Documente Academic

Documente Profesional

Documente Cultură

Resource Documents SRPs RL 004-077

Încărcat de

vikkoo7Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Resource Documents SRPs RL 004-077

Încărcat de

vikkoo7Drepturi de autor:

Formate disponibile

1.

General

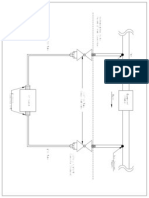

1.1 This procedure describes a general sheath removal

method for non-armored ALTOS

cables.

1.2 Corning Cable Systems ALTOS cable is a rugged

fiber optic cable featuring buffer tubes and a dielectric

central member protected by waterblocking tape and yarn

(Figure 1).

NOTE: Steps that reference dielectric strength yarns are only

required for cable designs incorporating these yarns.

1.3 This issue include a new precaution about filler rods.

2. Precautions

2.1 General Precautions

2.2 Chemical Precautions

2.3 Cable Handling Precautions

Figure 1

2.4 Filler Rod Precautions

3. Tools and Materials

3.1 This procedure requires the following basic tools:

Utility knife with hook blade

Fiber-Clean

cleaning wipes if filling compound is

present

Scissors

Diagonal cutting pliers

Vinyl tape

Sheath ripper

Tape measure

Small screwdriver

All of these items are contained in the Corning

cable systems Sheath Removal Tool Kit (TKT-005),

or in the Fusion Splicing Tool Kit (M67-003).

4. Cable Preparation

4.1 Refer to the documentation for the hardware in

which you are installing the cable for the required sheath

removal lengths.

Corning Cable Systems

SRP-004-077

Issue 10 December 2008

Page 1 of 5

Sheath Removal of Non-armored ALTOS Fiber Optic Cables

Waterblocking tape

Buffer tubes

Binders

Fibers

Yarn

Sheath

Rip cord

Central

member

Waterblocking yarn

CAUTION: The wearing of safety gloves to pro-

tect your hands from accidental injury when using sharp-

bladed tools is strongly recommended. Use extreme care when

the utility knife's blade is exposed. Dispose of used blades

properly.

WARNING: The wearing of safety glassesto pro-

tect the eyes from accidental injury is strongly recommended

when cutting central members and fiber.

SRP-004-077

CAUTION: Fiber optic cable is sensitive to excessive

pulling, bending and crushing forces. Consult the cable specifi-

cation sheet for the cable you are installing. Do not bend cable

more sharply than the minimum recommended bend radius.

Do not apply more pulling force to the cable than specified. Do

not crush the cable or allow it to kink. Doing so may cause

damage that can alter the transmission characteristics of the

cable- the cable may have to be replaced.

Fiber-Clean Wipes

WARNING: Contains hydrocarbons. Apply in rooms

having normal room ventilation. For prolonged and/or

repeated use, gloves are recommended. Avoid eye contact.

Keep away from open flames and ignition sources.

If ingested, do not induce vomiting. Consult a physician. If

contact with eyes, wash eyes with water for 15 minutes.

CAUTION: Filler rod color may vary from cable to

cable. Typical filler rod colors are natural (off-white) and

black. Careful attention should be taken to avoid accidental

cutting of live buffer tubes; particularly white and black tubes.

In mid-span applications, CCS recommends coiling all tubes

and filler rods in the slack storage area of the splice closure;

especially for cables with fiber counts above 96 fibers. Avoid

cutting any filler rods unless necessary for storage space consid-

erations. When in doubt regarding the buffer tube color code

and filler rod placement, contact CCS Engineering Services for

assistance prior to cutting.

4.2 Mark the cable at the appropriate distance from the

cable end with a wrap of tape (Figure 2).

Figure 2

5. Sheath Removal

Note: Before proceeding with the following steps, anchor the

cable securely to the work area using tape or cable ties; otherwise,

two craftspersons will be required.

5.1 Use the hook blade to carefully make a ring cut 15 cm

(6 in) from the end of the sheath (Figure 3) Use care to

avoid damaging the buffer tubes.

Figure 3

5.2 Position the blade of the hook blade knife at the ring

cut so that it can travel down the cable between the sheath

and the cable core towards the cable end.

Hold the knife at a 45 angle to the cable to prevent the blade

from slipping out of the sheath.

Slit the 15 cm (6 in.) section of cable sheath by holding

the arm which has the knife out straight and pulling the

cable "through" the hook blade with your other hand

(Figure 4).

Figure 4

5.3 Remove the 15 cm (6 in.) section of sheath from the

end of the cable use care during this step to avoid damaging

the buffer tubes (Figure 5).

Figure 5

5.4 Locate and separate the orange rip cord from the

yarn surrounding the cable core. Cut a starting notch in

the cable sheath as shown in Figure 6.

Figure 6

5.5 Wrap the rip cord around the shaft of a screw-

driver, short section of scrap cable, or other object which

can serve as a handle.

5.6 Pull the rip cord through the sheath to the tape wrap

(Figure 7). Cut the rip cord flush at the tape wrap.

Figure 7

5.7 Carefully separate the sheath from the yarn-covered

cable core back to the tape wrap (Figure 8).

Strip length

Wrap of tape

Page 2 SRP-004-077 Issue 10

15 cm

(6 in.)

Ring cut

t

o

c

a

b

l

e

e

n

d

D

i

r

e

c

t

i

o

n

o

f

"

p

u

l

l

"

45

Rip cord

Yarn

Cable core

Sheath

Cable

core

Tape mark

Figure 8

5.8 Trim off the split section of sheath at the tape mark

with side cutters (Figure 9) or scissors.

Figure 9

5.9 Starting near the tape mark, pull the yarn away from

the cable core until the core is exposed exposed for a

length of 25 cm (10 in.) (Figure 10).

Figure 10

5.10 Cut the yarn at the 25 cm point with a pair of scis-

sors (Figure 11). Fold the 25 cm length of yarn back out of

the way.

Figure 11

5.11 Starting at the cut point, slide the yarn off the end

of the cable (Figure 12). The yarn will bunch up, but will

slide to the end of the cable.

USE CARE TO PREVENT ANY DAMAGE TO THE

BUFFER TUBES. ALWAYS SLIDE THE YARN AWAY

FROM THE CABLES ANCHOR POINT.

5.12 Use a seam ripper every 5 cm (2 in.) to cut the sin-

gle binding tape that secures the waterblocking tape to the

cable core. USE EXTREME CAUTION to prevent

buffer tube damage (Figure 13).

Figure 13

5.13 Starting at the tape mark, slide the binder tape to

the end of the cable core. Slide the tape off the cable.

USE CARE TO PREVENT ANY DAMAGE TO THE

BUFFER TUBES.

5.14 Separate the water blocking tape from the cable

core (Figure 14). Use scissors to cut the water-blocking

tape flush with the end of the cable sheath.

Figure 14

5.15 Use a seam ripper every 5 cm (2 in. ) to cut the

binding tape(s) that secures the buffer tubes to the dielec-

tric central member. USE EXTREME CAUTION to

prevent buffer tube damage (Figure 15).

Figure 15

5.16 Starting at the tape mark, slide the binder tape off

the end of the cable. USE CARE TO PREVENT ANY

DAMAGE TO THE BUFFER TUBES.

Issue 10 SRP-004-077 Page 3

25 cm (10 in.)

Cable core

Figure 12

5.17 Separate the buffer tubes as follows:

a) Working from the end of the cable back to the

tape mark, carefully unwind the buffer tubes from

around the central member of the cable (Figure

16). Be careful not to bend or kink any of the

buffer tubes.

Figure 16

b) Examine each buffer tube for damage.

If you find any damaged tubes, report the damage

to your supervisor. Do not cut out a damaged

section or continue the installation with damaged

fibers.

c) Using scissors, cut the water blocking yarn flush

with the end of the cable sheath.

b) Examine each buffer tube for damage.

If you find any damaged tubes, report the damage

to your supervisor. Do not cut out a damaged

section or continue the installation with damaged

fibers.

c) Using scissors, cut the water blocking yarn flush

with the end of the cable sheath.

Note:The central member length called for in this procedure

should be adequate for most hardware - most closures will

require additional trimming of the central member. Always ver-

ify the central member length your installation requires before

cutting.

5.18 Use side cutters to cut the dielectric central mem-

ber to a length of 15 cm (6 in.) (Figure 17).

Figure 17

6. Accessing the Optical Fibers

6.1 Use an Ideal coaxial cable stripper to score the buffer

tubes. Scoring the circumference of the tube will enable

you to make a clean break in the tube with minimal risk to

the fibers inside.

Before using the stripper, make sure that it is properly

adjusted. Use a small screwdriver to adjust one of the

blades on the side of the buffer tube cutter so that it seats

against the lower jaw but does not force the jaw open

(Figure 18).

Leave the blades on the front and other side of the tool fully

retracted so that they do not extend into the grooves of the lower

jaw.

Figure 18

6.2 Use the last 2 to 3 inches (5 to 7.5 cm) at the end of

the cable end to determine the sharpness of the stripper's

blade and how many turns of the tool will be required to

score the tube.

To minimize damage to the fibers inside the tube, always use the

tool to score the tube, not ring cut it.

Page 4 SRP-004-077 Issue 10

Central

member

CAUTION: Use extreme care when cutting or

stripping coating from central members to prevent damage to

the buffer tubes. WEAR EYE PROTECTION WHENEV-

ER YOU CUT A CENTRAL MEMBER. Hold the portion

of the central member which will be cut from the cable to

prevent it from causing possible injuries.

15 cm

(6 in.)

6.3 To score a buffer tube:

a) Open the tool by squeezing its handles together

and place the stripper's blade on the buffer tube at the

desired scoring point.

b) Hold the buffer tube steady with one hand to prevent it

from twisting.

c) Use your other hand to rotate the tool around the buffer

tube two to three complete turns to score it (Figure 19).

Remove the tool from the buffer tube.

Figure 19

If the stripper completely cuts through the tube during

this trial step, move the tool to a new trial area at the end

of the buffer tube and repeat a) through c) with fewer

rotations in step c). If the blade cuts completely though

the tube, damage to the fibers inside can result.

d) Carefully flex the tube to break it at the score point.

The break should be clean and free of rough edges

(Figure 20). Carefully slide the severed section of

buffer tube off of the fibers.

If the break is not clean, repeat the trial at a new location at the

end of the tube with an additional rotation or two.

6.4 Once you have determined the number of rotations

needed to score the tube, place the tool at the actual score

point and carefully repeat steps 6.3 a) through d).

6.5 If the buffer tube is Gel-free, carefully cut out the

water block yarns if present and proceed to step 7.1. If fill-

ing compound is present, use a Fiber-Clean wipe to clean

the fibers. Use a dry tissue for final cleaning.

7. Hardware Placement

7.1 Route and secure the cable into the selected termina-

tion or splice hardware, following all hardware instructions

and procedures. BE EXTREMELY CAREFUL NOT TO

DAMAGE THE EXPOSED FIBERS DURING THIS

STEP.

7.2 Terminate or splice the individual fibers according to

the appropriate procedures.

Issue 10 SRP-004-077 Page 5

Figure 20

Corning Cable Systems reserves the right to improve, enhance, and modify

the features and specifications of Corning Cable Systems products without

prior notification.

All trademarks are the property of their respective holders

Corning Cable Systems is ISO 9001 certified.

2008 Corning Cable Systems LLC. All rights reserved.

Printed in U.S.A.

Corning Cable Systems LLC

PO Box 489

Hickory, NC 28603-0489 USA

For US and Canada 1-800-743-2673

International 828-901-5000

FAX: 828-901-5973

http:www.corning.com/cablesystems

Corning Cable Systems offers comprehensive, integrated training pro-

grams. Courses are structured for: Telephony, CATV, LAN, Intelligent

Transportation Systems and Power Utilities.

For information on Engineering Services Training call: 800-743-2671.

Special Note:

Fiber Optic

Training

Programs

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- 04.23 Pórtico Porta Gantry Rapide DimensionesDocument1 pagină04.23 Pórtico Porta Gantry Rapide Dimensionesvikkoo7Încă nu există evaluări

- Adaptors Reducers Brochure PDFDocument20 paginiAdaptors Reducers Brochure PDFvikkoo7Încă nu există evaluări

- Washers PDFDocument1 paginăWashers PDFvikkoo7Încă nu există evaluări

- Cable Glands: Hazardous AreaDocument1 paginăCable Glands: Hazardous Areavikkoo7Încă nu există evaluări

- Explosion Proof Junction Box For Detect-A-Fire UnitsDocument3 paginiExplosion Proof Junction Box For Detect-A-Fire Unitsvikkoo7Încă nu există evaluări

- RFI FormatDocument2 paginiRFI Formatvikkoo7Încă nu există evaluări

- ESD DCS TaggingDocument1 paginăESD DCS Taggingvikkoo7Încă nu există evaluări

- Fire RTD SensorDocument4 paginiFire RTD Sensorvikkoo7Încă nu există evaluări

- Fiber Installation GuideDocument12 paginiFiber Installation GuideTahar HajjiÎncă nu există evaluări

- Confined Spaces: A Brief Guide To Working SafelyDocument7 paginiConfined Spaces: A Brief Guide To Working SafelyGanesh BaskerÎncă nu există evaluări

- Yokogawa PDT ManualDocument83 paginiYokogawa PDT Manualvikkoo7Încă nu există evaluări

- Megger InsulationtesterDocument67 paginiMegger InsulationtesterNh Chuminda YapaÎncă nu există evaluări

- Fiber Installation GuideDocument12 paginiFiber Installation GuideTahar HajjiÎncă nu există evaluări

- Radar Book Chapter2Document22 paginiRadar Book Chapter2Neeraj SharmaÎncă nu există evaluări

- Flare SystemDocument29 paginiFlare Systemvikkoo7100% (4)

- Company ListDocument11 paginiCompany Listvikkoo7Încă nu există evaluări

- DP Hook-UpDocument1 paginăDP Hook-Upvikkoo7Încă nu există evaluări

- DP Hook-UpDocument1 paginăDP Hook-Upvikkoo7Încă nu există evaluări

- DP Hook-UpDocument1 paginăDP Hook-Upvikkoo7Încă nu există evaluări

- CMP Catalogue Sheet0001Document2 paginiCMP Catalogue Sheet0001vikkoo7Încă nu există evaluări

- RTD and Thermocouple Assemblies Reference ManualDocument26 paginiRTD and Thermocouple Assemblies Reference ManualTejas JasaniÎncă nu există evaluări

- Armoured Cables - Manufacturer of Armoured Power Cables and Armoured ElectriDocument9 paginiArmoured Cables - Manufacturer of Armoured Power Cables and Armoured Electrivikkoo7Încă nu există evaluări

- Radar Book Chapter2Document22 paginiRadar Book Chapter2Neeraj SharmaÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Tales Billy The Kid: His Friends, Lovers, Mother Murder TrialDocument92 paginiTales Billy The Kid: His Friends, Lovers, Mother Murder TrialAnonymous yAH8LaVDUCÎncă nu există evaluări

- Sharp KnifeDocument4 paginiSharp Knifegorlan67% (3)

- Pork9 PDFDocument24 paginiPork9 PDFSean Aaberg100% (2)

- AVAILABLE PARTS UPGRADES SANDIACRE MACHINES VERTICAL FORM FILL and SEAL ... (PDFDrive)Document36 paginiAVAILABLE PARTS UPGRADES SANDIACRE MACHINES VERTICAL FORM FILL and SEAL ... (PDFDrive)Ahmad عfiaÎncă nu există evaluări

- Tupperware Spring Summer Catalogue 2012Document29 paginiTupperware Spring Summer Catalogue 2012nay_lea21Încă nu există evaluări

- Cryostat Operations Manual - Minotome Plus - OM2563Document23 paginiCryostat Operations Manual - Minotome Plus - OM2563ATR Assistência Técnica (ATR)Încă nu există evaluări

- Manms2730 090117 V3.3 UkDocument58 paginiManms2730 090117 V3.3 Uk1234100% (2)

- Tle8 4PTDocument4 paginiTle8 4PTLOVELY DELA CERNAÎncă nu există evaluări

- Super Fishing Jar: Instruction Manual 4100Document21 paginiSuper Fishing Jar: Instruction Manual 4100RourouÎncă nu există evaluări

- 4rth EXAM COOKERY 9Document7 pagini4rth EXAM COOKERY 9Donna Mae CeralvoÎncă nu există evaluări

- Import BladedWeaponsDocument2 paginiImport BladedWeaponsDeagle_zeroÎncă nu există evaluări

- Extrema Ratio Glauca B1Document5 paginiExtrema Ratio Glauca B1Twobirds Flying PublicationsÎncă nu există evaluări

- SOG 2009 CatalogDocument40 paginiSOG 2009 Catalogbrzydal100Încă nu există evaluări

- The Wonder of Gobekli TepeDocument9 paginiThe Wonder of Gobekli TepeCliff100% (2)

- Histopathology & Histotechniques Honing & StroppingDocument3 paginiHistopathology & Histotechniques Honing & StroppingAyie PaggabaoÎncă nu există evaluări

- Dewalt Table Saw PDFDocument52 paginiDewalt Table Saw PDFstummel6636100% (1)

- Tools and Equipment in Preparing SandwichesDocument33 paginiTools and Equipment in Preparing Sandwichesnhfdbhddhsdeyterhguy100% (1)

- Senior Capstone Research Paper Culinary ArtDocument6 paginiSenior Capstone Research Paper Culinary Artapi-358080767Încă nu există evaluări

- Paper Models - Miniature GamesDocument36 paginiPaper Models - Miniature Gamesweb moricca100% (1)

- TLE FoodProcessing8 Q2M1 Week1 2Document19 paginiTLE FoodProcessing8 Q2M1 Week1 2Choie Gumera67% (3)

- Military Illustrated Modeller 066 2016-10Document68 paginiMilitary Illustrated Modeller 066 2016-10Don100% (3)

- Folding Karambit Knives Fixed Blade Karambit KnivesDocument7 paginiFolding Karambit Knives Fixed Blade Karambit KnivesAdrian Rocha0% (1)

- Knife SharpeningDocument19 paginiKnife Sharpeninggbrn100% (1)

- C24 User ManualDocument39 paginiC24 User ManualMiguel MedinaÎncă nu există evaluări

- Carpentry Shop PDFDocument21 paginiCarpentry Shop PDFfimiwm100% (1)

- Leica CM1850 UV Manual en 1v4Document56 paginiLeica CM1850 UV Manual en 1v4chito_1018100% (1)

- Book Art Studio Handbook Techniques and Methods For Binding Books Creating Albums Making Boxes and Enclosures and MoreDocument161 paginiBook Art Studio Handbook Techniques and Methods For Binding Books Creating Albums Making Boxes and Enclosures and MoreMariana Gaete Venegas100% (8)

- MODULE 1.culinaryDocument6 paginiMODULE 1.culinaryCherry Ann Joy AbonÎncă nu există evaluări

- Garment Manufacturing Technology: RTW Apparel ProductionDocument12 paginiGarment Manufacturing Technology: RTW Apparel Productionnalinkumar944Încă nu există evaluări

- Cabezal WarathaDocument28 paginiCabezal WarathaAndres Emilio Veloso Ramirez0% (1)