Documente Academic

Documente Profesional

Documente Cultură

Buildability Attributes at Design Phase in Malaysian Building Construction

Încărcat de

Mohd Yazid Mohamad Yunus0 evaluări0% au considerat acest document util (0 voturi)

12 vizualizări20 paginixxxx

Titlu original

IJSCETv2n1p3

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentxxxx

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

12 vizualizări20 paginiBuildability Attributes at Design Phase in Malaysian Building Construction

Încărcat de

Mohd Yazid Mohamad Yunusxxxx

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 20

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 24

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

Buildability Attributes at Design Phase in Malaysian Building

Construction

Shaik Hussein Mydin

1

, Rosli Mohamad Zin*

2

, Muhd Zaimi Abd Majid

3

,

Mardiyah

Zahidi

4

and Aftab Hameed Memon

5

4 , 3 , 2 , 1

Construction Technology & Management Centre (CTMC), Faculty of Civil

Engineering (FKA), Universiti Teknologi Malaysia (UTM) Skudai, Johor

5

Faculty of Civil and Environmental Engineering, Universiti Tun Hussein Onn Malaysia,

86400 Parit Raja - Batu Pahat, Johor, Malaysia

* Corresponding author, e-mail: roslizin123@yahoo.com

ABSTRACT

In Malaysian construction industry, construction problem is a common occurrence that

hinders the project to run smoothly, notably in traditional contracting system where the

design and construction process are separated. Previous research revealed that buildability

is able to minimise these problems as it link the design and construction. This study

outlines the buildability attributes in building design. Extensive reviews have been carried

out on previous researches on buildability concepts, attributes, principles and other areas

related to, and contributing to buildability mainly in the design phase. The term

buildability attribute has been selected in this study to describe those characteristics

which directly or indirectly optimize integration of construction knowledge in the

building process and balancing the various project and environment constraints to

maximize project goals and building performance. Close examinations of available

references revealed that altogether there are 19 buildability attributes that can be

implemented during the design phase. The results of survey conducted in the study show

that Malaysian construction industry practitioners rate the attributes Provide Clear and

Complete Design Information and Less Work Below Ground as the most important and

least important buildability attributes respectively. The client, consultant and contractor

share the same opinion regarding the level of importance of the identified buildability

attributes. Out of 19 attributes, 11 attributes have significantly high mean values

indicating that these buildability attributes have to be considered in future building design.

This study has successfully measured the level of importance of design buildability

attributes for building construction in Malaysia

Keywords: Buildability Attribute, Design Phase

*Corresponding Author

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 25

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

1.0 INTRODUCTION

There are a lot of problems occurred during construction where buildings or facilities

could not be built as designed or could not be constructed efficiently. Particularly in

traditional contracting system, the design and construction are separated. Nevertheless,

buildability is seen to be able to solve some of the problems in the construction industry.

It is a concept that has been extensively being developed and applied in various countries

such as the USA, UK and later in Australia, where their studies have demonstrated that

improved buildability has lead to significant savings in both cost and time required for

completing construction projects [1-4].

Buildability, as known in the U.K., is the extent to which the design of a building

facilitates ease of construction subject to the overall requirements for the completed

building [5]. In the U.S., it is known as constructability, is defined as the optimum use of

construction knowledge and experience in planning, engineering, procurement and field

operations to achieve overall project objectives [6].

Designers, together with other project participants involved in the design stage,

should stay alert to the impact of building designs on the downstream activities. The

integration of good buildability into good overall design is the responsibility of the design

team. The processes are executed by altering the attributes of the design, such as structure

layout or the element size, that contribute to constructability problems based on

construction aspects such as dimensional tolerances, rebar congestion etc. Buildability

attribute is the term used in this study to describe buildability characteristic in optimising

integration of construction knowledge in the building process. Proper and timely

consideration of buildabilty will ensure that the final design outcome will meet all the

performance criteria that have been set.

New developments in the construction industry highlight the importance and

continued relevance of buildability. If adequate considerations are made during the design

stage in buildability aspects, it would help save wasteful efforts throughout the whole

process of building development and increase efficiency. [7] stated that the early efforts

of buildability implementation can oblige the engineer to make the best efforts at each

stage of the project. However, in Malaysia construction industry, research into

buildability is still relatively not well developed. There is lack of available sources and

reliable documentation that detail those buildability concepts and guide their application.

Hence, Malaysian engineers have a disadvantage by not knowing what, when and how

they should enhance the project buildability compared with the engineers in more

developed countries [3]. Besides, the concepts for improving buildability of projects vary

between one country to the other where it depends on the nature of the construction

industry.

This study has been carried out with the following objectives:

i. To identify buildability attributes in building design phase for Malaysian

construction industry; and

ii. To measure the level of importance the buildability attributes in building design

phase among Malaysian construction practitioner

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 26

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

2.0 BACKGROUND OF THE STUDY

2.1 Buildability in Building Construction

Buildings constructed with the least variation to design are known to give satisfaction to

all the major parties of a building project - client, design team and construction team. It is

believed that the use of experienced construction knowledge from the outset to the

completion of a project that integrate the methods of construction in to the design process,

providing benefits and solutions to achieve the design intent in a cost effective and timely

manner. In the construction process it is used to drive out waste and enhance cost and

program certainty, through properly planning the works and construction logistics and

using modern construction techniques.

Buildability is increasingly becoming a major requirement in building construction

practice. The aim of buildability is to improve efficiency of the overall building process

by developing construction sensitive designs [8]. The expected results from implementing

constructability are efficient and effective construction of a building, with an economical

project cost and at agreed quality specified by the clients. [9] highlighted that buildability

must be considered from the first notional idea suggested by the client, and is quite

simply a prerequisite throughout what may be considered to be a staged process (see

Figure 1).

Figure 1: The wider framework of buildability [10]

It is essential to consider buildability at an early stage in the total construction

process, because the ability to influence project cost, and so value for money from the

clients viewpoint, diminishes as the project progresses in time. During the project

lifecycle, buildability consideration should focus on the buildability attributes for each

stage throughout the project lifecycle.

2.2 Buildability Attributes in Design Phase

This study outlines the discussion on buildability concepts in design phase. For this

purpose, extensive reviews have been carried out on previous researches on buildability

concepts, attributes, principles and other areas related to, and contributing to buildability

mainly in the design phase. Even though different terms have been used to describe the so

called buildability characteristics, generally the term buildability attribute has been

selected in this study to describe those characteristics which directly or indirectly

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 27

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

optimize integration of construction knowledge in the building process and balancing the

various project and environment constraints to maximize project goals and building

performance.

The studies of buildability and constructability in different countries have

demonstrated their different focuses of interest. For example in Singapore the government

has enforced the law to require minimum buildability of submitted building plans before

granting approval. In UK, researchers emphasised the integration of design and

construction, introducing construction experts into the design phase as well as developing

procurement structures to achieve improvement of buildability. In Hong Kong, where

most construction sites are congested with restrictive surrounding conditions in busy

urban areas, buildability becomes critical in ensuring smooth projects delivery. So, there

is a real and immediate need for local construction industry to improve its overall

buildability performance. In US and Australia, more practical approaches were adopted.

The CII United State (US) and the CII Australia published guidelines for implementing

the concepts of constructability. [11], [3] and [12] summarized most of the studies on

buildability attributes for the whole project lifecycles.

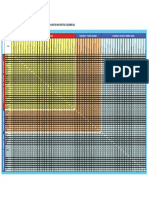

Close examinations of available references revealed that altogether there are 19

buildability attributes that can be implemented during the design phase. Table 1 shows the

summary of buildability attributes as identified by researchers in different countries.

Table 1: Buildability attributes identified by researchers in different countries

No. Buildability Attribute

C

I

R

I

A

[

5

]

T

a

t

u

m

e

t

a

l

[

1

3

]

A

d

a

m

[

2

6

]

F

e

r

g

u

s

o

n

[

2

3

]

C

I

I

[

6

]

C

I

I

[

1

4

]

H

o

n

[

8

]

C

I

I

A

u

s

t

r

a

l

i

a

[

1

0

]

B

C

A

(

B

D

A

S

)

[

1

5

]

C

I

R

C

R

e

p

o

r

t

[

1

6

]

R

o

s

l

i

M

o

h

a

m

a

d

Z

i

[

3

]

T

a

m

[

4

]

G

a

n

a

h

[

2

5

]

N

i

m

a

[

1

1

]

L

a

m

e

t

a

l

.

[

1

2

]

BA1

Consider Innovative/efficient

Construction Methods

BA2

Provide Clear and Complete Design

Information

BA3 Maximise Prefabrication

BA4 Maximise Standardization

BA5 Less Work Below Ground

BA6 Simple Detailing

BA7 Allow Flexibility

BA8 Simple Installation

BA9 Employ Visualization Tools

BA10 Optimise Labour/Skills Usage

BA11 Optimise Materials Usage

BA12 Optimise Plant and Equipment Usage

BA13 Effective Site Layout

BA14 Minimise/Avoid Return Visit

BA15 Consider Construction Sequence

BA16 Sufficient Tolerance

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 28

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

BA17 Consider Impact of Weather

BA18 Consider Safety

BA19 Encourage Sustainable Construction

In order to provide a more clear representation of buildability for ease of

understanding by practitioners, the identified buildability attributes listed in Table 1 is

further explored and described as follows (also as in Table 2):

BA1 - Consider Innovative/efficient Construction Methods

The design solution encourages the usage of efficient and innovative construction

methods. Iterating design approaches with the construction method can improve the

project quality and safety performances [17]. Suggestions for non-obligatory

construction methods for contractor are considered in this attribute.

BA2 - Provide Clear and Complete Design Information

This attribute consider the co-ordinating of drawings and specifications and

updating specifications and removing ambiguities or misunderstandings.

Information related to site-specific such as site conditions and terrain characteristics

should also be accurate and readily available during the design process. The

underlying premise for this aspect is that every construction site is unique and

special attention needs to be devoted to the design to facilitate construction.

BA3 - Maximise Prefabrication

Precast or prefabricated self-contained bathrooms and kitchens, etc. reduce the

amount of wet trade activities on site. Since building elements are then made under

the controlled factory environment, messy and polluting works vulnerable to

adverse weather conditions are eliminated. When standardisation and prefabrication

are used together, facilitating a better management [18].

BA4 - Maximise Standardization

Standardization can be manifested through the repetition of grids, sizes of

components and connection details. It enhanced ease of construction by increasing

project performance and reduction of the project cost [17, 19-21]. Site personnel

find it easier to acquaint themselves with the repeated working logistics, as it

reduces learning time [22]. Standard size components, e.g. columns, doors and

construction details, also allow saving of time and efforts because of less variation

in formwork based on common dimensions.

BA5 - Less Work below Ground

In condition where the ground is hazardous, poor or wet, it will slow down the

speed and flow of the project [3]. It is crucial to obtain a clear understanding of the

conditions likely to be met beforehand. The designer must always bear in mind that

work below ground is always difficult to carry out They must have knowledge on

various design alternatives to suit the condition on site. Previous experience in

design and supervision on works below ground such as foundation and excavation

works will definitely assist the designers.

BA6 - Simple Detailing

Details should be kept as simple where possible to reduce the learning curve effect

of site tradesmen. Reasonable tolerances should be specified [22-23]. In the case of

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 29

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

innovative details or combinations of materials, which are being used for the first

time, it is beneficial to have mock-up models or prototypes erected to study the

installation process and iron out possible problems before full scale production.

BA7 - Allow Flexibility

The high adaptability of building elements help save resources and increase the

flexibility for change according to actual site conditions being encountered.

Interchangeable components, e.g. optional left/right orientation of cabinets, sanitary

ware or universal assemblies that can be fitted in positions other than the designated

ones shown on drawings, should be adopted.

BA8 - Simple Installation

Irregular shapes, complex geometrical profiles, complicated installation details and

multi-disciplinary designs could burden contractors with additional resources for co-

ordination and site assembly. As such, building designs with simple configurations

enable works to be executed in a straightforward manner and facilitate ease of

construction [18]. However, this aspect must be balanced with the aesthetic

requirements of clients and artistic aspiration of designers. If complexity is

necessarily required, the design process should be coordinated properly to ensure

that minimum cross-referencing of documents is required, otherwise expensive

errors are prone to occur on site.

BA9 - Employ Visualization Tools

The rapid development of information technology has enabled advanced software to

be used for preparing design that integrates visualization features [24]. Visualisation

has been cited improve the collaboration between site and design teams in solving

buildailty problems that may arise during construction [3]. It irons out difficulties

that may occur before construction commences on site. Common buildability

problems that can be solved by employing visualisation tools are interfaces between

components and difficult assembly [25].

BA10 - Optimise Labour/Skills Usage

[26] pointed out that any design is only good as skills available to execute it, either

off-site or on-site. Labour and skills requirements vary between one project to

another, between one locality to another. Design must include a realistic assessment

of the level of skill likely to be available from appropriately chosen contractors and

specialists.

BA11 - Optimise Materials Usage

Products and materials to be specified during design should be selected with care,

particularly, any which have not long been established and accepted within the

industry. It is recommended that only products and materials, which have been

proven suitable to be used are selected. At the same time more economical benefit

can be gained if local materials are used as in many cases materials produced locally

are cheaper and easy to get.

BA12 - Optimise Plant and Equipment Usage

Designing for optimum use of plant and equipment and having the knowledge of

them, also designing for temporary plant and equipment anchorage in permanent

structures are some important issues which are discussed here.

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 30

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

BA13 - Effective Site Layout

The environment around the construction site has significant influence on the whole

development process [11, 26-27]. Confined sites possess characteristics concerning

the imposed restrictions which substantially hinder the construction process. The

smoothness of construction is susceptible to nearby traffic conditions, especially

when exits and ingress often encroach upon pedestrian pavements and vehicular

routes.

BA14 - Minimise/Avoid Return Visit

This attribute will optimise the usage of certain trade by enabling the trade to work

with as few return visits as possible. [26] presented an example related to this

attribute. In this design, the gable end structure was design using similar materials

as with other intermediate steel frame structures instead of gable wall simply

because to ensure the steel workers complete the whole work with minimum

interruption. The benefit is gained from material saving through gable wall design

did not outweigh the cost of erecting steel gable end.

BA15 - Consider Construction Sequence

The sequence of installation should not be dictated in design document but left for

the contractor to decide on the sequence for the entire works. For example, ground

floor slabs can be constructed before or after superstructure construction to allow

flexibility in the timing of underground drainage works.

BA16 - Sufficient Tolerance

The tolerances which are normally achievable in site conditions should be properly

considered in the design especially interfacing between different building

components such as different products, methods of construction, materials and

method of manufacture. For example sufficient tolerance needs to be specified to

allow window frame to be fixed onto window opening without having to do any

adjustment or modification.

BA17 - Consider Impact of Weather

Considering possible timing to avoid carrying out structural work, external finishes,

etc., during rainy days, typhoon seasons for high rise buildings is an important issue.

BA18 - Consider Safety

In high rise building, allowing safe sequence of trades is an issue. Designers should

look into the impact of the design solution on safety of manpower during handling

of materials and components or wherever requirement for access is necessary. [3]

added the design should be arranged so as to facilitate safe working in area prone to

accidents such as underground and high elevation works.

BA19 - Encourage Sustainable Construction

With heightened awareness of environmental pollution, natural resource depletion

and accompanying social problems, sustainable development and sustainable

construction have become a growing concern throughout the world [28]. Buildings

are one of the heaviest consumers of natural resources and account for a significant

portion of the greenhouse gas emissions. Conventional on-site construction methods

have long been criticized for low productivity, poor quality and safety records, long

construction time, and large quantities of waste in the industry.

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 31

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

Table 2: The considerations in enhancing design buildability

Buildability

Attribute

Considerations

BA1 Use of Industrialised Building System (IBS)

Less in-situ works

BA2 Coordination of drawings and specifications

Avoidance of missing information

BA3 Allowing offsite work for typical floor buildings and for non-typical

floor buildings

Enabling the adoption of single integrated elements (e.g., whole toilet

completed with sanitary ware, piping & finishes) at the discretion of

contractor

Optimising the mix of offsite work (e.g., precasting) and onsite work

(e.g., final levelling)

BA4 Allowing modular layout of components

Allowing a high degree of standardisation and repetition for floor

buildings

Allowing use of standard details with lots of repetitions

BA5 Designing for minimum construction time below ground

Designing for safe construction below ground

Considering effects of below ground work on surrounding buildings,

e.g., destabilising foundations

BA6 Designing to aid visualisation of finished work

Referring to typical/standard details for repetitive items

Using blow up details to examine possible clashes in the design, e.g.,

building services clashing with reinforcements.

BA7 Using interchangeable components, e.g. optional left/right orientation

of cabinets, sanitary ware or universal assemblies

BA8 Allowing adaptation (e.g. piping around obstacles instead of

penetrations) by contractor on site without extensive re-work

Allowing flexibility in erection/trade sequences (e.g. G/F slab laid after

all upper floors)

Allowing for early removal of temporary support to leave clear working

space

BA9 Enabling design requirements to be easily visualized and ordinated by

site staff

BA10 Allowing use of know-how and labour skills available locally

Allowing economical use of labour (e.g. balancing between labour and

plant use d)

Avoiding as far as possible multiple handling and visits by different

trades

BA11 Allowing use of wide range of materials to fulfil required performance

Giving rise to lower cutting wastages (e.g. tiles, rebars)

BA12 Designing for optimum use of plant and equipment

Designing with knowledge of plant and equipment capacities

Allowing use of local plant and equipment available

BA13 Allowing sufficient working space for labour and plant

Causing less environmental nuisance (e.g. noise, vibration, waste water,

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 32

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

chemical waste and dust) to surroundings for urban sites

Allowing for early enclosures from weather for high rise buildings

Allowing for construction traffic on permanent structure early after

erection (e.g. left-in steel decking on structural steel)

BA14 Avoiding as far as possible multiple visits by different trades

BA15 Letting Contractor decide on the sequence for the entire works.

BA16 Specifying tolerances for as many items as possible

Co-ordinating tolerances specifications for interfacing items (e.g.

window frame vis--vis window opening)

BA17 Considering possible timing to avoid carrying out structural work,

external finishes, etc., during rainy/typhoon season for high rise

buildings

BA18 Allowing safe sequence of trades (e.g. heavy M&E plant hoisted into

position before building is fully enclosed) for high rise buildings

Sizes and weights of materials and components are safe for workers to

handle using commonly available plant for high rise buildings

BA19 Design for sustainable material in the project

Design for method of construction that preserves the environment.

3.0 METHODOLOGY

Figure 2 illustrates the schematic of research methodology that has been adopted.

Figure 2: Schematic of the research methodology

To achieve the objectives of the study, the methodologies adopted were through

literature review and online questionnaire surveys. At the beginning, the study involved

extensive review on design-phase buildability concepts. The literature search enables the

buildability attributes in design stage to be identified. After the buildability attributes

were extracted, the questionnaire was constructed. A brief meeting was conducted to

ensure that the questionnaire is applicable before posting it online. The online surveys

were conducted for about 3 months. The questionnaire was targeted to professionals who

worked with the clients, contractor, consultant or other organisations; and have direct

Books Journals

Paper Thesis

Establish online at

kwiksurveys.com

Using Likerts scale

Pilot survey

Literature Review

Questionnaire Survey

Data Analysis &

Discussion

Conclusion &

Recommendation

Identify Problem,

Objective & Scope

Using SPSS software

Frequency Statistic

Descriptive Statistic

Compare Means

Nonparametric Test

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 33

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

involvement in building project construction. Various organisation had been contacted

personally to invite them participating in the survey.

In order to determine the degree of importance of the buildability attributes

considered in this study, the classification of the rating scales had been used. The

responses to the questionnaire are based on Likert scale of five ordinal measures which is

from one to five according to the level of effects of variation orders attributed to the

question. Likert scale is a widely used instrument in measuring opinions, beliefs and

attitudes. The classifications of the rating scales are as follows:

5 = Most Important

4 = Important

3 = Moderately Important

2 = Little Important

1 = Least Important

For the purpose of data analysis collected through questionnaire survey, the

Statistical Package for Social Science (SPSS) software version 18.0 was adopted. The

data from questionnaires were extracted into the SPSS software. With the aid of the SPSS,

the following statistical methods have been used;

(a) Frequency Statistic - for obtaining summaries of individual data variables;

(b) Descriptive Statistic - for obtaining summary comparisons of approximately

normally distributed scale data variables and for easily identifying unusual

cases across those data variables by computing z score;

(c) Compare Means - to characterize the central tendency and dispersion of data

variable. It tests for differences between group means using one-way

ANOVA. The one-way ANOVA in Means provides with linearity tests and

association measures to help understand the structure and strength of the

relationship between the groups and their means.

(d) Nonparametric Test (Kruskall-Wallis Test) - for determining whether or not

the values of a particular data variable differ between two or more groups.

This study has multiple independent samples; hence the Kruskal-Wallis test is

adopted. It tests the null hypothesis that multiple independent samples come

from the same population. The Kruskal-Wallis statistic measures how much

the group ranks differ from the average rank of all groups but it does not tell

how the groups are different, only that some difference is present.

4.0 RESULTS AND DISCUSSION

4.1 Demographic of Respondent

Section A of the questionnaire is related to demographic of respondent. Table 3 shows the

type of company or organization that participated in the survey with a total number of 201

respondents. They are client, consultant, contractor and also higher institution (university).

From Figure 3, it illustrates that the client dominate the survey with 87 out of 203. Then,

it is followed by the consultant with 72 respondents, the contractor with 42 respondents

and lastly 2 respondents from the higher institution. Based on the huge respond, it shows

that the practitioners in Malaysian construction industry are open for improvement in

their future project especially from the client.

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 34

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

Table 3: The type of company or organisation

involved in the survey

Company Frequency Percent

Client 85 42.3

Consultant 72 35.8

Contractor 42 20.9

Institution 2 1.0

Total 201 100.0

Figure 3: The type of company or organisation

involved in the survey

In Table 4, it tabulates the role of respondent in their company or organisation. They

comprise of architect, engineer, lecturer, project manager, quantity surveyor and site

supervisor. Figure 4 demonstrates the result in percentage value. It clearly can be seen

that the major involvement are from the engineer with 79.3%. The second highest are

project manager with 12.8%. The architect and the quantity surveyor share the same

percentage with 3.0% and; also the lecturer and supervisor with 1.0%.

Table 4: The role of respondent in their company

or organisation

Roles Frequency Percent

Architect 6 3.0

Engineer 160 79.6

Lecturer 2 1.0

Project Manager 25 12.4

Quantity Surveyor 6 3.0

Site Supervisor 2 1.0

Total 201 100.0

Figure 4: The role of respondent in their company

or organisation

The year of experience in construction work for the respondents are tabulated and

exhibited in Table 5 and Figure 5. Meanwhile, the year of experience in design work of

the respondents are shown in Table 6 and Figure 6. Majority of the respondent have less

than 4 years of experience in construction work and also in design, with percentage

39.3% and 66.7% respectively.

Table 5: The respondents years of experiences in

construction work

Years of

Experience

Frequency Percent

Less than 4 Years

5-9 Years

79

51

39.3

25.4

10-14 Years 24 11.9

15-19 Years 17 8.5

20 Years and

above

30 14.9

Total 201 100.0

Figure 5: The respondents years of experience

in construction work

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 35

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

Table 6: The respondents years of experiences

in design work

Years of

Experience

Frequency Percent

Less than 4 Years 134 66.7

5-9 Years

10-14 Years

33

18

16.4

9.0

15-19 Years 11 5.5

20 Years and

above

5 2.5

Total 201 100.0

Figure 6: The respondents years of experience

in design work

Table 7 and Figure 7 demonstrate the distribution of respondents company location.

Nine states took part in the survey. Four major states involved are Pulau Pinang, Selangor,

Kelantan and Johor with each hold more than 20% of respondent, which means more than

40 respondents participated in the survey. The minor states are Perak, Negeri Sembilan,

Pahang, Perlis and Kedah.

Table 7: The distribution of respondents

according to states

State Frequency Percent

Johor 44 21.9

Kedah 1 .5

Kelantan 45 22.4

Negeri Sembilan 2 1.0

Pahang 2 1.0

Perak 3 1.5

Perlis 1 .5

Pulau Pinang 54 26.9

Selangor 49 24.4

Total 201 100.0

Figure 7: The distribution of respondents according

to states

4.2 The Level of Importance of Buildability Attributes in Malaysian Construction

Industry

Section B of the questionnaire focused on to determine the degree of importance of the

buildability attributes in design phase among practitioner in the Malaysian construction

industry. For each of the attributes, their mean values are obtained by using SPSS

software and then the attributes are ranked based on this value. The higher the mean value

indicates that the builadbility attribute must be considered in design stage.

Based on the survey results, the attribute with the highest mean is Provide Clear and

Complete Design Information, 4.56 (see Table 8). Thus, it means this attribute is very

important to be considered during the design stage. This attribute enables a smooth and

success construction project, which is by co-ordinating of drawings and specifications and

updating specifications and removing ambiguities or misunderstandings.

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 36

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

Table 8: The rank of buildability attributes in building design based on mean value

Buildability Attributes Mean

Std.

Deviation

Skewness

Provide Clear and Complete Design

Information

4.56 .638 -1.284

Consider Safety 4.34 .810 -.934

Encourage Sustainable Construction 4.23 .740 -.768

Effective Site Layout 4.22 .724 -.767

Consider Innovative/efficient Construction

Methods

4.20 .700 -.384

Consider Construction Sequence 4.18 .756 -.320

Optimise Materials Usage 4.17 .696 -.430

Maximise Standardization 4.12 .732 -.731

Simple Installation 4.10 .771 -.446

Optimise Plant and Equipment Usage 4.10 .703 -.497

Optimise Labour/Skills Usage 4.08 .724 -.281

Allow Flexibility 3.96 .826 -.775

Sufficient Tolerance 3.91 .729 -.017

Maximise Prefabrication 3.87 .773 -.026

Employ Visualization Tools 3.87 .753 -.412

Simple Detailing 3.86 .900 -.884

Consider Impact of Weather 3.86 .784 -.055

Minimise/Avoid Return Visit 3.70 .895 -.305

Less Work Below Ground 3.60 .917 -.462

By referring to Figure 8, there are 10 other buildability attributes with mean value

above 4.00 and 8 attributes with mean values below 4.00. The lowest is Less Work Below

Ground with 3.60 mean value. Most of the respondent point out that this attribute is less

important to be considered during the design stage.

Figure 8: The rank of buildability attributes in building design based on mean value

Table 9 show the Chi-square values and significance levels for each buildability

attributes, yield from analysing mean value by using Kruskall-Wallis test. The test checks

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 37

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

whether the distribution of means among the company has significance difference or

otherwise. With significance level of 0.05, there are only two attributes has significance

value less than 0.05. Those attributes are Consider Construction Sequence and Consider

Safety, with value 0.027 and 0.049 respectively. This suggests that there is no

significance difference of ratings on the degree of importance of buildability attributes

among the company or organisation.

Table 9: The significance difference of buildability attributes between company or

organisation (Kruskall-Wallis H-test)

Buildability Attributes

Chi-

square

Asymptotic

Sigfinicance

Consider Innovative/efficient Construction Methods 2.736 0.434

Provide Clear and Complete Design Information 1.151 0.765

Maximise Prefabrication 5.556 0.135

Maximise Standardization 1.827 0.609

Less Work Below Ground 2.128 0.546

Simple Detailing 7.192 0.066

Allow Flexibility 4.487 0.213

Simple Installation 3.764 0.288

Employ Visualization Tools 1.470 0.689

Optimise Labour/Skills Usage 4.715 0.194

Optimise Materials Usage 0.745 0.862

Optimise Plant and Equipment Usage 0.820 0.845

Effective Site Layout 4.023 0.259

Minimise/Avoid Return Visit 0.326 0.955

Consider Construction Sequence 9.184 0.027

Sufficient Tolerance 3.373 0.338

Consider Impact of Weather 3.030 0.387

Consider Safety 7.871 0.049

Encourage Sustainable Construction 2.379 0.498

4.2.1 The importance level of buildability attributes from clients view

The result presented in Table 9 only shows the overall analysis of buildability attributes

among 201 respondents. Since for each organisation, different opinion towards the level

of importance of buildability attributes may exist, therefore, detail analysis for each types

of organisation has been carried out. Table 10 tabulates the rank of buildability attributes

in four organisations involved, which are the client, consultant, contractor and higher

institution. The attributes in the table are organised from BA1 to BA19, not according to

its mean value.

Table 10: The rank of buildability attributes in building design between the companies

respectively

Mean Value

Builadbilitty Attribute

Client Consultant Contractor Institution

Consider Innovative/efficient

Construction Methods

4.27 4.19 4.05 4.50

Provide Clear and Complete

Design Information

4.56 4.61 4.48 4.50

Maximise Prefabrication 3.92 3.72 3.98 4.50

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 38

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

Maximise Standardization 4.15 4.11 4.05 4.50

Less Work Below Ground 3.51 3.64 3.71 4.00

Simple Detailing 3.67 3.99 4.02 4.00

Allow Flexibility 3.84 4.06 4.02 4.00

Simple Installation 4.02 4.24 4.05 4.00

Employ Visualization Tools 3.89 3.89 3.79 3.50

Optimise Labour/Skills Usage 4.13 4.03 4.02 5.00

Optimise Materials Usage 4.20 4.17 4.12 4.50

Optimise Plant and Equipment

Usage

4.09 4.14 4.05 4.50

Effective Site Layout 4.27 4.25 4.07 4.50

Minimise/Avoid Return Visit 3.66 3.72 3.76 3.50

Consider Construction Sequence 4.02 4.36 4.19 4.50

Sufficient Tolerance 3.80 4.00 3.98 4.00

Consider Impact of Weather 3.86 3.78 4.00 3.50

Consider Safety 4.34 4.50 4.07 4.50

Encourage Sustainable

Construction

4.29 4.24 4.10 4.00

Figure 9 is the ranking of buildability attributes from the clients perspective. The

clients rated attribute Provide Clear and Complete Design Information (BA2) as the most

important attribute to be considered in design stage with 4.56 mean value. Meanwhile, the

attribute Less Work Below Ground has the smallest mean value (3.51), thus considered as

less important buildability attribute in design stage. Out of 19 attributes, only 8 attributes

have mean values less than 4.00.

Figure 9: The rank of buildability attributes in building design among the client

4.2.2 The importance level of buildability attributes from consultants view

From consultants view, the most important attribute is Provide Clear and Complete

Design Information and the less important is Less Work Below Ground (see Figure 10).

By comparing the results between the client and consultant, the ranking for the first,

second and nineteenth ranked attributes are quite similar. However, from the third until

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 39

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

seventeenth ranked attributes the ranking show significant difference. Out of nineteen

attributes, only six have mean values below 4.00.

Figure 10: The rank of buildability attributes in building design among the consultant

4.2.3 The importance level of buildability attributes from contractors view

By referring to Figure 11, it demonstrates that the contractor seems to be in agreement

with the client and the consultant opinion for the highest and lowest rank buildability

attributes in design stage. The highest is 4.48 mean value for Provide Clear and Complete

Design Information and the lowest is 3.71 mean value for Less Work Below Ground. Out

of nineteen attributes, only five have less than 4.00 mean values.

Figure 11: The rank of buildability attributes in building design among the contractor

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 40

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

4.2.4 The importance level of buildability attributes from institutions view

For higher institution, there were only two respondents involved. Thus, the buildability

attributes ranking is unique from other organisations. The highest mean value attribute is

Optimise Labour/Skill Usage, 5.00, while the lowest mean is Employ Visualisation Tools,

3.50 (see Figure 12).

Figure 12: The rank of buildability attributes in building design among the institution

4.3 Buildability in Construction Method

Section C of the questionnaire seeks the repondent opinion regarding the influence of

construction method towards buildabilty. Figure13 indicates the result of the importance

level of considering building construction method at design stage. Meanwhile, Figure 14a

and 14b show the respondents opinion regarding the influence of construction method

towards project cost and duration respectively.

Figure 13: The consideration of building construction method at design stage

Based on the bar chart above, 92 respondents pointed out that building

construction method is strongly important to be considered at design stage. Only one

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 41

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

respondent mentioned it as least important. From Figure 14, 90 respondents highlighted

that construction method is very influential towards project cost while 98 of respondents

emphasized that it is very influential toward project duration. Also, only one respondent

singled out construction method as least influential toward both project cost and duration.

a) b)

Figure 14: a) The influential of construction method toward project cost, and b) The

influential of construction method toward project duration

5.0 CONCLUSION

This study has identified 19 buildability attributes in building design phase for Malaysian

construction industry. From the results of survey, the attribute Provide Clear and

Complete Design Information, with mean value of 4.56 is considered as the most

important while Less Work Below Ground, with mean value of 3.60, is considered as the

least important attribute. The client, consultant and contractor share the same opinion

regarding the most important and the least important attributes, only higher institutions

view is slightly different. From Kruskall-Wallis test, only the attributes of Consider

Construction Sequence and Consider Safety have significance value less than 0.05, but

the rest show no significance difference of ratings on the degree of importance of

buildability attributes among the company or organisation. The study has successfully

assessed the importance level of buildability attributes among Malaysian construction

practitioner.

6.0 REFERENCES

[1] Russell, J., Gugel, J., and Radke, M. W. (1992). Benefits of Constructability: Four

Case Studies. The Construction Industry Institute, Austin, Texas.

[2] Jergeas, G., and Van der Put, J. (2001). Benefits of Constructability on Construction

Projects. Journal of Construction Engineering and Management. 127(4): 281290.

[3] Rosli Mohamad Zin. ( 2004). Constructability Assessment of Project at Design Phase.

Faculty of Civil Engineering, Universiti Teknologi Malaysia: PhD. Thesis,

Unpublished.

[4] Tam V.W.Y., Tam C.M. and Ng W.C.Y. (2007). On prefabrication implementation

for different project types and procurement methods in Hong Kong. Journal of

Engineering, Design and Technology. 5(1): 68-80.

[5] CIRIA. (1983). Buildability: An Assessment. Special Publication 26: Construction

Industry Research and Information Association.

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 42

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

[6] CII. (1986). Constructability A Primer. Publication 3-1. Austin, Texas: Construction

Industry Institute.

[7] Trigunarsyah, B., Bakti, E.S. and Majid, M.Z.A. (2011). Constructability Innovation

in Piperack Design for Refinery Project. In Hughes, Will, Eds. Proceedings

Construction Management and Economics. Reading, UK.

[8] Hon, S.L., Gairns, D.A. and Wilson, O.D. (1988). Buildability: A Review of Research

and Practice. Australian Institute of Building Papers: 3.

[9] Griffith A. and Sidwell A.C. (1997). Development of constructability concepts,

principles and practices. Engineering, Construction and Architectural Management,

4(4), 295-310.

[10] CII, Australia. (1993). Constructability Principles File. University of South Australia,

Adelaide, Australia: Construction Industry Institute.

[11] Nima, M.A. (2001). Constructability Factors in the Malaysian Construction Industry.

Universiti Putra Malaysia: Ph.D. Thesis.

[12] Lam P.T.I., Wong F.W.H. and Chan A.P.C. (2006). Contributions of Designers to

Improving Buildability and Constructability. Journal of Design Studies. 27(4): 457-

479.

[13] Tatum, C.B., Vanegas, J.A., and Williams, J.M. (1985). Constructability Improvement

Using Prefabricated, Preassembly, and Modularisation. Technical Report No. 297.

Dept. of Civil Engineering, University of Stanford, Stanford, CA.

[14] CII (1987). Constructability Concepts File. Publication 3-3. Austin, Texas:

ConstructionIndustry Institute.

[15] BCA. (2005). Code of Practice on Buildable Design. Singapore: Building and

Construction Authority.

[16] CIRC. (2001). Construct for Excellence: Report of the Construction Industry Review

Committee. Hong Kong, China: Construction Industry Review Committee.

[17] Trigunarsyah, B. (2007). Project Designers Role in Improving Constructability of

Indonesian Construction Projects. Construction Management and Economics. 25(2):

207215.

[18] Wong F.W.H., Lam P.T.I., Chan A.P.C., and Chan E.H.W. (2006). A Review of

Buildability Performance in Hong Kong and Strategies for Improvement. Surveying

and Built Environment. 17(2): 37-48.

[19] Griffith, A and Sidwell, T. (1995). Constructability in Building and Engineering

Projects. Mac Millan Press. Ltd., London.

[20] Low S.P. and Abeyegoonasekera B. (2001). Integrating buildability in ISO 9000

quality management systems: case study of a condominium project. Building and

Environment, 36(3), 299-312.

[21] Egan J. (1998). Rethinking Construction: the Report of the Construction Task Force

to the Deputy Prime Minister, John Prescott, on the Scope for Improving the Quality

and Efficiency of UK Construction. Dept. of the Environment, Transport and the

Regions, London.

[22] Griffith, A. (1984). A Critical Investigation of Factors Influencing Buildability and

Constructability. Heriot-Watt University, UK: Ph.D. Thesis.

[23] Ferguson, I. (1989). Buildability in Practice. Mitchells Professional Library, 1

st

.

Edition, London.

[24] Mahalingam, A., Kashyap, R. and Mahajan, C. (2010). An evaluation of the

applicability of 4D CAD on construction projects. Automation in Construction 19:

148159.

International Journal of Sustainable Construction Engineering & Technology

Vol 2, Issue 1, June 2011

Published by:Universiti Tun Hussein Onn Malaysia (UTHM) and Concrete Society of Malaysia (CSM) 43

http://penerbit.uthm.edu.my/ejournal/index.php/journal/ijscet

[25] Ganah, A., Anumba, C. and Bouchlaghem, N. (2000). The Use of Visualisation to

Communicate Information to Construction Sites. ARCOM 16th. Annual Conference.

6-8 September. Glasgow Caledonian University, UK: 833-842.

[26] Adams, S. (1989). Practical Buildability. The Construction Industry Research and

Information Association, London.

[27] Ballal T.M.A. and Sher W.D. (2003). Artificial Neural Network for the selection of

buildable structural systems. Engineering, Construction and Architectural

Management, 10(4), 263-271.

[28] Pulaski, M.H., Horman, M.J. and Riley, D.R. (2006). Constructability Practices to

Manage Sustainable Building Knowledge. Journal of Architectural Engineering.

12(2): 83-92.

S-ar putea să vă placă și

- Al-Fadhli 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012040Document12 paginiAl-Fadhli 2020 IOP Conf. Ser. Mater. Sci. Eng. 737 012040عبدالسلام البرهوÎncă nu există evaluări

- A Review of Optimization Cost in Infrastructure Construction by Improving Construction MethodsDocument5 paginiA Review of Optimization Cost in Infrastructure Construction by Improving Construction MethodsIJRASETPublicationsÎncă nu există evaluări

- CITAÇÃO 39 - Operacionalidade e Manutenção Fatores ConstrutibilidadeDocument11 paginiCITAÇÃO 39 - Operacionalidade e Manutenção Fatores ConstrutibilidadedelciogarciaÎncă nu există evaluări

- ARTIGO 5B - Buildability - Constructability Practice and Project Nigerian PDFDocument12 paginiARTIGO 5B - Buildability - Constructability Practice and Project Nigerian PDFdelciogarciaÎncă nu există evaluări

- Alshammari, Et Al., 2020Document10 paginiAlshammari, Et Al., 2020states mphinyaneÎncă nu există evaluări

- Garuda 1400622Document13 paginiGaruda 1400622MuthiahÎncă nu există evaluări

- Value Management: A Systematic Approach For Improving Time Performance in Construction ProjectsDocument6 paginiValue Management: A Systematic Approach For Improving Time Performance in Construction ProjectsZulfiqar Ahmed AbbasiÎncă nu există evaluări

- Rashid 2, 2018Document6 paginiRashid 2, 2018Cheng Ling YongÎncă nu există evaluări

- An Integrated Quality Index of High-Rise ResidentiDocument21 paginiAn Integrated Quality Index of High-Rise Residenti55723110049Încă nu există evaluări

- adejayas15,+Journal+manager,+12.+Planning+Analysis+on+Bridge+Construction+Possibilities+and+Challenges+A+ReviewDocument10 paginiadejayas15,+Journal+manager,+12.+Planning+Analysis+on+Bridge+Construction+Possibilities+and+Challenges+A+ReviewNettyÎncă nu există evaluări

- PM influence key to construction project successDocument25 paginiPM influence key to construction project successMahendra paudel PaudelÎncă nu există evaluări

- AaaaaaaaaaaaaaaaaaaaaaaaaaaaaDocument2 paginiAaaaaaaaaaaaaaaaaaaaaaaaaaaaaAnna Jane CagangÎncă nu există evaluări

- Critical Success Factors For Construction Project: Articles You May Be Interested inDocument7 paginiCritical Success Factors For Construction Project: Articles You May Be Interested inTaddyBestÎncă nu există evaluări

- Causes of cost overrun in construction projects categorized into ten groupsDocument11 paginiCauses of cost overrun in construction projects categorized into ten groupsCavalliÎncă nu există evaluări

- Const Guide and RiskDocument9 paginiConst Guide and RiskerodrguezÎncă nu există evaluări

- Adding Value in Construction Design Management by Using Simulation ApproachDocument22 paginiAdding Value in Construction Design Management by Using Simulation ApproachkrmchariÎncă nu există evaluări

- 30R-03 Implementing Project ConstructionDocument9 pagini30R-03 Implementing Project Constructionmaifi100% (2)

- A Critical Literature Review On Application of Value Engineering in Building Construction ProjectDocument4 paginiA Critical Literature Review On Application of Value Engineering in Building Construction ProjectjayÎncă nu există evaluări

- Critical Success Factors For Construction ProjectDocument7 paginiCritical Success Factors For Construction Projectcivilengakbari78Încă nu există evaluări

- Managing The Building Design Process For Sustainabilty and Improved QualityDocument7 paginiManaging The Building Design Process For Sustainabilty and Improved QualityWissam NumanÎncă nu există evaluări

- Factors of Design Errors in Construction Project ADocument6 paginiFactors of Design Errors in Construction Project AjahnerickaÎncă nu există evaluări

- Keynote AddressDocument11 paginiKeynote AddressOlayemi ObembeÎncă nu există evaluări

- Articulo AlgoritmiaDocument21 paginiArticulo AlgoritmiaJane DDÎncă nu există evaluări

- Rationalizing construction costs with lean integrationDocument20 paginiRationalizing construction costs with lean integrationAlexandre GelsiÎncă nu există evaluări

- Study of Quality Management in Construction Industry: I J I R S E TDocument8 paginiStudy of Quality Management in Construction Industry: I J I R S E TJamsheedÎncă nu există evaluări

- Study of Quality Management in Construction Industry: I J I R S E TDocument8 paginiStudy of Quality Management in Construction Industry: I J I R S E Trizwan hassanÎncă nu există evaluări

- Effect of Procurement Systems on Building Project PerformanceDocument15 paginiEffect of Procurement Systems on Building Project PerformanceIfiokobong AkpanÎncă nu există evaluări

- In Construction: Case Analysis of UK Construction Sector: Module Code: EG7302 Module Name: Engineering Management ProjectDocument14 paginiIn Construction: Case Analysis of UK Construction Sector: Module Code: EG7302 Module Name: Engineering Management ProjectRaghav GoyalÎncă nu există evaluări

- Constructability Program BenefitsDocument15 paginiConstructability Program Benefitsparamarthasom1974Încă nu există evaluări

- Structural Equation Model For Evaluating Factors Affecting Quality of Social Infrastructure ProjectsDocument25 paginiStructural Equation Model For Evaluating Factors Affecting Quality of Social Infrastructure ProjectsDalowar HossanÎncă nu există evaluări

- Green Buildings Life Cycle Cost Analysis and Life Cycle Budget Development: Practical ApplicationsDocument21 paginiGreen Buildings Life Cycle Cost Analysis and Life Cycle Budget Development: Practical ApplicationsNur SyahiraÎncă nu există evaluări

- The Application of Earned Value Management (Evm) in Construction Project ManagementDocument12 paginiThe Application of Earned Value Management (Evm) in Construction Project ManagementAhmed ShaheenÎncă nu există evaluări

- IJEME 4 (3-4) Optimisation of Construction Resource Using Lean TechniquesDocument16 paginiIJEME 4 (3-4) Optimisation of Construction Resource Using Lean TechniquesDevkumar JaniÎncă nu există evaluări

- Willar Finalmanuscript ICAST2018Document7 paginiWillar Finalmanuscript ICAST2018Cm GabitoÎncă nu există evaluări

- VE and Optimal Building ProjectDocument4 paginiVE and Optimal Building ProjectAli KamelÎncă nu există evaluări

- Cost Implication To DesignDocument6 paginiCost Implication To DesignShahrol Faizal AbdullahÎncă nu există evaluări

- Project ManagerDocument37 paginiProject Managergashaw yemataw100% (1)

- Lean Construction Management An Effective Approach For Efficient ConstructionDocument15 paginiLean Construction Management An Effective Approach For Efficient ConstructionSam CharlesÎncă nu există evaluări

- Expert Opinion On Risk Level For Factors Affecting Time and Cost Overrun Along The Project Lifecycle in Malaysian Construction ProjectsDocument7 paginiExpert Opinion On Risk Level For Factors Affecting Time and Cost Overrun Along The Project Lifecycle in Malaysian Construction ProjectsBrian LukeÎncă nu există evaluări

- Mohd Khalil Bin Abdul KadirDocument24 paginiMohd Khalil Bin Abdul KadirSaurabh GargÎncă nu există evaluări

- ksoat cp ẩn dựa trên hệ thống tinh gọnDocument8 paginiksoat cp ẩn dựa trên hệ thống tinh gọnNguyễn Thị Hồng NhânÎncă nu există evaluări

- Sustainability 11 05542 v3 PDFDocument19 paginiSustainability 11 05542 v3 PDFmat general contractorÎncă nu există evaluări

- Factors of Complexity in Construction Projects: Hannah Wood and Philip AshtonDocument10 paginiFactors of Complexity in Construction Projects: Hannah Wood and Philip AshtonEduardo MenaÎncă nu există evaluări

- Implementing Value Management As A Decision-MakingDocument18 paginiImplementing Value Management As A Decision-MakingMutahir YousafÎncă nu există evaluări

- Buildings 10 00035 v2Document16 paginiBuildings 10 00035 v2David InoñanÎncă nu există evaluări

- Integrated Design Office Arrangements For Effective Management in Complex Infrastructure ProjectsDocument13 paginiIntegrated Design Office Arrangements For Effective Management in Complex Infrastructure ProjectsJamesÎncă nu există evaluări

- Construction Industry Research RationaleDocument12 paginiConstruction Industry Research RationaleAmirul AmmarÎncă nu există evaluări

- Impact of Efective Construction PlanningDocument12 paginiImpact of Efective Construction Planningabajifar2004Încă nu există evaluări

- Factrors Effecting Cost Mangement in Construction ProjectsDocument7 paginiFactrors Effecting Cost Mangement in Construction ProjectsMohammad Hassan BashirÎncă nu există evaluări

- Case Study On BIM and Value Engineering Integration ForDocument13 paginiCase Study On BIM and Value Engineering Integration ForMazen AbdelfattahÎncă nu există evaluări

- Constructability GuidelinesDocument34 paginiConstructability GuidelinesDavid SueldoÎncă nu există evaluări

- 41 - BIM Integrating Cost Estimates at InitialDesign StageDocument13 pagini41 - BIM Integrating Cost Estimates at InitialDesign StageJean-paul AgbohÎncă nu există evaluări

- Project PDFDocument6 paginiProject PDFfkkfoxÎncă nu există evaluări

- Integrated Project Planning and Construction Based on ResultsDe la EverandIntegrated Project Planning and Construction Based on ResultsÎncă nu există evaluări

- Project Management Casebook: Instructor's ManualDe la EverandProject Management Casebook: Instructor's ManualÎncă nu există evaluări

- How Do Architects Work with Engineers: A Brief GuideDe la EverandHow Do Architects Work with Engineers: A Brief GuideÎncă nu există evaluări

- Lab SignageDocument11 paginiLab SignageMohd Yazid Mohamad YunusÎncă nu există evaluări

- How to make chemical solutions from solidsDocument6 paginiHow to make chemical solutions from solidsMohd Yazid Mohamad YunusÎncă nu există evaluări

- Jurnal Teknologi: Nilai Profesionalisme Bakal Guru Berteraskan Indikator Standard Guru Malaysia (SGM)Document7 paginiJurnal Teknologi: Nilai Profesionalisme Bakal Guru Berteraskan Indikator Standard Guru Malaysia (SGM)jayanthanÎncă nu există evaluări

- KLSM KBSM KSSMDocument1 paginăKLSM KBSM KSSMMohd Yazid Mohamad YunusÎncă nu există evaluări

- Job Application FormDocument4 paginiJob Application FormMohd Yazid Mohamad YunusÎncă nu există evaluări

- Matecconf Ibcc2016 00107Document9 paginiMatecconf Ibcc2016 00107Mohd Yazid Mohamad YunusÎncă nu există evaluări

- Application Form Osh Award 2016Document23 paginiApplication Form Osh Award 2016Mohd Yazid Mohamad YunusÎncă nu există evaluări

- KTM KOMUTER FARES EFFECTIVE DEC 2ND 2015Document1 paginăKTM KOMUTER FARES EFFECTIVE DEC 2ND 2015Hamka HidayahÎncă nu există evaluări

- Job Application Form - IIUM SchoolsDocument1 paginăJob Application Form - IIUM SchoolsMohd Yazid Mohamad YunusÎncă nu există evaluări

- Jilid 11 Artikel 01Document15 paginiJilid 11 Artikel 01munirahÎncă nu există evaluări

- Rizwan 2015Document63 paginiRizwan 2015Mohd Yazid Mohamad YunusÎncă nu există evaluări

- Construction Safety and Health Factors at The Industry Level: The Case of SingaporeDocument19 paginiConstruction Safety and Health Factors at The Industry Level: The Case of SingaporeMohd Yazid Mohamad YunusÎncă nu există evaluări

- Ujian Mac TMP Tahun 5Document89 paginiUjian Mac TMP Tahun 5Mohd Yazid Mohamad YunusÎncă nu există evaluări

- Construction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaDocument19 paginiConstruction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaMohd Yazid Mohamad YunusÎncă nu există evaluări

- Ask Bab 3Document50 paginiAsk Bab 3Mohd Yazid Mohamad YunusÎncă nu există evaluări

- Paper Keng RazakDocument19 paginiPaper Keng RazakNur MajÎncă nu există evaluări

- Research Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranDocument15 paginiResearch Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranMohd Yazid Mohamad YunusÎncă nu există evaluări

- Paper Keng RazakDocument19 paginiPaper Keng RazakNur MajÎncă nu există evaluări

- Ijaiem 2015 01 11 16Document10 paginiIjaiem 2015 01 11 16International Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Construction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaDocument19 paginiConstruction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaMohd Yazid Mohamad YunusÎncă nu există evaluări

- Ijerph 14 00045Document17 paginiIjerph 14 00045Mohd Yazid Mohamad YunusÎncă nu există evaluări

- Rizwan 2015Document63 paginiRizwan 2015Mohd Yazid Mohamad YunusÎncă nu există evaluări

- TS07K Muiruri Mulinge 6847 PDFDocument14 paginiTS07K Muiruri Mulinge 6847 PDFMohd Yazid Mohamad YunusÎncă nu există evaluări

- TS07K Muiruri Mulinge 6847 PDFDocument14 paginiTS07K Muiruri Mulinge 6847 PDFMohd Yazid Mohamad YunusÎncă nu există evaluări

- 555Document4 pagini555Mohd Yazid Mohamad YunusÎncă nu există evaluări

- Ch2 Literature ReviewDocument11 paginiCh2 Literature ReviewMohd Yazid Mohamad YunusÎncă nu există evaluări

- Research Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranDocument15 paginiResearch Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranMohd Yazid Mohamad YunusÎncă nu există evaluări

- Assessment of Safety and Health Measures (Shassic Method) in Construction SitesDocument9 paginiAssessment of Safety and Health Measures (Shassic Method) in Construction SitesMohd Yazid Mohamad YunusÎncă nu există evaluări

- Challenges and Needs For Support in Managing Occupational Health and Safety From Managers' ViewpointsDocument21 paginiChallenges and Needs For Support in Managing Occupational Health and Safety From Managers' ViewpointsMohd Yazid Mohamad YunusÎncă nu există evaluări

- Ijaiem 2015 01 11 16Document10 paginiIjaiem 2015 01 11 16International Journal of Application or Innovation in Engineering & ManagementÎncă nu există evaluări

- Homework 4Document119 paginiHomework 4indiraÎncă nu există evaluări

- Assessment of Density and Anatomical Properties of Nigerian Grown Cocos Nucifera WoodDocument7 paginiAssessment of Density and Anatomical Properties of Nigerian Grown Cocos Nucifera Woodcharize burgosÎncă nu există evaluări

- Parental Personality and Parenting StyleDocument13 paginiParental Personality and Parenting StyleMaria AprilitaniaÎncă nu există evaluări

- Elvie Baugbog 10.11.18Document16 paginiElvie Baugbog 10.11.18Bergo AgustinÎncă nu există evaluări

- EJ1080292Document8 paginiEJ1080292Marian LunaÎncă nu există evaluări

- MANOVA Benefits for Assessing Multiple Dependent VariablesDocument5 paginiMANOVA Benefits for Assessing Multiple Dependent VariablesSherry JohnÎncă nu există evaluări

- Mathematics and Statistics (Unit IV & V)Document61 paginiMathematics and Statistics (Unit IV & V)denish gandhi75% (4)

- MBA SyllabusDocument89 paginiMBA SyllabusMAADHAV HAIEBTTEÎncă nu există evaluări

- Diabetic Footwear: Is It An Assistive Technology Capable of Reducing Peak Plantar Pressures in Elderly Patients With Neuropathy?Document8 paginiDiabetic Footwear: Is It An Assistive Technology Capable of Reducing Peak Plantar Pressures in Elderly Patients With Neuropathy?José MorenoÎncă nu există evaluări

- BivariateDocument54 paginiBivariateAnkit KapoorÎncă nu există evaluări

- Neuroscientific Neuropsychological and Psychological Evidence Comparably Impact Legal Decision Making Implications For Experts and Legal PractitionersDocument30 paginiNeuroscientific Neuropsychological and Psychological Evidence Comparably Impact Legal Decision Making Implications For Experts and Legal PractitionersMaye VásquezÎncă nu există evaluări

- Sample ProposalDocument36 paginiSample ProposalChristine Ann Sangalang SebesÎncă nu există evaluări

- FRM291-Applied Statistical Analysis-Jan-May2018Document3 paginiFRM291-Applied Statistical Analysis-Jan-May2018Dexter RosalesÎncă nu există evaluări

- 3 Starch-Soiled Stainless Steel Cleaning Using SurfactantsDocument9 pagini3 Starch-Soiled Stainless Steel Cleaning Using SurfactantsNataly YupaÎncă nu există evaluări

- The Impact of HRM Practices On Organisational Performance in TheDocument28 paginiThe Impact of HRM Practices On Organisational Performance in TheBona RidyaÎncă nu există evaluări

- Epidemiology and Biostatistics: Fundamentals of Research MethodologyDocument7 paginiEpidemiology and Biostatistics: Fundamentals of Research MethodologyAbdulaziz AlQahtaniÎncă nu există evaluări

- Food Control: Heba H.S. Abdel-Naeem, Khalid Ibrahim Sallam, Nermeen M.L. MalakDocument10 paginiFood Control: Heba H.S. Abdel-Naeem, Khalid Ibrahim Sallam, Nermeen M.L. Malakfawole olaniyiÎncă nu există evaluări

- AsadDocument21 paginiAsadAhmed Moh'd El-KiniiÎncă nu există evaluări

- The Effects of Music Tempo On Memory Performance Using Maintenance Rehearsal and ImageryDocument19 paginiThe Effects of Music Tempo On Memory Performance Using Maintenance Rehearsal and ImagerySunway University100% (1)

- AIJJS Print A Study On Credit Facility Offered by Bank and Its Impact On Manufacturing IndustryDocument10 paginiAIJJS Print A Study On Credit Facility Offered by Bank and Its Impact On Manufacturing IndustryDrdev SinghÎncă nu există evaluări

- Statistics Notes 4 (F-Test (ANOVA), Pearson R and Linear Regression)Document5 paginiStatistics Notes 4 (F-Test (ANOVA), Pearson R and Linear Regression)Charmaine V. Bañes0% (1)

- Employability of Business Education GradDocument7 paginiEmployability of Business Education Gradoluwafemi MatthewÎncă nu există evaluări

- Using A Game-Based Mobile App To Enhance Vocabulary Acquisition For English Language LearnersDocument24 paginiUsing A Game-Based Mobile App To Enhance Vocabulary Acquisition For English Language LearnersJadzia ZhaoÎncă nu există evaluări

- Statistics For Psychology 6th Edition Aron Solutions ManualDocument38 paginiStatistics For Psychology 6th Edition Aron Solutions Manualedithelizabeth5mz18100% (20)

- Optimizingthe Shrinkageand Bursting Strengthof Knitted Fabricsafter Resin FinishingDocument7 paginiOptimizingthe Shrinkageand Bursting Strengthof Knitted Fabricsafter Resin FinishingAyman SebaeiÎncă nu există evaluări

- Data Science Training in Bangalore-Learnbay - inDocument13 paginiData Science Training in Bangalore-Learnbay - inKrishna Kumar100% (1)

- Lewandowski 2007 PersonalityGoesALongWay PersonalRelationshipsDocument16 paginiLewandowski 2007 PersonalityGoesALongWay PersonalRelationshipsJUAN JOSE MARIN PARRAÎncă nu există evaluări

- Ch7svol1 PDFDocument27 paginiCh7svol1 PDFRisdiyanto Edy SaputroÎncă nu există evaluări

- How To Write A Thesis PaperDocument7 paginiHow To Write A Thesis Paperbkxgnsw4100% (2)

- StatisticsDocument9 paginiStatisticsJennilyn Paguio CastilloÎncă nu există evaluări