close can occur when the

EPC phase of the Project is ready to begin.

Figure 3.1- Refinery Project Implementation Timeline

3.6 Investment Cost Estimate

The table below summarizes the economic parameters for the proposed refinery for the

60,000 BPD investment .

June 2014

5

Table 3.3 - economic parameters

60,000 BPSD Economic parameter

265 CAPEX ($US million)

37.7 OPEX ($US million/year)

1760 Feedstock costs (US$ mil lion/year)

1980 Product revenues (US$ million/year)

45 IRR (%)

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Case2-Forbidden CItyDocument10 paginiCase2-Forbidden CItyqzbtbq7y6dÎncă nu există evaluări

- CRPC MCQ StartDocument24 paginiCRPC MCQ StartkashishÎncă nu există evaluări

- Assessment Task-2Document7 paginiAssessment Task-2Parash RijalÎncă nu există evaluări

- Coral Dos Adolescentes 2021 - Ônibus 1: Num Nome RG / Passaporte CPF Estado Data de NascDocument1 paginăCoral Dos Adolescentes 2021 - Ônibus 1: Num Nome RG / Passaporte CPF Estado Data de NascGabriel Kuhs da RosaÎncă nu există evaluări

- RamadanDocument12 paginiRamadanMishkat MohsinÎncă nu există evaluări

- Conduct Disorder ChecklistDocument1 paginăConduct Disorder Checklistiswarya vellaisamyÎncă nu există evaluări

- Berkshire Hathaway Inc.: United States Securities and Exchange CommissionDocument48 paginiBerkshire Hathaway Inc.: United States Securities and Exchange CommissionTu Zhan LuoÎncă nu există evaluări

- Procure To Pay (p2p) R12 - ErpSchoolsDocument20 paginiProcure To Pay (p2p) R12 - ErpSchoolsMadhusudhan Reddy VangaÎncă nu există evaluări

- 23-12-22 National ConferenceDocument4 pagini23-12-22 National ConferenceNIKITA CHAUHANÎncă nu există evaluări

- Information Security NotesDocument15 paginiInformation Security NotesSulaimanÎncă nu există evaluări

- Lesson 9 Government Programs and Suggestions in Addressing Social InequalitiesDocument25 paginiLesson 9 Government Programs and Suggestions in Addressing Social InequalitiesLeah Joy Valeriano-QuiñosÎncă nu există evaluări

- Eo - Bhert 2023Document3 paginiEo - Bhert 2023Cyrus John Velarde100% (1)

- Malaysian Business Law Week-11 Lecture NotesDocument3 paginiMalaysian Business Law Week-11 Lecture NotesKyaw Thwe TunÎncă nu există evaluări

- WFP Specialized Nutritious Foods Sheet: Treating Moderate Acute Malnutrition (MAM)Document2 paginiWFP Specialized Nutritious Foods Sheet: Treating Moderate Acute Malnutrition (MAM)elias semagnÎncă nu există evaluări

- Lesson Agreement Pronoun Antecedent PDFDocument2 paginiLesson Agreement Pronoun Antecedent PDFAndrea SÎncă nu există evaluări

- Rada Trading 1200#119-07-2019Document5 paginiRada Trading 1200#119-07-2019Ing. Ramon AguileraÎncă nu există evaluări

- Sibayan, Patrick Jorge - Weekly Accomplishment (July 8-14, 2019)Document2 paginiSibayan, Patrick Jorge - Weekly Accomplishment (July 8-14, 2019)Patrick Jorge SibayanÎncă nu există evaluări

- 202E13Document28 pagini202E13Ashish BhallaÎncă nu există evaluări

- Introduction To Cybersecurity: Nanodegree Program SyllabusDocument15 paginiIntroduction To Cybersecurity: Nanodegree Program SyllabusaamirÎncă nu există evaluări

- Managerial AccountingDocument7 paginiManagerial AccountingKim Patrick VictoriaÎncă nu există evaluări

- Scupin and DeCorse Chapter 20Document29 paginiScupin and DeCorse Chapter 20Sana FarshbafiÎncă nu există evaluări

- Alembic LTD.,: International Standards Certifications (South Asia) Pvt. LTDDocument7 paginiAlembic LTD.,: International Standards Certifications (South Asia) Pvt. LTDJamil VoraÎncă nu există evaluări

- ACR Format Assisstant and ClerkDocument3 paginiACR Format Assisstant and ClerkJalil badnasebÎncă nu există evaluări

- Project ReportDocument63 paginiProject Reportdeepak singhÎncă nu există evaluări

- Country in A Box ProjectDocument6 paginiCountry in A Box Projectapi-301892404Încă nu există evaluări

- Edgeworth, Matt. 2018. Rivers As Material Infrastructure: A Legacy From The Past To The FutureDocument14 paginiEdgeworth, Matt. 2018. Rivers As Material Infrastructure: A Legacy From The Past To The FutureMauro FernandezÎncă nu există evaluări

- Chinua Achebe: Dead Men's PathDocument2 paginiChinua Achebe: Dead Men's PathSalve PetilunaÎncă nu există evaluări

- Jordan Leavy Carter Criminal ComplaintDocument10 paginiJordan Leavy Carter Criminal ComplaintFOX 11 NewsÎncă nu există evaluări

- Romances of RizalDocument4 paginiRomances of RizalMaria Elena PanchoÎncă nu există evaluări

- 2018 Vaccine Services enDocument200 pagini2018 Vaccine Services enCiprian BalcanÎncă nu există evaluări