Documente Academic

Documente Profesional

Documente Cultură

Condenser

Încărcat de

Amr AliDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Condenser

Încărcat de

Amr AliDrepturi de autor:

Formate disponibile

Steam turbine condenser

A condenser is a device where the exhaust steam from turbine is condensed; it operates at a

pressure lower than the atmospheric pressure.

There are two main objectives of the steam condensers

1. To reduce the turbine exhaust pressure so as to increase

the specific work output of the turbine so if the

condensate goes to lower temperatures as low as

(say

) that means pressure of the condenser will be

the saturation pressure corresponding to that temperature

, and its known that the enthalpy drop between the

turbine and condenser is the measure of the work output

from the turbine, so lower pressure in the condenser

means larger enthalpy drop .

By lowering the condenser operating pressure the following will occur :

Increase the turbine output

Increase plant efficiency and reduce the steam flow (for a given plant output)

2. To recover high quality feedwater in the form of condensate and feed it right back to the

boiler without any further treatment .

In al-mukha power plant they have 4 condensers of surface type in which sea water at 30

gets

heated by the 40 MW turbines to 35

.

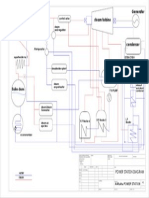

Surface condensers which are shell-and-tube heat exchangers where the steam and cooling water

(sea water) doesnt come in direct contact , and the heat released during the condensation process

is first transferred to the walls of the tubes and to the cooling water.

Air removal:-

Air leaks into the condenser shell through flanges, some air also comes along with steam, which

has leaked into the exhaust end of the turbine along the shaft, this air affects the condenser

performance badly because of the following reasons

It reduces the heat transfer considerably .

It reduces the condenser vacuum and increases the turbine exhaust pressure thus

reducing turbine output.

The amount of air infiltrating into the shell maybe estimated by the term of partial pressures

P

Sh

= P

Air

+ P

St

Assuming that air behaves as an ideal gas at such a low pressure we have :-

P

air

*

s

*

2

=

a

*R

a

*(t

s

+ 273 )

Where :

2

= specific volume of exhaust steam.

s

= rate of air leakage.

R

a

= gas constant of air = 0.287 kj/kg .

So the air leakage can be estimated from those equations thus this amount of air has to be

continuously removed from the condenser.

A steam air ejector, SJAE , is mostly used to remove air from condenser shell from the coldest

part of the condenser to reduce the loss of vapor accompanying it and hence, to reduce the air

ejector load , steam from the boiler is taken as a motive steam for the ejector, the vacuum created

at the nozzle throat due to high velocity of steam draws air from the shell along with some steam

and the combined flow gets compressed while flowing through the diffuser part , the escaping

vapor is condensed in the inter cooler and the remaining air is again drawn by the vacuum

created at the nozzle throat of the second stage. In the after condenser the vapor is condensed and

air now become at a pressure higher than the atmospheric pressure is vented out .

Where :

P

st

=

saturation pressure at the condenser temp

P

sir

=

partial pressure of air

P

SH

=total pressure of the condenser

S-ar putea să vă placă și

- CamomileDocument1 paginăCamomileAmr AliÎncă nu există evaluări

- Start Your Day Right with a Cup of Breakfast TeaDocument1 paginăStart Your Day Right with a Cup of Breakfast TeaAmr AliÎncă nu există evaluări

- CeylonDocument1 paginăCeylonAmr AliÎncă nu există evaluări

- Draught System:: MMW Air Air MMWDocument1 paginăDraught System:: MMW Air Air MMWAmr AliÎncă nu există evaluări

- T..,. So, L/N, " - 119 And" - : II 8. 7) - Iilmwise NusseltDocument1 paginăT..,. So, L/N, " - 119 And" - : II 8. 7) - Iilmwise NusseltAmr AliÎncă nu există evaluări

- VersionDocument1 paginăVersionAmr AliÎncă nu există evaluări

- EP2351910A2Document11 paginiEP2351910A2Amr AliÎncă nu există evaluări

- Air Compr - Spare PartsDocument5 paginiAir Compr - Spare PartsAmr AliÎncă nu există evaluări

- New Microsoft Word DocumentDocument7 paginiNew Microsoft Word DocumentAmr AliÎncă nu există evaluări

- Boilers Work ListDocument1 paginăBoilers Work ListAmr AliÎncă nu există evaluări

- 2كلمة الشكر والملخص والمحتوىDocument3 pagini2كلمة الشكر والملخص والمحتوىAmr AliÎncă nu există evaluări

- NM Dan NE (Yang Bener)Document61 paginiNM Dan NE (Yang Bener)Andri RulandiÎncă nu există evaluări

- New Microsoft Office Word DocumentDocument1 paginăNew Microsoft Office Word DocumentAmr AliÎncă nu există evaluări

- Diagram Final 2Document1 paginăDiagram Final 2Amr AliÎncă nu există evaluări

- R 2Document2 paginiR 2Amr AliÎncă nu există evaluări

- r12 P-H DiagramDocument1 paginăr12 P-H DiagramAmr AliÎncă nu există evaluări

- Seminar FormatDocument4 paginiSeminar FormatAmr AliÎncă nu există evaluări

- 10 1 1 69 1112Document6 pagini10 1 1 69 1112Maruthi KalpaguriÎncă nu există evaluări

- HendersonDocument3 paginiHendersonAmr AliÎncă nu există evaluări

- Boiler CalculationsDocument16 paginiBoiler CalculationsBilly Moerdani100% (1)

- Fundamentals of Engineering Thermodynamics: by Michael J. Moran, Howard N. Shapiro, Daisie D. Boettner, Margaret BaileyDocument1 paginăFundamentals of Engineering Thermodynamics: by Michael J. Moran, Howard N. Shapiro, Daisie D. Boettner, Margaret BaileyAmr AliÎncă nu există evaluări

- 2 - Advanced Operator InterfacesDocument78 pagini2 - Advanced Operator InterfacesAmr AliÎncă nu există evaluări

- Carrier psychrometric chart analysisDocument1 paginăCarrier psychrometric chart analysisonspsnons100% (3)

- 6 ExaminationDocument9 pagini6 ExaminationAmr AliÎncă nu există evaluări

- NematodesDocument5 paginiNematodesAmr AliÎncă nu există evaluări

- Mechanical InventionsDocument4 paginiMechanical InventionsAmr AliÎncă nu există evaluări

- 10.04.06 Phichith CNS ToxoplasomosisDocument29 pagini10.04.06 Phichith CNS ToxoplasomosisAmr AliÎncă nu există evaluări

- 2 Reversed Carnot CycleDocument2 pagini2 Reversed Carnot CycleAlok GargÎncă nu există evaluări

- InstrumentationDocument34 paginiInstrumentationAmr AliÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Paper 1 Introduction of 50 HZ SC 660800MW Steam TurbineDocument23 paginiPaper 1 Introduction of 50 HZ SC 660800MW Steam TurbineMuhammad Fahmi MahmudÎncă nu există evaluări

- Analysis of Stress and Strain On High Pressure Steam Turbine Steam Turbine Shaft Due To Mechanical Loading-ReviewDocument8 paginiAnalysis of Stress and Strain On High Pressure Steam Turbine Steam Turbine Shaft Due To Mechanical Loading-Reviewsemarasik_651536604Încă nu există evaluări

- Exergoeconomic Optimization of A Novel Cascade Kalina Cycle Using Geothermal Heat Source and LNG Cold Energy Recovery PDFDocument64 paginiExergoeconomic Optimization of A Novel Cascade Kalina Cycle Using Geothermal Heat Source and LNG Cold Energy Recovery PDFM Rama YudhantoÎncă nu există evaluări

- Turbine SopDocument8 paginiTurbine SopDominic Daniel100% (1)

- Nuclear Training Centre RAPP RAWATBHATADocument70 paginiNuclear Training Centre RAPP RAWATBHATADevendra Sharma100% (2)

- TurbineDocument66 paginiTurbinedipankar_mnm5920100% (1)

- 0040 10 - R1Document39 pagini0040 10 - R1tinhÎncă nu există evaluări

- Power Plant Types and ComponentsDocument32 paginiPower Plant Types and ComponentsmarlitoÎncă nu există evaluări

- Applied Thermal Engineering: Unit - 2: Steam Turbines and CondensersDocument16 paginiApplied Thermal Engineering: Unit - 2: Steam Turbines and CondensersShripad DhokeÎncă nu există evaluări

- Exergy Analysis in ThermodynamicsDocument17 paginiExergy Analysis in ThermodynamicsGerry Lou QuilesÎncă nu există evaluări

- Taming Condenser Tube Leaks - David G. DanielsDocument15 paginiTaming Condenser Tube Leaks - David G. DanielsMarioÎncă nu există evaluări

- Thermo CycleDocument59 paginiThermo CycleDries CaersÎncă nu există evaluări

- Engineering ThermodynamicsDocument20 paginiEngineering Thermodynamicssurya prakash0% (1)

- Gas & Steam Turbine Materials - 1Document18 paginiGas & Steam Turbine Materials - 1Raden Mas100% (1)

- Chapter 4-Power Turbines 5Document20 paginiChapter 4-Power Turbines 5Abdullatif AlOmair100% (1)

- DS HZM AUS SITEC Xtend CGC-T Steam Turbine Control eDocument8 paginiDS HZM AUS SITEC Xtend CGC-T Steam Turbine Control ekeneeyoÎncă nu există evaluări

- Internal II Question Paper Etd Set IIDocument2 paginiInternal II Question Paper Etd Set IItagoreboopathyÎncă nu există evaluări

- PPTDocument20 paginiPPTSriram ramsÎncă nu există evaluări

- PANIPAT THERMAL POWER STATION BASICSDocument26 paginiPANIPAT THERMAL POWER STATION BASICSratrideviinhostelÎncă nu există evaluări

- Turbine Blades: Impulse Blading System DesignDocument10 paginiTurbine Blades: Impulse Blading System DesignPappuRamaSubramaniamÎncă nu există evaluări

- Topic 6 - Regenerative Power Cycle and PlantDocument23 paginiTopic 6 - Regenerative Power Cycle and PlantMike MikeÎncă nu există evaluări

- Steam Turbines and Gearing GJ Roy PDFDocument48 paginiSteam Turbines and Gearing GJ Roy PDFHarpreet Singh50% (2)

- Machine Vibration Balancing and Condition MonitoringDocument70 paginiMachine Vibration Balancing and Condition MonitoringcarlosÎncă nu există evaluări

- Dead Ship Start-Up and Black Out Re-Start Procedures 4059-KA-00289231 - D - 02 Docx IMAM REVDocument16 paginiDead Ship Start-Up and Black Out Re-Start Procedures 4059-KA-00289231 - D - 02 Docx IMAM REVarviel_lea3150% (2)

- Final PPT On Gas TurbinesDocument31 paginiFinal PPT On Gas TurbinesKRISHNA KUMARI100% (2)

- SLK G9-Q4wk5 AAcademia EditedDocument15 paginiSLK G9-Q4wk5 AAcademia EditedArthur CapawingÎncă nu există evaluări

- World's Largest Class High-Efficiency Dual-Shaft H-100 Gas TurbineDocument5 paginiWorld's Largest Class High-Efficiency Dual-Shaft H-100 Gas TurbineAnubhav100% (1)

- Green TurbineDocument27 paginiGreen TurbineAnghel Curty Jr.Încă nu există evaluări

- GT11N toGT11NM V004T10A008 98 GT 219Document12 paginiGT11N toGT11NM V004T10A008 98 GT 219atfrost4638Încă nu există evaluări

- Practical Guide To Industrial Boiler SystemsDocument375 paginiPractical Guide To Industrial Boiler Systemssumeet0827100% (19)