Documente Academic

Documente Profesional

Documente Cultură

Specific Gravity of Palm Kernel Shell

Încărcat de

Chidi HenryDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Specific Gravity of Palm Kernel Shell

Încărcat de

Chidi HenryDrepturi de autor:

Formate disponibile

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 6

ISSN 2229-5518

IJ SER 2013

http://www.ijser.org

Characterisation of Pulverised Palm

Kernel Shell for Sustainable Waste

Di versification

R.S. Fono-Tamo* and O.A. Koya

ABSTRACT

The paper presents a report on the physico-thermal properties and elemental composition of pulverized palm kernel shell to enhance its

use in engineering applications. Clean palm kernel shell were dried, milled and screened to obtain particles 0.23 mm mean diameter.

Experiments were conducted to evaluate the physical and thermal properties of the pulverized palm kernel shell and its differential thermal

analysis. Its elemental composition was determined by X-Ray Fluorescent analysis. Test results showed that pulverized palm kernel shell

consist mainly of non-ferrous metals. Its bulk density was 560 kg/m

3

; specific gravity, 1.26. Its thermal properties were characterized by

thermal conductivity of 0.68 W/m K; specific heat capacity, 1.98kj/kg K, and phase change at 101.4

0

C. The report established significant

potentials in the diversification of palm kernel shell from waste to fuel in improved combustion systems and as a future element in bio-

material composites.

Keywords: Bio-diversity, Combustion, DTA, palm kernel shell, Sustainability, Waste, XRF.

1. INTRODUCTION

The Millennium Development Goals (MDGs)

recognize, explicitly, the interdependence between

growth, poverty reduction and sustainable

development; resting on good governance, toward

time-bound and measurable targets, through

collective contributions of the developed and

developing countries [1]. And , whilst the worlds

main development challenges are multifaceted,

enhancement of environmental sustainability is one

of the eight identified goals. Documented potential

strategies include a significant reduction in

biodiversity loss: such as, reducing loss in green land

area, and emission of greenhouse gases.

Researchers have therefore focused on alternative

energy or, improved combustion technology, with

the view to reducing pollutant emissions [2], [3], [4],

[5], [6], [7]. Furthermore, researchers continue to seek

alternative uses of agricultural wastes, which had

constituted environmental pollution, because they

were disposed indiscriminately or burnt haphazardly

without energy recovery [3], [8], [9], [10], [11], [12],

[13]. However, the common trend in the

diversification of these wastes was to focus on one or

two bio-materials at a time, for a specific application

[12], [14], [15], [16], [17].

R.S. Fono-Tamo is currently pursuing a PhD degreeprogram in

Mechanical engineering in Obafemi Awolowo University,Ile-Ife,

Nigeria.22005. E-mail: ftr_romeo@yahoo.com

O.A. Koya is currently an AssociateProfessor in Mechanical

engineering in Obafemi Awolowo University,Ile-Ife,Nigeria,22005.

E-mail: femikoya@oauife.edu.ng

But, it is reasonable to expect increasing exploitation

of the numerous agricultural wastes by providing

comprehensive data on their engineering properties,

to facilitate their selection for use, deductively.

Palm Kernel Shell (PKS) is one of such abundant

agricultural wastes, which are not optimally used.

Palm Kernel Shell is recovered as residual waste in

the extraction of the kernel from the nut, after palm

oil had been expressed from the mesocarp of the oil

palm fruit. In 2001 alone, an estimated 3.06 million

metric tons was produced by the two highest palm oil

producing countries: Indonesia and Malaysia [18].

Until 1970, Nigeria produced about 80% of world

palm oil, with the attendant PKS wastes; but her

production had declined to meagerly 2% by 2001 [18]

[19] [20]. Overall, limited quantities of the PKS are

used, primarily for fuel.

Recent research efforts have, however, established the

suitability of ground PKS (0.2 to 0.4 mean particle

diameter) as friction material in the formulation of

non-asbestos brake lining [8], [21]. The physical

properties of the PKS were prime concern; whilst, its

biodegradability gave promise of environmental

friendliness when the product wear debris

decomposes. Also, in a renewed interest in fluidized

bed combustion, coconut milled to between 3.3 and

10.0 mm showed satisfactory thermal combustion

characteristics, improving with smaller particle size.

Based on the result of the investigation, better

performances were anticipated with finer particle

sizes [3]. The physical and thermal properties of the

shell were the figures of merit. Furthermore, it has

been shown [22] that the required suspension velocity

of the particle can be estimated from some of its

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 7

ISSN 2229-5518

IJ SER 2013

http://www.ijser.org

physical properties: its mass, density and mean

diameter.

It is, therefore, expected that more engineering

applications of PKS will be readily undertaken if it

properties are known. Such technological revolution

will provide safer and economical disposal of the

waste, and a sustainable lifestyle for the developing

countries generating such waste. The objective of this

contribution, therefore, is to present the elemental

composition, and the physical and thermal properties

of pulverized PKS, for possible engineering

application.

2. MATERIALS AND METHODS

2.1 Materials Preparation

About 150 kg of PKS was obtained from a local palm

oil processing mill in Abagboro village, in Ile-Ife. The

shells were cleansed by sorting to remove whole nuts,

kernels and other extraneous materials; and by

elutriation in soapy and clean water, in sequence, to

eliminate traces of oil and other fine particles

adhering to the shells. The PKS was then sufficiently

sun-dried before it was ground in the mill, in two

stages, using a hammer mill (Samtag Flour Mill Ltd.,

Ile-Ife) and a conventional burr mill. The ground PKS

was graded using a set of BS 410 Standard sieves

(Endecotts Ltd, London, England) with apertures of

0.212, 0.425 and 0.6 mm. the fraction passing through

the 0.425 mm sieve, but retained on the 0.212 mm

sieve was used in the experiments, to exclude fines

and granular particles [23]. The sample was kept in

desiccators, to eliminate moisture re-absorption;

while its actual moisture content at the time of

experiments was determined using the oven method,

as recommended in Standard S352 [24].

2.2 Physico-Thermal Characterisation

The bulk density of the pulverized PKS was

determined using the mass/volume relationship [25],

[26]. A cylindrical container of specified diameter and

height was used. The measurements of the diameter

and height were done using a Vernier caliper with

0.001 mm accuracy. The empty container as well as

the container filled with the material was weight on a

table top digital balance (Melter Toledo) to determine

the mass of the sample. Measurements were

replicated five times and, the average standard

deviation of the measurements was computed. The

relative density was determined using a specific

gravity jar, to divide the weight of the sample by the

weight of water occupying the volume taken up by

the sample, based on Archimedes principle.

The specific heat capacity and other thermal

attributes of the pulverized PKS were evaluated

using a computer integrated differential thermal

analyser (DTA 404 PC H Eos, NETZSCH). A

corundum crucible holder in the DTA was filled with

the required quantity of the sample, and the

equipment was operated at 0-150

0

C, for 30 minutes.

Air was used as the inert gas in the experiments. The

heating rate was in the range of 15-23 k/m. the

resulting DTA was generated

The thermal conductivity of the sample was

computed based on Fourier law of heat transfer

which is given [27] as,

T A

L

t

Q

k

(1)

Where, k is the thermal conductivity in W/m k; Q,

the quantity of heat transmitted in J, during the time

t in s; L is the thickness of the material in m, in a

direction normal to A; A is the surface of area in m

2

and T, a temperature difference in k, under steady

conditions, assuming that the heat transfer is only on

the temperature gradient.

Sample of the pulverized material was placed in a

cylindrical dish (90 mm diameter and 12.7 mm high)

on a hot plate, which had been prepared for 3

minutes. The hot plate was disconnected from the

power source and a thermocouple was used to

measure the temperature at the bottom of the pan

and also at the surface of the material contained in

the pan. Thus, the variables required in the

evaluation of Equation 1 were determined.

2.3 Determination of Elemental Composition

The elemental composition of the PKS

particles was determined based on the X-Ray

Fluorescence (XRF) analysis. Samples of the

material were formed into pellets in a

pelletizer with hydraulic press (Carver Inc).

The pellets were then sealed into the chamber

of the XRF (Amptek Inc) and allowed to run

for 1000 s at a voltage of 25 kV, and a current

of 50A. The resulting spectrum measured the

elemental composition of the material.

3. RESULTS AND DISCUSSION

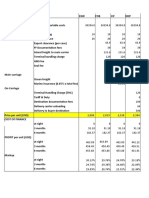

The observed moisture content of the sample at the

time of the experiments was 13.4% (w.b). A summary

of the physic-thermal properties of the pulverized

PKS is shown in Table 1.

Table 1: Summary of Physico-thermal properties of

the pulverized palm kernel shell

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 8

ISSN 2229-5518

IJ SER 2013

http://www.ijser.org

The ground shell exhibited a bulk density of 560

kg/m

3

and a specific gravity of 1.26, indicating a

porosity of 56%. This shows that the pulverized PKS

holds a good promise of high compressibility, which

is desirable in constituents of fuel briquettes [28]. The

voids may also embed other ingredients in the

formulation of bio-material composites, as being

currently investigated in the development of non-

asbestos brake pads [8].

Figure 1: Spectrum of the pulverized palm kernel shell

Figure 1 is the spectrum of the pulverized PKS

particles containing about 13 elements, mainly non

ferrous-metals. These elements are either insulators,

or weak conductors. The only element which might

have been increased due to contribution from

grinding equipment is the Fe particles, because of the

contamination from wear of the hammer and the burr

mill during grinding; albeit, all the elements are

degradable and non-carcinogenic. The proportion of

elements is shown in Table 2.

Table 2: Major elemental composition of the

pulverized palm kernel shell

40 60 80 100 120 140

Temperature /C

-2.0

-1.5

-1.0

-0.5

0.0

0.5

DTA /(mW/mg)

Main 2008-11-1209:59 User: Administrator

Peak: 101.4 C, 0.6995 mW/mg

Peak: 86.0 C, -1.037 mW/mg

Peak: 88.7 C, -0.9058 mW/mg

Area: 64.3 J /g

Crystallinity: 1607.47 %

Delta Cp: 1.983 J /(g*K)

[1]

exo

Figure 2: Differential thermal analysis of the pulverized palm

kernel shell

From the DTA curve in Figure 2, the specific heat

capacity is 1.98 kJ/kg k and it is higher than the

values for asbestos, coal, wood and coconut shell

[3],[8],[29]. This parameter is important in the

consideration of the material as primary fuel in

fluidized bed combustion, swirl burner, or other

improved combustion technology [3],[6],[30]. It is also

required in determining its degree of hotness when

employed as an insulator in heat conduction systems;

but, since it experiences a phase change at 101.4C, it

must be fortified against thermal degradation in such

applications. The observed thermal conductivity is

0.68 W/m K and this complements its requirement for

use as insulators, such as glass, wool, asbestos fibres

and wood; but lower for plaster, glass and asphalt

[29]. Apparently, the Fe contamination might have

contributed to increase the observed value.

4. CONCLUSION

The physical and thermal properties and elemental

composition of pulverized palm kernel shell were

evaluated to enhance its diversification from waste,

or environmental pollutant to a viable engineering

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 9

ISSN 2229-5518

IJ SER 2013

http://www.ijser.org

material. In view of its constituent bio-degradable

elements, bulk density of 560 kg/m

3

, porosity of 56%,

specific heat capacity of 1.983 kJ/kg K, and thermal

conductivity of 0.68 W/m K, PKS showed a strong

potential for use both as particulate and

environmentally friendly bio-fuel and as an

ingredient in bio-material composites. Pulverized

PKS, thus, provides stimulation for sustainable

lifestyle change in waste diversification.

AKNOWLEDGEMENT

The authors wish to appreciate the Centre for Energy

Research and Development, Obafemi Awolowo

University, Ile-Ife, Nigeria, for making the testing

equipments available for the realization of this work.

REFERENCES

[1] United Nations Development Programme,

Millennium Development Goals.

http://www.undp.org/mdg/.2002.

[2] D.L. Klass, Biomass of Renewable Energy, Fuels and

Chemicals, Academic Press, London, 1998.

[3] S.A. Adio & A.A. Asere, A Study of thermal and

emission characteristics of coconut shell in a fluidized

bed combustor. Proceedings of 22

nd

Annual General

Meeting and International Conference of the Nigerian

Institution of Mechanical Engineers, Osun, pp. 215-

219, October, 21-23, 2009.

[4] S. Ravelli, A. Perdichizzi & G. Barigozzi,

Description, application and numerical modeling of

bubbling fluidized bed combustion in waste-to-

energy plants. Progress in Energy and Combustion

Science,34, 2007, 224-253.

[5] W. A. W. Ghani, R.A. Moghadam, M. A.

Mohdsalleh & A.A. Alias, Air gasification of

agricultural wastes in a fluidized bed gasifier:

hydrogen production performance. Energy 2, 2009,

258-268.

[6] K.N. Fujimura, V.N. Sharifi & K. Naruse,

Fluidised-bed gasification and slagging combustion

system. Paper presented at the IT3 Conference,

Philadelphia, USA, May, 14-18, 2001.

[7] J.T. Oladeji, Comparative fuel characterization of

paralyzed sawdust and rice husk. Proceedings of 22

nd

Annual General Meeting and International

Conference of the Nigerian Institution of Mechanical

Engineers, Osun, pp. 229-231, October, 21-23, 2009.

[ 8] T.R. Fono, A study on the use of palm kernel shell

as friction material in automotive brake pads and

lining, Unpiblished M.Sc. Thesis, department of

Mechanical Engineering, Obafemi Awolowo

University, Ile-Ife, Nigeria.

[9] S.M. Sapuan, M. Harimi & M.A Maleque,

mechanical properties of epoxy/coconut shell filler

particle composition. Arabian journal for Science and

Engineering, 28, 2003, 2B

[10] O.A. Kuti, Impact of charred palm kernel shell on

the calorific value of composite sawdust briquettes.

Journal of Engineering and Applied Science, 2(1),

2007, 62-65.

[11] U.J. Alegaram, M.Z. Jumaat & H. Mahmud,

Ductility behavior of reinforced palm kernel shell

concrete beams. European Journal of Scientific

Research, 23, 2008, 406-420.

[12] P. N. Ndoke, Performance of Palm Kernel Shells

as a Partial replacement for Coarse Aggregate in

Asphalt Concrete. Leonardo Electronic Journal of

Practices and Technologies 5(9), 2006, 145-152

[13] M. M. Sharon, preparation and charaterisation of

palm kernel shell activated carbons M.Sc. Thesis,

University Putra Malaysia,

http://psasir.upm.edu.my/230/1/549516_FK_2004_66

pdf, 2003.

[14] Y. A. Salako, O. K. Owolarafe & A. N. Anozie,

Characterization of sun-dried palm fruit waste

biomass materials. Proceedings of 1

st

National

Conference of the Faculty of Technology, Obafemi

Awolowo University, Ile-Ife, pp. 114-118, November,

17-19, 2009.

[15] S. Mohanty & Y.P. Chugh, Development of fly

ash-based automotive brake lining. Tribology

International, 40, 2007, 1217-1224

[16] R.N. Singh, U. Jena, J.B. Patel & A.M. Sharma,

Feasibility study of cashew nut shells as an open core

gasifier feedstock. Renewable Energy, 31, 2006, 481-487.

[17] R. Bhandari & H. Gaese, Evaluation of box type

dryers in South Sumatra, Indonesia. CIGR E-journal,

manuscript FP 08 011 Vol.X, July, 2008.

[18] J. Crutchfield, United States Department of

Agriculture Commodity Intelligence Report, 7-8, 2007

[19] C.O. Akubuo & B.E. Eje, Palm kernel and shell

separator. Biosystems Engineering, 81(2), 2002, 193-

199.

[20] FAO. The Oil Palm Food and Agricultural

Organisation, Rome, Italy, 1970.

[21] A.O.A. Ibhadode & I.M. Dagwa, Development of

asbestos-free friction lining material from palm

kernel shell. Journal of the Brazilian Society of

Mechanical Science and Engineering, XXX(2), 2008, 166-

173.

[22] B.Y. Gorial & J.B. OCallaghan, Aerodynamic

properties of grain/straw materials. Journal of

Agricultural Engineering Research, 46, 1990, 275-290.

[23] O.N. Simeon, Fluidized Bed Combustion. Marcel

Dekker, Inc., New York, 2004.

[24] American Society of Agricultural Engineers,

Standard S352, In: Agricultural Engineers Yearbook.

American Society of Agricultural Engineers, p. 345,

1982.

[25] O.O. Fasina, Physical properties of peanuts hull

pellets. Bioresource Technology 99, 2007, 1259-1266.

[26] R.K. Jain & S. Bal, Properties of pearl millet. Journal

of Agricultural Engineering Research, 66:85-91, 1997.

[27] B.V. Karlekar & R.M. desmond, Engineering

Heat Transfer West Publishing Company, USA, 1982.

[28] M.O. Faborode & J.R. OCallaghan, Theoretical

analysis of the compression of fibrous agricultural

International Journal of Scientific & Engineering Research, Volume 4, Issue 4, April-2013 10

ISSN 2229-5518

IJ SER 2013

http://www.ijser.org

materials. Journal of Agricultural Engineering Research,

35, 1986, 175-191

[29] C.P. Kothandaraman & S. Subramanyan, Heat

and Mass Transfer Data Book, John Wiley and Sons,

New York, 1977.

[30] K.N. Finney, V.N. Sharifi & J. Swithenbank,

Combustion of spent mushroom compost and coal

tailing pellets in a fluidized bed. Renewable Energy, 34,

2009, 860-868.

S-ar putea să vă placă și

- Anec 81Document5 paginiAnec 81Adan Farias de PinaÎncă nu există evaluări

- Terms of Business: For Market Maker Types of Accounts (Standard, Micro, Pamm Standard)Document8 paginiTerms of Business: For Market Maker Types of Accounts (Standard, Micro, Pamm Standard)Badril AminÎncă nu există evaluări

- Engen Transformer Oil PDFDocument5 paginiEngen Transformer Oil PDFUrsula JohnsonÎncă nu există evaluări

- Malaysian Halal Export Market Case StudyDocument9 paginiMalaysian Halal Export Market Case Studyanna21180110Încă nu există evaluări

- "Soybean Volatile Week Ends in Red: Analyst SpeaksDocument10 pagini"Soybean Volatile Week Ends in Red: Analyst Speaksapi-234732356Încă nu există evaluări

- Volvo Color CodesDocument2 paginiVolvo Color Codesbbryce8960Încă nu există evaluări

- ANEC 41 - SoybeansDocument5 paginiANEC 41 - Soybeansstevenverbeek100% (1)

- Calgaz Company BrochureDocument10 paginiCalgaz Company BrochureWasintonHaratuaMarpaungÎncă nu există evaluări

- EELabManual FinalDocument98 paginiEELabManual FinalCHLORINE SHAKEÎncă nu există evaluări

- Qualifying Criteria For Signing MSPA With GAIL For LNG Supply July 2010Document2 paginiQualifying Criteria For Signing MSPA With GAIL For LNG Supply July 2010shashwatrishuÎncă nu există evaluări

- Mazut-100 Specification (Russia Origin)Document1 paginăMazut-100 Specification (Russia Origin)Tariq B ShamsiÎncă nu există evaluări

- Frequently Asked Questions and AnswersDocument4 paginiFrequently Asked Questions and AnswersDr-moustafa Elafandy100% (1)

- EIF The IMO Number Explained PDFDocument8 paginiEIF The IMO Number Explained PDFhelga perangin anginÎncă nu există evaluări

- Strategic ManagementDocument37 paginiStrategic ManagementAbbasÎncă nu există evaluări

- Kotak Nifty ETF PDFDocument4 paginiKotak Nifty ETF PDFkayÎncă nu există evaluări

- Customs DocumentationDocument2 paginiCustoms DocumentationDHL Express UKÎncă nu există evaluări

- Seller's Mandate Ncnda-Imfpa For Euro-4Document6 paginiSeller's Mandate Ncnda-Imfpa For Euro-4john simonÎncă nu există evaluări

- ADC MethodDocument16 paginiADC MethodPhilip K MathewÎncă nu există evaluări

- Qq88 Gosyen Haromain IntergrationDocument9 paginiQq88 Gosyen Haromain IntergrationFebri GunawanÎncă nu există evaluări

- WhatsApp Image 2023-05-18 at 8.57.39 PM (3 Files Merged)Document3 paginiWhatsApp Image 2023-05-18 at 8.57.39 PM (3 Files Merged)Riyad HasanÎncă nu există evaluări

- Irrevocable Corporate Purchase Order (Icpo/Loi) For: Contract 12 MonthsDocument4 paginiIrrevocable Corporate Purchase Order (Icpo/Loi) For: Contract 12 MonthsjungÎncă nu există evaluări

- Example of Full Corporate Order - For - SellersDocument3 paginiExample of Full Corporate Order - For - SellersazharÎncă nu există evaluări

- Acacia GumDocument2 paginiAcacia GummohsinÎncă nu există evaluări

- Quantitative Discernments of The Different Calcium Compounds in The Tarfaya Oil Shale (Morocco)Document11 paginiQuantitative Discernments of The Different Calcium Compounds in The Tarfaya Oil Shale (Morocco)IJAR JOURNALÎncă nu există evaluări

- Hud PDFDocument5 paginiHud PDFPhan van ThanhÎncă nu există evaluări

- Export Price CalculationDocument5 paginiExport Price Calculationphuc hauÎncă nu există evaluări

- Lab-X3500 Brochure PDFDocument2 paginiLab-X3500 Brochure PDFdejavu77100% (1)

- STS1500014-001 Rev 4 HAZID Report For OceanGuard BWMS CompleteDocument71 paginiSTS1500014-001 Rev 4 HAZID Report For OceanGuard BWMS Completele huyÎncă nu există evaluări

- FX Forward ContractsDocument2 paginiFX Forward ContractsQuant_GeekÎncă nu există evaluări

- FL - CB - Organic Chloride Test Methods - USA (1) 11.1.20Document1 paginăFL - CB - Organic Chloride Test Methods - USA (1) 11.1.20Marvin Mendez GonzalesÎncă nu există evaluări

- Pennsylvania Steel Color Codes Cold Finished Bars: Red/white Red/white Red/white Red/whiteDocument2 paginiPennsylvania Steel Color Codes Cold Finished Bars: Red/white Red/white Red/white Red/whiteHammondMachineÎncă nu există evaluări

- Ship Classification, Ship Design and On Board Apparatus 2015Document96 paginiShip Classification, Ship Design and On Board Apparatus 2015Maurizio BernasconiÎncă nu există evaluări

- Molecular Weight DeterminationsDocument14 paginiMolecular Weight DeterminationsEdwin Kamalha0% (1)

- ChemistryDocument17 paginiChemistryYash RajputÎncă nu există evaluări

- Notice On Lodgement of Import - Export DeclarationDocument2 paginiNotice On Lodgement of Import - Export DeclarationMr YiÎncă nu există evaluări

- Pricing of Port ServicesDocument130 paginiPricing of Port ServicesvenkateswarantÎncă nu există evaluări

- Supply Chain ScorecardDocument4 paginiSupply Chain ScorecardbumbiazarkaÎncă nu există evaluări

- Welder CTS2.0 NSQF-3Document40 paginiWelder CTS2.0 NSQF-3Prasanta DasÎncă nu există evaluări

- DKSH Employment Application Form 2022Document6 paginiDKSH Employment Application Form 2022syariel haziqÎncă nu există evaluări

- SGS EN455 Test Report SDocument4 paginiSGS EN455 Test Report SAhmad Yani S NoorÎncă nu există evaluări

- HCIP-Transmission V2.0 Mock ExamDocument4 paginiHCIP-Transmission V2.0 Mock ExamGhallab AlsadehÎncă nu există evaluări

- Labuan IBFC Business Guide2Document102 paginiLabuan IBFC Business Guide2iori42Încă nu există evaluări

- Bureau Veritas 2011 HighlightsDocument17 paginiBureau Veritas 2011 HighlightsvictoriaroomÎncă nu există evaluări

- Transfer PricingDocument15 paginiTransfer PricingJulie Marie Anne LUBIÎncă nu există evaluări

- NEXT TFD Elder (1) 1Document13 paginiNEXT TFD Elder (1) 1Ruffabbey06Încă nu există evaluări

- UntitledDocument239 paginiUntitledAndreiconstantin ChiritaÎncă nu există evaluări

- Characterization of Coconut Shell Ash For PotentiaDocument9 paginiCharacterization of Coconut Shell Ash For PotentiaLuisÎncă nu există evaluări

- Hussain2019 PDFDocument8 paginiHussain2019 PDFĐức HòaÎncă nu există evaluări

- Journal of Analytical and Applied Pyrolysis: Korkut Ac Ikalın, Fatma KaracaDocument9 paginiJournal of Analytical and Applied Pyrolysis: Korkut Ac Ikalın, Fatma KaracaAbdisalamÎncă nu există evaluări

- MayurDocument15 paginiMayurMayur PatelÎncă nu există evaluări

- Potential of The Residual Fibers of Pisum Sativum (PS), For Use in A Development of A Thermal Insulator MaterialDocument9 paginiPotential of The Residual Fibers of Pisum Sativum (PS), For Use in A Development of A Thermal Insulator MaterialJuan Pablo Cárdenas RamírezÎncă nu există evaluări

- Characterization of Bismuth Telluride Aerogels For Thermoelectric ApplicationsDocument6 paginiCharacterization of Bismuth Telluride Aerogels For Thermoelectric Applicationssumit bhatnagarÎncă nu există evaluări

- Porosity Development in Activated Carbons Obtained FromDocument13 paginiPorosity Development in Activated Carbons Obtained FromMinou MakhloufÎncă nu există evaluări

- Shells 3Document8 paginiShells 3Donna HayesÎncă nu există evaluări

- Contenido Ceniza AC Art ASTM D2866 - 94Document8 paginiContenido Ceniza AC Art ASTM D2866 - 94gaby1Încă nu există evaluări

- 387 OushabiDocument8 pagini387 Oushabiziadslimane1995Încă nu există evaluări

- Hazelnut Shells PDFDocument13 paginiHazelnut Shells PDFHalime Erol YücelÎncă nu există evaluări

- 1 s2.0 S1876610215011017 MainDocument6 pagini1 s2.0 S1876610215011017 MainVerdy A. KoehuanÎncă nu există evaluări

- 10 ReviewComparisonofagriculturalby-productsactivatedcarbon PDFDocument11 pagini10 ReviewComparisonofagriculturalby-productsactivatedcarbon PDFRohan ChauguleÎncă nu există evaluări

- Oil PalmDocument16 paginiOil Palmedison avvaiÎncă nu există evaluări

- Flow Measurement Methods in Open ChannelsDocument227 paginiFlow Measurement Methods in Open ChannelsWILBER CUTIMBO CHOQUE100% (1)

- Field TripDocument16 paginiField TripChidi HenryÎncă nu există evaluări

- Study of Noise Pollution in Kolhapur City, Maharashtra, IndiaDocument5 paginiStudy of Noise Pollution in Kolhapur City, Maharashtra, Indiajubinmb4181Încă nu există evaluări

- Electrolux Refrigeration Using Solar Heat Solar RefrigerationDocument82 paginiElectrolux Refrigeration Using Solar Heat Solar RefrigerationChidi HenryÎncă nu există evaluări

- Scientific Paper WritingDocument4 paginiScientific Paper WritingPartha SenguptaÎncă nu există evaluări

- Water ResourcesDocument87 paginiWater Resourcessofianina05Încă nu există evaluări

- Workin Dwg2aDocument37 paginiWorkin Dwg2aChidi HenryÎncă nu există evaluări

- Article 05Document5 paginiArticle 05Chidi HenryÎncă nu există evaluări

- G. The Highway Cross Sectional ElementsDocument10 paginiG. The Highway Cross Sectional ElementsChidi HenryÎncă nu există evaluări

- Ufa Town Planning DocumentsDocument1 paginăUfa Town Planning DocumentsChidi HenryÎncă nu există evaluări

- CSS 443 Traffic Road Safety EquipmentDocument156 paginiCSS 443 Traffic Road Safety EquipmentChidi Henry100% (2)

- Workin Dwg2aDocument37 paginiWorkin Dwg2aChidi HenryÎncă nu există evaluări

- CEG 507 Assignment 3 2014Document1 paginăCEG 507 Assignment 3 2014Chidi HenryÎncă nu există evaluări

- Calc. Cover SheetDocument3 paginiCalc. Cover SheetChidi HenryÎncă nu există evaluări

- Uses of Fire Dynamics Simulator V4Document28 paginiUses of Fire Dynamics Simulator V4Chidi HenryÎncă nu există evaluări

- 1C1 Storey: 1Document18 pagini1C1 Storey: 1Chidi HenryÎncă nu există evaluări

- Performance Based BLDG Codes - What Will Happen To BLDG Safety (Babrauskas)Document7 paginiPerformance Based BLDG Codes - What Will Happen To BLDG Safety (Babrauskas)fire-1Încă nu există evaluări

- NIJ Compartment Fires Vol 2 Modeling FinalDocument214 paginiNIJ Compartment Fires Vol 2 Modeling FinalChidi HenryÎncă nu există evaluări

- The Fire-Induced Ceiling-Jet RevisitedDocument22 paginiThe Fire-Induced Ceiling-Jet RevisitedChidi HenryÎncă nu există evaluări

- BeamsDocument42 paginiBeamsChidi HenryÎncă nu există evaluări

- NIST Sponsored Research in Sprinkler Performance ModelingDocument9 paginiNIST Sponsored Research in Sprinkler Performance ModelingChidi HenryÎncă nu există evaluări

- Virtual Fires Via ComputersDocument9 paginiVirtual Fires Via ComputersChidi HenryÎncă nu există evaluări

- Texas Forensic Science Commission September 7 2010.00 Revision 1aDocument2 paginiTexas Forensic Science Commission September 7 2010.00 Revision 1aChidi HenryÎncă nu există evaluări

- FS11 Proc Chiti PDFDocument12 paginiFS11 Proc Chiti PDFJarrod CurrinÎncă nu există evaluări

- FM Global - Fire Suppression Physics For Sprinkler ProtectionDocument14 paginiFM Global - Fire Suppression Physics For Sprinkler ProtectionChidi Henry100% (1)

- Modelling Water Spray - From Laboratory Scale To Fire Safety ApplicationDocument16 paginiModelling Water Spray - From Laboratory Scale To Fire Safety ApplicationChidi HenryÎncă nu există evaluări

- FS11 Proc Chiti PDFDocument12 paginiFS11 Proc Chiti PDFJarrod CurrinÎncă nu există evaluări

- Water Mist in OfficesDocument4 paginiWater Mist in OfficesChidi HenryÎncă nu există evaluări

- Knowing The Fire Sprinkler SprayDocument10 paginiKnowing The Fire Sprinkler SprayChidi HenryÎncă nu există evaluări

- Pool Fire Extinction by Remotely Controlled Application of Liquid NitrogenDocument12 paginiPool Fire Extinction by Remotely Controlled Application of Liquid NitrogenChidi HenryÎncă nu există evaluări

- Ready Reckoner - Solid Waste Management For ULBS in TNDocument343 paginiReady Reckoner - Solid Waste Management For ULBS in TNSherine David SAÎncă nu există evaluări

- SEC EO NO 3 2023 SolidwasteDocument3 paginiSEC EO NO 3 2023 SolidwasteJohn Benedict Aquino100% (1)

- Olea National High School Youth For Environmental in School Organization (Yes - O) Accomplishment ReportDocument6 paginiOlea National High School Youth For Environmental in School Organization (Yes - O) Accomplishment ReportLea Diaz100% (2)

- Nickel Revolution Has Indonesia Chasing Battery Riches Tinged With Risk - BloombergDocument10 paginiNickel Revolution Has Indonesia Chasing Battery Riches Tinged With Risk - Bloombergandrew hendersonÎncă nu există evaluări

- Summer Training Report: Shreya Bharti (1403213098)Document69 paginiSummer Training Report: Shreya Bharti (1403213098)Tarun SethiaÎncă nu există evaluări

- Ramboll: ROM Rash To ReasureDocument36 paginiRamboll: ROM Rash To ReasureAvijitÎncă nu există evaluări

- Waste Management SOPDocument30 paginiWaste Management SOPEtta JeneeÎncă nu există evaluări

- Minor Projecty Green MarektingDocument19 paginiMinor Projecty Green MarektingAshutosh MishraÎncă nu există evaluări

- CAG ReportDocument36 paginiCAG Reportnakul.heble6385Încă nu există evaluări

- Winsomsform 2022 07 15Document18 paginiWinsomsform 2022 07 15Lovely LimÎncă nu există evaluări

- Busted Flourescent Bulb LabelDocument16 paginiBusted Flourescent Bulb LabelBong PerezÎncă nu există evaluări

- Review of Related LiteratureDocument6 paginiReview of Related LiteratureAdrian IntrinaÎncă nu există evaluări

- Environment and Sustainable DevelopmentDocument31 paginiEnvironment and Sustainable Developmentshobhit mishraÎncă nu există evaluări

- Composting & Our Products: EN 13432 CertifiedDocument2 paginiComposting & Our Products: EN 13432 CertifiedJohn Andrae MangloÎncă nu există evaluări

- Case History On Use of Recycled Aggregates On A6 Alvaston Bypass (Scott Wilson Et Al, 2004)Document10 paginiCase History On Use of Recycled Aggregates On A6 Alvaston Bypass (Scott Wilson Et Al, 2004)sandycastleÎncă nu există evaluări

- Blowroom CalculationDocument14 paginiBlowroom CalculationIrfan Ali100% (1)

- Achalpur City Waste Management PlanDocument39 paginiAchalpur City Waste Management PlanVishal SinghÎncă nu există evaluări

- Minidart v3 Manual (090506)Document79 paginiMinidart v3 Manual (090506)Zoffi PedersenÎncă nu există evaluări

- Safety Data Sheets Interior Sealer A500Document10 paginiSafety Data Sheets Interior Sealer A500ariash mohd100% (1)

- Control of Financial Fraud RisksDocument5 paginiControl of Financial Fraud Risksjohn gabriel elordeÎncă nu există evaluări

- Q1 Health Ed. 9 (Comm Health)Document36 paginiQ1 Health Ed. 9 (Comm Health)sophia luÎncă nu există evaluări

- Federacija FBiH Godišnjak 2011Document555 paginiFederacija FBiH Godišnjak 2011SaffijaÎncă nu există evaluări

- Green Tech. KeTTHADocument44 paginiGreen Tech. KeTTHAShazwanShahÎncă nu există evaluări

- Maintenance Catalog Reach Stacker Kalmar DRU 450Document266 paginiMaintenance Catalog Reach Stacker Kalmar DRU 450Ridho Ahmad100% (2)

- The Issue of Plastic Bags: Shawn Huan English (C Period) Miss JensenDocument7 paginiThe Issue of Plastic Bags: Shawn Huan English (C Period) Miss JensenswiftiesÎncă nu există evaluări

- BS 400Document377 paginiBS 400Anonymous GhWU5YK8100% (2)

- 5 CSDocument82 pagini5 CSMajor LoonyÎncă nu există evaluări

- Jay Bryson H. Ruiz: FactorsDocument9 paginiJay Bryson H. Ruiz: FactorsJay Bryson RuizÎncă nu există evaluări

- Evolution of Pakistan National Conservation StrategyDocument103 paginiEvolution of Pakistan National Conservation StrategyAkhtar RashidÎncă nu există evaluări

- Waste Manifest Attachment III: P A R TDocument1 paginăWaste Manifest Attachment III: P A R TSanthoshÎncă nu există evaluări