Documente Academic

Documente Profesional

Documente Cultură

Atlas Copco DIAMEC: 262 Skid Version

Încărcat de

EVCYTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Atlas Copco DIAMEC: 262 Skid Version

Încărcat de

EVCYDrepturi de autor:

Formate disponibile

Atlas Copco DIAMEC 262 Skid version

DIAMEC 262

Core drilling rig for surface and underground operations

For wireline AN and conventional 46131 mm

DIAMEC 262

ME

262

DIA

Fig. 1

3 260 mm (128 in.)

Fig. 2

Fig. 3

Safe and fast rod handling. Automatic

synchronisation between chuck and rod holder.

A choice of three rotation units to ensure

optimal torque and speed.

Easy to convert from one to the other. Easy to

adapt for different diameters and geological

conditions.

Simple and reliable chuck. Very few moving

parts, widely adjustable gripping force, easy to

service. 76 mm (N-size) core barrels pass through

the chuck spindle, 131 mm core barrels through

the rod holder.

Double feed cylinders. For quick rod

handling at all depths. Can be set for slow feed,

high force (two active cylinders) or high

speed, low force (one active cylinder).

Drill in any direction (See Fig. 1,2,3 and 4)

Standard equipment includes a manually

operated turntable and worm gear. For easy

positioning an optional hydraulic powered worm

gear is available. Strongly recommended when the

drill rig is fitted with feed version 3300.

640 mm (25 in.)

Seven Benefits to Improve your

Drilling Effectiveness

Fig. 4

Simple, robust power unit with a double

hydraulic pump. Double pump permits

independent regulation of feed and rotation.

Equipped with a power take-off for driving a flush

pump. Easy access for maintenance.

Optional rod rack with stand

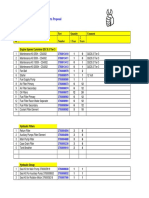

DIAMEC 262 SKID SPECIFICATIONS

Choose from three different stroke lengths

Drilling Capacity Guide

Three different stroke lengths are available, 850, 1800 and 3300

mm. The feed movement is achieved by two hydraulic cylinders

and chain system.

It is possible to select between high speed/low force or slow

speed/high force by activating one or both feed cylinders.

Data, feed version

Feed length

Feed retraction (A)

850

1800

3300

2 120 mm

83.5 in.

2 920 mm

115 in.

4 420 mm

174 in.

850 mm

33.4 in.

1 800 mm

70.9 in.

3 300 mm

130.0 in.

Drill rod size

ling

depth

Approx. dril-

43 Alu

53 Alu

43 Compolite

53 Compolite

AWJ 43

BWJ 53

NW 70

AK (AQ)

AGM (AQTK)

BK (BQ)

BGM

1 000

800

900

700

900

650

400

700

700

550

650

m

m

m

m

m

m

m

m

m

m

m

3

2

2

2

2

2

1

2

2

1

2

300

650

980

320

980

150

330

320

320

820

150

ft

ft

ft

ft

ft

ft

ft

ft

ft

ft

ft

Due to highly variable drilling conditions, the above

capacities should be considered simply as guidelines.

DIAMEC 262

A

A

Feed force

65 kN

14 300 lbf

65 kN

14 300 lbf

65 kN

14 300 lbf

Pull force

65 kN

14 300 lbf

65 kN

14 300 lbf

65 kN

14 300 lbf

Rod running speed

low speed

high speed

Torque - Rev/min relationship

Nm

2000

1800

0.5 m/s

1.65 ft/s

1.0 m/s

3.3 ft/s

0.5 m/s

1.65 ft/s

1.0 m/s

3.3 ft/s

0.5 m/s

1.65 ft/s

1.0 m/s

3.3 ft/s

1600

1400

1200

0-600 rpm

1000

800

600

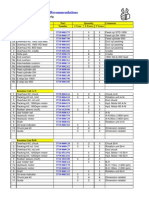

A choice of three Rotation units

400

Consists of a hydraulic motor, a gear box, a hollow spindle and

an Atlas Copco patented hydraulic chuck.

Rotation is transmitted via the gear box to the chuck that, by

hydraulic pressure, grips and rotates the drill rod.

200

11

13

rpm (x100)

15

17

19

21 22

17

19

21 22

17

19

21 22

0-600 Rev/min

The chuck and the rod holder are synchronized by an integral

sequential logic system for safe and easy rod handling.

The rotation unit can easily be swung aside for off-hole

clearance. Rotation speed and axial holding force of the chuck

are adjustable from the control panel. Easy conversion between

Standard > High torque > Heavy duty rotation units.

Nm

2000

1400

Rotation characteristics

Standard

1200

High torque

Heavy duty

1000

800

Speed range

low gear

0-2 200 rev/min 0-900 rev/min

0-1 700 rev/min

Spindle inner

0-600 rev/min

78 mm

3.07 in.

78 mm

3.07 in.

78 mm

3.07 in.

100 kN

22 000 lbf

100 kN

22 000 lbf

100 kN

22 000 lbf

700 Nm

510 lbf.ft

1 350 Nm

990 lbf.ft

2 000 Nm

1 475 lbf.ft

0-900 rpm

600

400

200

Chuck axial holding force

Maximal torque

11

13

rpm (x100)

15

0-900 Rev/min

Nm

A reliable easy-to-operate Rod holder

Rod holder of hydraulic mechanical type. Holding force is achieved by a spring set and is released by hydraulic pressure.

400

0-2200 rpm

200

Data

Maximal rod size

Bore without jaws

Axial Holding force

with TC inserts

2000

600

114 mm (4.5 in.)

132 mm (5.2 in.)

22 kN (4 840 lbf)

33 kN (7 260 lbf)

11

13

rpm (x100)

15

0-2 200 Rev/min

DIAMEC 262 SKID SPECIFICATIONS

Power units 45E and 40DT with double hydraulic pump

The power unit has two variable-flow hydraulic pumps, mounted in tandem. They are integrated in the hydraulic

system in such way as to adjust their output to the power requirements of the drill unit in a most efficient way.

Connections for an optional hydraulic driven flush pump are standard. Supplied complete with 70 litre oil tank, oil

cooler and filters.

The electrical power unit 45E is powered by an asynchronous electric motor, and the diesel power unit 40DT with a

Deutz turbo diesel, type BF4L 913.

Power unit 45E

Power unit 40DT

Motor rating

45 kW (61 hp) at 1450 rpm

68 kW (92 hp) at 2200 rpm

Main pump

flow

pressure

75 l/min (19.8 US gpm)

260 bar (3770 psi)

75 l/min (19.8 US gpm)

260 bar (3770 psi)

Service pump

flow

pressure

29 l/min (7.4 US gpm)

210 bar (3045 psi)

44 l/min (11.5 US gpm)

210 bar (3045 psi)

Weights - Power units

615 kg (1353 lb)

810 kg (1782 lb)

1 600 (63)

1 850 (72.8)

595 (23.4)

2 020 (79.5)

975 (38.4)

2 190 (86.2)

890 (35)

40 DT

1 110 (43.7)

1 380 (54.3)

45 E

820 (33)

1 260 (49.6)

Measurements in mm (in.)

800 (31.5)

975 (38.4)

2 700 (106.3)

Version

850

1800

3300

Drill unit**

1 040 kg (2 280 lb) 1 090 kg (2 400 lb) 1 170 kg (2 570 lb)

Control panel

170 kg (374 lb)

170 kg (374 lb)

170 kg (374 lb)

1 260 (49.6)

Weights in kg (lb) - Drill unit

** Incl. Control panel

350 (13.8)

510 (20)

890 (35)

DIAMEC 262

800 (31.5)

850 (33.4), 1 800 (70.9), 3 300 (130)

DIAMEC

DIAMEC

262

650 (25.6)

262

1 240 (48.8)

2 120 (83.5), 2 920 (115), 4 420 (174)

800 (31.5)

400 (15.7)

3 000 (118.1)

2 350 (92.5)

DIAMEC 262 SKID OPTIONS

1. Flush pump alternatives Flow

Pressure

TRIDO 45 H . . . . . . . . . . . . . 45 l/min (12 US gpm) 45 bar (643 psi)

TRIDO 80 H . . . . . . . . . . . . . 70 l/min (19 US gpm) 40 bar (571 psi)

A Repro Original AB, 97-09

TRIDO 140 H . . . . . . . . . . . 135 l/min (36 US gpm) 35 bar (428 psi)

2. Two Wireline hoists meet all drilling needs

WL-300/425 m (A) drum capacity of 6 mm and 5 mm wire diameter respectively (1 000 / 1 400 ft of 0.25 in. / 0.19 in.) mounted

underneath the feed frame.

2A

pull force

-minimum (full drum) . . . . . . . . . . . . . . . . . . . . 3 400 N (765 lbf)

-maximum (empty drum) . . . . . . . . . . . . . . . 5 800 N (1 305 lbf)

hoisting speed

-minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.0 m/min (9.9 ft/s)

-maximum . . . . . . . . . . . . . . . . . . . . . . . . . . 5.0 m/min (16.5 ft/s)

WL-800 m (B) drum capacity of 5 mm wire diameter (2 600 ft of

0.19 in) with a wire levelling device, mounted underneath the feed

frame.

2B

pull force

-minimum (full drum) 3200 N (720 lbf)

-maximum (empty drum) . . . . . . . . . . . . . . . 7 400 N (1 665 lbf)

hoisting speed

-minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 m/min (7.2 ft/s)

-maximum . . . . . . . . . . . . . . . . . . . . . . . . . . 5.0 m/min (16.5 ft/s)

3. The right Tools for the Job

Diatest set (3A), for testing and adjusting the hydraulic system

Field kit

Replacing

Instructions

Tool set (3B), with tools for service.

Field kit (3C) with replacing instructions.

3B

3A

3C

4. Adjustable Mast ensures effective drilling

The mast mounts on top of the feed frame. It extends from

3.5 metres (11 ft) up to 7 metres (23 ft).

4

5. Optinal Feed extension gives another 5 metres (16 ft)

To increase the total length of the feed frame by maximum

5 metres (16 ft).

6. Easy positioning with Hydraulic worm gear

Atlas Copco reserves the right to make modifications without prior notice.

6991 0779 01

Strongly recommended when the drill rig is fitted with 3300 feed frame.

S-ar putea să vă placă și

- Tiempo Geologico PDFDocument2 paginiTiempo Geologico PDFRoy SupaÎncă nu există evaluări

- Diamec U4Document2 paginiDiamec U4geovanny_ort100% (1)

- Trido 80 ATLAS COPCODocument31 paginiTrido 80 ATLAS COPCOAlexis ValleÎncă nu există evaluări

- 6991 1820 01 - Diamec Smart 8 Technical Specification - EnglishDocument8 pagini6991 1820 01 - Diamec Smart 8 Technical Specification - EnglishPABLOÎncă nu există evaluări

- Drilling Depth Guidelines: Fluid Filled Metric U.S. Drill Rod/Core Barrel Hole Depth (Meters) Hole Depth (Feet)Document10 paginiDrilling Depth Guidelines: Fluid Filled Metric U.S. Drill Rod/Core Barrel Hole Depth (Meters) Hole Depth (Feet)Peter Leano100% (1)

- 6991 1131 01b 262 Service KitsDocument74 pagini6991 1131 01b 262 Service KitsJuan Camilo EspitiaÎncă nu există evaluări

- Cs 14Document4 paginiCs 14mhasansharifi100% (1)

- V80703 Detroit Diesel Series 40 Parts CatalogueDocument61 paginiV80703 Detroit Diesel Series 40 Parts CatalogueNeilÎncă nu există evaluări

- 140-03780 Rev B Rotation Unit lx16Document15 pagini140-03780 Rev B Rotation Unit lx16cristopher romero100% (3)

- CS 1000Document2 paginiCS 1000Villa Lau67% (3)

- Epiroc DB40-80 Light Spec Brochure A4 - LoRes - Spreads PDFDocument7 paginiEpiroc DB40-80 Light Spec Brochure A4 - LoRes - Spreads PDFDavid MartinezÎncă nu există evaluări

- 4 CS14 SpecificationsDocument2 pagini4 CS14 SpecificationsY.Ebadi100% (1)

- CS4002 U-Deck Recommended SparesDocument5 paginiCS4002 U-Deck Recommended SparesedwinÎncă nu există evaluări

- CS 3001 Marketing PresentationDocument15 paginiCS 3001 Marketing PresentationJailson Dantas100% (1)

- Christensen 140: Surface Core Drilling RigDocument12 paginiChristensen 140: Surface Core Drilling RigAriel100% (2)

- Cyclone Operating SystemDocument7 paginiCyclone Operating SystemShuriqqÎncă nu există evaluări

- 6991 1274 01a APCDocument15 pagini6991 1274 01a APCpeter_157608700Încă nu există evaluări

- B-20 Underground Codigos ManualDocument79 paginiB-20 Underground Codigos ManualAnibal Guajardo (O'Ryan)Încă nu există evaluări

- HYDX-6 Specifications in EnglishDocument4 paginiHYDX-6 Specifications in Englishcototo33Încă nu există evaluări

- DS311 8 - 3040-ADocument4 paginiDS311 8 - 3040-AsanamehÎncă nu există evaluări

- T685WS11 05Document2 paginiT685WS11 05govindsr0% (1)

- CS1000 - CatalogoDocument199 paginiCS1000 - CatalogoVinicius FelipeÎncă nu există evaluări

- Dd01 À Dd04 Spec Cs14 & Cs1000Document3 paginiDd01 À Dd04 Spec Cs14 & Cs1000Philippe DumontÎncă nu există evaluări

- SCH 5000Document2 paginiSCH 5000Anonymous xxFArUCS100% (3)

- 90 400 - Funk X SpecDocument3 pagini90 400 - Funk X SpecMATTHEWS HENRIQUE COTA ARAUJOÎncă nu există evaluări

- Atlas Copco Blasthole Drills Dm45-SeriesDocument4 paginiAtlas Copco Blasthole Drills Dm45-SeriesfelipeÎncă nu există evaluări

- Diamec U6 Spare PartDocument3 paginiDiamec U6 Spare PartJairo Boechat JuniorÎncă nu există evaluări

- 2 CS1000P6 SpecificationsDocument2 pagini2 CS1000P6 SpecificationsHerabrabe HsbÎncă nu există evaluări

- SCOUT 700: Technical DescriptionDocument4 paginiSCOUT 700: Technical DescriptionGerko Berrios GarcíaÎncă nu există evaluări

- Cubex Mining Products 2006Document10 paginiCubex Mining Products 2006Diogo Cordova100% (1)

- Sandvik Du311-Tk Underground Drill: Technical SpecificationDocument4 paginiSandvik Du311-Tk Underground Drill: Technical SpecificationGabriel Ulloa100% (2)

- T3WDocument4 paginiT3WDam100% (1)

- 3344 f2440Document4 pagini3344 f2440Darwin AjomadoÎncă nu există evaluări

- 6991 5084 62e - Diamec U6 PHCDocument260 pagini6991 5084 62e - Diamec U6 PHCRıfat Bingül0% (1)

- List of Proposed Spare Parts - Boyles C5CDocument8 paginiList of Proposed Spare Parts - Boyles C5CRafael Castillo LimachiÎncă nu există evaluări

- DTH Drill StringsDocument16 paginiDTH Drill StringsCarlos RegalizaÎncă nu există evaluări

- F125 8009 Hydraulic Diagram RigDocument1 paginăF125 8009 Hydraulic Diagram RigmcprevencionchileÎncă nu există evaluări

- Christensen CS3001 Truck Mounted Core DrillDocument2 paginiChristensen CS3001 Truck Mounted Core DrillJulio Jesus Quijano VargasÎncă nu există evaluări

- Th60dh WW CycloneDocument12 paginiTh60dh WW CycloneWILY EBER VIDAL RUIZÎncă nu există evaluări

- Service News: DIAMEC 232 - Spare Parts ListDocument2 paginiService News: DIAMEC 232 - Spare Parts Listorlando chullo llave100% (1)

- 6991 5005 01 DIAMEC 232 ManualDocument76 pagini6991 5005 01 DIAMEC 232 ManualОлег100% (1)

- Atlas 9851 3497 01 - LDocument4 paginiAtlas 9851 3497 01 - LYiğit ErpakÎncă nu există evaluări

- CT20 2010-11-05 SOI Red File SizeDocument62 paginiCT20 2010-11-05 SOI Red File Sizegustavo caicedo100% (2)

- Spare Part ListDocument645 paginiSpare Part ListJose luis VargasÎncă nu există evaluări

- TSNB - SDE Installation CT20Document9 paginiTSNB - SDE Installation CT20Jose luis VargasÎncă nu există evaluări

- LM Chuck Cylinder - Jaws MK2 - UpgradeDocument7 paginiLM Chuck Cylinder - Jaws MK2 - UpgradeOrlandoÎncă nu există evaluări

- Sandvik Hl1560T Hydraulic Rock Drill: Technical SpecificationDocument2 paginiSandvik Hl1560T Hydraulic Rock Drill: Technical SpecificationBerat HasolliÎncă nu există evaluări

- CT20 Performace Specifications - v0.1Document2 paginiCT20 Performace Specifications - v0.1gustavo caicedoÎncă nu există evaluări

- CatalogoDocument5 paginiCatalogoDiego Alonso Velez Villegas0% (1)

- Stop e MasterDocument0 paginiStop e MasterAngels Córdova AlegríaÎncă nu există evaluări

- Pit Viper 235 High Resolution US Tcm1241-3515574Document4 paginiPit Viper 235 High Resolution US Tcm1241-3515574Mackarena Isabel Santander Alegre100% (1)

- Atlas Copco Service & Maintenance InstructionsDocument20 paginiAtlas Copco Service & Maintenance Instructionsaaron alicanoÎncă nu există evaluări

- CS4002 U-Deck Recommended Spare Parts ListDocument4 paginiCS4002 U-Deck Recommended Spare Parts ListRuben Segovia SegoviaÎncă nu există evaluări

- Sandvik DL430Document2 paginiSandvik DL430Nelson MezaÎncă nu există evaluări

- D75KS Commission PDFDocument96 paginiD75KS Commission PDFtommy lanyon100% (1)

- Diamec 262 Crawler Underground Electric 6991 0777 01Document4 paginiDiamec 262 Crawler Underground Electric 6991 0777 01gemin0204100% (1)

- Top Drive Data SheetDocument11 paginiTop Drive Data SheetWagner Ramos100% (1)

- Dredger SpecificationsDocument8 paginiDredger SpecificationsSherin Shihabudeen100% (2)

- lm75 SpecDocument4 paginilm75 SpecheberÎncă nu există evaluări

- Aehq7680 04Document4 paginiAehq7680 04EVCYÎncă nu există evaluări

- Performance Report: Cat 6050 FS and 6060 FS at La Herradura Gold Mine (Sonora, Mexico)Document24 paginiPerformance Report: Cat 6050 FS and 6060 FS at La Herradura Gold Mine (Sonora, Mexico)EVCY100% (1)

- Effect of Bulk Modulus On Performance of A HydrostDocument15 paginiEffect of Bulk Modulus On Performance of A HydrostEVCYÎncă nu există evaluări

- CAT Product LineDocument16 paginiCAT Product LineKas Kasanova100% (1)

- Kenr5710kenr5710-05 SisDocument15 paginiKenr5710kenr5710-05 SisEVCY100% (1)

- 600AJDocument1 pagină600AJEVCYÎncă nu există evaluări

- STX.8 Circuit DiagramDocument12 paginiSTX.8 Circuit DiagramEVCYÎncă nu există evaluări

- t45 Atlas CopcoDocument4 paginit45 Atlas CopcoEVCYÎncă nu există evaluări

- 80HX Series: Telescopic Boom LiftsDocument2 pagini80HX Series: Telescopic Boom LiftsRavi RathodÎncă nu există evaluări

- DX 700Document16 paginiDX 700EVCY100% (2)

- Trakker E4Document74 paginiTrakker E4EVCYÎncă nu există evaluări

- D8T and D9T Track-Type Tractors Event Code ListDocument5 paginiD8T and D9T Track-Type Tractors Event Code ListEVCYÎncă nu există evaluări

- Pipelayer: Engine Weights Lift CapacityDocument16 paginiPipelayer: Engine Weights Lift CapacityEVCYÎncă nu există evaluări

- Powershift SpecificationsDocument3 paginiPowershift SpecificationsEVCY0% (1)

- Capacities (Refill) : CP56B, CP68B, CP74B, CS56B, CS68B, CS74B, CS78B and CS79B Vibratory Soil CompactorsDocument2 paginiCapacities (Refill) : CP56B, CP68B, CP74B, CS56B, CS68B, CS74B, CS78B and CS79B Vibratory Soil CompactorsEVCYÎncă nu există evaluări

- Msds en Shell Spirax s4 CX 50Document9 paginiMsds en Shell Spirax s4 CX 50EVCYÎncă nu există evaluări

- StartDocument1 paginăStartEVCYÎncă nu există evaluări

- Subaru Generators Commercial Sgx3500 Sgx5000 Sgx7500e ServiceDocument46 paginiSubaru Generators Commercial Sgx3500 Sgx5000 Sgx7500e ServiceEVCY100% (2)

- Catalogo XAS300 DDDocument2 paginiCatalogo XAS300 DDEVCYÎncă nu există evaluări

- c7 Engine Electrical Renr7933renr7933 03 - SisDocument12 paginic7 Engine Electrical Renr7933renr7933 03 - SisEVCY100% (2)

- ROCD5D7Document4 paginiROCD5D7EVCYÎncă nu există evaluări

- Roc 442PC PDFDocument4 paginiRoc 442PC PDFEVCYÎncă nu există evaluări

- Spec ST710 - 9851 2256 01Document4 paginiSpec ST710 - 9851 2256 01EVCYÎncă nu există evaluări

- TesmacDocument44 paginiTesmacJianJianti0% (1)

- Product Data: Castrol Transmax TQ 95Document3 paginiProduct Data: Castrol Transmax TQ 95Bruceli CWBÎncă nu există evaluări

- Dominator 106-96 BroszuraDocument11 paginiDominator 106-96 BroszuraKrzysiek UrynowiczÎncă nu există evaluări

- Cat FiltersDocument168 paginiCat Filterskiko100% (1)

- Ddrive Transmission ReportDocument43 paginiDdrive Transmission Reportelah150% (2)

- Volvo Trucks MID Fault CodeDocument1 paginăVolvo Trucks MID Fault CodeJan Svein HammerÎncă nu există evaluări

- Liebherr 954Document265 paginiLiebherr 954sebastianÎncă nu există evaluări

- 27 StabilizerDocument32 pagini27 StabilizerTarik Benzineb100% (1)

- Overview of Rolling Stock - SiddharthDocument57 paginiOverview of Rolling Stock - SiddharthGaurav MullickÎncă nu există evaluări

- 09e 1Document24 pagini09e 1ruslan1580100% (1)

- Iseki TLE BrochureDocument8 paginiIseki TLE BrochureTomas MigilinskasÎncă nu există evaluări

- TM 9-752 M10Document448 paginiTM 9-752 M10Advocate100% (2)

- Passat Car To KitDocument3 paginiPassat Car To KitmehrudinÎncă nu există evaluări

- GF4EATDocument112 paginiGF4EATVENDA DE PEÇAS CAMBIOÎncă nu există evaluări

- Drivetrain BrochureDocument12 paginiDrivetrain BrochureWidodo MuisÎncă nu există evaluări

- 9243Document682 pagini9243Hector ManÎncă nu există evaluări

- 54862dfa34adfcfcaac5843f3c0d7ff8Document17 pagini54862dfa34adfcfcaac5843f3c0d7ff8Ricardo LunaÎncă nu există evaluări

- DBCM 01 April 2021 Awal Shift IDocument4 paginiDBCM 01 April 2021 Awal Shift IHenny Komala Sari SibaraniÎncă nu există evaluări

- ListadoDocument310 paginiListadoapi-34687573550% (2)

- DNEPR M72 Manual EnglishDocument76 paginiDNEPR M72 Manual Englishdaemonium666100% (2)

- Service Manual - TruckDocument523 paginiService Manual - Truckdubimou67% (3)

- Eaton Fuller RTX 14715Document43 paginiEaton Fuller RTX 14715Mauricio DuranÎncă nu există evaluări

- NissanDocument44 paginiNissanJesus Rojas100% (1)

- All Products S Mcs BookletDocument37 paginiAll Products S Mcs Bookletdiego velez foreroÎncă nu există evaluări

- ATR Notes Part1Document33 paginiATR Notes Part1Peter Chantrachumnongjit100% (1)

- Road Reclaimer: Maximum Production - Rotor Driven by CatDocument8 paginiRoad Reclaimer: Maximum Production - Rotor Driven by CatFabiano_PÎncă nu există evaluări

- Neugart PLN enDocument6 paginiNeugart PLN enpeterÎncă nu există evaluări

- Damen 511205 6 7Document38 paginiDamen 511205 6 7zzz zzz100% (1)

- Design and Analysis of Hydraulic Roller Press Frame AssemblyDocument7 paginiDesign and Analysis of Hydraulic Roller Press Frame AssemblydemasÎncă nu există evaluări