Documente Academic

Documente Profesional

Documente Cultură

機動HW

Încărcat de

Yuan-Po LinDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

機動HW

Încărcat de

Yuan-Po LinDrepturi de autor:

Formate disponibile

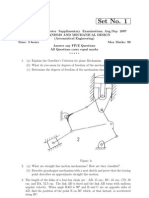

DESIGN OF MACHINERY

SOLUTION MANUAL 6-9a-1

PROBLEM 6-9a

Statement:

The general linkage configuration and terminology for an inverted fourbar slider-crank linkage are

shown in Fig P6-3. The link lengths and the values of 2 and 2 and are defined in Table P6-3.

For row a , using an analytic method, find the velocities of the pin joints A and B and the velocity of

slip at the sliding joint. Draw the linkage to scale and label it before setting up the equations.

Given:

Link lengths:

Link 1

d

6

Link 2

c

4

Link 4

a

2

90

deg

30

deg

10

atan2 (x

y)

return 0.5

if x = 0 y 0

Two argument inverse tangent

return 1.5

if x = 0 y 0

y if x 0

return atan

x

y

atan

otherwise

Solution:

1.

See Mathcad file P0609a.

Draw the linkage to scale and label it.

B

y

90.0

127.333

c

142. 666

a

30.000

x

04

02

B'

169. 040

79. 041

2.

Determine the values of the constants needed for finding 4 from equations 4.8a and 4.10a.

Q

a

sin

cos

a

cos

d

sin

P

a

sin

sin

a

cos d

cos

3.

Q 4.268

R

c

sin

R 4.000

T

2

P

T 2.000

S

R Q

S 0.268

U

Q R

U 8.268

Use equation 4.22c to find values of 4 for the open and crossed circuits.

OPEN

CROSSED

4.

P 1.000

2

2

atan2

2

S

T T 4

S

U

2

atan2 2

S

T T 4

S

U

142.667 deg

169.041 deg

Use equation 4.18 to find values of 3 for the open and crossed circuits.

DESIGN OF MACHINERY

5.

6.

7.

SOLUTION MANUAL 6-9a-2

OPEN

232.667 deg

CROSSED

259.041 deg

Determine the magnitude of the instantaneous "length" of link 3 from equation 4.20a.

OPEN

b1

CROSSED

b2

sin

a

sin c

sin

b1 1.793

sin

a

sin c

sin

b2 1.793

Determine the angular velocity of link 4 using equation 6.30c:

OPEN

CROSSED

cos

b 1 c

cos

10.292

cos

b 2 c

cos

3.639

Determine the velocity of pin A using equation 6.23a:

VA

a

sin j

cos

VA 10.000 17.321i

8.

VA 20.000

Determine the velocity of point B on link 4 using equation 6.31:

OPEN

VB4x1

c

sin

VB4x1 24.966

VB4y1 32.734

VB4y1

c

cos

2

VB41

VB4x1 VB4y1

VB41 41.168

VB1

atan2

VB4x1

VB4y1

CROSSED

VB4x2

c

sin

VB42

VB4x2 VB4y2

VB1 52.667 deg

VB4x2 2.767

VB4y2

c

cos

VB4y2 14.289

VB42 14.555

VB2

atan2

VB4x2

VB4y2

9.

arg VA 120.000 deg

VB2 79.041 deg

Determine the slip velocity using equation 6.30a:

OPEN

Vslip1

CROSSED

Vslip2

cos

cos

sin b 1

sin c

sin

sin b 2

sin c

sin

Vslip1 33.461

Vslip2 33.461

DESIGN OF MACHINERY

SOLUTION MANUAL 6-13-2

3,6

1,3

1,6 at infinity

2,5

to 2,4

5,6

6

to 2,4

1,5

2,3

1

1,6 at infinity

2

3

1,6 at infinity

3

4

3,4; 3,5; and 4,5

1

4

1,2

1,4

2,6

4,6

1,6 at infinity

1

c.

This is a sixbar with slider and roller with n

6.

1.

Determine the number of instant centers for this mechanism using equation 6.8a.

C

2.

n

( n 1)

C 15

2

Draw the linkage to scale and identify those ICs that can be found by inspection.

2,5

5,6

3.

Use Kennedy's Rule and a linear graph to find the

remaining 8 ICs.

1,2

6

1

2,3

I2,6: I1,2 -I1,6 and I2,5 -I5,6

1

I1,5: I1,6 -I5,6 and I1,2 -I2,5

1,6

3

I4,5: I1,4 -I1,5 and I2,4 -I2,5

I3,6: I3,6 -I5,6 and I2,3 -I2,6

I1,3: I1,2 -I2,3 and I1,4 -I3,4

I3,5: I3,4 -I4,5 and I2,5 -I2,3

I2,4: I1,2 -I1,4 and I2,5 -I2,4

I4,6: I4,5 -I5,6 and I3,4 -I3,6

4

3,4

3,5

2,5

4,5

1,4 at infinity

1,5

5,6

1,2

1

6

2,6

2,3

2,4

1,4 at infinity

5

1,6

4,6

3,6

4

3,4

6-13d.

1.

1,4 at infinity

This is a sixbar with slider and roller with n

6.

Determine the number of instant centers for this mechanism using equation 6.8a.

C

n

( n 1)

C 15

2

2.

3

4

Draw the linkage to scale and identify those ICs that can be found by inspection.

1,3

1,4 at infinity

DESIGN OF MACHINERY

SOLUTION MANUAL 6-13-3

3,4

4

1

1,4

3

5,6

5

1,2

6

2,3; 2,5; and 3,5

1,6 at infinity

3.

Use Kennedy's Rule and a linear graph to find the remaining 7 ICs.

I1,3: I1,2 -I2,3 and I1,4 -I3,4

I3,6: I1,6 -I1,3 and I3,5 -I5,6

I2,6: I1,2 -I1,6 and I2,5 -I5,6

I1,5: I1,6 -I5,6 and I1,2 -I2,5

I4,5 : I1,4 -I1,5 and I3,5-I3,4

I2,4: I1,2 -I1,4 and I2,3 -I3,4

I4,6: I1,6 -I1,4 and I4,5 -I5,6

2,4

4,6

3,4

4,5

1,3

1

1

1,4

6

3

1,5

1,6 at infinity

3

4

2,6

5,6

5

1,2

2

1

6

2,3; 2,5; and 3,5

3,6

1,6 at infinity

1,6 at infinity

DESIGN OF MACHINERY

SOLUTION MANUAL 6-21b-1

PROBLEM 6-21b

Statement:

The linkage in Figure P6-6b has L1 = 61.9, L2 = 15, L 3 = 45.8, L4 = 18.1, L5 = 23.1 mm. 2 is 68.3 deg

in the xy coordinate system, which is at -23.3 deg in the XY coordinate system. The X component

of O2C is 59.2 mm. Find, for the position shown, the velocity ratio VI5,6/VI2,3 and the mechanical

advantage from link 2 to link 6. Use the instant center graphical method.

Given:

Link lengths:

Solution:

1.

Link 1

d

61.9

mm

Link 2

a

15.0

mm

Link 3

b

45.8

mm

Link 4

c

18.1

mm

Link 5

e

23.1

mm

Offset

f

59.2

mm

from O2

Crank angle:

45

deg

Coordinate rotation angle

23.3

deg Global XY system to local xy system

Global XY system

See Figure P6-6b and Mathcad file P0621b.

Draw the linkage to scale in the position given, find the instant centers, distances from the pin joints to the

instant centers and the angles that links 3 and 4 make with the x axis.

From the layout:

2.

AI13

44.594

mm

BI13

50.121

mm

BI15

22.683

mm

CI15

11.377

mm

1,3

5,6

Choose an arbitrary value for the magnitude of the

velocity at I2,3 (point A). Let link 2 rotate CCW.

6

1,5

2,3

A

mm

VA

10

sec

50.12 1

22.68 3

O2

VC

90

deg

B

1

VC 135.000 deg

3.

11 .3 77

44.59 4

Y

Determine the angular velocity of link 3 using equation

6.9a.

O4

1

VA

0.224

AI13

rad

CW

sec

4.

Determine the magnitude of the velocity at point B using equation 6.9b. Determine its direction by inspection.

mm

VB

BI13

VB 11.239

sec

5.

Determine the angular velocity of link 5 using equation 6.9a.

6.

VB

0.495

BI15

The ratio V

/V

I5,6

8.

CW

sec

Determine the magnitude of the velocity at point C using equation 6.9b. Determine its direction by inspection.

VC

CI15

7.

rad

is

I2,3

VC

VA

VC 5.637

mm

downward

sec

0.56

Use equations 6.12 and 6.13 to derive an expression for the mechanical advantage for this linkage where the

input is a rotating crank and the output is a slider.

DESIGN OF MACHINERY

Tin

Fin =

rin

Fout =

mA =

SOLUTION MANUAL 6-21b-2

Pout

Vout

Fout

Fin

Pin

rin

in

=

Pin

VA

Pout

VC

Pout VA

VC Pin

mA

VA

VC

mA 1.77

DESIGN OF MACHINERY

SOLUTION MANUAL 6-33-1

PROBLEM 6-33

Statement:

The offset slider-crank linkage in Figure P6-8f has the dimensions and crank angle given below.

Find VA, and VB for the position shown for 2 = 25 rad/sec CW. Use the instant center graphical

method.

Given:

Link lengths:

Link 2

a

63

mm

Crank angle:

51

deg

Link 3

b

130

mm

Offset

c

52

mm

25

rad

sec

Input crank angular velocity

Solution:

1.

CW

See Figure P6-8f and Mathcad file P0633.

Draw the linkage to scale in the position given, find the instant centers, distances from the pin joints to the

instant centers and the angles that links 3 and 4 make with the x axis.

166.309

4

B

1,3

1

3

118.639

O2

From the layout above:

AI13

118.639

mm

2.

Use equation 6.7 and inspection of the layout to determine the magnitude and direction of the velocity at point

A.

mm

VA

a

VA 1575.0

sec

VA

90

deg

3.

VA 39.0 deg

Determine the angular velocity of link 3 using equation 6.9a.

4.

BI13

166.309

mm

VA

AI13

13.276

rad

CCW

sec

Determine the magnitude of the velocity at point B using equation 6.9b. Determine its direction by inspection.

VB

BI13

VB

270

deg

VB 2207.8

mm

sec

DESIGN OF MACHINERY

SOLUTION MANUAL 6-34-1

PROBLEM 6-34

Statement:

The offset slider-crank linkage in Figure P6-8f has the dimensions and crank angle given below.

Find VA, and VB for the position shown for 2 = 25 rad/sec CW. Use an analytical method.

Given:

Link lengths:

Link 2

a

63

mm

Link 3

b

130

mm

Offset

c

52

mm

141

deg

Crank angle:

Local xy coordinate system

Input crank angular velocity

25

rad

sec

Solution:

See Figure P6-8f and Mathcad file P0634.

1.

Draw the linkage to a convenient scale.

2.

Determine 3 and d using equations 4.16 for the crossed circuit.

sin c

a

asin

1

3

d 141.160 mm

52.000

2

Determine the angular velocity of link 3 using equation 6.22a:

a cos

b cos

4.

44.828 deg

d

a

cos b

cos

3.

13.276

rad

141.000

sec

Determine the velocity of pin A using equation 6.23a:

X, y

O2

VA

a

sin j

cos

VA ( 991.180 1224.005i )

mm

mm

sec

VA

arg

VA 90

deg

In the global coordinate system,

5.

VA 1575.000

sec

arg

VA51.000 deg

VA 39.000 deg

Determine the velocity of pin B using equation 6.22b:

VB

a

sin b

sin

VB 2207.849

mm

sec

VB

VB

In the global coordinate system,

VB

arg

VB 90

deg

VB 90.000 deg

DESIGN OF MACHINERY

SOLUTION MANUAL 6-55a-1

PROBLEM 6-55a

Statement:

Figure P6-18 shows a powder compaction mechanism. Calculate its mechanical advantage for the

position shown.

Given:

Link lengths:

Link 2 (A to B)

a

105

mm

Link 3 (B to D)

b

172

mm

c

27

mm

Offset

Distance to force application:

Solution:

1.

Link 2 (AC)

rin

301

mm

Position of link 2:

44

deg

Let

1

rad

sec

See Figure P6-18 and Mathcad file P0655a.

Draw the linkage to scale and label it.

X

2.

Determine 3 using equation 4.17.

4

D

sin c

a

asin

164.509 deg

3.

Determine the angular velocity of link 3 using equation 6.22a:

44.000

a cos

b cos

4.

B

2

Determine the velocity of pin D using equation 6.22b:

VD

a

sin b

sin

5.

Positive upward

Calculate the velocity of point C using equation 6.23a:

VC

rin

sin j

cos

VC

VC

6.

Calculate the mechanical advantage using equation 6.13.

mA

VC

VD

mA 3.206

DESIGN OF MACHINERY

SOLUTION MANUAL 6-55b-1

PROBLEM 6-55b

Statement:

Figure P6-18 shows a powder compaction mechanism. Calculate and plot its mechanical advantage

as a function of the angle of link AC as it rotates from 15 to 60 deg.

Given:

Link lengths:

Link 2 (A to B)

a

105

mm

Link 3 (B to D)

b

172

mm

Offset

c

27

mm

Distance to force application:

rin

301

mm

Link 2 (AC)

Initial and final positions of link 2:

Solution:

1.

15

deg

60

deg

See Figure P6-18 and Mathcad file P0655b.

Draw the linkage to scale and label it.

X

4

D

C

B

2

2.

Determine the range of motion for this slider-crank linkage.

1

deg

3.

Determine 3 using equation 4.17.

sin c

a

asin

4.

Determine the angular velocity of link 3 using equation 6.22a:

a cos

b cos

5.

Determine the velocity of pin D using equation 6.22b:

VD

a

sin b

sin

6.

Calculate the velocity of point C using equation 6.23a:

Let

1

rad

sec

Positive upward

DESIGN OF MACHINERY

SOLUTION MANUAL 6-55b-2

VC

rin

sin j

cos

VC

VC

Calculate the mechanical advantage using equation 6.13.

mA

VD

VC

MECHANICAL ADVANTAGE

12

11

10

9

8

Mechanical Advantage

7.

m A 6

5

4

3

2

1

0

15

20

25

30

35

40

deg

Crank Angle, deg

45

50

55

60

S-ar putea să vă placă și

- Design and Implementation of Large-Range Compliant Micropositioning SystemsDe la EverandDesign and Implementation of Large-Range Compliant Micropositioning SystemsÎncă nu există evaluări

- P0666Document3 paginiP0666Ramalho12345Încă nu există evaluări

- MP2002-Tut 4-5Document7 paginiMP2002-Tut 4-5Ashwin Kumar ChandranÎncă nu există evaluări

- ch02 2Document7 paginich02 2Siow Shung Churn75% (4)

- Problemas de Dinamica de MaquinasDocument60 paginiProblemas de Dinamica de MaquinasUlises Castillo FloresÎncă nu există evaluări

- Machine dynamic 2 tutorial problemsDocument3 paginiMachine dynamic 2 tutorial problemsDestiny Cheun YeeÎncă nu există evaluări

- Velocity - Acceleration DiagramDocument9 paginiVelocity - Acceleration DiagramvisheshÎncă nu există evaluări

- MECH 314 Dynamics of Mechanisms: 1 Problem SpecificationDocument6 paginiMECH 314 Dynamics of Mechanisms: 1 Problem SpecificationLarbi ElbakkaliÎncă nu există evaluări

- Machine theory tutorial acceleration analysis solutionsDocument11 paginiMachine theory tutorial acceleration analysis solutionskalirajgurusamyÎncă nu există evaluări

- 1: The Sketch IsDocument15 pagini1: The Sketch IsashinkumarjerÎncă nu există evaluări

- Assignment1 Questions MEC219TDocument21 paginiAssignment1 Questions MEC219Tm sriÎncă nu există evaluări

- ME203 MOM July16 IC&Acceleration Tutorial 02Document3 paginiME203 MOM July16 IC&Acceleration Tutorial 02Pradyumna KSÎncă nu există evaluări

- MECHANISM MOTIONDocument31 paginiMECHANISM MOTIONhamryÎncă nu există evaluări

- Chapter 4.7 Solutions of Triangles PDFDocument5 paginiChapter 4.7 Solutions of Triangles PDFjiiÎncă nu există evaluări

- Chapter 5-MechanismDocument28 paginiChapter 5-MechanismDanielRaoÎncă nu există evaluări

- Mechanism Synthesis, Graphical - Lect1Document22 paginiMechanism Synthesis, Graphical - Lect1Naveen KanchiÎncă nu există evaluări

- Ch.6 Solucionario Mechanisms and Dynamics of MachineryDocument44 paginiCh.6 Solucionario Mechanisms and Dynamics of MachineryNico Mingo100% (1)

- 90 Consider Peg Interval On Long Chord As 3mDocument2 pagini90 Consider Peg Interval On Long Chord As 3mvikasÎncă nu există evaluări

- Experiment 4 For B.electronicDocument12 paginiExperiment 4 For B.electronicUmmu Umar Wa AisyahÎncă nu există evaluări

- Statement:: PROBLEM 6-29Document4 paginiStatement:: PROBLEM 6-29AmalinaÎncă nu există evaluări

- Practice Problems Set1Document21 paginiPractice Problems Set1Adalric LeungÎncă nu există evaluări

- Mechanisms and Mechanical DesignDocument9 paginiMechanisms and Mechanical DesignNizam Institute of Engineering and Technology LibraryÎncă nu există evaluări

- Diseño de MaquinasDocument10 paginiDiseño de MaquinasDavidCPÎncă nu există evaluări

- Question BankDocument103 paginiQuestion BankMushini NagabhushanÎncă nu există evaluări

- Mikrokopter's DocumentationDocument41 paginiMikrokopter's DocumentationMiguel Ángel QueroÎncă nu există evaluări

- R05 Set No. 2Document12 paginiR05 Set No. 2Rajesh KannanÎncă nu există evaluări

- AMS1.Advance Theory of MechanicsDocument3 paginiAMS1.Advance Theory of MechanicsamitÎncă nu există evaluări

- Chap 01 Solutions Ex 1 5 MethodDocument8 paginiChap 01 Solutions Ex 1 5 MethodnioÎncă nu există evaluări

- Lic 100 Marks QPDocument2 paginiLic 100 Marks QPprofharishjoshiÎncă nu există evaluări

- Math 17 4.7Document25 paginiMath 17 4.7jiiÎncă nu există evaluări

- A.R Engineering College: Villupuram Department of Mechanical EngineeringDocument14 paginiA.R Engineering College: Villupuram Department of Mechanical EngineeringVENKATESHÎncă nu există evaluări

- Lab 1Document7 paginiLab 1shahid rasheedÎncă nu există evaluări

- Problem 4.1: Solutions To Chapter 4 Exercise ProblemsDocument48 paginiProblem 4.1: Solutions To Chapter 4 Exercise ProblemsKevin Dwi Prasetio86% (7)

- Assignment For SurveyingDocument4 paginiAssignment For SurveyingSakshi GuptaÎncă nu există evaluări

- EJERCICIOS MECANISMOS - Javier Fuentes CDocument10 paginiEJERCICIOS MECANISMOS - Javier Fuentes CVictor MartinezÎncă nu există evaluări

- Advanced Kinematics and Dynamics of MachineryDocument50 paginiAdvanced Kinematics and Dynamics of MachineryMc SparkÎncă nu există evaluări

- Kinematics and Dynamics of Machines ProblemsDocument8 paginiKinematics and Dynamics of Machines ProblemsAmadeo ErebaraÎncă nu există evaluări

- Presented To The Faculty of The Department of Civil Engineering College of Engineering, de La Salle UniversityDocument13 paginiPresented To The Faculty of The Department of Civil Engineering College of Engineering, de La Salle UniversityDustin GrimaresÎncă nu există evaluări

- Tut (2-3-4) Mech of Mach Winter 2011Document10 paginiTut (2-3-4) Mech of Mach Winter 2011Mahmoud El-MahdyÎncă nu există evaluări

- 4.DC Biasing - BJTsDocument77 pagini4.DC Biasing - BJTsNimra AftabÎncă nu există evaluări

- Kinematics of Machinery May2006 Rr222105Document11 paginiKinematics of Machinery May2006 Rr222105Nizam Institute of Engineering and Technology LibraryÎncă nu există evaluări

- 1406 Advanced Kinematics and Dynamics of MachineryDocument13 pagini1406 Advanced Kinematics and Dynamics of MachineryChiranjeev JainÎncă nu există evaluări

- Question Bank KomDocument11 paginiQuestion Bank KomStar SathishÎncă nu există evaluări

- Mechanism Synthesis, GraphicalDocument32 paginiMechanism Synthesis, GraphicalShobhitAgarwalÎncă nu există evaluări

- Term Assignment 2ME304 – Theory of Machines Div-BDocument12 paginiTerm Assignment 2ME304 – Theory of Machines Div-BDEVAM SHETHÎncă nu există evaluări

- P0748Document3 paginiP0748Alex FernandoÎncă nu există evaluări

- Rr411405 Advanced Kinematics and DynamicsDocument11 paginiRr411405 Advanced Kinematics and DynamicsSRINIVASA RAO GANTAÎncă nu există evaluări

- Unit Wise 16 Mark QuestionsDocument29 paginiUnit Wise 16 Mark QuestionsPreethi SharmiÎncă nu există evaluări

- 18ME44 AssignmentDocument1 pagină18ME44 AssignmentbalajiÎncă nu există evaluări

- Tut-1 Modified PDFDocument8 paginiTut-1 Modified PDFShailendra DhakadÎncă nu există evaluări

- Olytechnic of Amibia: Department of Mechanical Engineering Theory of Machines (TOM320S)Document3 paginiOlytechnic of Amibia: Department of Mechanical Engineering Theory of Machines (TOM320S)andrewzulu4455Încă nu există evaluări

- Model Question Paper SurveyDocument5 paginiModel Question Paper SurveyVikram Rao100% (2)

- Ecen 326 - Lab 11 ReportDocument9 paginiEcen 326 - Lab 11 Reportapi-241454978Încă nu există evaluări

- Review SynthesisDocument11 paginiReview Synthesissam hamÎncă nu există evaluări

- Caed ProblemsDocument20 paginiCaed ProblemsPardeepÎncă nu există evaluări

- Practice Class 10 SolutionsDocument13 paginiPractice Class 10 SolutionsMalika NavaratnaÎncă nu există evaluări

- Digital Electronics 2: Sequential and Arithmetic Logic CircuitsDe la EverandDigital Electronics 2: Sequential and Arithmetic Logic CircuitsEvaluare: 5 din 5 stele5/5 (1)

- Advanced Electric Circuits: The Commonwealth and International Library: Applied Electricity and Electronics DivisionDe la EverandAdvanced Electric Circuits: The Commonwealth and International Library: Applied Electricity and Electronics DivisionÎncă nu există evaluări

- Brain WaveDocument1 paginăBrain WaveYuan-Po LinÎncă nu există evaluări

- Chapter 10Document78 paginiChapter 10Yuan-Po LinÎncă nu există evaluări

- Taylor Series Expansion: AppendixDocument4 paginiTaylor Series Expansion: AppendixYuan-Po LinÎncă nu există evaluări

- 熱傳HW4解答 (僅供參考 不負任何責任)Document3 pagini熱傳HW4解答 (僅供參考 不負任何責任)Yuan-Po LinÎncă nu există evaluări

- Lesson One General Macarthur'S Prayer For His Son: 遠東新高三關鍵句型 2 課 SampleDocument12 paginiLesson One General Macarthur'S Prayer For His Son: 遠東新高三關鍵句型 2 課 SampleYuan-Po LinÎncă nu există evaluări

- Maplestory: LL LL L HDocument3 paginiMaplestory: LL LL L HYuan-Po LinÎncă nu există evaluări

- NORTON ch04 - SolmanDocument134 paginiNORTON ch04 - SolmanYuan-Po LinÎncă nu există evaluări

- 99英文銜接教材本解答Document5 pagini99英文銜接教材本解答Yuan-Po LinÎncă nu există evaluări

- Chapter 1Document87 paginiChapter 1Yuan-Po LinÎncă nu există evaluări

- 材力HW14解答Document3 pagini材力HW14解答Yuan-Po LinÎncă nu există evaluări

- 1ft's fttnd'/lP/1 F: P) Fe'li't1f-Ln? Lit (I Inee)Document18 pagini1ft's fttnd'/lP/1 F: P) Fe'li't1f-Ln? Lit (I Inee)Yuan-Po LinÎncă nu există evaluări

- Beiser 01Document81 paginiBeiser 01Yuan-Po LinÎncă nu există evaluări

- 材力HW14解答Document3 pagini材力HW14解答Yuan-Po LinÎncă nu există evaluări

- International Conference on Mathematical Advances and Applications Abstract BookDocument179 paginiInternational Conference on Mathematical Advances and Applications Abstract BookMUSTAFA BAYRAMÎncă nu există evaluări

- 2.161 Signal Processing: Continuous and Discrete: Mit OpencoursewareDocument14 pagini2.161 Signal Processing: Continuous and Discrete: Mit Opencoursewarelovelyosmile253Încă nu există evaluări

- 06 CSL38 Manual LDDocument9 pagini06 CSL38 Manual LDJoshua Daniel RajÎncă nu există evaluări

- Sajc 2010 Prelim Math p2Document6 paginiSajc 2010 Prelim Math p2lauyongyiÎncă nu există evaluări

- Urriculum Itae Et TudiorumDocument21 paginiUrriculum Itae Et TudiorumEnricoÎncă nu există evaluări

- Design and Drawing of RC Structures: Dr. G.S.SureshDocument40 paginiDesign and Drawing of RC Structures: Dr. G.S.SureshvipinÎncă nu există evaluări

- Cereals and Pulses - Specs & Test Methods Part-1 RiceDocument43 paginiCereals and Pulses - Specs & Test Methods Part-1 RiceGhulam MustafaÎncă nu există evaluări

- 4 Integral Equations by D.C. Sharma M.C. GoyalDocument200 pagini4 Integral Equations by D.C. Sharma M.C. GoyalManas Ranjan MishraÎncă nu există evaluări

- Calculating Surface Integrals and Parameterizing SurfacesDocument28 paginiCalculating Surface Integrals and Parameterizing SurfacesKenn SharpeyesÎncă nu există evaluări

- Lecture 5Document7 paginiLecture 5sivamadhaviyamÎncă nu există evaluări

- 1-15-15 Kinematics AP1 - Review SetDocument8 pagini1-15-15 Kinematics AP1 - Review SetLudwig Van Beethoven100% (1)

- Demand: - Demand (D) Is A Schedule That Shows The Various Amounts of ProductDocument2 paginiDemand: - Demand (D) Is A Schedule That Shows The Various Amounts of ProductRaymond Phillip Maria DatuonÎncă nu există evaluări

- Data Exploration in Python PDFDocument1 paginăData Exploration in Python PDFTuncay SakaogluÎncă nu există evaluări

- Radix 64 ConversionDocument13 paginiRadix 64 ConversionRajendra Prasad100% (1)

- Pump CavitationDocument5 paginiPump Cavitationjrri16Încă nu există evaluări

- A Survey of Deep Learning Techniques For Autonomous DrivingDocument25 paginiA Survey of Deep Learning Techniques For Autonomous DrivingtilahunÎncă nu există evaluări

- Bending Moment Normal Forces in Tunnel Linings PDFDocument8 paginiBending Moment Normal Forces in Tunnel Linings PDFhendrawanÎncă nu există evaluări

- Aerodynamics MCQs on Low Speed AerodynamicsDocument4 paginiAerodynamics MCQs on Low Speed AerodynamicsHarish MathiazhahanÎncă nu există evaluări

- Powershape: Training CourseDocument18 paginiPowershape: Training CourseZulhendriÎncă nu există evaluări

- Preparation of Vector Group DiffDocument5 paginiPreparation of Vector Group DiffvenkateshbitraÎncă nu există evaluări

- Divergence and CurlDocument8 paginiDivergence and CurlaliÎncă nu există evaluări

- For Every Linear Programming Problem Whether Maximization or Minimization Has Associated With It Another Mirror Image Problem Based On Same DataDocument21 paginiFor Every Linear Programming Problem Whether Maximization or Minimization Has Associated With It Another Mirror Image Problem Based On Same DataAffu ShaikÎncă nu există evaluări

- ME 171 SyllabusDocument7 paginiME 171 SyllabusLucas Penalva Costa SerraÎncă nu există evaluări

- Noorul Islam Centre For Higher Education Noorul Islam University, Kumaracoil M.E. Biomedical Instrumentation Curriculum & Syllabus Semester IDocument26 paginiNoorul Islam Centre For Higher Education Noorul Islam University, Kumaracoil M.E. Biomedical Instrumentation Curriculum & Syllabus Semester Iisaac RÎncă nu există evaluări

- 4th Periodical Test in Math 5-NewDocument9 pagini4th Periodical Test in Math 5-NewMitchz Trinos100% (2)

- No SystemDocument15 paginiNo SystemAjeet Singh RachhoyaÎncă nu există evaluări

- PHAR 7633 Chapter 19 Multi-Compartment Pharmacokinetic ModelsDocument23 paginiPHAR 7633 Chapter 19 Multi-Compartment Pharmacokinetic ModelsBandameedi RamuÎncă nu există evaluări

- ATOA CAE Multiphysics and Multimaterial Design With COMSOL Webinar PDocument31 paginiATOA CAE Multiphysics and Multimaterial Design With COMSOL Webinar PRaj C ThiagarajanÎncă nu există evaluări

- Factorials Permutations and Combinations Answer KeyDocument4 paginiFactorials Permutations and Combinations Answer KeyAlrian Jay SampalayÎncă nu există evaluări