Documente Academic

Documente Profesional

Documente Cultură

Solid-Gas Separation

Încărcat de

Mark LoraTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Solid-Gas Separation

Încărcat de

Mark LoraDrepturi de autor:

Formate disponibile

Solid-Gas Separation

The separation of solids from gas streams is a common unit operation in production plants. Gas-

solid separation is important both as a device to recover product but also a key technology for

environmental control. An incredible array of process technologies (for example, cyclones, bag

houses, spray towers, venturi scrubbers) is available to accomplish the task of separating the

solids from gas.

This webinar first examines the concept of grade efficiency, a key concept for describing the

efficiency of a solids separation device. Second, it addresses the topic of selecting a particular

process technology for a given gas-solid separation problem. We also examine advantages and

trade-offs of the most common solid-gas separation devices. Lastly, the fundamental science

associated with the devices such as cyclones, bag houses (dust collectors), and some wet

scrubbing technologies are addressed.

Particulate solids are separated from gas streams for a variety of reasons. In some instances, the

interest is in the recovery of solids as a product, e.g., following a milling operation for which a

combined classification and separation is often required [Prasher ( 1987)]. In other cases, the

emission of fine particulate solids and dust from a unit operation may be excessive and, therefore,

a reduction and control of particulate level is required for the protection of subsequent process

equipment or for the environmental emission [Strauss (1975, and Theodore and Buonicore

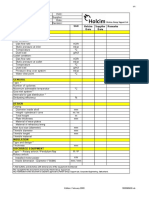

(1976)]. This is illustrated inFigure 1 for the case of advanced power generation from coal,

where it is desirable to expand the hot gases in a gas turbine before exhaust to atmosphere to

enhance the efficiency of power generation. Typical particulate effluent from a pilot-scale

fluidized bed combustor is shown, together with upper limits of allowable emission to

atmosphere, and of the inlet dust tolerance of high performance gas turbines [Henry et al. (1982)].

In this section, an overview of the principles of gas-solids separation is given. Details of various

technologies are addressed in the next three sections.

The most commonly used techniques for the separation of particulate solids from gases

are inertial separators, Electrostatic Separators and Filters. The physical phenomena involved

in the separation of solids from gases are influenced by a number of important factors such as the

properties of the gas, and gas-particle and particle-particle interactions. These factors are briefly

reviewed here first before addressing the principles of various types of gas-solids separators.

Figure 1. Industrial process and environmental requirements for gas-solids separation.

Gas Properties

Over the range of pressures commonly used in industrial gas-solids separation processes,

departures from ideal gas behavior are negligible. Therefore the density of a gas at pressure P

and absolute temperature T can be approximated by

(1)

where Mw is the mean molecular weight of the gas, the molar volume, and the universal

gas constant.

Elementary kinetic theory gives a first approximation for the effect of temperature and pressure

on gas viscosity. Viscosityis predicted to be independent of pressure, and proportional to the

square root of absolute temperature.

In addition to these macroscopic properties, the Mean Free Path of gas molecules, , is of

interest for removal of fine particles. Elementary kinetic theory predicts that is inversely

proportional to density, so that

(2)

Gas-Particle Interaction

Almost any particle removal process requires the particles to migrate relative to the gas, so that

the drag of the gas on the particle is of prime interest. The particle Reynolds Number is defined

as

(3)

where d

p

is the particle diameter and u the velocity of the particle relative to the gas and the gas

viscosity. In most applications, Re

p

remains small. The drag force, F

D

, can then be estimated

from Stokes' Law with a correction to allow for "slip effects" which arise when the particle

diameter is comparable to the mean free path of gas molecules:

(4)

where C is the slip correction factor or "Cunningham coefficient" defined as

(5)

C can be estimated empirically from Davies' correlation (1945):

(6)

where Kn is the Knudsen Number:

(7)

Equation (6) is applicable to spherical particles, and Beard (1976), and Gift et al., (1978)

summarize modifications for nonspherical particles. Some representative values for C are given

by Clift et al., (1981). It is worth noting that, whereas C only departs significantly from unity for

submicron particles at ambient conditions and at elevated pressure, slip effects are significant for

particles several microns in diameter at elevated temperatures and ambient pressure.

For Reynolds numbers larger than, say, 0.1, Equation (4) is better replaced by the general form:

(8)

where C

D

is an empirical function of Re

p

Of the many forms suggested for C

D

(Re

p

), that due to

Schiller and Nauman (1933) is probably most accurate for Re

p

< 800:

(9)

When Re

P

is sufficiently large that Equation (8) must be used rather than Eq. (4), then slip

effects can be ignored, unless u is significant by comparison with the speed of sound in the gas.

However, this is not normally the case in industrial gas-solids separation processes.

For a particle settling freely under its own weight in a gas, the drag force counterbalances the

immersed weight of the particle. For low Re

p

, terminal velocity then follows from Equation

(4) as

(10)

where

p

is the particle density. Normally

p

g

, so that Eq. (1) can be written

(10a)

Increasing temperature, through its effect on gas viscosity, increases fluid-particle drag, reduces

settling velocity, and generally makes removal of particles from gases more difficult. The effect

of pressure is smaller, and acts through the slip effect so that it is only significant for particles

typically smaller than about 1 m; in general, the effect of increasing pressure is again to make

particle removal more difficult. Electrostatic precipitators can be an exception to this rule

because of the effect of pressure on the electrical properties of a gas. Increasing the pressure,

within the range of interest here, widens the gap between the corona-starting and sparkover

voltages. Therefore, the effect of increased drag on the particle at high pressure and high

temperature may be compensated or even overcome by increasing the electrostatic field intensity

(see below).

In certain types of filter the Brownian diffusivity of particles in the gas is of concern. This is

usually best evaluated by theStokes-Einstein equation [Clift et al. (1981)]:

(11)

where k

B

is Boltzmann's constant, 1.38062210

23

JK

1

. Taking the effect of temperature on

viscosity into account, for given particle size

(11a)

so that the Brownian diffusivity increases with increasing temperature. Pressure has a weaker

effect, through the slip correction factor, C, increasing pressure decreases D

AB

It follows from

the above that, if the efficiency of a gas-solids separation process is to be investigated, it is more

important to match the process temperature than pressure. Pressure is important for fine particles,

so that devices such as electrostatic precipitators intended to collect micron-sized particles would

be tested at process temperature and pressure; electrical properties also dictate that both pressure

and temperature should be matched.

Particle-Particle Interaction

In some devices for particle collection, most notably electrostatic precipitators and some types of

filter, it is essential for the collected particles to form relatively large agglomerates which can

then be removed easily. Particle-particle cohesive forces arising from electrostatic, van der

Waals and capillary effects are then important.

Electrostatic effects act over the longest range and may therefore be effective in separating

particles from gases. However, they can only contribute to the cohesiveness of a deposited

particulate if the constituent particles carry both positive and negative charges. Corny and Clift

(1984) have shown that fly-ash from fluidized combustion can carry such charges, and be highly

cohesive as a result. However, it is not known whether this phenomenon occurs more generally

nor, for example, whether ash which has been raised above the fusion temperature carries

significant charges. More generally, particles are likely to carry charges of the same sign, so that

interparticle Coulombic repulsion acts against cohesion. Leakage of this charge requires a

conductive path to an earthed surface, and this depends in particular on the surface

characteristics of the particles. If the particles have for some reasons low surface resistivity, then

electrical contact between particles can be good and the charge can leak away relatively rapidly.

This is particularly important in electrostatic precipitation.

The other two types of force act over shorter ranges, and thefore represent genuine cohesion.

Whereas electrostatic forces result from overall surplus of deficit of electrons, van der Waals

forces arise from the attraction between atomic or molecular dipoles. Because they result from

processes occurring on a molecular scale, van der Waals forces act over much shorter ranges

than electrostatic forces. The strength of van der Waals cohesion depends on the value of

the Hamaker constant, a characteristic property of the material comprising the particles. The

Hamaker constant is effectively independent of pressure, and the dependence on temperature is

not well understood but is probably weak. Hence the environment affects van der Waals

cohesion mainly through its effect on surface properties. Dahneke (1972) showed that local

deformation of the contacting surfaces can increase substantially the strength of interparticle

cohesion.

Capillary forces, which result from a liquid film on the surface of the particles, are orders of

magnitude stronger than van der Waals forces (see also Capillary Action). Figure 2 shows

schematically a "pendular bridge" between two idealized particles of diameter d

p

For zero

particle separation ( = 0) and a fully-wetting liquid (contact angle, = 0) the attractive force

between the particles is [Fisher (1926)]:

(12)

where is the angle defining the size of the bridge and is the tension at the gas/liquid interface.

According to Equation 12, the cohesive force increases as the liquid bridge becomes smaller, to

a limiting value for of d. This theoretical result is not applicable to real particles with

rough surface [Cheng (1970)]; for particles which contact at points of asperity the cohesive force

increases with liquid film thickness [Coughlin et al. (1982)].

Figure 2. Pendular liquid bridge between solid particles.

Principles of Gas-Solids Separation Devices

Inertial Separators cover devices in which the main property used in recovering particles is their

density, so that they are removed by centrifugal action. Deliberate changes in the direction of gas

flow causes the particles trajectories to deviate from the gas streamlines, thus concentrating and

separating the particles from the gas. Inertial separators are varied in design. Most separators in

this category use passive mechanical separation with induced centrifugal motion, such as

cyclones. There are however separators in which the centrifugal motion is induced by a rotating

propeller. These devices are often used for classification purposes, and are covered in Classifiers.

Inertial separators can be used in a wide range of pressure and temperature conditions. Their

performance is satisfactory for coarse particles, but as the particle size decreases much below 10

m the collection efficiency deteriorates very rapidly. Of the various types of design, the reverse

flow cyclone with tangential entry is the most common type of inertial separators due to its

compactness, simplicity of construction and operation, and high throughput. The inlet can be

made either truly tangential or wrapped around the body, commonly referred to as "tangential

entry" and "volute entry" or "scroll inlet", respectively. The former has a higher collection

efficiency, but at the expense of higher pressure drop. There are, of course, other designs using

axial entry with vanes installed within the cyclone to induce rotation, direct through-flow of gas

without reversing, and blowdown, where a small fraction of the gas is allowed to flow with the

collected solids [Strauss (1975)].

Performance analysis of cyclones has been approached on both phenomenlogical as well

mechanistic levels. On a phenomenological level, conventional dimensional analysis leads to the

definition of groups which can be used to "scale" cyclone performance for effects of size,

throughput and process conditions, see Abrahamson (1981). The collection efficiency, E, for

particles of diameter d

p

and density

p

from a gas of density

g

and viscosity is given by a

relationship of the form

(13)

while the pressure drop across the cyclone, P, follows a relationship with the general form

(14)

In Eqs. (13) and (14), is the volumetric flowrate of gas through the cyclone, and D is the

cyclone barrel diameter. Therefore represents a characteristic gas velocity, such as the

mean inlet gas velocity, as the inlet dimensions are fixed relative to the barrel diameter for a

given design. The two independent dimensionless groups in Eq. (13) can be regarded as

the cyclone Stokes number, St

c

, and Reynolds number, Re

c

(15)

(16)

The Stokes number describes the tendency of the particle trajectories to deviate from gas

streamlines, and the Reynolds number describes the gas flow condition within the cyclone. The

above analysis is only valid for low particle concentrations, where the probability of collection of

any individual particle is unaffected by other particles present. For industrial cyclones, the gas

flow in the cyclone is turbulent and Re

c

is very large. It is therefore commonly assumed that the

collection efficiency is not affected by the gas flow pattern, and the effect of Re

c

is neglected.

This leads to the commonly used scaling laws, see, for example, Strauss (1975):

(17)

(18)

Equations (17) and (18) have been shown to work well for low particle loadings and for

particles carrying low levels of electric charge [Giles (1982)]. However, for the cases where

particle/particle interactions are significant, including electrical effects, the above correlations

are not satisfactory and E is less sensitive to St

c

The effect of temperature and pressure is in principle reflected in the density and viscosity of the

gas. However, care must be taken in the use of Equation (17) in this case because temperature

and pressure can also modify Re

c

, which it can then alter the flow condition, thus producing an

effect which is not taken into account in Equation (17).

The alternative approach to analysis of cyclone performance is by mechanistic modelling, which

is necessary to account for the effect of pressure and temperature, as well as for predicting the

effects of changing cyclone geometry. Clift et al. (1991) have recently reviewed a number of

widely used models of cyclones, i.e., those due to Leith and Licht (1972), Muschelknautz (1970),

Dietz (1981) and Mothes and Lffler (1988). It emerges from their analysis that the models of

Dietz (1981) and Mothes and Lffler (1988) provide the best agreement with a very wide range

of experimental data reported in the literature.

Electrostatic Separators cover devices in which the main separating effect is migration of

electrically charged particles in an imposed electric field. These devices have a high collection

efficiency for a wide range of particle sizes, and are particularly suitable for submicrometer

solids. They have at the same time a high throughput and low pressure drop, which are the main

attributes for their wide use in the power generation industry. Operation under extreme

conditions of temperature (i.e., above about 800C) is difficult unless it is accompanied by high

pressures, as it will be described below. Apart from the problems of integrity of materials of

containment and construction, further considerations limit operation at elevated temperature and

pressure. Insulating materials are required to prevent excessive current leakage between the

electrodes. Breakdown of the gas between the electrodes must also be avoided. The minimum

potential gradient causing ionic breakdown of a gas generally decreases with increasing

temperature but increases with pressure. Therefore, at elevated temperature, there is generally a

minimum pressure, dependent on gas composition, below which a precipitator cannot be

operated. The electric properties of the particulate are also relevant: if it is highly resistive, then

collected dust retains its charge and reduces the efficiency of collection of further particulates. It

is also necessary for the collected dust to be removed from the precipitating electrode. This is

normally achieved intermittently by some mechanical action such as "rapping" and the detached

particles are allowed to settle to the base of the equipment. For this to be possible, the dust must

detach as agglomerates with high terminal settling velocity; thus some cohesiveness of the

collected dust is necessary to avoid excessive re-entrainment on electrode cleaning.

The process of electrostatic precipitation involves three stages:

a. charging of suspended particles by corona discharge;

b. migration and deposition of the charged particles under the influence of an applied

electrostatic field;

c. removal of the collected material from the collecting electrode and transfer to a suitable

receptacle outside the precipitator.

In industrial-scale electrostatic precipitation, stages (a) and (b) are generally combined and the

electrostatic field also produces the necessary corona discharge for particle charging. The

principles of operation are described by Strauss (1975) and by Bhm (1982). It is important to

establish a stable corona having adequate current to provide complete charging of the particles,

without getting sparkovers. The onsets of corona voltage and sparkover voltage depend on the

geometry of the electrodes, type of gas and the operating temperature and pressure. The corona-

starting voltage increases slowly as the pressure is increased, for both positive and negative

corona. The effect of pressure on sparkover voltage is more prominent. The sparkover voltage

increases rapidly as the pressure is increased above atmospheric, but reaches a maximum and

declines, to coincide eventually with the corona-starting voltage, see Robinson (1971). The

pressure at which the corona-starting and sparkover voltages coincide is called the "critical

pressure". The interaction of two opposing effects is considered responsible for the existence of

the critical pressure point as the pressure is raised (at constant temperature).

a. shorter mean-free paths impede ionization by collision, and so tend to raise the sparkover

level;

b. enhanced photoionization and reduced ion diffusion tend to facilitate streamer propagation

from the anode across the gas.

As the pressure increases, the initially dominant first effect gives way to the second, the streamer

develops across the gas, and at the critical pressure, spark breakdown ensues.

The effect of temperature has been studied by various authors and the results of the earlier work

have been summarized by Robinson (1971). Briefly, the earlier works indicated that, for

temperatures up to about 1073 K (800C), the current-voltage relations for positive corona were

a function of relative gas density only, but for negative corona the density and temperature had

independent influences for temperatures above 823 K (550C). At temperatures higher than

800C, thermal ionization was considered to become high enough to play a significant role and

eventually lead to breakdown. In this case a positive corona was predicted to be required for

most types of gases, as the space charge produced by thermal ionization would generally be

positive due to sweeping out of highly mobile electrons.

In more recent years, Bush et al. (1977 and 1979) investigated the range of temperature and

pressure in which stable corona discharge may be obtained, and established current-voltage

characteristics in a particle-free electrostatic precipitator for dry air, a simulated combustion gas

and a substitute fuel gas at temperatures up to 1366K (1093C) and pressures up to 35.5 bar.

Their results show that excessive current and sparkover due to thermal ionization, anticipated

previously, are not encountered within the range tested. The results also reveal the tendency for

the positive sparkover voltage to exceed that of the negative sparkover for temperatures above

533 K and low relative air densities (below about 2), a trend which had been observed by earlier

workers. However, experience with dust-laden gases has consistently shown that positive

coronas are inherently less stable than negative, and also yield a lower collection efficiency due

to lower corona currents.

The results of Bush et al. show that the critical pressure increases with temperature. The critical

pressure for negative corona discharge is much higher than for positive. It is worth noting that,

due to the increase of critical pressures with temperature, the range of pressure for stable corona

becomes wider at high temperatures. Thus precipitation could be made more efficient by

applying higher voltages as temperature and pressure increase together. However, these

conclusions are based on dust-free gases, and the performance evaluations reported so far cannot

confirm with confidence their extension to dust-laden gases.

The bulk of the particles passing through the charging zone acquire electric charges of the same

polarity as the discharge electrode; i.e., negative for negative corona. Two distinct mechanisms

are involved in the charging process:

a. Field charging, caused by bombardment of the particles by ions migrating under the influence

of the overall electric field.

b. Diffusion charging, resulting from attachment to the particles of ions which contact them in

the course of their random movement through the gas.

Field charging is the dominating mechanism for large particles, typically greater than 1.0 m. Its

rate depends on the field intensity as well as on ion concentration. Diffusion charging is

dominant for very fine particles, smaller than 0.1 m. In industrial precipitators the particle

residence time in the charging zone is large, and the particles reach their saturation charge level,

which may be estimated from Equation (19) due to Cochet (1956 and 1961). This equation

includes the effect of diffusion charging in the field charging process, hence taking into account

both mechanisms

(19)

where q is the charge acquired by a particle of diameter d

p

in the field of strength E

0

, k

p

is the

relative dielectric constant of the particle,

0

is the permittivity of free space, and is the gas

mean free path.

Under the influence of the electric field, charged particles migrate towards the collecting

electrode. The migration velocity, , is commonly calculated from the quasi-steady force

balance between Stokes' drag and the applied electrostatic force:

(20)

where E

p

is the precipitating electric field. Hence,

(21)

where C is the slip correction factor. In practice, is determined empirically because of various

complicating factors such as the presence of particle size and shape distributions, turbulence and

ionic wind.

The collection efficiency of an electrostatic precipitator is related to the migration velocity by the

celebrated Deutsch (1922) model. Details of this model and other technological issues such as

the grade efficiency and particle collection and discharge are given in the section on the

electrostatic precipitators.

Filters cover all devices in which the gas to be cleaned passes through a porous or permeable

medium which collects and retains particles carried by the gas. In a membrane-type filler, the

passages through the medium are comparable to or smaller than the particulate. Filtration then

occurs by mechanical obstruction, and the particulate builds up as a filter "cake" on the upstream

face of the filter. The filtration efficiency is essentially absolute, and virtually all the dust is

retained on the upstream surface of the filter. In other types of filter, such as granular

bed or fibre filters, the passages through the medium are typically large compared to the

particulate to be collected. The particulate is therefore collected initially within the bed by the

individual granules or fibres. This process is called depth filtration, and it continues until the

passages on the upstream side of the filter narrow down, leading to bridging over the openings

where a cake starts to form. In the initial stage of filtration here, the efficiency of the filter mid

retention of the particulate by the medium is of concern, while in the later stage of filtration,

where a cake has formed, the efficiency is high and the increase in the pressure drop across the

filter is of concern as in the membrane-type filters.

Filters require regular cleaning as the level of dust builds up on the filter. Various methods of

cleaning are used depending on the filter type. Membrane filters are sometimes used just once

and are then replaced or they are cleaned in situ by some intermittent mechanical process such as

vibration or reverse pressure pulse or reverse gas flow rate. A similar cleaning process is applied

to those filters which may operate initially by depth filtration, but rely on cake formation as the

main filtration mechanism. The granular type filters, on the other hand, employ beds of

unbounded filter elements, which are. usually removed continuously or intermittently for

regeneration of the filter medium. In some cases, the elements are cleaned in situ, as for a

membrane filter.

The range of materials used as filter medium is very wide indeed; it includes natural and man-

made fibres, and porous sintered polymer, metal and ceramic sheets and tubes. The main filter

medium requirements are:

a. durability of the medium at process conditions;

b. the ability of the dust to form a cake on the medium;

c. filter performance during the initial stage of cake formation following cleaning;

d. ability of the medium to withstand mechanical stresses during cleaning;

e. form of cake detached during cleaning;

f. "blinding" of the filter medium either by depth filtration or by permanent adhesion of cake to

medium.

Appropriate choice of filter medium depends on the process conditions and type of dust material.

High temperature applications impose a great constraint on the choice of filter medium. Recent

developments in this field have been addressed in a symposium on gas cleaning at high

temperatures [see Clift and Seville (1993)].

The process of filtration is analyzed in terms of three fundamental aspects of primary collection

of dust from the gas, retention or rebound of dust from the collector, and the effect of collected

dust on the filter structure.

For primary collection, the important mechanisms in general are: (i) deposition by diffusion; (ii)

gravitational settling; (iii) inertial deposition; (iv) direct interception; (v) electrostatic deposition.

Magnetic and thermal deposition may also occur depending on the application. The collection

efficiency of each individual mechanism is conventionally presented in terms of single fibre or

granule collection efficiency, E, defined by

(22)

with E a function of dust and granule or fibre size and charge, dust density, gas properties, and

bed voidage. For a particular dust size in a given filter, the penetration is defined as:

(23)

The single particle collection efficiency depends on type and structure of filter medium.

Furthermore, its relationship with the penetration is established through mathematical modelling

of filtration process. For granular type filters, the single particle collection efficiency of the first

four mechanical collection mechanisms has been summarized by Ghadiri et al. (1993). The

electrical deposition mechanism is given by Coury (1983), and the magnetic collection by Birss

and Parker (1981). For depth filters using fabric medium, various correlations for E have been

summarized by Strauss (1975) and Lffler (1971). For granular bed filters, the relationship

between E and f has been outlined by Ghadiri et al. (1993) and by Clift et al. (1981).

Applications to fluidised bed filters at elevated temperatures have been discussed by Ghadiri et al.

(1986). For fabric filters, the relationship between E and f has been analyzed by Schweers and

Lffler (1994), taking account of the distribution of inter-fibre spacings.

When a dust particle makes contact with a filter element, it is essential that it is retained rather

than rebounding, as it may lead to the re-entrainment of the particle. Retention is dominated by

short-range adhesive forces. The analysis of retention was initiated by Dahneke (1971), and

developed further by Stenhouse and Freshwater (1976), Hiller and Lffler (1978), Clift (1983)

and more recently by Ning (1995). The approach is based on an energy balance between the

kinetic energy of the approaching particle, E

i

, and the detachment energy, E

d

In addition to E

i

,

the particle acquires further energy in approaching the collector due to the very short van der

Waals forces, E

v

The energy at the instant of rebound is then e

2

(E

i

+ E

v

), where e is the

coefficient of restitution; the kinetic energy lost is due to the dispersion of elastic waves as well

as plastic deformation of the particle or the collector. In order to detach from the surface, the

particle energy must exceed the detachment energy, E

d

Thus the particle adheres if

(24)

The above inequality indicates a critical impact velocity above which a particle will rebound

from the filter element. The detachment energy Ed is the sum of energies due to van der Waals

forces, and electrostatic and capillary attractions if they are present. Plastic deformation enhances

cohesion because of the larger contact area than otherwise possible with elastic deformation

alone, and this has recently been modelled by Ning (1995).

Cake formation is essential in those filter types whose medium has large passages and the initial

stage of filtration is by depth filtration. Interparticle cohesion is essential for cake formation to

occur. The process starts with particle chain formation, leading to arching over the openings of

the filter, hence providing the foundation for build up of a cake. If the interparticle cohesion is

low or the span of the passages is too wide, the arch may be weak and it may fail under stresses

due to the pressure drop in the cake. In this case, the dust particles will break into the filter, i.e.,

pinhole formation, which causes long-term "blinding" of the filter. Ghadiri et al. (1989) showed

that pinhole formation can be reduced by electrical enhancement of the interparticle cohesion.

Coury (1983) has shown that particles that carry substantial electrical charges of both signs, such

as fly-ash, readily form a cake, where uncharged and uncohesive particles, such as coal char, fail

to form a cake under otherwise identical conditions. Cake formation is therefore strongly

influenced by interparticle forces including van der Waals, electrostatic and capillary forces.

Filter cleaning is another important aspect of filter operation. It should be carried out in such a

way that the cake is detached completely from the filter, i.e., without leaving patches of particles

still adhering to the filter. At the same time, the cake coherence should be preserved so that the

particles are not redispersed in the gas stream. Current practice in filter cleaning is largely

empirical. However, much of recent work has centered on developing an understanding of the

mechanisms involved from which some operational guidelines have emerged [see Cliff and

Seville (1993)].

S-ar putea să vă placă și

- Simulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesDocument8 paginiSimulation of Gas-Solid Flow & Design Modifications of Cement Plant CyclonesNael100% (1)

- International Bag FilterDocument4 paginiInternational Bag FilterRAJAMANICKAMÎncă nu există evaluări

- Rosin Ramml Er RegressionDocument5 paginiRosin Ramml Er RegressionJhon Barzola PalominoÎncă nu există evaluări

- Bulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropDocument2 paginiBulletin 9 - CFD Analysis and Flow Smoothening in PH Down Comer Duct To Reduce Pressure DropSivaram KrishnamoorthyÎncă nu există evaluări

- Hot Air Generator PDFDocument1 paginăHot Air Generator PDFAnkur SinghÎncă nu există evaluări

- Cement Plant VIPDocument51 paginiCement Plant VIPengr kazamÎncă nu există evaluări

- In VoluteDocument3 paginiIn Voluteds693Încă nu există evaluări

- Cpb-Sem2011-P11-Axial Sampling and Tromp CurveDocument54 paginiCpb-Sem2011-P11-Axial Sampling and Tromp Curvechibssa alemayehu100% (1)

- 1.) Introduction: Soham Ferro Manganese Private Limited Nagpur Page 4Document67 pagini1.) Introduction: Soham Ferro Manganese Private Limited Nagpur Page 4anand7602Încă nu există evaluări

- Energy ManagementDocument9 paginiEnergy Managementhasan_jafri_2Încă nu există evaluări

- Paper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit DesignDocument13 paginiPaper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit Designcuberbill1980Încă nu există evaluări

- Cement Kiln Co-ProcessingDocument11 paginiCement Kiln Co-ProcessingflukemonsterÎncă nu există evaluări

- Cyclone SeparatorDocument1 paginăCyclone SeparatordadÎncă nu există evaluări

- Ball Mill Design - CompressDocument6 paginiBall Mill Design - CompressSuresh VedalaÎncă nu există evaluări

- VRM Fan ..Document2 paginiVRM Fan ..harikrushnaÎncă nu există evaluări

- 4 MPDocument33 pagini4 MPSyed Shahzaib ShahÎncă nu există evaluări

- Study of The Grinding Balls Distribution Inside The MillDocument2 paginiStudy of The Grinding Balls Distribution Inside The Millsempatik721Încă nu există evaluări

- (Cyclone Separator) PDFDocument11 pagini(Cyclone Separator) PDFهاجر صالح جبارÎncă nu există evaluări

- Effect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierDocument51 paginiEffect of GA On Model Parameters of A Cement Ball Mill and An Air ClassifierNam HuynhÎncă nu există evaluări

- The Cement Grinding Office: Home About Us Services Mining AreaDocument3 paginiThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarÎncă nu există evaluări

- Kiln SimuDocument6 paginiKiln SimuJesus Castañon AlcalaÎncă nu există evaluări

- Problem21 07Document1 paginăProblem21 07IENCSÎncă nu există evaluări

- SeparatorsDocument6 paginiSeparatorsKADİR durmaz100% (1)

- Ball Mill GrindingDocument6 paginiBall Mill GrindingShyanu Udeshika WijerathnaÎncă nu există evaluări

- Ball Mill OperatingDocument14 paginiBall Mill OperatingCao Ngoc AnhÎncă nu există evaluări

- 1Document5 pagini1Dee HsÎncă nu există evaluări

- (J-1) Burner TypesDocument1 pagină(J-1) Burner Typesgie pradanaÎncă nu există evaluări

- StanexDocument2 paginiStanexSamehibrahemÎncă nu există evaluări

- Melamine ProductionDocument49 paginiMelamine ProductionImtiaz HussainÎncă nu există evaluări

- Combustion Studies of Fuel-Rich PropellantsDocument156 paginiCombustion Studies of Fuel-Rich PropellantsĐăng Khôi TrầnÎncă nu există evaluări

- Transfer of Solids: 5.1. Slurry TransportDocument8 paginiTransfer of Solids: 5.1. Slurry TransportKevin Alberto Tejera PereiraÎncă nu există evaluări

- Thermos Design of Rotary Kiln For Reduction of Radiation Losses-10Document17 paginiThermos Design of Rotary Kiln For Reduction of Radiation Losses-10Madhav Krishna MÎncă nu există evaluări

- Tromp CurveDocument3 paginiTromp CurveShakil AhmadÎncă nu există evaluări

- Cascade Air Separator KVT enDocument6 paginiCascade Air Separator KVT enkamjulajayÎncă nu există evaluări

- Gravity Conveyor With Air FluidizeDocument3 paginiGravity Conveyor With Air Fluidizechem_taÎncă nu există evaluări

- EAU-1,19000 CFM at 75 MM StaticDocument1 paginăEAU-1,19000 CFM at 75 MM StaticdesignhvacÎncă nu există evaluări

- Vibration Analysis of Rotary Cement Kiln Using Fin 2Document5 paginiVibration Analysis of Rotary Cement Kiln Using Fin 2nunchakuÎncă nu există evaluări

- Blast Furnace Slag Weathering StudyDocument8 paginiBlast Furnace Slag Weathering StudyARNALDO BATTAGIN100% (3)

- Cross-Bar CoolerDocument8 paginiCross-Bar CoolernaikÎncă nu există evaluări

- Cyclone SeparationDocument75 paginiCyclone Separationcevapcic100100% (1)

- MS 06 16 PDFDocument4 paginiMS 06 16 PDFPrateek RajÎncă nu există evaluări

- Ecway Technologies: Design and Fabrication of Cyclone Seperator Using Vane PumpDocument9 paginiEcway Technologies: Design and Fabrication of Cyclone Seperator Using Vane Pumpieee4mybusinessonly100% (1)

- Wear Rate Calculator MonoDocument2 paginiWear Rate Calculator MonoBùi Hắc HảiÎncă nu există evaluări

- A Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueDocument3 paginiA Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueVerónica CharresÎncă nu există evaluări

- Ball Mills - Guidelines For Sample Amount and Ball ChargeDocument4 paginiBall Mills - Guidelines For Sample Amount and Ball ChargeAndrejs AndrejsÎncă nu există evaluări

- T7111-DAS-1053-A-IFA-Baghouse Datasheet - 20170930 PDFDocument4 paginiT7111-DAS-1053-A-IFA-Baghouse Datasheet - 20170930 PDFtiantaufikÎncă nu există evaluări

- Calculation of Max. Ball Size: Plant: Mill Nr. Mill SizeDocument1 paginăCalculation of Max. Ball Size: Plant: Mill Nr. Mill SizeAbul QasimÎncă nu există evaluări

- Helical Gearbox InstallationDocument8 paginiHelical Gearbox InstallationKUNALJAYÎncă nu există evaluări

- Fan LawsDocument39 paginiFan LawsbhatrkÎncă nu există evaluări

- Ball-Cement-Mill-Monitoring-Inspection-Evaluation PerformanceDocument7 paginiBall-Cement-Mill-Monitoring-Inspection-Evaluation PerformanceMin MCLÎncă nu există evaluări

- CycloneDocument10 paginiCyclonepradeep4545Încă nu există evaluări

- ABC Cooler Inlet PDFDocument4 paginiABC Cooler Inlet PDFSushant GuptaÎncă nu există evaluări

- 03mill SlidesDocument21 pagini03mill SlidesNael El SayyadÎncă nu există evaluări

- The Republic of The Union of Myanmar Ministry of ConstructionDocument8 paginiThe Republic of The Union of Myanmar Ministry of ConstructionZEC LIMITEDÎncă nu există evaluări

- Chlorine: International Thermodynamic Tables of the Fluid StateDe la EverandChlorine: International Thermodynamic Tables of the Fluid StateÎncă nu există evaluări

- Yyzzzz Scaling Parameters For PFBC Cyclone Separator Sistems AnalysisDocument17 paginiYyzzzz Scaling Parameters For PFBC Cyclone Separator Sistems AnalysisJosé Pedro Casagrande TrentínÎncă nu există evaluări

- Preprint Ces AustDocument40 paginiPreprint Ces Austnehal_rizk2944Încă nu există evaluări

- DETERMINATION OF CLEARANCE DISTANCES For Venting H2Document12 paginiDETERMINATION OF CLEARANCE DISTANCES For Venting H2JoshHongÎncă nu există evaluări

- Ipc2012 90137Document7 paginiIpc2012 90137Marcelo Varejão CasarinÎncă nu există evaluări

- Cyclones: (Adapted From Air Pollution Control by C. D. Cooper & F.C - Alley, 1986)Document9 paginiCyclones: (Adapted From Air Pollution Control by C. D. Cooper & F.C - Alley, 1986)ePuL69Încă nu există evaluări

- Parts of Feasibility StudyDocument5 paginiParts of Feasibility StudyMark LoraÎncă nu există evaluări

- List of Delegates: National Youth Day (NYD)Document2 paginiList of Delegates: National Youth Day (NYD)Mark LoraÎncă nu există evaluări

- Atomic Structure and Interatomic BondingDocument32 paginiAtomic Structure and Interatomic BondingMark LoraÎncă nu există evaluări

- Bioreactors Instrumentation and ControlDocument27 paginiBioreactors Instrumentation and ControlMark LoraÎncă nu există evaluări

- Integral Control - OdpDocument16 paginiIntegral Control - OdpMark LoraÎncă nu există evaluări

- My Custom QuizDocument9 paginiMy Custom Quizismael gonzalezÎncă nu există evaluări

- Physics Model PaperDocument63 paginiPhysics Model Paperapi-3699388100% (2)

- Quantitative Risk Assessment of The Italian Gas Distribution Network Journal of Loss Prevention in The Process IndustriesDocument13 paginiQuantitative Risk Assessment of The Italian Gas Distribution Network Journal of Loss Prevention in The Process IndustriesRaúlÎncă nu există evaluări

- JEE Mains 1 - 2024Document16 paginiJEE Mains 1 - 2024Ronit BiswalÎncă nu există evaluări

- Chemistry With Vernier 4th EdDocument368 paginiChemistry With Vernier 4th Edj.pardillaÎncă nu există evaluări

- Experiment 1Document20 paginiExperiment 1Shelvin NaiduÎncă nu există evaluări

- Nso Class-8Document3 paginiNso Class-8sachinÎncă nu există evaluări

- Science Scope and Sequence f-6Document6 paginiScience Scope and Sequence f-6BronwynÎncă nu există evaluări

- Applied ThermodynanmicsDocument93 paginiApplied ThermodynanmicsDiana Catalina Gallo100% (1)

- Reserves Estimation For A Coal Bed Methane Well PETSOC-03-11-01-PDocument6 paginiReserves Estimation For A Coal Bed Methane Well PETSOC-03-11-01-Psaladinayubi1234Încă nu există evaluări

- Riello Burners Gas3-2 RMG PDFDocument16 paginiRiello Burners Gas3-2 RMG PDFchnanduÎncă nu există evaluări

- Mole Concept Numericals For PracticeDocument1 paginăMole Concept Numericals For PracticemayurbuddyÎncă nu există evaluări

- Combustion of Two Phase Reactive MediaDocument569 paginiCombustion of Two Phase Reactive MediaKalyani Gangulian50% (2)

- 2018 - Hallaaoui - One Dimensional Phosphate Flash Dryer Model For Design ApplicationDocument11 pagini2018 - Hallaaoui - One Dimensional Phosphate Flash Dryer Model For Design ApplicationGuilherme Venturi RonchiÎncă nu există evaluări

- Chapter 1 - Chemistry and MeasurementDocument33 paginiChapter 1 - Chemistry and MeasurementSai RaghavaÎncă nu există evaluări

- S2Document5 paginiS2NorphinÎncă nu există evaluări

- Adv PT1Document23 paginiAdv PT1AdvaithÎncă nu există evaluări

- EHB en 7.5 Sizing According To ISO 4126 1Document10 paginiEHB en 7.5 Sizing According To ISO 4126 1Teguh SetionoÎncă nu există evaluări

- CSEC 2021 June Workshop SolutionsDocument16 paginiCSEC 2021 June Workshop Solutionspoet100% (1)

- BS 5258 PART 8 (Specifications For Safety of Domestic Gas Appliances-Combined Appliances-Gas, FireDocument36 paginiBS 5258 PART 8 (Specifications For Safety of Domestic Gas Appliances-Combined Appliances-Gas, Fireminsara madtÎncă nu există evaluări

- AS Edexcel Chemistry Formulae and EquationsDocument23 paginiAS Edexcel Chemistry Formulae and EquationsTheMagicCarpet100% (1)

- Conduction and Breakdown in Gases - SVDocument85 paginiConduction and Breakdown in Gases - SVtawanda daniel dengu67% (3)

- Stirling Engine ProposalDocument8 paginiStirling Engine ProposalSaibhargavi BkÎncă nu există evaluări

- Effect of Factors On The Hydrogen Composition in The Carburizing ProcessDocument7 paginiEffect of Factors On The Hydrogen Composition in The Carburizing ProcessAndi PrayogaÎncă nu există evaluări

- Engineering Thermodynamics MCQDocument50 paginiEngineering Thermodynamics MCQShriram Pandian100% (2)

- Spray Simulation Modeling and Numerical Simulation of Sprayforming MetalsDocument288 paginiSpray Simulation Modeling and Numerical Simulation of Sprayforming MetalsRattikarn Ratti100% (1)

- GT ControlDocument81 paginiGT ControlGnanaseharan ArunachalamÎncă nu există evaluări

- Introduction To The Ideal Gas LawDocument17 paginiIntroduction To The Ideal Gas Lawgdfeiu dionwdnÎncă nu există evaluări

- Well Performance ReportDocument4 paginiWell Performance ReportTamer Hesham Ahmed50% (2)

- Test 7 ReviewDocument63 paginiTest 7 Reviewmetalover36Încă nu există evaluări