Documente Academic

Documente Profesional

Documente Cultură

Ferro Fab

Încărcat de

sd.ehteshamDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ferro Fab

Încărcat de

sd.ehteshamDrepturi de autor:

Formate disponibile

Overview

Overview

Ferrofab was established in 1998 as an Engineering Manufacturing Company

with its head ofce in the Jebel Ali Free Zone, UAE that comprises of a 6000

sq. ft. administration building and a 490,000.00 sq. ft manufacturing facility.

The state of art Heavy engineering and manufacturing facility is one of the

best equipped organizations within the region for primarily the manufacture

of High Pressure Vessels, associated Pipe work, Heat Exchangers and Tanks.

Ferrofab has a highly qualied and motivated team, full accreditations

and certications from International bodies to facilitate and carryout most

critical projects including material such as Duplex, Super Duplex Stainless

steels, Copper Nickel & other Non-Ferrous & exotic materials.

Spread over an area of 12 acres, manufacturing and handling facility has the

follows : -

50,000 sq. ft of covered area with 20MT EOT Crane: 4 nos.

27,000 sq. ft of area fully concreted foor with 20MT Goliath Crane: 2 nos.

27,000 sq. ft of isolated stainless steel manufacturing facility with 10 ton

Goliath Crane

54,000 sq. ft of concreted / asphalted area serviced by 2 nos. of 80ton &

35ton Mobile cranes, 3 nos. 10 tons forklift .

160,000 sq. ft Hard faced area for open fabrication of extra large shapes.

P. O. Box 17815, Jebel Ali Free Zone, Dubai, U.A.E.

Tel: +971 4 8860070 | Fax: +971 4 8860071

email: ferrofab@eim.ae | www.ferrofab.com

Corporate Offce & Factory

Ferrofab FZE Jebel Ali Free Zone (South Area)

Ferrofab has a wide range of Engineering

capabilities with a team of experienced

Design Engineers, who are well versed

with International codes like ASME, PED,

API and other standards.

We are equipped with the most

advance and up to date software to

ensure compliance with the required

specications of our clients.

Dubai Ofce & Factory

Engineering

Dubai Ofce & Factory

Engineering

Ferrofab L.L.C.

P. O. Box 37839, Dubai Investment Park U.A.E.

Tel: +971 4 885 9541 | Fax: +971 4 885 9542

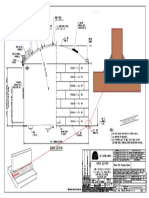

Shell 3

Shell 4

Shell 5

Shell 6

Shell 7

Right head

Noz K5

Noz N3

Noz N1A

LIQUID

LIQUID

LIQUID

LIQUID

LIQUID

LIQUID

LIQUID

LIQUID

LIQUID Noz N8

Noz N5

Shell 1 Shell 2

Left head

1030.00 mm

0.00 mm

4980.00 mm

8970.00 mm

12000.00 mm

10970.00 mm

6980.00 mm

3030.00 mm

50.00 mm

11950.00 mm

Noz N1B

Noz M1

Noz N6

Noz N4 Noz N2

Noz N4

Noz N11

Noz N13

Noz N12

Noz N14

Noz N7

Noz N8

Noz N17

Noz N9

Noz N10

Noz M

Noz N6

Noz

Noz N16

TOP DISHED HEAD

SHELL

BOTTOM DISHED HEAD

SKIRT

Noz N15

Dalum 0.00 mm 0.00m

Equipped with 3 nos. of CNC profle cutting machines of bed length of 3 meter x 15 meters

with plasma cutting capacity of up to 80 mm thickness.

Hydraulic dishing press with manipulator which can handle 60mm thk dish blanks

Hydraulic dishing press capacity 2400 tons which can handle crown and petal, dishes and

cones of up to 150 mm thk having a opening width of 7 meters.

Dishing press 900 ton x 4.2 meters 2 nos.

Dishing and fanging capacity from 5 mm up to 170 mm thk & Diameter from 300 mm to

6000 mm in single piece beyond that crown & petal construction.

We can produce dish heads with maximum thickness in the smallest possible diameter.

Toricone up to 150 mm thk & transitional pieces as per the requirement.

Plate rolling up to 100 mm thk.

Plate bending up to 150 mm thk.

Tank rotators up to 150 ton with suitable column and boom welding 8 sets.

Pipe roll bending (cold bending) from 2 to 16 dia pipe of heavy wall thickness.

Heat treatment - Stress relieving and normalizing furnace can handle up to a size of 25 meter

lenght x 5 meter height x 4.5 meter width.

Automatic shot blasting and painting facilities.

Machining up to 3.2 meter dia (VTL).

Automatic beveling of dish heads (including stainless steel).

Machineries & Capabilities

Machineries & Capabilities

Certication

We have been awarded ISO 9001 : 2000 by RWTUV Germany.

Authorized for the use of ASME U, S, U2, PP stamp by ASME for manufacturing of Pressure

Vessels under Sec. VIII. Facility to manufacture tanks and piping under API Monogram (API 2B,

API 5L, API 6A and API 12F)

Activities undertaken in this unit are Design and Manufacture of Pressure Vessels and Heat

Exchanger to ASME and PED codes, manufacture of tanks, Silos, to API codes, refurbishment of

entire offshore structures.

Manufacture of Desalination plants, Offshore / land rig structures and complete drilling mud

handling packages.

We have isolated stainless steel manufacturing bay, capable of handling up to 900 tons of

Stainless Steel fabrication per month.

Certication

ISO Certificate

National Board Certificate

NB

National Board Certificate

R

ASME Certificates

U, U2, PP, S

API Certificates

5L, 6A, 2B, 12F, 4F, 650

IGF Process Skid

Client : Merpro Limited, Scotland U.K. /

NPCC Abudhabi, U.A.E. / Maersk Oil

Major Projects

Top side of FPSO

FPSO- Golfnno, Abudhabi

Client: Veola Water Services

West Garth Ltd, U.K./ Saipem

Major Projects

Oil Flotation Cell

Frade FPSO

Client: Siemens

Water Technologies / SBM

Water Treatment Package

Client: Aquatech / QGPC

HP Flare K.O. Drum

Jihar Stage 3 Project, Syria

Client: Petrofac International

/ Hayan Petroleum Company

3 Stage Separator - 1440 PSI Separator

Client: Power Well Services

Dual Compartment Acid Tank

Client: Haliburton

Titanium Tube Brine Heater

Client: Aquatech Intl./ Al Kai, KGOC/AGOC

Fuel Gas Filter

Client: Perry Equipment

/ Yanbu Saudi Arabia

Amine Still Column (2150mm dia x 26 mtr H)

Client: RamaFab Odessa Texas/ Kuwait Petroleum

Gas Filter w/quick clossure

Marand & Margan Lar Compressor Station

Client: Tyco Thermal/ National Iranian Oil Co.

1440 psi separator skid

Client: Halliburton

Marand Compressor Station

Cyclone Separators

Client: Tyco Thermal / National Iranian Oil Co

Stainless Steel Vessels

Jebel Ali L Station

Client: Fisia Italimpianti / DEWA, U.A.E

Sea water intake Duplex S.S. Piping

Jebel Ali Power & Desalination Plant L Stn

Client: Fisia Italimpianti / DEWA, U.A.E

HP Knock Out Drum

Marand & Margan Lar

Compressor Station

Client: Tyco Thermal / National

Iranian Oil Co.

Insulated Amine Contactor Vessel

Client: Rama Fabrication Odessa Texas / Kuwait Petroleum

HCL Injection Skid

Client: Doosan / DEWA,U.A.E

Gas Filters

Hamriya Pipeline Project

Gas Pipe

Client: Perry Equipment

Filter Separator

Aweer Gas Turbine Power Station II & Phase III

Client: Process Group / DEWA- U.A.E

Deethanizer (Stainless Steel)

Dana Gas Cresent Petroleum-Khor Mor LPG

Recovery Plant

Client: Exterran Compression LP Huston U.S.A

Stainless Steel Process Vessel

Gusto Talisman Jack up Mopu IGC Package

Client: Gas Services International

Gas Filters Separator

Hamriya Pipeline Project Gas Pipe

Client: Perry Equipment / UGTCL

Dished Heads Manufacturing Facility

Dished Heads Manufacturing Facility

2:1 Ellipsoidal Dish Head

Semi - Ellipsoidal Dish Head

Toricone

Crown & Petal Construction - Spheres and Hemispheres

Transition Pieces for Offshore Rig Crane Base

Hemispherical Dish Head

www.ferrofab.com

2400 tons

Dishing Press

2400 tons

Dishing Press

S-ar putea să vă placă și

- Webforge Access 2020 Web 3 PDFDocument32 paginiWebforge Access 2020 Web 3 PDFFaris MahmoodÎncă nu există evaluări

- Approved Itp-Dss - 28 Sep 2016Document4 paginiApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianÎncă nu există evaluări

- B2020-TDC-SR-006 Shell Rolling R0Document2 paginiB2020-TDC-SR-006 Shell Rolling R0Ramalingam PrabhakaranÎncă nu există evaluări

- Sample QAPDocument3 paginiSample QAPsniperiÎncă nu există evaluări

- Project: Fuel Storage Tank 20.000KL With Facilty Loc.Document9 paginiProject: Fuel Storage Tank 20.000KL With Facilty Loc.basukiÎncă nu există evaluări

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 paginiA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableÎncă nu există evaluări

- Design and Construction of BMW IncineratorDocument3 paginiDesign and Construction of BMW IncineratorManish PatelÎncă nu există evaluări

- Manhole QuotationDocument2 paginiManhole QuotationArun UdayabhanuÎncă nu există evaluări

- Introduction To Storage Tanks & Api650Document12 paginiIntroduction To Storage Tanks & Api650Dhakshina KÎncă nu există evaluări

- CTL Brochure-Storage Tanks & TerminalsDocument7 paginiCTL Brochure-Storage Tanks & TerminalsSameer BawaÎncă nu există evaluări

- Example of Tank Field ErectionDocument12 paginiExample of Tank Field Erectionfazeel mohammedÎncă nu există evaluări

- TDC 1150Document3 paginiTDC 1150shazanÎncă nu există evaluări

- Method Statement For Tank Erection by Hydraulic JackDocument4 paginiMethod Statement For Tank Erection by Hydraulic Jackmanish pathrabeÎncă nu există evaluări

- Hydro Test ProcedureDocument11 paginiHydro Test ProcedureRohit SharmaÎncă nu există evaluări

- Condensate Tank WELDING LOGDocument6 paginiCondensate Tank WELDING LOGhasan shahriarÎncă nu există evaluări

- JMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006Document9 paginiJMS For Erection of Stiffener Angle With Existing Curb Channel With Erection of Deflector Plate Arrangement For Tank006AshutoshÎncă nu există evaluări

- The NEW Company ProfileDocument26 paginiThe NEW Company ProfilewisandhaÎncă nu există evaluări

- Pressure Vessel Dimension Inspection PDFDocument17 paginiPressure Vessel Dimension Inspection PDFEqubal KhanÎncă nu există evaluări

- AKP Storage TanksDocument51 paginiAKP Storage Tankscris_2010Încă nu există evaluări

- Job Specification Shop & Field PaintingDocument47 paginiJob Specification Shop & Field PaintingVikash TiwariÎncă nu există evaluări

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDocument15 paginiPengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- Job Methodology For DRT Tank Procedure - 0618-R1Document15 paginiJob Methodology For DRT Tank Procedure - 0618-R1purshottam GHÎncă nu există evaluări

- Jms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0013Document11 paginiJms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0013amir hakimÎncă nu există evaluări

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 paginiBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteÎncă nu există evaluări

- BRT-PAU-T01-SP-007 Fabrication Procedure For Storage Tank (R2 AS FINAL)Document10 paginiBRT-PAU-T01-SP-007 Fabrication Procedure For Storage Tank (R2 AS FINAL)Ponaryo AnggaraÎncă nu există evaluări

- ITP Heat ExchangerDocument1 paginăITP Heat Exchangersarmad009Încă nu există evaluări

- BOQ Air Liquide Project (Diesel Tank)Document19 paginiBOQ Air Liquide Project (Diesel Tank)Remmo S Ardiansyah100% (1)

- Mcnichols GratingsCat09Document21 paginiMcnichols GratingsCat09jasonvigilÎncă nu există evaluări

- LPG Storage Tanks LPG Tank 100 M Ton Qty LPG Tank 100 M Ton QtyDocument69 paginiLPG Storage Tanks LPG Tank 100 M Ton Qty LPG Tank 100 M Ton QtyIqra AngelsÎncă nu există evaluări

- RFI Chipping & PaddingDocument80 paginiRFI Chipping & Paddingcrys suryo prayogoÎncă nu există evaluări

- DPR - Product Storage Tank 07.06.2023Document6 paginiDPR - Product Storage Tank 07.06.2023ashfaque khanÎncă nu există evaluări

- API Tank Estimate SheetDocument3 paginiAPI Tank Estimate SheetKjunwolf100% (1)

- Storage Tank ErectionDocument20 paginiStorage Tank ErectionMohamed RizwanÎncă nu există evaluări

- SECTION 16270 Transformers Rev 0Document26 paginiSECTION 16270 Transformers Rev 0syedanwerÎncă nu există evaluări

- 3 - Pressure Vessel (Fabrikasi)Document14 pagini3 - Pressure Vessel (Fabrikasi)Wahyu Lailil FaisÎncă nu există evaluări

- Storage Tank DetailDocument22 paginiStorage Tank DetailRamu NallathambiÎncă nu există evaluări

- Oil Tank 750 m3Document15 paginiOil Tank 750 m3Lutfi AndreansyahÎncă nu există evaluări

- BTE Dome Brochure Jun 10Document2 paginiBTE Dome Brochure Jun 10م.ذكى فضل ذكىÎncă nu există evaluări

- Pttep Painitng of Offshore FacilitiesDocument66 paginiPttep Painitng of Offshore FacilitiesSufianÎncă nu există evaluări

- The Basics of API 650: Ir - SadaniDocument98 paginiThe Basics of API 650: Ir - SadaniFadhilah QomariyantoÎncă nu există evaluări

- MOS of BackfillingDocument2 paginiMOS of BackfillingPoru ManÎncă nu există evaluări

- ABJ PresentationDocument51 paginiABJ PresentationMarvin CastelinoÎncă nu există evaluări

- Is 2062 - E250 Vs Is-1367 ComparisonDocument2 paginiIs 2062 - E250 Vs Is-1367 ComparisonDevang JaniÎncă nu există evaluări

- List Welder PT - InstrucomDocument4 paginiList Welder PT - InstrucomHerlan HutabaratÎncă nu există evaluări

- Erection Tank Settlement Check Schedule 103 110 165Document8 paginiErection Tank Settlement Check Schedule 103 110 165hrdsby100% (1)

- Dinesh Qa-Qc EngineerDocument6 paginiDinesh Qa-Qc EngineerDinesh SomwanshiÎncă nu există evaluări

- SikaBit W-15 Page 1 - 39Document52 paginiSikaBit W-15 Page 1 - 39Keesh RonoloÎncă nu există evaluări

- Oisd STD 118Document26 paginiOisd STD 118Tarun SahuÎncă nu există evaluări

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptDocument13 paginiJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaÎncă nu există evaluări

- List of Lifting EquipmentDocument1 paginăList of Lifting EquipmentSuwandi WijayaÎncă nu există evaluări

- Manufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsDocument4 paginiManufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsBhanu Pratap ChoudhuryÎncă nu există evaluări

- Exhibit A - Scope of Works For TE#04 & TE#09 Wellpad ConstructionDocument5 paginiExhibit A - Scope of Works For TE#04 & TE#09 Wellpad ConstructionAsep FirmansyahÎncă nu există evaluări

- FSK-E290-006-A4-0 Quality Control Plan (QC Plan)Document4 paginiFSK-E290-006-A4-0 Quality Control Plan (QC Plan)Amir Reza RashidfarokhiÎncă nu există evaluări

- CV - Project ManagerDocument2 paginiCV - Project ManagerDARA SINGHÎncă nu există evaluări

- Tank GADocument1 paginăTank GASubramanian100% (1)

- PWPS Eksperimen Super DuplexDocument33 paginiPWPS Eksperimen Super Duplexryan.sÎncă nu există evaluări

- Test Report FOR Compacted Density of Mix Aggregate Astm D-1559Document9 paginiTest Report FOR Compacted Density of Mix Aggregate Astm D-1559Jovanni RodriguezÎncă nu există evaluări

- Lot Inspection Report For LPG New CylindersDocument3 paginiLot Inspection Report For LPG New CylindersJagannath MajhiÎncă nu există evaluări

- 105-Structural Steel ErectionDocument7 pagini105-Structural Steel Erectionzaki fadlÎncă nu există evaluări

- ITL Corporate PresentationDocument21 paginiITL Corporate PresentationRashedul HasanÎncă nu există evaluări

- AngelsDocument93 paginiAngelsshiraaaz100% (1)

- Al-Zahrawi AbulcasisDocument2 paginiAl-Zahrawi Abulcasissd.ehtesham100% (2)

- Names of AllahDocument1 paginăNames of Allahsd.ehteshamÎncă nu există evaluări

- Facts About WashersDocument27 paginiFacts About Washerssd.ehteshamÎncă nu există evaluări

- Welding CalculationsDocument24 paginiWelding Calculationssd.ehtesham100% (4)

- Schedule of The ProjectDocument1 paginăSchedule of The Projectsd.ehteshamÎncă nu există evaluări

- List of Hospitals in IndiaDocument28 paginiList of Hospitals in Indiasd.ehtesham91% (34)

- Al-Zahrawi AbulcasisDocument2 paginiAl-Zahrawi Abulcasissd.ehtesham100% (2)

- MP65557-1 Manual Técnico - 4900Document371 paginiMP65557-1 Manual Técnico - 4900Tecnico IncoderÎncă nu există evaluări

- Synchronous Motor AC DrivesDocument40 paginiSynchronous Motor AC DrivesHarshal Thakur100% (1)

- Directional: 12 1/4in Sdi519 PDCDocument1 paginăDirectional: 12 1/4in Sdi519 PDCKhairatul Nada BurhanuddinÎncă nu există evaluări

- HPB Brochure 0708Document12 paginiHPB Brochure 0708musaluddinÎncă nu există evaluări

- D6588Document6 paginiD6588Pulak DebnathÎncă nu există evaluări

- Lecture Note On Photovoltaic CellDocument1 paginăLecture Note On Photovoltaic CellHaseeb NawazÎncă nu există evaluări

- Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationDocument8 paginiHydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationINOPETRO DO BRASILÎncă nu există evaluări

- Community Policing EssaysDocument7 paginiCommunity Policing Essaysgqdknjnbf100% (2)

- h2s Naoh Equilibrium CurveDocument22 paginih2s Naoh Equilibrium Curvesmartleo_waloÎncă nu există evaluări

- TA-Modulator EN LowDocument16 paginiTA-Modulator EN Lowkap4enijÎncă nu există evaluări

- Stelma & Cameron PDFDocument35 paginiStelma & Cameron PDFCatarinaÎncă nu există evaluări

- PSCADDocument10 paginiPSCADkaran976Încă nu există evaluări

- Exercicios de PhonicsDocument51 paginiExercicios de Phonicsms. TeixeiraÎncă nu există evaluări

- Surface TensisonDocument28 paginiSurface TensisonJAWAD AHMAD BURTÎncă nu există evaluări

- The 28th Santa Fe Symposium On Jewelry Manufacturing TechnologyDocument6 paginiThe 28th Santa Fe Symposium On Jewelry Manufacturing Technologyชนพัทธ์ คงพ่วงÎncă nu există evaluări

- The Effect of The Gastrocnemius On The Plantar Fascia: Javier Pascual HuertaDocument18 paginiThe Effect of The Gastrocnemius On The Plantar Fascia: Javier Pascual HuertamarcelonorisÎncă nu există evaluări

- Gma 5013Document10 paginiGma 5013janurtpatÎncă nu există evaluări

- Background of The Study: Than IdealDocument3 paginiBackground of The Study: Than IdealClint CamilonÎncă nu există evaluări

- Audio Level Meter - ProjectDocument4 paginiAudio Level Meter - ProjectMircea PanzariuÎncă nu există evaluări

- SVC200Document5 paginiSVC200fransiskus_ricky3329Încă nu există evaluări

- Alpha 20 TDS (EN) 100063006 1Document5 paginiAlpha 20 TDS (EN) 100063006 1Ariel Gallardo Galaz100% (1)

- San Beda University: Integrated Basic Education DepartmentDocument3 paginiSan Beda University: Integrated Basic Education DepartmentEmil SamaniegoÎncă nu există evaluări

- Flotech Corporate FlyerDocument6 paginiFlotech Corporate FlyerPrasetyo PNPÎncă nu există evaluări

- Term Paper On Strategic ManagementDocument8 paginiTerm Paper On Strategic Managementea7j5ys3100% (1)

- Prepared For: Assignment On Workforce DiversityDocument28 paginiPrepared For: Assignment On Workforce DiversityGolam RabbeÎncă nu există evaluări

- Laundry Center Dryer Tech Data Sheet: NO - Normally Open NTC - NTC Thermistor MCF - Machine Configuration FileDocument40 paginiLaundry Center Dryer Tech Data Sheet: NO - Normally Open NTC - NTC Thermistor MCF - Machine Configuration FilePedro IsmaelÎncă nu există evaluări

- The Cheetah Light CL-360 - A Short Review: Blog - Wedding & Portrait NewsDocument3 paginiThe Cheetah Light CL-360 - A Short Review: Blog - Wedding & Portrait NewsSupratim ChoudhuryÎncă nu există evaluări

- Missouri Department of Transportation: Standard Inspection and Testing Plan (ITP)Document32 paginiMissouri Department of Transportation: Standard Inspection and Testing Plan (ITP)mohamedamine.zemouriÎncă nu există evaluări

- MMC 16101 - Positive Displacement Pump - 01Document19 paginiMMC 16101 - Positive Displacement Pump - 01HET DEDHIAÎncă nu există evaluări