Documente Academic

Documente Profesional

Documente Cultură

Cat - Dcs.sis - Controller 3412 X

Încărcat de

Kariem R NoweerTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Cat - Dcs.sis - Controller 3412 X

Încărcat de

Kariem R NoweerDrepturi de autor:

Formate disponibile

K

E

N

R

8

6

9

9

2

4

P

a

g

e

,

(

D

i

m

e

n

s

i

o

n

s

:

3

4

i

n

c

h

e

s

x

2

8

i

n

c

h

e

s

)

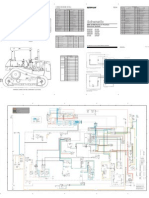

KENR8699

February 2010

3412C Gener at or Set w i t h EMCP 3

El ec t r i c al Syst em

4BZ1-UP

2010 Caterpillar

All Rights Reserved

Printed in U.S.A.

EARTH FAULT RELAY

1

10

30 7

5 8 9

74

30

14

12

13

2

G

E

N

EF1 EF2

CURRENT TRANSFORMER

T3

T2

T1

CORE BALANCE

SWITCH

LEVEL

FUEL

LOW-LOW

72 30

REMOTE CONTACTS

FOR GENERAL ALARM

:11

ALR/3

:9

66 65 64

:8

:10

ALR

:2

6

C C C

2

GRR

:10

:2

33 32 31

87

FOR GENSET RUNNING

REMOTE CONTACTS

C

88

C

89

C

58

:8

87

57

:9

59

88

:11

89

GRR/3

2

38

137

6

:5

6

HC

:A2

131

131

m

m

2

131

:6

6

m

m

2

137 137

:A1

137 137

19

m

m

2

131

WATER

J ACKET

ENGINE

HEATER

139

134

136

CR/1

66

:1

38

:4

17

(2A)

136 136 136

F16

COPPER BUSBAR

131 131 131

(32A)

F19

NOTE: CUSTOMER CABLE TO NOTE: CUSTOMER CABLE TO

TERMINALS.

ENTER DIRECTLY ONTO

mm2 6

132

131

6

6

134

mm2

mm2

AC SUPPLY

200V TO 250V

CUSTOMER

C

C

:1

131 131

6

HC

:A1

:A2

137 137 131

66

19

m

m

2

137 137

137

HEATER

2 131

m

m

2

5 .

142

ALTER-

NATOR

2

141

:3

:4

m

m

2

5 .

ENTER DIRECTLY ONTO

NOTE: CUSTOMER CABLE TO NOTE: CUSTOMER CABLE TO

AC SUPPLY

TERMINALS.

CUSTOMER

200V TO 250V

COPPER BUSBAR

17

38

CR/1

:4

136

136 136 136 131 131 131

F16

(2A) 6 mm2 131

141

6mm2

C

F18

(4A)

132 mm2 6 C

FOR 5A CHARGER FIT 6A FUSE

FOR 10A CHARGER FIT 10A FUSE

F15 36

49 11 36

2 --

++

CONSTANT

VOLTAGE CHARGER

140

131

HC

:2

131

:A2

131 140

:1 :A1

137

19

m

m

2

6

38

66

17

:4

137

CR/1

:1

136

(2A)

F16 F17

(6A)

136 136 136 131 131 131 135

COPPER BUSBAR

CUSTOMER

200V TO 250V

ENTER DIRECTLY ONTO

mm2 6

NOTE: CUSTOMER CABLE TO NOTE: CUSTOMER CABLE TO

6mm2 TERMINALS.

131 C

AC SUPPLY

6 mm2 132 C

DC POSITIVE 1

135

S-SPD

152 151 153 150

LOADSHARING C.T.s

P1

P1

S1

S1

P2

S2

P2

S2

S1

P1

S2

P2

CT6

CT5

CT4

LOAD

6

WARNING INTERNAL CT BURDEN MUST BE CONNECTEDACROSS POWER SOURCE CURRENT TRANSFORMERS AT ALL TIMES TO PREVENT LETHAL HIGH VOLTAGE.

151

152

153

150

108

110

109

106

104

106

105

104 105

151

B0

POTENTIAL

A0

2 1 4

C0

3

CT

5

A0

FOR LOADSHARING OPERATION,

PARALLEL LINES TO BE CONNECTED

ANDSCREEN TO BE EARTHEDONE

ENDONLY (TERMINAL :12).

C

NOTE:

152

153

150

LS1

LS2

LS1

LS2

C

29

PARALLEL

+

10 8

CT

B0

7

CT

C0

9 12

LINES

-

11 13

OPEN FOR DROOP

0

DROOP GAIN

10

AUXILIARY

CONTACT

(SUPPLIED

BY OTHERS)

24102

18-32VDC

AUX CONTACT

15

+

14 16

-

10 0

30

GENERATOR

-

23

LOADSIGNAL

TEST POINT

LOADSENSOR

18 17 22

+

PWM

OUTPUT

26

-

25

+

24

SYNC

INPUT

21 28 27

TRIM

SPEED

19

+

POTENTIOMETER

(10K , 10T)

SPEEDADJ UST

:1 :3

43

CW

42

:2

44S-SPD

W

-

20

D-SPD

2

97 95 5 3 1 O/L

131

33

70

DC POSITIVE 1

210

5

131

2

5 .

m

m

2

2

mm2 5 .

FUEL

PUMP

2

M

.

2

211

6 4

209

131 131

mm2

96 98

4 18

:10

2

PR

83

:2

FUEL

SWITCH

-

+

81

9

LEVEL

FUEL

HIGH

LEVEL

SWITCH

LOW

PR/1

:1

:3

84

10

81

RUN

84

(2A)

F23

PUMP

84

5

203 202

:X1

40

1

:X2

202

RUN

PUMP

203

STOP

131

:X2

TRIP/

PUMP

:X1

42

3

AUX

:14

:13

PUMP

STOP

O/L

:98

:97

131 131 208 203 206 131

131

2

204

PC

131

A2

:11

A1

2 6 4

208

1 5

211

3

O/L

:95

PR/3

205

:96

:9 5 .

m

m

2

2

14

13

131

131

.5

m

m

2m

m

2

6

206

24

64

206

36

207 207

F21

(6A) (2A)

F22

BUSBAR

COPPER

131 131 131

ENTER DIRECTLY ONTO

TERMINALS. mm2 6

NOTE: CUSTOMER CABLE TO NOTE: CUSTOMER CABLE TO

AC SUPPLY

CUSTOMER

200V TO 250V

6 132 mm2

131 6 mm2

C

C

HIGH 81

SWITCH

LEVEL

FUEL

83

LOW

SWITCH

LEVEL

FUEL

:3

PR/1

:1

84

10

4

84

85

:6

:7

MV PR

2

:10 -

2

:1

:2 + :2

DC POSITIVE

F23

(2A)

1 84

MV PR

2

2

:10

2

-

:1

84

4

10

84

83

HIGH

:2

SWITCH

LEVEL

FUEL

LOW

SWITCH

LEVEL

FUEL

+ :2

85

:3

PR/1

:1

:6

PR/2

:7

81

9

18

81

RUN

PUMP

mm2

PUMP

FUEL

131 131

70

33

131

m

m

2

2 .5

.5 2

A2

131

O/L

203

:X2

:X1

40

:X2

:X1

202

PUMP

RUN

203

1

202

PUMP

TRIP/

STOP

42

PC

A1

204

:9

205

PR/3

:11

3 :95

O/L

:96

24

203 206

M

131 131

14

97

mm2

98

209 211

2 4 6

210

. 2 5

2

1

4

3

6

5

96

95

131

13

211 208

1 3 5

131

m

m

2

.5

2

m

m

2

5 .2

208 131

m

m

2

131

6

131 131

COPPER

BUSBAR

:97

O/L

207

:98

AUX

:13

:14

207

36

STOP

PUMP

206

64

206

5

F22

(2A) (6A)

F21

mm2

131 131 131

6 131 C

mm2 6 132 C

ENTER DIRECTLY ONTO 200V TO 250V

mm2 AC SUPPLY 6 TERMINALS.

NOTE: CUSTOMER CABLE TO NOTE: CUSTOMER CABLE TO CUSTOMER

DC POSITIVE

(2A)

1 F23 84

VOLTAGE

MODULE/NETWORK

STATUS

SPARE

AIR SHUTDOWN

DAMPER

BATTERY CHARGER

AC FAILURE

LOWSTARTING

AIR PRESSURE

VOLTAGE

LOWBATTERY

LOWFUEL LEVEL

CONTROLLING SWITCH

CONTROLLING SWITCH

NOT INAUTO

HIGH BATTERY

EPS SUPPLYING

LOAD

LOWCOOLANT LEVEL

OVERSPEED

ACKNOWLEDGE

ALARM

LOWOIL PRESSURE

LOWCOOLANT TEMPERATURE

HIGH COOLANT TEMPERATURE

EMERGENCY STOP

FAIL TO START (OVER CRANK) TEST

LAMP

CONNECTOR

10

9

8

5

11

12

6

7

6

6 PIN DEUTSCH

4

5

3

1

J 1

2

CAN2+

SCR2

CAN2-

2

55

WARNING

11 10 6 1 2

9 8 7 5 4 3 CR

F2 F1

GRR

11 10 6 1 2

9 8 7 5 4 3

F11F12F13

11 10 6 1 2

9 8 7 5 4 3

-B +B S D

1 2 3 ALR

SECONDARY

SERVICE

CONNECTOR

(FRONT VIEW)

A

1 2 5 6 7

A B C DE F G H I J

set point adjust

read

11 10 6 1 2

9 8 7 5 4 3

DC

1 2 5 6 7

A B C DE F G H I J

set point adjust

read

AC

1 2 5 6 7

A B C DE F G H I J

set point adjust

read

BTR

1 2 5 6 7

A B C DE F G H I J

set point adjust

read

ATR

DC CHASSIS

ATR

11 10 6 1 2

9 8 7 5 4 3

11 10 6 1 2

9 8 7 5 4 3

KWR

ATR

ALR PR

VIEWA-A

CHASSIS ONLY SHOWN

D

C

TER

M

S

AC

TER

M

S

AC CHASSIS

EFR

F22

BC

F17 F16 F19 F18 F21

HC

2 4 6 8

1 3 5 7BF20.4..

OV/UV F32F33

TX

AR

11 10 6 1 2

9 8 7 5 4 3

4 2 6 14

3 1

MC9

5 13

A2

A1

PC

I

O

TEST

on

off

SACE S6 ABB

A

PWM

DC TERMINAL

STRIP

AC TERMINAL

STRIP

DC TERMINAL

STRIP

KILOWATT

RELAY

ALARM

RELAY

PUMP

RELAY

WINDING

TEMPERATURE

RELAYS

BEARING

TEMPERATURE

RELAYS

DC 40 PIN CONNECTOR

AC 40 PIN CONNECTOR

VOLTAGE REGULATOR

AC TERMINAL

STRIP

HEATER

CONTACTOR

ENGINE FAILURE

RELAY

PUMP

CONTACTOR

FUSE BLOCKS

OVER/UNDER

VOLTAGE RELAY

FUSE BLOCKS

BATTERY CHARGER

CUSTOMER

TERMINAL STRIP

GENERATOR

RUNNING

RELAY

ALARMRELAY CRANK RELAY

EARTH LEAKAGE OPTION

5A/10A BATTERY CHARGER OPTION

LOAD SHARE GOVERNOR OPTION

ENGINE HEATER OPTION ALTERNATOR HEATER OPTION

COMMON ALARM/SHUTDOWN

RELAY OPTION

GENERATOR RUNNING

RELAY OPTION

LOW FUEL LEVEL

ALARM OPTION

FUEL TRANSFER SYSTEM 1 OPTION

FUEL TRANSFER SYSTEM 3 OPTION

FUEL TRANSFER SYSTEM 2 OPTION

ANNUNCIATOR OPTION

MARSHALLING BOX

CONTROL PANEL

K

E

N

R

8

6

9

9

2

4

P

a

g

e

,

(

D

i

m

e

n

s

i

o

n

s

:

3

4

i

n

c

h

e

s

x

2

8

i

n

c

h

e

s

)

THIS SCHEMATIC IS FOR THE 3412C EMCP 3 FOR PEEC ENGINES

PART NUMBER: 254-1263, CHANGE: 00, VERSION: DK

Components are shown installed on a fully operable generator set with the key and engine off.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations.

36

1

15

3

33

19

24 64

70

131

66

137

131

206

137

SP4

63 34

49

31 57

87

88

89

59

58

33

32

36

55

51

N

11

159

70B

54

46

44

1

36

61

42

43

40

203

13

202

131

206

137

SP4

C

C

89

C

88

87

N

36

159

54

C

70B

C

203

61

202

5

13

14

11

29

17

98

36

38

136

34

207

136

28

96

97

91

32

33

31

8

18

39

157

23

31

27

29

25

117

29

158

74

22

21

178

37

4 10

17 17

72

81

18 9

84

RDM

7 7

71

1 16

C

C

207

136

C

98

C

96

97

C

91

157

117

31

158

178

74

72

81

C

RDM

84

71

NOTE: IF 4 POLE BREAKER FITTED

B08

REF.

G

N

4

E

E

T2

T3

T1

CHANGE N T0

N

E

T2

T3

T1

REMOTE TERMS

OPEN & CLOSED

(IF REQUIRED)

FOR BREAKER

POSITIONS

231 C

C 232

C 233

POWER

WIRING FROM

GENERATOR

POWER

WIRING TO

BREAKER N

REF.E02

2

6

E

T2

T3

T1

6 22 6

REF. F02/F03

GENERATOR

POWER

WIRING FROM

OPEN & CLOSED

FOR BREAKER

POSITIONS

REMOTE TERMS

:C2

:12

BREAKER

AUXILIARY

:11

:14

SHUNT

TRIP

ST

:C1

24V DC

N

E

L2

L3

L1

:C12

BREAKER

AUXILIARY (IF REQUIRED)

233

232 C

C

C 231

:14 :13

:11 :12

Q/2

Q/1

:C11

ST

N

REF.E02

6

2

E

T2

T3

T1

24V DC

SHUNT

TRIP

4 POLE BREAKER OPTIONAL

(SEE NOTE REF.F08)

4 POLE BREAKER OPTIONAL

(SEE NOTE REF.F08)

N

E

L2

L3

L1

ENCLOSURE

STOP

EMER.

STOP

EMER.

BATTERY (+)

BATTERY (-)

2

2

11

12

2

BATTERY

REMOVABLE

ISOLATOR

30

KEY

SWITCH

(OPTIONAL)

-

24V

+

DC MARSHALLING BOX

AC MARSHALLING BOX

CONTROL PANEL BODY

CONTROL PANEL TOP COVER

CONTROL PANEL REAR COVER

CONTROL PANEL DOOR

CONTROL PANEL CHASSIS

REF.

C07

E

E

E

68 21

E

21 47

E

E

E

E

E REF.

E05

F08

SMMS1/1

PS1

2 2 20 2

PS1

SM1

25

PS2

50 REF.

SM2

PS2

26

SMMS2/1

mm 2 6

40

ALT CHARGING

ALTERNATOR

2 19

13 P+

CB3

(15A)

2.5

2.5mm 2

24

CB2

(20A)

mm 2

+

mm 2 2.5

24

mm 2 6

2

1

1

1

+

mm 2

(60A)

CB1

6

:30

PEECR/1

:87

ESDR

PEECR

:30 :86

:86

:85

10

9 5

2

SATS

60

1

SASV

2

60

59

1

59

33

44 43 42

:3 :1

:2

ADJ. POT.

(1K , 10T) W

SPEED

R

4

5

7

D-SPD

S-SPD

1

2

10

E

ENGINE SHUTDOWN

DROOP

:31

ENGINE

MOUNTED

C

:37

27 14

REF.

B06 10

3

FUEL SHUTOFF

SOLENOID

GROUND

PRIMARY THROTTLE

IDLE/RATED

P

E

:21 :22

:8

:33

:1 :17

PEEC

FSOS

45A 1

9

6 45

B08

REF.

7 41

20

REF.

:87a

27

:85

10

10

B05

45A B04

REF.

45

C05

REF. 41

41

20

S-SPD

S

10

D-SPD30

D +B -B

CONTROL

SPEED 1 2 3

23A 23A

39

SWITCH

START

ETHER

59 59

:1

:2

(OPTIONAL)

ON

CR

2

:10

30

4

30

B06

REF.

2

4 TO 34

45A TO 46

12 TO 11

FITTED

THEN LINK

:2

12

IF NOT

11

30 30

30 17

REF.B06

41

17

20

LIGHTS

PANEL 9 9

45

9

SWITCH

PANEL

LIGHT

:3

:2

45A 2

45 46

56

35 15

16

2 2 2

C

C

6

2

17

MARSHALLING BOX CUSTOMER AC TERMINAL

MARSHALLING BOX CUSTOMER DC TERMINAL

MARSHALLING BOX 40 WAY AC CONNECTOR

MARSHALLING BOX 40 WAY DC CONNECTOR

PANEL 70 WAY CONNECTOR 12

SATS 2 WAY CONNECTOR

SASV 2 WAY CONNECTOR

2

C

1

18

ENGINE TEMPERATURE ENGINE CONNECTOR

A.C. CONNECTOR FROM ALTERNATOR (GREEN)

D.C. CONNECTOR No.1 FROM ENGINE (BLACK)

D.C. CONNECTOR No.2 FROM ENGINE (GREY)

INTERNAL PANEL TERMINAL

POWER TERMINAL

OIL TEMPERATURE ENGINE CONNECTOR

MAGNETIC PICK-UP ENGINE CONNECTOR

24 WAY PEEC ENGINE CONNECTOR

COOLANT LOSS ENGINE CONNECTOR

OIL PRESSURE ENGINE CONNECTOR

MARSHALLING BOX TERMINAL

OUTGOING/INCOMING PANEL TERMINAL

3

2

3

11

1

SYMBOLS

C

B

C

B

A

NOTE A: ALL WIRE SIZES 1.5mm UNLESS OTHERWISE STATED

22 21 CAN1+

55 2

120

1 3 2

53 51 52

12 10 11

B08

REF. 50

50 50 50

METERING C.T.s

P1

P1

S1

S1

S1

P1

P2

S2

P2

S2 CT3

CT2

S2

P2

CT1

6

4

4

34

IF REQUIRED

SMMS1 SMMS2

55

:9

CR/3

:11

REF.

B06/B07

10

10

45

12

10

C

55

REF.

B06

15

30

START

C

CONTACT

C

REMOTE

30

COOLANT

LOSS

C B A

10

18

8

62

10

18

10

RATED

SPEED

RLY5

GFR

RLY4

SWITCH

32 41 33 43 40

ASR

SWITCH

RLY3

58 35

FUEL

RLY2

_

52

ENG

CRANK

RLY1

+

61 48 51 DC

CONTROL

BATTERY (12/24Vdc)

31

IA

AC 47

IB

66

+ -

67

PICKUP

MAG

65

EARTH (MOUNTING SCREW)

SINK O/P 1

44

I/P 6

SPARE

INPUT 1

I/P 5

45

I/P 4

53

EMERG

STOP

REMOTE

START

70

I/P 1 I/P 2

55

COOLANT

LOW

I/P 3

LEVEL

54

O/P

PROG

RLY8

24 1 15 14

PROG

O/P

RLY7

25 2 27

GRR

RELAY

RLY6

26

OIL

TEMP

29 37

PASSIVE

OIL

PRESSURE

46

ANALOG 1-

PASSIVE

30

TEMP

ENGINE

38

ANALOG 2+

PASSIVE PASSIVE

TEMP

ANALOG 3+

OIL TEMP

ENGINE

ANALOG 2-

OIL

I/P 8

PROG

28

I/P 8

36

I/P 7

I/P 7

PROG PRESSURE

ANALOG 1+

PASSIVE

56

PASSIVE

ANALOG 3-

11

VB

VA

VC

13 7 9 39 57

IC I RETURN

LCD DISPLAY

4 5

+

63

SRN -

62

+

42

SRN

CAN2 J1939

64 3

-

RS485

SRN

34

-

50

+

CAN1 J1939

EMCP3.2

69

8 6 108 108

(2A) (2A) (2A)

110 108 109 101

9

F13

T1 T2

7 5

T3

F11 F12

8

TO

12

109

110

10

109

110 10

8

14

101 101 38

38 6 37

2

6 2

REF.

C02

C05

REF.

PRIMARY SERVICE CONNECTOR

C E H G F A B D

SECONDARY SERVICE CONNECTOR

55 2

A B D E F H G C

1

1 56

REF.

C06

REF.

B04

A

B

C

D

E

F

8 7 6 5 4 3 2 1

A

B

C

D

E

F

8 6 7 5 2 4 3 1

MAGNETIC

PICK UP No.1

22

2 1

21

22 21

19

9

16 15

REF.

D03

B07

REF.

REF.

B07

C06

REF. 55

2

REF.

D03

15 16 19 62 62 62

19 16 15

SP3 74 72 SP4 SP5 55 55 55 55 41 20 14 39

2

55

37 38 6 17 57 18

CAN1-

CAN2+

CAN2-

M+M-

CAN1+

CAN1-

CAN2+

CAN2-

18 2

120

CAN1+

CAN1-

INPUT 2

SPARE

INPUT 3

SPARE

30

52 51 53 50

53 52 51 50 101 110 109 108

SCR1

SCR2

SCR3

SCR1

SCR2

SCR1

30

57

57

10 14 39

OP3

OP4

OP5 (2A)

F1

(10A)

F2

206

SP4

89

88

87

36

202

203

74

72

81

84

71

B06

REF.

REF.

A04

62

7 6

A03

REF.

B08

REF.

12 11 3

8 10

SP2

61

SP2 14 SP2

4 SP1

60

SP1 SP1

SP3

62

SP3 24 SP3

55

PRESS

OIL

TEMP

ENG OIL

TEMP

POTENTIOMETER

VOLTS ADJUST

(10K , 5 TURN)

80 82

:3

80

:1

82

:2

VOLTS

RAISE/LOWER

SWITCH

CONNECT

TO DVR

RAISE

9-5 9-6 9-4

LOWER

FITTED IF REQUIRED

OP1

OP2

REF.

B02

55 55

NOTE B: WIRING REQUIRED FOR EMCP3.2 CONTROLLERS

FOR SETS WITH DVR

FOR SETS WITH AVR

MCCB ACB

NOTE B

NOTE B

NOTE B

NOTE B

NOTE B NOTE B

IF REQUIRED

AC ALTERNATING CURRENT

ACRONYMS

ACB AIR CIRCUIT BREAKER

ALR ALARM RELAY

ASR AIR SHUTOFF RELAY

ATR ALTERNATOR TEMPERATURE RELAY

AVR ANALOG VOLTAGE REGULATOR

BC BATTERY CHARGER

CT CURRENT TRANSFORMER

DC DIRECT CURRENT

DVR DIGITAL VOLTAGE REGULATOR

EFR ENGINE FAILURE RELAY

FSOS FUEL SHUTOFF SOLENOID

GFR GENSET FAULT RELAY

GRR GENERATOR RUNNING RELAY

HC HEATER CONTACTOR

KWR KILOWATT RELAY

ESDR ENGINE SHUTDOWN RELAY

MV MOTORIZED VALVE

OV/UV OVER VOLTAGE/UNDER VOLTAGE

PC PUMP CONTACTOR

PEEC PROGRAMMABLE ELECTRONIC ENGINE CONTROL

PR PUMP RELAY

MCCB MOLDED CASE CIRCUIT BREAKER

PS PINION SOLENOID

PWM PULSE WIDTH MODULATION

SASV START AID SOLENOID VALVE

SATS START AID TEMPERATURE SWITCH

SM STARTING MOTOR

SMMS STARTING MOTOR MAGNETIC SWITCH

CR CRANK RELAY

CIRCUIT CONNECTED

GENERATOR (CHASSIS) GROUND

CIRCUIT NOT CONNECTED

ENGINE GROUND

ADDITIONAL WIRES

LOCATED IN MARSHALLING

BOX/ PANEL CONNECTING

LOOMS FOR OPTIONS.

S-ar putea să vă placă și

- AC GENERATOR WIRING DIAGRAMDocument15 paginiAC GENERATOR WIRING DIAGRAMAndriano Dasri100% (15)

- Caterpillar Global Solutions: 50/60 HZ Switchable Genset Ipp Application (Wiring)Document19 paginiCaterpillar Global Solutions: 50/60 HZ Switchable Genset Ipp Application (Wiring)Jonathan Javier Ceballos Bonilla100% (2)

- Diagrama D6HDocument2 paginiDiagrama D6HPepe Alonzo71% (7)

- 3412E-3408E Engine Electrical SchematicsDocument2 pagini3412E-3408E Engine Electrical SchematicsGanapati Hegde95% (21)

- Cat 3508-B Electr - DiagramDocument2 paginiCat 3508-B Electr - DiagramCésar Pérez88% (8)

- Cat c15 Diagramma4Document11 paginiCat c15 Diagramma4Harlinton descalzi100% (2)

- 3406C Eng SchematicDocument4 pagini3406C Eng Schematicmurugu197983% (12)

- Wiring Diagram 3512Document2 paginiWiring Diagram 3512Clever Negrete NovaÎncă nu există evaluări

- Caterpillar EMCP II+ schematics wiring diagramsDocument46 paginiCaterpillar EMCP II+ schematics wiring diagramsjaliltaghdareh83% (6)

- PWM Signal Converter - CaterpillarDocument4 paginiPWM Signal Converter - CaterpillarImad Hmd100% (6)

- 950F Wheel Loader Electrical System: Vehicle Harness Connector and Component LocationsDocument2 pagini950F Wheel Loader Electrical System: Vehicle Harness Connector and Component LocationsBrahian Mijael Garrado Gonzales100% (1)

- C18 Generator Set With EMCP II, EMCP II +and EMCP 3 - Electrical System - RENR7934-01 - March 2006 - CATERPILLAR PDFDocument6 paginiC18 Generator Set With EMCP II, EMCP II +and EMCP 3 - Electrical System - RENR7934-01 - March 2006 - CATERPILLAR PDFpevare100% (3)

- Industrial Rb211Document12 paginiIndustrial Rb211rrcardoso230Încă nu există evaluări

- 3512 ScematicDocument2 pagini3512 Scematicmohamed hamedÎncă nu există evaluări

- Cat EMCP3 CONTROL PDFDocument21 paginiCat EMCP3 CONTROL PDFddzoningcomÎncă nu există evaluări

- Upgrade Emcp 3.1 To Emcp 4.2Document24 paginiUpgrade Emcp 3.1 To Emcp 4.2Rajkumar Mudaliar100% (2)

- Emcp II+3512c CaterpillarDocument4 paginiEmcp II+3512c CaterpillarManuel Otero85% (20)

- Schematic 3408E Electrical SystemDocument2 paginiSchematic 3408E Electrical Systemmontana12345100% (3)

- Senr6477 06 00 AllDocument112 paginiSenr6477 06 00 AllAgustín Touriño100% (2)

- Emcp I - Testing Amd Adjusting - CaterpillarDocument64 paginiEmcp I - Testing Amd Adjusting - Caterpillarpevare94% (18)

- 3412 Peec Ecm TroubleshootDocument8 pagini3412 Peec Ecm TroubleshootB E Balaramenterprise100% (1)

- Esquematico C9, CATDocument2 paginiEsquematico C9, CATramahua126075% (4)

- 3412Document2 pagini3412asadiqbalansari100% (1)

- Esquma Eléctrico SencilloDocument2 paginiEsquma Eléctrico SencilloJorge100% (3)

- Electrical and Starting System: 9X-8085 Control Gp-Engine ElectronicDocument2 paginiElectrical and Starting System: 9X-8085 Control Gp-Engine ElectronicwilsonÎncă nu există evaluări

- 9x-9591 Electrical Converter GP (Pulse Width ModulatedDocument5 pagini9x-9591 Electrical Converter GP (Pulse Width ModulatedSergio Alvarez67% (6)

- Emcp IiDocument14 paginiEmcp IiMohamed Bakheet78% (9)

- C13, C15 and C18 Generator Set Electrical SystemDocument2 paginiC13, C15 and C18 Generator Set Electrical Systemzoman zoman100% (1)

- Electrical Connectors and Functions 3412Document45 paginiElectrical Connectors and Functions 3412Abdul Khaliq75% (4)

- Group 2 Electrical Circuit (1/2) : HL7407 1WIRG1Document19 paginiGroup 2 Electrical Circuit (1/2) : HL7407 1WIRG1Priscila RodriguesÎncă nu există evaluări

- Instruction Manual: Installation - Operation - MaintenanceDocument20 paginiInstruction Manual: Installation - Operation - MaintenanceЕлена АхметзяноваÎncă nu există evaluări

- 3412 SchematicsDocument3 pagini3412 SchematicsErick Lopez Hdz100% (10)

- Diagrama Electrico 315l CaterpillarDocument2 paginiDiagrama Electrico 315l CaterpillarEdwin Carrera75% (4)

- Renr1242 02Document2 paginiRenr1242 02Mohamed Abdelazim Bakr Adam100% (2)

- RENR2344RENR2344 - SIS Peec Emcp 2 +Document4 paginiRENR2344RENR2344 - SIS Peec Emcp 2 +Sayed Younis SadaatÎncă nu există evaluări

- Cxdi 701g - 701c Service ManualDocument244 paginiCxdi 701g - 701c Service Manualsamuel debebeÎncă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- 3512 Electronico PDFDocument2 pagini3512 Electronico PDFPedro Zafra83% (12)

- Cat 3512B/3516BDocument2 paginiCat 3512B/3516Bmohammad hazbehzad100% (2)

- Caterpillar 3412 SchematicsDocument3 paginiCaterpillar 3412 SchematicsAhmad Hamouda100% (6)

- 10-Emcp 3Document79 pagini10-Emcp 3Mohammed Elbadri100% (1)

- Emcp 2 +P Wiring Diag - Google SearchDocument4 paginiEmcp 2 +P Wiring Diag - Google Searchahmedco100% (2)

- Diagrama Electrico 3412 PDFDocument2 paginiDiagrama Electrico 3412 PDFMilton Hernandez Pérez100% (3)

- 3412C EMCP II+ For PEEC Engines Electrical System: Tgc1-Up Ptl1-Up 9EP1-UP Bcw1-Up Lry1-Up 4BZ1-UPDocument4 pagini3412C EMCP II+ For PEEC Engines Electrical System: Tgc1-Up Ptl1-Up 9EP1-UP Bcw1-Up Lry1-Up 4BZ1-UPMuhammad Shoaib HussainÎncă nu există evaluări

- 4.ageing 01.01.21Document4.991 pagini4.ageing 01.01.21Mukesh ManideepÎncă nu există evaluări

- Emcp 2Document4 paginiEmcp 2Muhammad Ahsen100% (2)

- Presentasi ADP OMU Rev 06 Mar 2020 Buat SPI-1Document50 paginiPresentasi ADP OMU Rev 06 Mar 2020 Buat SPI-1Widji SlametÎncă nu există evaluări

- 3512b-Main Elect WiringDocument8 pagini3512b-Main Elect WiringHany Atwa100% (7)

- EMCPIIDocument9 paginiEMCPIIpul896392% (12)

- Hydro Power Governor BrochureDocument8 paginiHydro Power Governor BrochureTitipong PulbunrojÎncă nu există evaluări

- Emcp 3 1Document150 paginiEmcp 3 1victoros27Încă nu există evaluări

- Sweco - ZS24 Manual PDFDocument76 paginiSweco - ZS24 Manual PDFdata493100% (1)

- 3412C EMCP II+ For PEEC Engines Electrical SystemDocument4 pagini3412C EMCP II+ For PEEC Engines Electrical Systemविशाल पुडासैनी100% (1)

- 3406Document2 pagini3406ibrahem100% (1)

- Guide For Generator Condition Assessment in Hydropower PlantDocument19 paginiGuide For Generator Condition Assessment in Hydropower PlantSanjin Mehinović100% (1)

- Renr2477renr2477-02 SisDocument4 paginiRenr2477renr2477-02 SisNanda PutriÎncă nu există evaluări

- RENR8077RENR8077 - 01 - SIS Emcp 2 + PDFDocument4 paginiRENR8077RENR8077 - 01 - SIS Emcp 2 + PDFsayeed younis sadaat100% (1)

- Systems Operation Troubleshooting Testing and Adjusting: Emcp 3Document148 paginiSystems Operation Troubleshooting Testing and Adjusting: Emcp 3Inot Depression Side100% (13)

- Perkins® 4012-46TWG2ADocument1 paginăPerkins® 4012-46TWG2AKariem R Noweer50% (2)

- A320 CB-PanelsDocument95 paginiA320 CB-Panelsyazan999Încă nu există evaluări

- Com 069 Agk 2030 EdDocument14 paginiCom 069 Agk 2030 EdSimamora Samuel HansenÎncă nu există evaluări

- CAT 3500B Generator Electrical SystemDocument4 paginiCAT 3500B Generator Electrical Systemedcoo100% (7)

- 1491911172gypsemna Product Catalogue 2017Document64 pagini1491911172gypsemna Product Catalogue 2017Kariem R NoweerÎncă nu există evaluări

- Common RailDocument3 paginiCommon RailKariem R Noweer100% (1)

- 4bz 3412 Gensets PeecDocument7 pagini4bz 3412 Gensets PeecSameh Rashad Ahmed67% (3)

- (IMechE Conference) M. J. Moore-Micro-turbine Generators-Wiley (2002)Document126 pagini(IMechE Conference) M. J. Moore-Micro-turbine Generators-Wiley (2002)SaadEddine AtifÎncă nu există evaluări

- GH Electrical Wiring DiagramDocument7 paginiGH Electrical Wiring DiagramJc LamÎncă nu există evaluări

- Handbook of RefractoryDocument331 paginiHandbook of RefractoryAamirMalikÎncă nu există evaluări

- RCS-9659 - X - Instruction Manual - EN - Domestic General - X - R1.02 - (EN - DYBH0319.0086.0003) PDFDocument116 paginiRCS-9659 - X - Instruction Manual - EN - Domestic General - X - R1.02 - (EN - DYBH0319.0086.0003) PDFTonyBui100% (2)

- Plano Elétrico D6HDocument2 paginiPlano Elétrico D6HSinSombra19750% (2)

- Visio-LCP 8FCU C&NDocument3 paginiVisio-LCP 8FCU C&Njohan_karimÎncă nu există evaluări

- Wiring Diagram Schema Electrique: 30RA 100 B0921 PEE 0000269480Document13 paginiWiring Diagram Schema Electrique: 30RA 100 B0921 PEE 0000269480Dinu Muralidharan MÎncă nu există evaluări

- Big Gear Box Oil StatusDocument1 paginăBig Gear Box Oil StatusKariem R NoweerÎncă nu există evaluări

- BAGS Purchase Request (Items) PDFDocument1 paginăBAGS Purchase Request (Items) PDFKariem R NoweerÎncă nu există evaluări

- Estimation Cost: Al Watania Gypsum Co. LTDDocument2 paginiEstimation Cost: Al Watania Gypsum Co. LTDKariem R NoweerÎncă nu există evaluări

- BAGS Purchase Request (Items) PDFDocument1 paginăBAGS Purchase Request (Items) PDFKariem R NoweerÎncă nu există evaluări

- Description: هدحولا consumption sales required in tons required material unit 5-Feb-19 STOCK IN 1 APRDocument24 paginiDescription: هدحولا consumption sales required in tons required material unit 5-Feb-19 STOCK IN 1 APRKariem R NoweerÎncă nu există evaluări

- Hotoil PumpDocument2 paginiHotoil PumpKariem R Noweer100% (1)

- 558Document1 pagină558Kariem R NoweerÎncă nu există evaluări

- Al Watinya Gyp c32 DecDocument4 paginiAl Watinya Gyp c32 DecKariem R NoweerÎncă nu există evaluări

- Capacity 8 Ton 5600kw Thermal Oil Heavy Oil Fired Boiler Quotation From Henan Yuanda Boiler FactoryDocument11 paginiCapacity 8 Ton 5600kw Thermal Oil Heavy Oil Fired Boiler Quotation From Henan Yuanda Boiler FactoryKariem R NoweerÎncă nu există evaluări

- Elec Invo PDFDocument1 paginăElec Invo PDFKariem R NoweerÎncă nu există evaluări

- Conect Plus (Unit 7)Document44 paginiConect Plus (Unit 7)Kariem R NoweerÎncă nu există evaluări

- Elec InvoDocument1 paginăElec InvoKariem R NoweerÎncă nu există evaluări

- New Items TempleteDocument10 paginiNew Items TempleteKariem R NoweerÎncă nu există evaluări

- Spherical Roller Bearings, On An Adapter Sleeve - 22208 EK + H 308Document1 paginăSpherical Roller Bearings, On An Adapter Sleeve - 22208 EK + H 308Kariem R NoweerÎncă nu există evaluări

- 101-Heating Procedures - InSULATING CastablesDocument1 pagină101-Heating Procedures - InSULATING CastablesKariem R NoweerÎncă nu există evaluări

- The Use of MPS VRM in Finish GrindingDocument7 paginiThe Use of MPS VRM in Finish GrindingLLÎncă nu există evaluări

- High Calcium Aluminate Cements and Chemical BindersDocument16 paginiHigh Calcium Aluminate Cements and Chemical BindersKariem R NoweerÎncă nu există evaluări

- Tyre Coupling CatalogDocument9 paginiTyre Coupling CatalogKariem R NoweerÎncă nu există evaluări

- 330BL SerialDocument1 pagină330BL SerialKariem R NoweerÎncă nu există evaluări

- Plaster Board ProductionDocument4 paginiPlaster Board ProductionKariem R NoweerÎncă nu există evaluări

- Competence in GypsumDocument12 paginiCompetence in Gypsumarieltorres2601Încă nu există evaluări

- Vertical Roller Mills 01Document6 paginiVertical Roller Mills 01Kariem R Noweer100% (1)

- Fall Gypsum Applications White Paper 11.15.13Document3 paginiFall Gypsum Applications White Paper 11.15.13Kariem R NoweerÎncă nu există evaluări

- Spin Prod 544004701Document26 paginiSpin Prod 544004701warriosoulm4Încă nu există evaluări

- ABB Wind Turbine Converters - LowresDocument12 paginiABB Wind Turbine Converters - LowresMaster Math.Încă nu există evaluări

- GH 5KW Greef Wind Turbine CatalgoueDocument7 paginiGH 5KW Greef Wind Turbine CatalgoueSanjayan MaratÎncă nu există evaluări

- BP Lesson 3.1 FundamentalsDocument38 paginiBP Lesson 3.1 Fundamentalsglen jlieza fuentecillaÎncă nu există evaluări

- 400 HZ SystemDocument33 pagini400 HZ SystemTaskÎncă nu există evaluări

- Modelo APD300C-6Document4 paginiModelo APD300C-6WilmerÎncă nu există evaluări

- Presentation On: Presented byDocument36 paginiPresentation On: Presented byShamimSarkar100% (1)

- Woodward Governor Troubleshooting Case StudyDocument0 paginiWoodward Governor Troubleshooting Case StudySofiane HalimiÎncă nu există evaluări

- Gencon - 2 PDFDocument43 paginiGencon - 2 PDFJosé Da Silva Mata100% (1)

- Achieving Flexible Power Distribution with ABB's Onboard DC GridDocument6 paginiAchieving Flexible Power Distribution with ABB's Onboard DC Gridashishdce7643Încă nu există evaluări

- Transient Stability Improvement of IEEE 9 Bus System With Shunt Facts Device StatcomDocument5 paginiTransient Stability Improvement of IEEE 9 Bus System With Shunt Facts Device StatcomBhavik PrajapatiÎncă nu există evaluări

- 7000 EXL Generator Owners ManualDocument24 pagini7000 EXL Generator Owners Manualabrote7114Încă nu există evaluări

- Footstep Power Generator Converts Mechanical EnergyDocument14 paginiFootstep Power Generator Converts Mechanical EnergySharmaÎncă nu există evaluări

- Elec 4 Synchronous Genrators PPT 2Document37 paginiElec 4 Synchronous Genrators PPT 2Jamir CalÎncă nu există evaluări

- Thesis 2008 SarkarDocument200 paginiThesis 2008 SarkarNivas VallavanÎncă nu există evaluări

- gg7500n SeriesDocument28 paginigg7500n SeriesAda SolucionesÎncă nu există evaluări

- 4th Semester Electronics Engg.Document24 pagini4th Semester Electronics Engg.PRAKASH GOSWAMIÎncă nu există evaluări

- Maintain System Frequency Automatic Load Frequency ControlDocument77 paginiMaintain System Frequency Automatic Load Frequency ControlDr. MUTHUKUMAR RÎncă nu există evaluări

- Design of HEVs A PrimerDocument44 paginiDesign of HEVs A PrimerK GOPALÎncă nu există evaluări

- Hobart 90c20Document224 paginiHobart 90c20Alem MartinÎncă nu există evaluări

- Reactive Power Supplied by Wind Energy Converters - Cost-Benefit-AnalysisDocument10 paginiReactive Power Supplied by Wind Energy Converters - Cost-Benefit-AnalysisLivia AlburguettiÎncă nu există evaluări

- Q 218 UnipolarDocument4 paginiQ 218 Unipolarsakti11Încă nu există evaluări