Documente Academic

Documente Profesional

Documente Cultură

Saes H 102

Încărcat de

HaleemUrRashidBangashTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Saes H 102

Încărcat de

HaleemUrRashidBangashDrepturi de autor:

Formate disponibile

Engineering Standard

SAES-H-102

Safety Requirements for Coating Applications

24 October 2012

Document Responsibility: Paints and Coatings Standards Committee

Saudi Aramco DeskTop Standards

Table of Contents

1

Scope............................................................. 2

Conflicts and Deviations................................. 2

References..................................................... 2

Safety Requirements...................................... 3

Previous Issue: 11 August 2007 Next Planned Update: 24 October 2017

Revised paragraphs are indicated in the right margin

Primary contact: Manuel, Anthony Tiong on 966-3-8809560

CopyrightSaudi Aramco 2012. All rights reserved.

Page 1 of 11

Document Responsibility: Paints and Coatings Standards Committee

SAES-H-102

Issue Date: 24 October 2012

Next Planned Update: 24 October 2017

Safety Requirements for Coating Applications

Scope

This Standard prescribes the minimum mandatory safety requirements applicable during

shop or field coating applications for construction, maintenance, and/or coating

maintenance programs of Saudi Aramco industrial facilities and equipment. The content

of this standard is added to the main coating standards SAES-H-001, SAES-H-003, and

SAES-H-004.

Conflicts and Deviations

2.1

Any conflicts between this standard and other applicable Saudi Aramco

Engineering Standards (SAESs), Materials System Specifications (SAMSSs),

Standard Drawings (SASDs), or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the

Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2

Direct all requests to deviate from this standard in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the Manager, Consulting Services Department of

Saudi Aramco, Dhahran.

References

The selection of material and equipment, and the design, construction, maintenance, and

repair of equipment and facilities covered by this standard shall comply with the latest

edition of the references listed below, unless otherwise noted.

3.1

Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302

Instructions for Obtaining a Waiver of a Mandatory

Saudi Aramco Engineering Requirement

Saudi Aramco Engineering Standards

SAES-H-001

Coating Selection & Application Requirements for

Industrial Plants & Equipment

SAES-H-003

Protective Coatings for Industrial Concrete

Structures

SAES-H-004

Protective Coating Selection & Application

Requirements for Offshore Structures and

Facilities

Page 2 of 10

Document Responsibility: Paints and Coatings Standards Committee

SAES-H-102

Issue Date: 24 October 2012

Next Planned Update: 24 October 2017

Safety Requirements for Coating Applications

Saudi Aramco General Instructions

3.2

GI-0002.100

Work Permit System

GI-0006.021

Safety Requirements for Abrasive Blasting

Industry Codes and Standards

American Society of Mechanical Engineers

ASME SEC VIII D1

NEC Article 500

Unfired Pressure Vessels

Hazardous (Classified) Locations

Occupational Safety & Health Administration (OSHA) - Construction Industry

Safety & Health Standards

29 CFR 1926 U. S. Department of Labor, Chapter XVII, Section 1926.105

4

Safety Requirements

4.1

4.2

Fire and Explosion Prevention

4.1.1

Smoking and/or the use of open flames shall be permitted only in

designated safe areas and never inside vessels. Welding and the use of

heating coils are prohibited in areas where coating is in progress.

4.1.2

All electrical lighting, equipment, and connections shall conform to

National Electric Code, Class I, Division 1, Group D explosion proof

requirements (NEC Article 500).

4.1.3

Solvents and paints shall not be applied to surfaces warmer than 80C if

practical alternatives exist.

4.1.4

Work Permits for hot work, cold work, and confined space entry shall be

obtained in accordance with GI-0002.100.

Ventilation

4.2.1

Forced ventilation shall be used in confined spaces whenever abrasive

blasting, solvent cleaning, and/or painting are in progress.

4.2.1.1

Forced ventilation shall continue until the coating is fully cured

and ready for service.

4.2.1.2

Natural ventilation (through opened manholes, etc.) shall not

be substituted for forced ventilation in confined spaces.

Page 3 of 10

Document Responsibility: Paints and Coatings Standards Committee

SAES-H-102

Issue Date: 24 October 2012

Next Planned Update: 24 October 2017

Safety Requirements for Coating Applications

4.2.2

4.3

Ventilation shall ensure good air circulation with no dead air pockets in

the confined space.

4.2.2.1

The fresh air inlet shall be located near the top of the confined

space whenever practical.

4.2.2.2

The discharge opening shall be located near the bottom of the

confined space.

4.2.2.3

Supplementary fans shall be used if necessary to ensure

adequate air circulation in low spots or dead spaces.

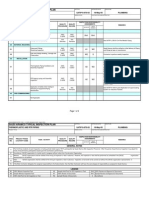

4.2.3

Ventilation requirements for various sizes of confined spaces are given

in Table 4-1.

4.2.4

Respirable air-fed hoods shall be worn by all personnel inside confined

spaces whenever:

4.2.4.1

Blasting or spray painting is in progress.

4.2.4.2

Solvent cleaning or brush painting is in progress in a confined

space having a volume of less than 16 m.

Health Hazards

4.3.1

If alkaline catalysts (such as used in many epoxy paints) come in contact

with the skin, they shall be immediately washed off with water to avoid

chemical burns.

4.3.2

The appropriate personnel protection equipment listed in Table 4-2 shall

be worn. In addition, safety belts and lines shall always be used by

personnel working from unguarded platforms or in confined spaces

where a manhole accessed by a ladder is the only exit.

4.3.3

Adequate washing facilities shall be readily available so that paints and

solvents splashed on the body or in the eyes can be immediately

removed.

4.3.4

Safety shoes and coveralls shall always be worn and safety hats shall be

worn as required by proponent organizations.

4.3.5

Air hoses shall not be used by personnel for cleaning or cooling

themselves.

4.3.6

Solvents shall not be used by personnel for washing up.

Page 4 of 10

Document Responsibility: Paints and Coatings Standards Committee

SAES-H-102

Issue Date: 24 October 2012

Next Planned Update: 24 October 2017

Safety Requirements for Coating Applications

4.3.7

4.4

Materials Safety Data Sheets for all coatings, solvents, and cleaners in

use shall be readily available on-site.

Equipment Hazards

4.4.1

4.4.2

Power tools

4.4.1.1

Electrically driven power tools shall be properly grounded to

prevent shock.

4.4.1.2

Power equipment shall be operated at the speeds recommended

by the manufacturer and shall have proper safety guards.

4.4.1.3

Hearing protection shall always be worn whenever chipping

guns or pneumatic hammers are in use.

4.4.1.4

Vessels such as air receivers that are used as a surge tank

between the compressor and the blasting pot shall be

manufactured and stamped in accordance with ASME SEC

VIII D1, Unfired Pressure Vessels. They shall be hydrotested

at a pressure as recommended by the vessel manufacturer at

ambient temperature using clean water. These vessels shall be

revalidated by hydrotesting at least annually and the test

certificates shall be submitted to the Saudi Aramco Inspector

for verification.

4.4.1.5

All pressure relief valves, gauges, and devices shall be tested

annually and tagged with the expiration date. The test

certificates shall be submitted to the Saudi Aramco Inspector

for verification.

4.4.1.6

All blasting and coating equipment and associated attachments

shall be adequately earthed to avoid electrostatic discharges.

Abrasive Blasting

4.4.2.1

Blasting shall be equipped with a remote control shut-off

"deadman".

4.4.2.2

The blast nozzle shall be electrically connected to an external

ground in order to prevent static electrical discharges or shocks

to operating personnel. Grounding wire shall be AWG-4 or

larger.

4.4.2.3

The blasting hose shall be the static dissipating type with

external couplings.

Page 5 of 10

Document Responsibility: Paints and Coatings Standards Committee

SAES-H-102

Issue Date: 24 October 2012

Next Planned Update: 24 October 2017

Safety Requirements for Coating Applications

4.4.3

4.4.2.4

Respirable air-fed abrasive blasting hoods and OSHAapproved in-line respirable air filters shall be utilized at all

times by abrasive blasting personnel.

4.4.2.5

Compressor hoses, air lines, and blast hoses shall be safety

wired at each coupling using proper safety pins.

4.4.2.6

Hearing protection shall be worn in confined spaces where

abrasive blasting is in progress.

Solvent Cleaning

Benzene, gasoline, carbon tetrachloride, and chlorinated hydrocarbons

with low threshold limit values (less than 20) shall not be used.

4.4.4

4.4.5

Paint Preparation and Equipment Cleaning

4.4.4.1

Coatings shall be mixed in an adequately ventilated area.

Use eye protection (goggles) and protective gloves.

4.4.4.2

Electrically driven power mixers shall be grounded.

4.4.4.3

Avoid splash or spillage during mixing. Clean spilled paints

immediately using proper cleaning solvent.

Airless Spray Paint Application

4.4.5.1

Airless spray guns shall never be pointed at anyone or at any

part of the body.

4.4.5.2

The tip guard shall always be in place on the airless gun while

spraying.

4.4.5.3

Leather gloves shall be worn by the operator whenever the

airless spray gun is in use.

4.4.5.4

The trigger safety catch shall be engaged whenever the airless

gun is left unattended.

4.4.5.5

Hoses, pumps, and accessories shall never be operated at

pressures exceeding their rated pressure. In no case shall the

working pressure in the paint line exceed 34.5 MPa (5000 psi).

Safety pressure relief valves shall be used on outbound side of

the pressure pump(s).

Page 6 of 10

Document Responsibility: Paints and Coatings Standards Committee

SAES-H-102

Issue Date: 24 October 2012

Next Planned Update: 24 October 2017

Safety Requirements for Coating Applications

4.4.5.6

The pump shall be shut down and the fluid pressure in the

system relieved before servicing or cleaning any components,

including clogged spray tips.

4.4.5.7

Hoses shall be grounded, anti-static type.

4.4.5.8

Airless spray equipment shall not be operated unless all

grounds (earths) are in place, connected, and in good condition.

Grounding wire shall be AWG-4 or larger.

4.4.5.9

Airless spray equipment shall not be operated if any of the

pressure system components is not in good condition.

4.4.5.10 Solvents shall not be flushed into containers that are hotter than

50C.

4.4.5.11 Emergency medical care shall be obtained immediately if any

high pressure fluid from the airless equipment penetrates the

skin. (High pressure fluid injection injuries can be extremely

serious, including the need for amputation).

24 October 2012

Revision Summary

Revised the "Next Planned Update". Reaffirmed the contents of the document, and reissued

with editorial revision to remove the committee members list and change the primary contact

person.

Page 7 of 10

Document Responsibility: Paints and Coatings Standards Committee

SAES-H-102

Issue Date: 24 October 2012

Next Planned Update: 24 October 2017

Safety Requirements for Coating Applications

Table 4-1 - Ventilation Requirements for Confined Spaces

Volume of Confined Area

Required Air Mover Capacity

BBL

L/s

cfm

16

100

472

1000

80

500

1180

2500

160

1000

2360

5000

800

5000

4720

10000

1600

10000

7080

15000

4000

25000

9440

20000

Page 8 of 10

Document Responsibility: Paints and Coatings Standards Committee

SAES-H-102

Issue Date: 24 October 2012

Next Planned Update: 24 October 2017

Safety Requirements for Coating Applications

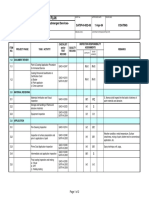

Table 4-2 - Personal Protective Equipment to be Worn

or Used During Surface Preparation & Paint Application

Key:

O

C

=

=

Outdoors

Confined Spaces

Type of Work to

be Performed

OSHA-Approved

Respirable

Airfed Hood

and Filter

21-444-934

21-443-500

O

Respirator;

Chemical

Cartridge

21-370-800

21-370-810

21-370-820

Face

Shield

(1)

21-426-121

21-426-125

21-426-142

Dust

Respirator

21-370-500

Surface Preparation

Wire Brushing,

Chipping, Scrapping

& Grinding

Sandblasting

- operator

- other workmen

X

X

Paint Removing

Solvent Cleaning

X

X

X

-----------------------------------------------------------------------------------------------------------------------------------------------------Brush Spray

Brush Spray

Brush Spray

Brush Spray

Paint Application

O C O C

O C O C

O C O C

O C O C

-----------------------------------------------------------------------------------------------------------------------------------------------------Epoxy and Coal\

Tar Epoxy

Alkyd

Inorganic Zinc

Chlorinated Rubber

X

X

X

X

Bituminous

X X

----------------------------------------------------------------------------------------------------------------------------------------------------Note: (1) Face shields shall always be used when working overhead.

Page 9 of 10

Document Responsibility: Paints and Coatings Standards Committee

SAES-H-102

Issue Date: 24 October 2012

Next Planned Update: 24 October 2017

Safety Requirements for Coating Applications

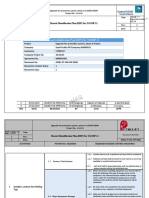

Table 4-2 - Personal Protective Equipment to be Worn

or Used During Surface Preparation & Paint Application (Cont'd)

Key:

O

C

=

=

Outdoors

Confined Spaces

Type of Work to

be Performed

Goggles

Safety Impact

21-434-249

O

C

Gloves;

Leather

21-432-353

O

C

Gloves;

Rubber

21-432-630

Hearing

Protection

21-327-100/105/110/272

O

C

Surface Preparation

Wire Brushing,

Chipping, Scrapping

& Grinding

Sandblasting

- operator

- other workmen

- in vicinity

X

X

Paint Removing

X

X

X

Solvent Cleaning

X

--------------------------------------------------------------------------------------------------------------------------------------------------Brush Spray

Paint Application

O C O C

ALL

--------------------------------------------------------------------------------------------------------------------------------------------------Epoxy and Coal\

Tar Epoxy

Alkyd

Inorganic Zinc

Chlorinated Rubber

Bituminous

Polyurethane

Page 10 of 10

S-ar putea să vă placă și

- Saes H 102Document10 paginiSaes H 102Kaleelur RahmanÎncă nu există evaluări

- Saes H 204Document34 paginiSaes H 204heartbreakkid132Încă nu există evaluări

- Method Statement For APCS-113A For Alloy Steel - Otc - Fbe-002Document7 paginiMethod Statement For APCS-113A For Alloy Steel - Otc - Fbe-002sharif339100% (2)

- Saes H 204Document33 paginiSaes H 204Rei Lizardo100% (1)

- Saes H 101V PDFDocument389 paginiSaes H 101V PDFQA QCÎncă nu există evaluări

- Saes H 101VDocument83 paginiSaes H 101Vacolombel100% (2)

- 09 Samss 060Document4 pagini09 Samss 060asimazami69Încă nu există evaluări

- SAIC-H-2032 Rev 7Document4 paginiSAIC-H-2032 Rev 7Satheesh Rama SamyÎncă nu există evaluări

- Aramco Painting SpecificationDocument6 paginiAramco Painting Specificationvicky100% (1)

- Materials System SpecificationDocument6 paginiMaterials System SpecificationAjeetKumarÎncă nu există evaluări

- Materials System SpecificationDocument7 paginiMaterials System Specificationaanouar77Încă nu există evaluări

- Saes H 004Document8 paginiSaes H 004kaleeswaran s100% (1)

- 09 SAMSS 089 (Final Draft - 2018)Document28 pagini09 SAMSS 089 (Final Draft - 2018)lhanx2Încă nu există evaluări

- Aramco Apcs 1bDocument55 paginiAramco Apcs 1bSadek Sad100% (2)

- Saep 1200Document9 paginiSaep 1200Anonymous 4IpmN7On100% (1)

- APCS DeatailsDocument3 paginiAPCS DeatailsnasirÎncă nu există evaluări

- SAES-Q-005 (Concrete Foundations)Document1 paginăSAES-Q-005 (Concrete Foundations)Nino Celso AstilleroÎncă nu există evaluări

- Saic H 2023Document2 paginiSaic H 2023Sivaratnam NavatharanÎncă nu există evaluări

- Saes H 201Document9 paginiSaes H 201heartbreakkid132Încă nu există evaluări

- Saes H 101Document77 paginiSaes H 101Henry Ocbina Luares100% (6)

- Saes B 006Document21 paginiSaes B 006Anonymous a4Jwz14W100% (2)

- SATIP H 002 08 Pipe Internal CoatingDocument3 paginiSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyÎncă nu există evaluări

- Saep 316Document20 paginiSaep 316brecht1980100% (18)

- SATR-H-2006 Rev 8Document3 paginiSATR-H-2006 Rev 8ravi ajith100% (1)

- Saes H 200Document9 paginiSaes H 200راجہ شہزاد انورÎncă nu există evaluări

- Saudi Aramco Typical Inspection PlanDocument10 paginiSaudi Aramco Typical Inspection PlanMoghal AliÎncă nu există evaluări

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 paginiSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliÎncă nu există evaluări

- SATIP S 070 03 ThermoplasticDocument2 paginiSATIP S 070 03 ThermoplasticMuhammad Farukh Manzoor100% (1)

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDocument2 paginiSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyÎncă nu există evaluări

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocument5 paginiTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcÎncă nu există evaluări

- 01 Samss 012 2014Document10 pagini01 Samss 012 2014lhanx2Încă nu există evaluări

- SAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersionDocument13 paginiSAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 VersiondanishÎncă nu există evaluări

- Saes Q 001 Saes-Q-006Document5 paginiSaes Q 001 Saes-Q-006Abdul Hannan100% (1)

- Saes-H-002 - ArmacoDocument29 paginiSaes-H-002 - ArmacoVenkat Gokila DT100% (1)

- Saudi Aramco Typical Inspection PlanDocument2 paginiSaudi Aramco Typical Inspection PlanMAZHARULÎncă nu există evaluări

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Document9 pagini09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- 01 Samss 031Document3 pagini01 Samss 031Awais CheemaÎncă nu există evaluări

- Saes A 114Document26 paginiSaes A 114abaanÎncă nu există evaluări

- APCS DeatailsDocument3 paginiAPCS DeatailsDandaman100% (3)

- Saes H 200 PDFDocument9 paginiSaes H 200 PDFSohail Aziz Ahmad Malik100% (1)

- SATIP H 002 08 Rev 4.unlockedDocument2 paginiSATIP H 002 08 Rev 4.unlockedMohamed Farhan B PositiveÎncă nu există evaluări

- Materials System SpecificationDocument7 paginiMaterials System SpecificationAjeetKumarÎncă nu există evaluări

- 175 000003Document1 pagină175 000003zhangÎncă nu există evaluări

- 09 Samss 101Document9 pagini09 Samss 101GOSP3 QC MechanicalÎncă nu există evaluări

- Ad 036821 001Document1 paginăAd 036821 001AmolÎncă nu există evaluări

- Saes N 100Document16 paginiSaes N 100aamirapiÎncă nu există evaluări

- Saic H 1003Document2 paginiSaic H 1003Hussain Nasser Al- NowiesserÎncă nu există evaluări

- 09 Samss 068Document7 pagini09 Samss 068AjeetKumarÎncă nu există evaluări

- Saep 316 2016 PDFDocument25 paginiSaep 316 2016 PDFAllan LindoÎncă nu există evaluări

- Schedule Q - Attachment VIDocument8 paginiSchedule Q - Attachment VISIVAÎncă nu există evaluări

- Satip M 100 07Document10 paginiSatip M 100 07munnaÎncă nu există evaluări

- SAES-Q-010 Cement Based, Non-Shrink GroutDocument8 paginiSAES-Q-010 Cement Based, Non-Shrink GroutWaqar AhmedÎncă nu există evaluări

- SAES-H-102-Safety Requirements For Coating Applications2Document12 paginiSAES-H-102-Safety Requirements For Coating Applications2محمد العيسوىÎncă nu există evaluări

- Internal Coatings For Vessels in Wet H2S Service-LCLDocument11 paginiInternal Coatings For Vessels in Wet H2S Service-LCLyusuf.yuzuakÎncă nu există evaluări

- SAEP-303: 2 Conflicts and DeviationsDocument19 paginiSAEP-303: 2 Conflicts and DeviationsnasirÎncă nu există evaluări

- Internal Coatings LCLDocument20 paginiInternal Coatings LCLyusuf.yuzuakÎncă nu există evaluări

- SAES-H-204Document32 paginiSAES-H-204anandml100% (1)

- Internal CoatingsEGDocument20 paginiInternal CoatingsEGyusuf.yuzuakÎncă nu există evaluări

- Internal Coatings For Vessels in Wet H2S Service-EGDocument11 paginiInternal Coatings For Vessels in Wet H2S Service-EGyusuf.yuzuakÎncă nu există evaluări

- Pa Painting SpecsDocument16 paginiPa Painting SpecsricÎncă nu există evaluări

- BI 10-02133, March 2020, Safety Statistics ReoportDocument3 paginiBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- BI 10-02133, March 23 2020, SAFETY STATISTICSDocument2 paginiBI 10-02133, March 23 2020, SAFETY STATISTICSHaleemUrRashidBangashÎncă nu există evaluări

- BI 10-02133, March 2020, Safety Statistics ReoportDocument3 paginiBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- BI 10-02133, WEEK 06, Safety Statistics Reoport NDocument1 paginăBI 10-02133, WEEK 06, Safety Statistics Reoport NHaleemUrRashidBangash100% (1)

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Document1 paginăBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashÎncă nu există evaluări

- Branch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020Document1 paginăBranch of Egyptian Projects Co.: Monthly Safety Statistics For: Jan, 2020HaleemUrRashidBangashÎncă nu există evaluări

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 paginiHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashÎncă nu există evaluări

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pagini5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- BI 10-02133, March 2020, Safety Statistics ReoportDocument3 paginiBI 10-02133, March 2020, Safety Statistics ReoportHaleemUrRashidBangash100% (2)

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 paginiHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashÎncă nu există evaluări

- 20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020Document27 pagini20) Hazard Identification Plan (HIP) For UGOSP-11 29-01-2020HaleemUrRashidBangash100% (2)

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pagini4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- 01 Safety Statistics by Haleem Ur Rashid, BI 10-02185Document3 pagini01 Safety Statistics by Haleem Ur Rashid, BI 10-02185HaleemUrRashidBangashÎncă nu există evaluări

- Hazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 paginiHazard Identification Plan (Hip) For Adgosp-2: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashÎncă nu există evaluări

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pagini9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- 13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020Document31 pagini13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocument31 paginiHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashÎncă nu există evaluări

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pagini9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- Hazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.Document27 paginiHazard Identification Plan (Hip) For Adgosp-1: Upgrade Fire Protection System, Phase Ii at Saoo Gosps Project No.HaleemUrRashidBangashÎncă nu există evaluări

- 13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020Document31 pagini13) Hazard Identification Plan (HIP) For ABGOSP-3 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pagini9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pagini9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pagini5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- 14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020Document31 pagini14) Hazard Identification Plan (HIP) For UGOSP-9 29-01-2020HaleemUrRashidBangash100% (1)

- 11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020Document36 pagini11) Hazard Identification Plan (HIP) For SHGOSP-5 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- 5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020Document36 pagini5) Hazard Identification Plan (HIP) For SHGOSP-2 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pagini4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- Hazard Identification Plan (HIP) Rev 01 For SAOO GOSPsDocument31 paginiHazard Identification Plan (HIP) Rev 01 For SAOO GOSPsHaleemUrRashidBangashÎncă nu există evaluări

- 9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020Document36 pagini9) Hazard Identification Plan (HIP) For ABGOSP-5 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- 4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020Document36 pagini4) Hazard Identification Plan (HIP) For ADGOSP-6 29-01-2020HaleemUrRashidBangashÎncă nu există evaluări

- Fore3 ManualDocument48 paginiFore3 ManualMARIA FE GETALLAÎncă nu există evaluări

- E - 2 - Effect of Casting Shape and Size On Solidification TimeDocument6 paginiE - 2 - Effect of Casting Shape and Size On Solidification Timeoğuz kağanÎncă nu există evaluări

- A Tribological Study of Synchronizing Devices UsedDocument7 paginiA Tribological Study of Synchronizing Devices UsedthisisjineshÎncă nu există evaluări

- Structure of Atoms-11th Cbse Text AnswersDocument33 paginiStructure of Atoms-11th Cbse Text AnswersKalai VananÎncă nu există evaluări

- 531 (1999) T. R. Golub: Science Et AlDocument8 pagini531 (1999) T. R. Golub: Science Et AlBair PuigÎncă nu există evaluări

- Unit 5.12 PrecipitationDocument16 paginiUnit 5.12 PrecipitationMutale InongeÎncă nu există evaluări

- CentrifugationDocument43 paginiCentrifugationSudeeksha RavikotiÎncă nu există evaluări

- CH 2 Chemical Bonding ICSE Solutions Class 10 ChemistryDocument18 paginiCH 2 Chemical Bonding ICSE Solutions Class 10 ChemistrylionelkenethÎncă nu există evaluări

- Agricultural Control Chemicals (1950)Document277 paginiAgricultural Control Chemicals (1950)Sveti JeronimÎncă nu există evaluări

- Cut Diet Lean MassDocument62 paginiCut Diet Lean Masspakzeeshan167% (3)

- Green Glue Material Safety DataDocument4 paginiGreen Glue Material Safety DatawilldoyeahÎncă nu există evaluări

- Iisc PHD Thesis FormatDocument4 paginiIisc PHD Thesis Formatmichelelataseattle100% (2)

- Auditor or ManagerDocument7 paginiAuditor or Managerapi-79118648Încă nu există evaluări

- Fibc Type A B C D Classification SafetyDocument2 paginiFibc Type A B C D Classification Safetydhineshbabu rÎncă nu există evaluări

- Mixture RequirementsDocument11 paginiMixture Requirementsrajesh0% (1)

- Electrozincados en 10152 (2009)Document18 paginiElectrozincados en 10152 (2009)joaopedrosousaÎncă nu există evaluări

- Principles of Crop Growth Simulation ModellingDocument57 paginiPrinciples of Crop Growth Simulation ModellingManuel P. Marcaida IIIÎncă nu există evaluări

- HEPA Cleanroom Filter Testing PDFDocument4 paginiHEPA Cleanroom Filter Testing PDFprovaoralÎncă nu există evaluări

- Experiment A Test For Lipid Result: Result When Added To WaterDocument5 paginiExperiment A Test For Lipid Result: Result When Added To WaterSuu Wan0% (2)

- Chemical Composition and Some Functional Properties of Soluble Fibro-Protein Extracts From Tunisian Date Palm SeedsDocument12 paginiChemical Composition and Some Functional Properties of Soluble Fibro-Protein Extracts From Tunisian Date Palm SeedsSakline MinarÎncă nu există evaluări

- Dissolution TestDocument5 paginiDissolution TestAlecza Mae SavellaÎncă nu există evaluări

- Publication PDFDocument80 paginiPublication PDFakshatjain3001Încă nu există evaluări

- Manual Overlay WeldingDocument8 paginiManual Overlay Weldingcarlmac6183% (6)

- Complete Practical DistillingDocument254 paginiComplete Practical DistillingMR X100% (5)

- Completions and WorkoverDocument309 paginiCompletions and WorkoverFan Jack67% (3)

- Nafees Nastaleeq v1.02Document2 paginiNafees Nastaleeq v1.02latifshaikh20Încă nu există evaluări

- 5 Minute Guide Electricity StorageDocument17 pagini5 Minute Guide Electricity StorageCarlos HolguinÎncă nu există evaluări

- Waterborne Acrylic Primer Nacorr Synergy With Halox SZP-391: Formulation Ci-101Document2 paginiWaterborne Acrylic Primer Nacorr Synergy With Halox SZP-391: Formulation Ci-101Swapnil AlandÎncă nu există evaluări

- Assignment 07 ADocument3 paginiAssignment 07 AsundusÎncă nu există evaluări

- Yanmar BulletinsDocument10 paginiYanmar BulletinsBill Carter100% (2)