Documente Academic

Documente Profesional

Documente Cultură

Vocabulário Inglês Soldadura

Încărcat de

bdromeiraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Vocabulário Inglês Soldadura

Încărcat de

bdromeiraDrepturi de autor:

Formate disponibile

Vocabulary Term

Definition

American Welding Society

AWS. A professional organization that supports the welding industry and

promotes welding and related processes.

arc blow

A condition resulting from the interaction of an electric current and the magnetic

field the current induces. Arc blow can cause excessive spatter, incomplete

fusion, and porosity.

AWS

American Welding Society. A professional organization that supports the

welding industry and promotes welding and related processes.

centerline crack

A gap or break in the surface of a weld parallel to the weld axis that may be

along the centerline of the weld or near the weld toes. A centerline crack is also

called a longitudinal crack.

concave

Curving inward like the inside of a bowl.

consumable

An electrode that conducts electricity to the arc but also melts into the weld as a

filler metal.

convex

Curving outward like the exterior of a circle or sphere.

crack

A discontinuity characterized by a break or gap in the surface of a weld. Cracks

can be classified as longitudinal, transverse, crater, and heat affected zone.

crater crack

A gap or break in the surface of a weld that occurs at the crater of a weld

because welding was improperly terminated. Crater cracks are also called star

cracks.

defect

An irregularity in the specified and expected composition of a weld that exceeds

the part design's tolerances. A defect is a rejectable discontinuity.

discontinuity

An irregularity in the specified and expected composition of a weld. A

discontinuity is not always a defect.

distortion

A disfigurement that signals that a weld joint was not prepared properly.

excess concavity

The distance from the weld face perpendicular to a line joining the weld toes that

arcs in and toward the weld joint.

excess convexity

The distance from the weld face perpendicular to a line joining the weld toes that

arcs out and away from the weld joint. Excess convexity has a greater potential

for weld failure, causing longitudinal cracking and crater cracking.

excess penetration

A discontinuity characterized by an excess of weld metal on the back side of the

joint. Excessive heat, slow movement, and poor joint alignment can cause

excessive penetration.

excessive reinforcement

The use of more weld metal than is required to fill a groove weld joint.

Excessive reinforcement creates high concentrations of stress at the weld toes.

fillet gage

A device that determines whether or not a fillet weld is within specified

tolerances. A fillet gage is a specific kind of weld gage.

Vocabulary Term

Definition

fillet weld

A type of weld that is triangular in shape and joins two surfaces at right angles to

each other in a lap joint, T-joint, or corner joint. Fillet welds are the most

common types of welds.

heat affected zone crack

A cold gap or break in the surface of a weld that forms in the heat-affected zone

of a base metal. Heat affected zone cracks are also called underbead cracks.

hold point

A predetermined stopping point in the fabrication process at which the weld

must be inspected. Hold points are used between passes of multi-layer welds to

assure a weld is properly cleaned between passes.

incomplete fusion

The lack of complete integration between the weld metal and adjoining weld

beads. Incomplete fusion is caused by faulty operator technique, improper

preparation of the base metal, insufficient welding heat, lack of access to the

adjoining beads, and improper joint design.

incomplete penetration

A discontinuity characterized by an unpenetrated and unfused area in a joint that

occurs when weld metal does not extend through the thickness of the joint.

Incomplete penetration can result from insufficient welding heat, improper joint

design, and improper lateral control of the welding arc.

internal stress

A force from within the material of an object that attempts to deform that object.

In a weldment, internal stress is caused by thermal expansion and contraction as

the weld metal cools and solidifies.

interpass temperature

A specific temperature range of the base material. The interpass temperature

should not fall below the preheat temperature.

longitudinal crack

A gap or break in the surface of a weld parallel to the weld axis that may be

along the centerline of the weld or near the weld toes. A longitudinal crack is

also called a centerline crack.

melt-through

The visible reinforcement of a weld root that happens when a joint is welded

from only one side.

non-destructive examination

The evaluation of a weld, or material to be welded, that does not affect the

servicability of the weld or material. Non-destructive examination costs less

because the part is not destroyed.

overlap

The protrusion of unfused weld metal beyond the weld toe or weld root. Overlap

is almost always unacceptable in a welded part.

part drawing

A document that includes the specifications for a part's production.

porosity

A discontinuity characterized by the appearance of tiny voids or bubbles on a

weld bead, resulting from trapped gases in a material. Excessive porosity can

weaken a weld.

preheat temperature

A specific temperature to which the base material is heated prior to welding.

root opening

The point at which fusion should occur between the weld metal and adjoining

weld beads. The root opening provides access to the root of a weld.

Vocabulary Term

Definition

root pass

The first layer of a multi-layer weld. The root pass is the most critical layer of a

weld because it is susceptible to slag inclusion and cracking.

slag inclusion

A discontinuity resulting from the mutual dissolution of flux and nonmetallic

impurities in some welding processes. Slag inclusion can affect the strength and

integrity of a weld in its final application.

specifications

The design parameters that set the limits of acceptable deviation for a part's

intended application. Specifications are also called specs.

specs

The design parameters that set the limits of acceptable deviation for a part's

intended application. Specs are also called specifications.

star cracks

A gap or break in the surface of a weld that occurs at the crater of a weld

because welding was improperly terminated. Star cracks are also called crater

cracks.

transverse crack

A gap or break in the surface of a weld perpendicular to the weld axis that may

be completely within the weld metal or may extend from the weld metal into the

base metal. Excess hydrogen, an excessively strong weld metal, and high levels

of residual stress result in transverse cracks.

underbead crack

A cold gap or break in the surface of a weld that forms in the heat-affected zone

of a base metal. Underbead cracks are also called heat affected zone cracks.

undercut

A groove melted into the base metal at the weld toe or weld root that is left

unfilled by weld metal. The groove concentrates stress on the weld, and could be

a defect if outside the part's tolerances.

underfill

The extension of a weld face or root surface of a groove weld below the adjacent

surface of the base metal. Underfill results from the failure of a welder to

completely fill the weld joint.

weld face

The exposed surface of a weld on the side from which the welding was done.

weld gage

A device that determines whether or not a weld is within specified tolerances.

Some weld gages are designed for specific weld types like the fillet weld gage.

weld root

The point at which the back of a weld intersects the surfaces of the base metal.

weld spatter

Small particles of nonmetallic material that are expelled during the fusion of the

weld and base metals. Weld spatter is considered a serious discontinuity if it

interferes with the servicability of the part or with an additional operation, like

painting.

weld toe

The point at which the weld face and the base metal meet. Weld toes can

experience cracking and undercut.

weldment

A welded joint.

S-ar putea să vă placă și

- Welding TerminologyDocument5 paginiWelding TerminologyKaruppiah ArunachalamÎncă nu există evaluări

- WeldingDocument41 paginiWeldinggigiphiÎncă nu există evaluări

- Definitions: I) /60v, Where V Voltage, I Amperage, V Weld Travel Speed (In./min.)Document2 paginiDefinitions: I) /60v, Where V Voltage, I Amperage, V Weld Travel Speed (In./min.)Michael JohnsonÎncă nu există evaluări

- Introduction To Oil Gas Drilling and Well OperationsDocument27 paginiIntroduction To Oil Gas Drilling and Well OperationsMohammed Safuvan KazhungilÎncă nu există evaluări

- Defects in WeldsDocument6 paginiDefects in WeldsSaran KumarÎncă nu există evaluări

- Figure 1: Groove Weld TerminologyDocument28 paginiFigure 1: Groove Weld TerminologyAmyÎncă nu există evaluări

- Welding Electrode ClassificationsDocument18 paginiWelding Electrode ClassificationsMansukh KahlonÎncă nu există evaluări

- Cracks in WeldsDocument19 paginiCracks in Weldsjesycuban100% (1)

- NDT Discontinuities - World of NDTDocument51 paginiNDT Discontinuities - World of NDTHòa NguyễnÎncă nu există evaluări

- Welding Imperfection and Material InspectionDocument62 paginiWelding Imperfection and Material Inspectionintfarha10Încă nu există evaluări

- IIW - Welding DefectsDocument31 paginiIIW - Welding Defectsvarundevil87Încă nu există evaluări

- Welding DefectsDocument15 paginiWelding DefectsAYUSH TRIVEDI100% (1)

- Forging Defects and Extrusion DefectDocument8 paginiForging Defects and Extrusion DefectVenkat KrishnaÎncă nu există evaluări

- Welding TolerancesDocument3 paginiWelding Tolerancessaeedsaeed31Încă nu există evaluări

- Types of Welding Defects PDFDocument12 paginiTypes of Welding Defects PDFDhiab Mohamed AliÎncă nu există evaluări

- Defects in MetallurgyDocument49 paginiDefects in Metallurgyraghavendrajoshi870% (1)

- Welding Defects: Defects May Occur Due To The Following ReasonsDocument5 paginiWelding Defects: Defects May Occur Due To The Following ReasonsRavi ShankarÎncă nu există evaluări

- Learning ObjectivesDocument19 paginiLearning Objectivesfred gallardoÎncă nu există evaluări

- Welding SeminarDocument18 paginiWelding SeminarJc Baril LlegueÎncă nu există evaluări

- Welding Defect: Hydrogen EmbrittlementDocument8 paginiWelding Defect: Hydrogen EmbrittlementShajin Mohammed ShamsudhinÎncă nu există evaluări

- AWS - Terms and DefinitionsDocument15 paginiAWS - Terms and DefinitionsHagen_of_TronjeÎncă nu există evaluări

- Weld Defects TrainingDocument77 paginiWeld Defects TrainingQC apollohx100% (1)

- Ultrasonic Testing HandbookDocument29 paginiUltrasonic Testing HandbookRafael HernandezÎncă nu există evaluări

- GougingDocument6 paginiGougingP Sandana NaraÎncă nu există evaluări

- Microstructure Study of Welded JointDocument17 paginiMicrostructure Study of Welded JointRatul Islam Antor100% (1)

- Fundamentals of Welding InspectionDocument53 paginiFundamentals of Welding InspectionIlyes kÎncă nu există evaluări

- DistortionDocument2 paginiDistortionmahendraÎncă nu există evaluări

- Visual Examination of Welds - Welds 3-14Document64 paginiVisual Examination of Welds - Welds 3-14carlos100% (1)

- Basic Types of Welded JointsDocument21 paginiBasic Types of Welded JointstranngÎncă nu există evaluări

- Welding Defects 1Document16 paginiWelding Defects 1Jaimes Patrick OvejasÎncă nu există evaluări

- Part-1, Basic Metallurgy of Fusion WeldsDocument29 paginiPart-1, Basic Metallurgy of Fusion WeldsTEJENDRA SINGH SINGHALÎncă nu există evaluări

- Welding Defects Types Causes and Remedies With PDF Amp QUIZZESDocument11 paginiWelding Defects Types Causes and Remedies With PDF Amp QUIZZESRAJESHÎncă nu există evaluări

- Welding DefectsDocument4 paginiWelding DefectsSidharth Kashyap BorthakurÎncă nu există evaluări

- Welding DefectsDocument13 paginiWelding DefectsVinay Kumar SharmaÎncă nu există evaluări

- Welding Defects: Their Causes and PreventionDocument18 paginiWelding Defects: Their Causes and PreventionsanjaykumarmauryaÎncă nu există evaluări

- Welding DefectsDocument38 paginiWelding Defectssajeev27100% (4)

- Requirme Assignment3Document4 paginiRequirme Assignment3Cyber RoseÎncă nu există evaluări

- Weld VocabDocument4 paginiWeld VocabRitwik SahooÎncă nu există evaluări

- WJM Technologies: Excellence in Material JoiningDocument5 paginiWJM Technologies: Excellence in Material Joiningarjun prajapatiÎncă nu există evaluări

- Welding DefectsDocument15 paginiWelding DefectsMohamed Al-OdatÎncă nu există evaluări

- KEMPPI Welding Technology Course: R.BanerjeeDocument78 paginiKEMPPI Welding Technology Course: R.BanerjeeAnoop KushwahaÎncă nu există evaluări

- Ultrasonic Testing HandbookDocument29 paginiUltrasonic Testing HandbookP A KumarÎncă nu există evaluări

- Welding GlossaryDocument6 paginiWelding GlossaryBurag HamparyanÎncă nu există evaluări

- Acceptable Weld ProfilesDocument14 paginiAcceptable Weld ProfilesMark Miano100% (1)

- Arc Welding NotesDocument9 paginiArc Welding Notespatrick kivutiÎncă nu există evaluări

- Weld Bead Exp MigDocument14 paginiWeld Bead Exp MigBhavyaGargÎncă nu există evaluări

- Field Welding Inspection ManualDocument40 paginiField Welding Inspection ManualrosennmÎncă nu există evaluări

- Residual StressDocument10 paginiResidual StressbalamuruganÎncă nu există evaluări

- Inherent: They Are Usually Related To Discontinuities Found in TheDocument10 paginiInherent: They Are Usually Related To Discontinuities Found in TheBhadresh PatelÎncă nu există evaluări

- Weld Joint DesignDocument2 paginiWeld Joint Designrahul063Încă nu există evaluări

- Welding DefectsDocument16 paginiWelding Defectstomas budrysÎncă nu există evaluări

- Welding Present A Ion 1Document87 paginiWelding Present A Ion 1Vishnu KumarÎncă nu există evaluări

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkDe la EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkÎncă nu există evaluări

- Tool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforDe la EverandTool-Steel - A Concise Handbook on Tool-Steel in General - Its Treatment in the Operations of Forging, Annealing, Hardening, Tempering and the Appliances ThereforÎncă nu există evaluări

- Soldering Electronic Components 2nd EditionDe la EverandSoldering Electronic Components 2nd EditionEvaluare: 3 din 5 stele3/5 (2)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesDe la EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesÎncă nu există evaluări

- The Value of Science in the Smithy and ForgeDe la EverandThe Value of Science in the Smithy and ForgeÎncă nu există evaluări

- MHWirth - Pile Top Drill Rigs - en (Brochure)Document12 paginiMHWirth - Pile Top Drill Rigs - en (Brochure)bdromeiraÎncă nu există evaluări

- More Classics. More: Multiflor 700Document15 paginiMore Classics. More: Multiflor 700bdromeiraÎncă nu există evaluări

- Soil Moisture MeasurementsDocument7 paginiSoil Moisture MeasurementsbdromeiraÎncă nu există evaluări

- Akai X 330 Service ManualDocument32 paginiAkai X 330 Service ManualbdromeiraÎncă nu există evaluări

- Hfe Akai X-330 330d SchematicsDocument2 paginiHfe Akai X-330 330d SchematicsbdromeiraÎncă nu există evaluări

- Intonation - The Trumpet Pedagogy ProjectDocument5 paginiIntonation - The Trumpet Pedagogy ProjectbdromeiraÎncă nu există evaluări

- Allegro Agreement TermsDocument296 paginiAllegro Agreement TermsbdromeiraÎncă nu există evaluări

- Ffi - Form - Guide - 2 - 4Document23 paginiFfi - Form - Guide - 2 - 4bdromeiraÎncă nu există evaluări

- List of Construction Trades - WikipediaDocument2 paginiList of Construction Trades - Wikipediabdromeira100% (1)

- Fast FKGDocument97 paginiFast FKGbdromeiraÎncă nu există evaluări

- Corsi FTA 2014 ENG Stampa-1Document16 paginiCorsi FTA 2014 ENG Stampa-1bdromeiraÎncă nu există evaluări

- Catálogo TEXSA Completo PDFDocument36 paginiCatálogo TEXSA Completo PDFbdromeiraÎncă nu există evaluări

- F 15CDocument8 paginiF 15CbdromeiraÎncă nu există evaluări

- Noise Control: Neighbourhood Noise Options To Reduce NoiseDocument4 paginiNoise Control: Neighbourhood Noise Options To Reduce NoisebdromeiraÎncă nu există evaluări

- Dubai-Ten Days Trekking TourDocument5 paginiDubai-Ten Days Trekking TourbdromeiraÎncă nu există evaluări

- Manual VHF Baofeng UV-5R PDFDocument74 paginiManual VHF Baofeng UV-5R PDFbdromeiraÎncă nu există evaluări

- CAPM Handbook4Document42 paginiCAPM Handbook4bdromeiraÎncă nu există evaluări

- Zero Energy Window DOE-FactSheetDocument2 paginiZero Energy Window DOE-FactSheetbdromeiraÎncă nu există evaluări

- Greek Alphabet: Al-Fah Bay-Tah Gam-Ah Del-Tah Ep-Si-Lon Zay-TahDocument1 paginăGreek Alphabet: Al-Fah Bay-Tah Gam-Ah Del-Tah Ep-Si-Lon Zay-TahbdromeiraÎncă nu există evaluări

- Ex# (7.1-7.5) Second Year StepDocument11 paginiEx# (7.1-7.5) Second Year StepAqeel AbbasÎncă nu există evaluări

- Expt Bevel ProtractorDocument3 paginiExpt Bevel ProtractorAnkan BeraÎncă nu există evaluări

- NL500, NL500G: Rotation LaserDocument32 paginiNL500, NL500G: Rotation LaserАлександр ПанкратовÎncă nu există evaluări

- A Review On Design and Flow Simulation in An Axial Flow Hydro TurbineDocument3 paginiA Review On Design and Flow Simulation in An Axial Flow Hydro TurbineAron H OcampoÎncă nu există evaluări

- (Maa 3.9) More Trigonometric FunctionsDocument18 pagini(Maa 3.9) More Trigonometric FunctionsAli GorganiÎncă nu există evaluări

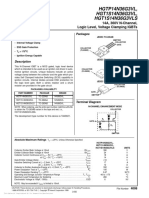

- Hgtp14N36G3Vl, Hgt1S14N36G3Vl, Hgt1S14N36G3Vls: 14A, 360V N-Channel, Logic Level, Voltage Clamping IgbtsDocument6 paginiHgtp14N36G3Vl, Hgt1S14N36G3Vl, Hgt1S14N36G3Vls: 14A, 360V N-Channel, Logic Level, Voltage Clamping IgbtsDeiry Katherine Marquez RamirezÎncă nu există evaluări

- Property SheetDocument6 paginiProperty SheetsivaÎncă nu există evaluări

- Ch.1 PacketDocument7 paginiCh.1 PacketClaire ShinÎncă nu există evaluări

- Hev - Chim.acta.200588523 545. DikonversiDocument24 paginiHev - Chim.acta.200588523 545. Dikonversiasmaul mashadÎncă nu există evaluări

- INTEGRAL VEKTOrDocument2 paginiINTEGRAL VEKTOrBaho Kristanti HutagalungÎncă nu există evaluări

- TJ-9000 - Trus Joist - Beams, Headers, and ColumnsDocument32 paginiTJ-9000 - Trus Joist - Beams, Headers, and ColumnsAdam GreenlawÎncă nu există evaluări

- 2 Conservation of Mass EnergyDocument30 pagini2 Conservation of Mass Energyvaughn santos100% (1)

- EMC 22 Electric Motor CheckerDocument1 paginăEMC 22 Electric Motor CheckerindustrialindiaÎncă nu există evaluări

- 14 - Evidence - For - A - Creator - 1Document34 pagini14 - Evidence - For - A - Creator - 1elinatheint.uumÎncă nu există evaluări

- U2 Activity4Document2 paginiU2 Activity4FELIX ROBERT VALENZUELAÎncă nu există evaluări

- Week 28 Spiral ReviewDocument2 paginiWeek 28 Spiral Reviewethan nguyenÎncă nu există evaluări

- Boyle's Law Hand-Out.Document3 paginiBoyle's Law Hand-Out.Rorisang MolotsiÎncă nu există evaluări

- Liners For Shaped Charges by Manfred Held (2001) PDFDocument1 paginăLiners For Shaped Charges by Manfred Held (2001) PDFMalikHodzicÎncă nu există evaluări

- الاستجابة الزلزالية للابنية الفولاذية العالية متضمنا تاثيرات تحليل الدرجة-الثانيةDocument11 paginiالاستجابة الزلزالية للابنية الفولاذية العالية متضمنا تاثيرات تحليل الدرجة-الثانيةmichelÎncă nu există evaluări

- Paginas WebDocument2 paginiPaginas Webesteban purillaÎncă nu există evaluări

- Topic 2 - MechanicsDocument104 paginiTopic 2 - MechanicsJunting HuÎncă nu există evaluări

- Circulation and Vorticity: Fluid RotationDocument22 paginiCirculation and Vorticity: Fluid RotationAristyo Rahadian WijayaÎncă nu există evaluări

- 2021 CAC CatalogueDocument100 pagini2021 CAC CatalogueRiyo SaputraÎncă nu există evaluări

- 5 Spheres and ConesDocument8 pagini5 Spheres and Conesstemtutor kakwongÎncă nu există evaluări

- Calero Caes Model Power SystemDocument13 paginiCalero Caes Model Power Systemzain ul AbideenÎncă nu există evaluări

- High Voltage Skywrap: Fiber Optic CableDocument1 paginăHigh Voltage Skywrap: Fiber Optic CableburvanovÎncă nu există evaluări

- Phase-Changes OriginalDocument4 paginiPhase-Changes Originalapi-293306937Încă nu există evaluări

- MID 082 - CID 0885 - FMI 05: TroubleshootingDocument4 paginiMID 082 - CID 0885 - FMI 05: TroubleshootingCory PurbaÎncă nu există evaluări

- Introduction To Electrical Engineering: Chapter 6: Parallel CircuitDocument19 paginiIntroduction To Electrical Engineering: Chapter 6: Parallel Circuitahnaf arnobÎncă nu există evaluări

- TFX02 Torque ChartDocument1 paginăTFX02 Torque ChartArnulfo SánchezÎncă nu există evaluări