Documente Academic

Documente Profesional

Documente Cultură

Plane Press June2014

Încărcat de

lacontrabarraDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Plane Press June2014

Încărcat de

lacontrabarraDrepturi de autor:

Formate disponibile

June 2014

We Fix it Right the First Time

Whatisthis?

SeeUnderstandingthe

TechOpsDaily

Scorecard,page2

How are we doing?

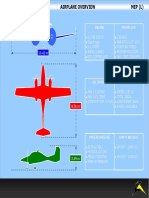

TechnicalOperationsDailyScorecard

6/20/2014

Planorbetterthanplan

Thresholdwithin5%ofplan

Worsethanplanby5%ormore

Cancellation%

Delays>120min%

D&C%

STAR%

OutofService(OOS)@0700CT

OTSInventory(Parts)

MELACOnly

FocusItems

Chronics

WorkAccomplishment%

ACDamageper10,000RON's*

4/18

QACompliance(PastdueCARs)MetricUnderreview

Daily

MTD

Actual

Actual

Rate/Count Rate

0.50%

0.54%

0.35%

0.42%

4.88%

5.38%

3.47%

3.80%

22

22.5

5

5.4

300

279

33

33

287

253

97.32%

96.93%

YTDDamages

Pending/Charged

Monthly

2014

YTD

Goal Actual

Rate

Rate

0.45% 0.34%

0.45% 0.39%

5.10% 4.84%

4.09% 3.87%

19.5

22.8

5.50

5.8

260

242

34

31

275

230

94.79% 96.33%

2014Goal

Rate

0.36%

0.38%

4.75%

3.72%

19.0

5.25

235

28

240

95.19%

0.00

2.15

2.17

2.15

LHRs Tech Ops teams

come together at new T2

Yeartodatethrough6/20:

Cancellation%0.34

Delays>120min%0.39

D&C%4.84

STAR%3.87

OTS@0700CT22.8

OTSInventory(Parts)5.8

MELAD+CDL275242

FocusItems31

Chronics230

WorkAccomplishment%96.33

A/CDamage2.17

AircraftMaintenanceEWRandRegionalManagingDirectorBobRuzich,fifthfromleft,visitedournewlyintegrated

LHRTechOpsstationonopeningdayforthenewQueensTerminal,June4.Below,ourfirstarrivalatthenew

terminalwasaB767,Flight958fromORD.

Also in this issue

MessagefromKen

Understandingthescorecard

SCEPTREupdate

NewIAHtoolingfacility

FirstQuarterUnited100

Withall17dailyUniteddeparturesatLHRnowoperatingfromTerminal2,

whichopenedJune4,wefinallyhaveasingle,integratedTechnicalOperations

stationatourlargestEuropeanlocation.

Combiningouroperationsenabled

ustoexpandthetechnician

workforcefrom25to37and

repatriateworkthatwashandledby

avendorwhentheEWRandIAH

flightsoperatedfromTerminal4.

WealsorelocatedourAOGmaterialswarehousefromLGW(LondonGatwick)toLHR,socan

betterrespondtotheneedsofEuropeanstationsthatLHRTechOpssupports.SeeFlying

TogetherforcoverageoftheofficialgrandopeningonJune23,andwatchformoreintheJuly

issueofPlanePress.

Understanding the daily scorecard

TechnicalOperationsDailyScorecard

ACDamageper10,000 RON's*

helps achieve goals

6/20/2014

Planorbetterthanplan

Thresholdwithin5%ofplan

Worsethanplanby5%ormore

Cancellation%

Delays>120 min%

D&C%

STAR%

OutofService(OOS)@0700CT

OTSInventory(Parts)

MELACOnly

FocusItems

Chronics

WorkAccomplishment%

Your input, feedback

4/18

QACompliance(PastdueCARs)MetricUnderreview

YTDDamages

Pending/Charged

Daily

Actual

Rate/Count

0.50%

0.35%

4.88%

3.47%

22

5

300

33

287

97.32%

MTD

Actual

Rate

0.54%

0.42%

5.38%

3.80%

22.5

5.4

279

33

253

96.93%

Monthly

2014

Goal

Rate

0.45%

0.45%

5.10%

4.09%

19.5

5.50

260

34

275

94.79%

YTD

Actual

Rate

0.34%

0.39%

4.84%

3.87%

22.8

5.8

242

31

230

96.33%

2014 Goal

Rate

0.36%

0.38%

4.75%

3.72%

19.0

5.25

235

28

240

95.19%

0.00

2.15

2.17

2.15

Every day, we issue the Tech Ops Daily Scorecard, which shows at a glance how we are

performing in 11 key areas that roll up to Uniteds overall operational performance. Coming

soon, you can access this from the Tech Ops home page of Flying Together.

Below are the metrics we track and which all of us in Tech Ops have a role in improving.

Consult Oracle Business Intelligence to learn how your team contributes to the division

performance. Contact richard.lung@united.com to get access to OBI.

Cancellation %: The percentage of mainline cancellations attributed to Tech Ops.

Delays > 120 min %: Long delays attributed to Tech Ops. As many of these long delays

affect international flights, and Tech Ops is the biggest contributor to this metric, reducing

these delays is a top priority.

D&C %: All delays and cancels attributed to Tech Ops. Since the vast majority of these

delays are of very short duration and have minimal impact, the goal is set much higher than

for long delays.

STAR %: Delays and cancellations on flights leaving before 0930 local time. When we can

Start the Airline Right, the rest of the day goes more smoothly as early delays and cancels

tend to have disruptive ripple effects throughout the system.

Out of Service (OOS) @ 0700CT: We have about 700 mainline aircraft; our operation can

generally handle a certain number being out of service each morning. Once we go above

the goal, which for this month is set at 19.5, disruptions are inevitable.

OTS - Inventory (Parts): Of the OTS count, planes that would otherwise be back in service

but for lack of parts. This is a paramount metric for our Supply Chain organization.

MEL A-C Only: We can defer the repair of many Minimum Equipment List items for varying

periods of time, and this number represents the total for the system at the start of each day.

We clear most of our MELs quickly while new ones are added, so while this number may

appear stable the items are being turned over constantly and quickly. Most items are

deferred just long enough to get the plane to a place it can be repaired.

Focus Items: We have assigned focus item priority to those pending repairs that can

impact crew workload, customer comfort, or dispatch restrictions.

Chronics: When we fix it right the first time we generate fewer chronics, although some

require complex troubleshooting.

Work Accomplishment %: How much of the work that was supposed to occur was

completed. This percentage takes into account work that was not completed on planes at

stations as well as that which could not be started on schedule due to routing disruptions.

AC Damage per 10,000 RON's: Most of the aircraft damages attributed to Tech Ops

involve slide deployments.

(The QA Compliance metric is under review, we will report on it at a later date.)

This months Plane Press

features a story on our Tech

Ops Daily Scorecard. We

use this scorecard to provide

high visibility for key

performance metrics that

reflect our operational

reliability. These metrics are

not goals unto themselves,

but they support our goal of

having an industry-leading

product that we are proud to

sell.

The top three metrics on the

scorecard reflect delay and

cancellation rates. These are

called output indicators

because they reflect the

output of all the processes

that we have in place to

deliver a reliable product.

The remaining metrics on

the scorecard are called

process indicators because

these reflect our

performance in key

processes that contribute to

good reliability. For example,

managing a low MEL count

is very important for good

reliability. While MELs allow

us to defer repairs to

redundant systems in order

to avoid delays and

cancellations, losing a level

of redundancy puts us at risk

for subsequent delays and

cancellations if another fault

to the affected system

occurs. If this happens at an

outstation, the operational

impact could be significant.

The Tech Ops Daily

Scorecard is an example of

the many tools we use in our

FAA-required Continuous

Analysis and Surveillance

System (CASS).

(continued next page)

Plane Press

June 2014

Tech Ops, IT working with other

groups on post-migration ops

Before the plane-by-plane migration of our aircraft onto SCEPTRE begins early next year,

the Tech Ops and IT teams managing the process need to know exactly how it will affect

other groups who rely on accurate data to make crucial operational decisions every shift,

every day. To ensure a smooth process, the integration team recently brought together

representatives from Maintenance, Dispatch, Routing, Flight Ops and Crew Scheduling to

discuss their needs and current uses of aircraft and maintenance information and to

determine what, if any, changes will occur as part of the migration.

Were taking proactive steps now to mitigate any issues, and our goal is simple no

operational impact. No delays or cancellations, said Operations Automation Managing

Director Julian Pachon.

The Tech Ops Day One planned for early 2015 will mark the consolidation of all materials

data and associated processes to SCEPTRE. It will be followed by the phased aircraft-byaircraft migration of AMIS-based fleets to SCEPTRE. Prior to cutover we will have

completed development and received FAA approval of our Electronic Log Book (ELB)

functionality in SCEPTRE and will begin transitioning SCEPTRE aircraft using a paper

aircraft logbook to the new ELB. Getting us to Day One has already involved hundreds of

employees and business partners and we have conducted two dress rehearsals and will

hold at least two more, said Maintenance Strategic Planning Managing Director Mark Miner.

IT Business Architecture Director Diane LeBeau helped set expectations for the

departments involved, updating them on the software development and soliciting input on

future requirements. We need to make sure that if anything is likely to change we know

about it now, she said.

Attendees at the daylong meeting in late May worked with the integration leadership team

and support staff to identify each transaction involved in routing and dispatching aircraft.

The workshop was very productive, said Network Operations Center System Director

Noam Alon. Our team walked away with increased confidence about the success of the

migration.

For ongoing updates, check the SCEPTRE section of Flying Together. Go to Flying

Together > Tech Ops > SCEPTRE using the left-side navigation menu. You can also send

questions or comments about the migration to TechOpsNews@united.com.

Message from Ken

(from previous page)

Our CASS continually

monitors and evaluates the

performance and

effectiveness of our

maintenance program and

processes to ensure that we

are complying with all

requirements and to ensure

that we are achieving

intended results. Our

primary obligation is, of

course, to ensure aircraft

airworthiness which, by FAA

definition, includes safety as

well as conformity to design

regulatory requirements.

Another intended result of

our maintenance program is

to achieve the level of

reliability that is inherent in

the design of the aircraft and

equipment. Metrics provide

quantitative performance

indicators for reliability, but

qualitative analysis is

required to assess

significance and to

determine the root causes of

any performance declines.

This can identify deficiencies

in our maintenance

programs and processes, or

it can identify deficiencies in

aircraft design which we can

then address through

modifications. We also have

to follow-up and close the

loop with further analysis

and surveillance to ensure

that corrective actions are

effective.

Metrics are important

performance indicators, but

the most valuable

information comes from your

input based on your firsthand experience supporting

our operation. Reporting

safety hazards is vitally

important, and we also need

all the feedback we can get

on anything that can help us

better achieve our goals

related to quality, delivery,

and cost. Were very grateful

for your vigilance and

dedication.

Ken

Plane Press

June 2014

New IAH tooling facility outfits us to better

serve growing 787 fleet, other widebodies

Technicians at IAH are now able to check out tooling and

kits for working on 787s and other widebodies from our

new, state-of-the-art facility that is located adjacent to our

widebody hangar and provides a more secure and

controlled environment for the valuable items.

Were already hearing a lot of positive input from the

techs, and, for us, it is a huge improvement in every way,

said Lead Utility Specialist Vic Ruiz (at left in photo). He

pointed out that all our widebody tooling is now located in

one place central to the work and the workers, and we

are shaving minutes off nearly every tooling transaction.

The 5,000-square-foot facility has capacity for all our

current widebody tooling and can handle expansion as

our 787 fleet grows and as we take delivery starting in 2018 of the Airbus A350-XWB. In addition to aircraft tools, test equipment,

and kits made up of tools and/or parts for specific maintenance jobs, it houses general-use tools and supplies ranging from

personal protective equipment to cleaning materials and solutions.

To accommodate those hundreds of tools and kits in a toolroom with a relatively modest footprint, we installed a three-section

vertical lift storage system similar to those used in the warehouses of giant retailers like Amazon. IAH Aircraft Maintenance

Supervisor Mark Green believes it to be the only one in use by a major airline or aircraft maintenance provider.

We can keep everything but the largest and heaviest kits in these units, and now it is easier than ever to keep track of them and

retrieve them when technicians need them, Mark said.

Mark credits Vic and Utility Specialist Billy Deguzman (at right with Vic in photo at top of page) with putting in countless hours and

days over several months to get the tool room in shape and working with its customers technicians who work on the 787s, 767s

and 777s in the adjacent hangar and ramp area. Mark said they succeeded in engineering the space and its contents to meet our

immediate needs and to enable improvements based on changing operational requirements and ongoing technician input.

At our new widebody tooling facility in IAH, tooling is much

easier to protect from the elements and to keep track of, and

the sophisticated retrieval system makes it nearly impossible

to issue or return the wrong tool or kit. There is a place for

everything, and everthings in its place or clearly checked out

and in use. Above left, Vic places an order; center, a closeup

of the interface; at right, a laser dot highlights the location of

the item. Left: Each items proper location is marked in a

custom cutout.

Plane Press

June 2014

Congratulations to our 1Q United 100 honorees

Victor Biro

Donny Borja

Juan Fernandez

Amjad Hussain

Mariya Ivleva

Scott Johnston

Ted Moore

Walter Morgan

Joel Ortiz

Freddy Robaina

Jose Rodriguez

Hemant Singh

We salute our latest group of United 100 winners. For the First Quarter, these 12 employees were selected for the honor from

among dozens who were nominated by their peers in Tech Ops for their above and beyond contributions to our airline. Here are

the names and jobs of all the winners, plus the name of the employee(s) who nominated them, and an excerpt from their

nominations. To see all the 100 winners this quarter, and to submit your nominations, go to Flying Together > Employee Services

> Rewards & Recognition > United 100.

Victor Biro, Powerplant Technician-Base, SFOPD, nominated by Kamkar Masood, SFOPD. Vic is a leader in the engine shop. He is

well respected by his fellow co-workers, management and engineering for his enthusiasm and commitment to excellence.

Donny Borja, Facility Maintenance Operations Supervisor, GUMGQ, nominated by Kikuo Soledad, GUMCS. For his support to the

GUM United Club and its customers: Thank you Donny for your quick response in a timely manner to help in time of need.

Juan Fernandez, GSE Technician-Line, IAHGX, nominated by Michael Furlinger, IAHAO. In assisting a customer who was having

trouble with a motorized wheelchair, Juan went above and beyond He not only solved the needs of a disabled veteran but saved

United several hundred dollars in repairs and travel cost.

Amjad Hussain, Storekeeper, IAHJJ, nominated by Dev Nandlal, IAHJJ. When trying to expedite AOG parts to a plane that was

stranded in GRU, We were very lucky Amjad was on duty the departing flight in GRU left without delay, saving [United] a lot of

money!

Mariya Ivleva, Project Engineer, WHQEG, nominated by Nicholas McAlister, WHQEG. Mariya has been tirelessly working to make

the United reliability a reality real for the 787.

Scott Johnston, Engine/APU Technical Planner, CSGPL, nominated by David Doucey, WHQVM. His motto is to never allow an

engine to have production delays due to parts within his control. In all of 2013, he was involved in the production of nearly 80 engines

- none of which were delayed due to parts.

Ted Moore, Technician-Line, IAHMM, nominiated by Capt. Antone Sacker, IAHFO. Working a charter flight to Alaska, Mr. Moore

tried to head off any problems that he anticipated, and met the requests of any maintenance issues the crew may have noticed.

Walter Morgan, Lead Line Technician, DENMM, nominated by Debra Franks, DENOO. Walter found and helped return things a

customer left on board. By taking a few extra minutes out of his day and going out of his way for this [customer], Walter extended

excellent customer service that this passenger won't soon forget!

Joel Ortiz, Avionics Technician-Base, SFOOV, nominated by Tim Vo, WHQEG. For ongoing work on systems including IFE and WiFi

systems, Joel is a incredible technician and is the go-to guy when it comes to avionics maintenance.

Freddy Robaina, Supervisor-Aircraft Maintenance, MIAMM, nominated by David Lucas, EWRSK. A passenger on a flght when IFE

failed, Freddy then worked endlessly during the next two hours troubleshooting the system in his attempts to get the IFE functional.

Jose Rodriguez, Technician-Line, BOSMM, nominated by David Peuser, BOSMX. Jose prevented a vechile from striking a parked

plane on an icy ramp: Quick action on Jose's part saved United thousands of dollars for repair and disrupting many customers for

their flight the following morning.

Hemant Singh, Lead Storekeeper, SFOJD, nominated by Marian Flores, SFOJD. He is safety conscious, finds ways to save our

company money, he focuses on customer needs and demands and is the epitome of safety.

Plane Press

June 2014

S-ar putea să vă placă și

- Case - The San Diego City SchoolsDocument2 paginiCase - The San Diego City SchoolsJaeHong MinÎncă nu există evaluări

- A320 Avsoft Quick Study Guide PDFDocument212 paginiA320 Avsoft Quick Study Guide PDFfresh_pearlie94% (31)

- C-1 Excel Logistics Services Case AnalysisDocument8 paginiC-1 Excel Logistics Services Case AnalysisSK CHANDAÎncă nu există evaluări

- Air Law Q1Document9 paginiAir Law Q1Iludiran KolaÎncă nu există evaluări

- Falcon 50 Training ExercisesDocument86 paginiFalcon 50 Training ExercisesJose Ariel Chejanovich100% (3)

- A Digital Twin - Ac Servo MotorsDocument2 paginiA Digital Twin - Ac Servo Motorsj.k.boseÎncă nu există evaluări

- Basic Maintenance KPI MetricsDocument20 paginiBasic Maintenance KPI MetricsKrishna Jasha100% (5)

- M17Document37 paginiM17Sundaram MohanÎncă nu există evaluări

- Ecam WarningDocument28 paginiEcam WarningBluto A Cuong100% (1)

- OEJNDocument16 paginiOEJNFajar Yoga WicaksonoÎncă nu există evaluări

- Metrics (KPI's) To Assess Process PerformanceDocument47 paginiMetrics (KPI's) To Assess Process PerformanceSergio Quintana Rodriguez88% (8)

- The Importance of Tracking CMMS Key Performance IndicatorsDocument5 paginiThe Importance of Tracking CMMS Key Performance IndicatorsM. YusufÎncă nu există evaluări

- TRM TAIC BP HandoutDocument82 paginiTRM TAIC BP Handoutdmmingo1271Încă nu există evaluări

- Ams - Asset Management SystemDocument5 paginiAms - Asset Management SystemcleitonmoyaÎncă nu există evaluări

- Reliability ReportingDocument5 paginiReliability ReportingT/ROXÎncă nu există evaluări

- Ebook Maintenance KPIsDocument26 paginiEbook Maintenance KPIsRamesh GodkarÎncă nu există evaluări

- I AddenergyassetandintegritywhitepaperFinal1Document22 paginiI AddenergyassetandintegritywhitepaperFinal1Mohammad NajibullahÎncă nu există evaluări

- Overall Equipment Effectiveness & Real-Time Visual ManagementDocument19 paginiOverall Equipment Effectiveness & Real-Time Visual Managementtlili-samir7290Încă nu există evaluări

- 8 Essential KPIs For Maintenance Management - TRACTIANDocument26 pagini8 Essential KPIs For Maintenance Management - TRACTIANsatya krishna chagantiÎncă nu există evaluări

- Vanaken AbsDocument5 paginiVanaken AbsGul sher BalochÎncă nu există evaluări

- DowntimeDocument13 paginiDowntimeWan Sek ChoonÎncă nu există evaluări

- Lec.03 Advanced Manufacturing SystemsDocument17 paginiLec.03 Advanced Manufacturing SystemsAmer Abd EL-hkimÎncă nu există evaluări

- Kpi 2Document8 paginiKpi 2walidderbel1981Încă nu există evaluări

- Kpi 3Document8 paginiKpi 3walidderbel1981Încă nu există evaluări

- OM Script ReportDocument8 paginiOM Script ReportThreeGee JoseÎncă nu există evaluări

- Questions of Reliability Centered MaintenanceDocument15 paginiQuestions of Reliability Centered Maintenancemariana100% (1)

- Production and Performance Management WP enDocument7 paginiProduction and Performance Management WP enbautistagian057Încă nu există evaluări

- Cxo Eam Arc BriefDocument5 paginiCxo Eam Arc Brief18085012Încă nu există evaluări

- The Top 3 Maintenance KPIs An Optimal CMMS Dashboard Should HaveDocument11 paginiThe Top 3 Maintenance KPIs An Optimal CMMS Dashboard Should HaveambuenaflorÎncă nu există evaluări

- Assignement of PMSDocument10 paginiAssignement of PMSahmadhanif82845Încă nu există evaluări

- A Business-Based Approach To Developing An Effective ProgramDocument8 paginiA Business-Based Approach To Developing An Effective ProgramWojtek MaczynskiÎncă nu există evaluări

- 11.debanshee Choudhury (MM Jury)Document23 pagini11.debanshee Choudhury (MM Jury)debanshee choudhuryÎncă nu există evaluări

- Process MetricsDocument47 paginiProcess MetricsJean Jacques ouandaÎncă nu există evaluări

- Plant Maintenance QueriesDocument103 paginiPlant Maintenance QueriesNagendra PrabhuÎncă nu există evaluări

- Reliability Centered Maintenance Literature ReviewDocument5 paginiReliability Centered Maintenance Literature Reviewfvehwd96Încă nu există evaluări

- Success Story UtlitiesTrans EmiratesDocument2 paginiSuccess Story UtlitiesTrans EmiratesjonnytannguyenÎncă nu există evaluări

- IT Architecture: Component Failure Impact Analysis (CFIA)Document23 paginiIT Architecture: Component Failure Impact Analysis (CFIA)Nieves Liranzo OrtegaÎncă nu există evaluări

- CP 2 Vibration Monitoring and Analysis GuideDocument5 paginiCP 2 Vibration Monitoring and Analysis GuideCristian GarciaÎncă nu există evaluări

- Assets Management Assets Hierarchy Assets Register Include Assets Spesification Attach Images & Assets Document To Assets RecordDocument6 paginiAssets Management Assets Hierarchy Assets Register Include Assets Spesification Attach Images & Assets Document To Assets Recordbrian qlpÎncă nu există evaluări

- Application of ManagementDocument2 paginiApplication of ManagementM Chandraman ECE KIOTÎncă nu există evaluări

- MaintenanceDocument47 paginiMaintenanceVincent Gabriel100% (1)

- ProposalDocument46 paginiProposaljade16087718Încă nu există evaluări

- Application Performance Management (APM) For TIBCO UsersDocument16 paginiApplication Performance Management (APM) For TIBCO UsersvenukreddyÎncă nu există evaluări

- Predictive Maintenance ExplainedDocument11 paginiPredictive Maintenance ExplainedShivaji ThubeÎncă nu există evaluări

- MaintenancescorecardsDocument2 paginiMaintenancescorecardsagus setiawanÎncă nu există evaluări

- Field Service Management 101 - 2023Document30 paginiField Service Management 101 - 2023K V Durga PrasadÎncă nu există evaluări

- 02 GestionIndicadores CATDocument47 pagini02 GestionIndicadores CATRenzo Manini100% (1)

- Wojakowski Plant 2015 5 4 04Document10 paginiWojakowski Plant 2015 5 4 04Edgar Gonzalez CarreonÎncă nu există evaluări

- Develop A Maintenance and Reliability PlanDocument5 paginiDevelop A Maintenance and Reliability Planjak4442001100% (1)

- BIS3003Document10 paginiBIS3003Kushal BajracharyaÎncă nu există evaluări

- Manutenção Preditiva - CEMADocument4 paginiManutenção Preditiva - CEMAadriano.chotolliÎncă nu există evaluări

- Advanced CMMS Metrics (KPI)Document18 paginiAdvanced CMMS Metrics (KPI)ambuenaflorÎncă nu există evaluări

- Information Technology Audit A and C Control E E-15Document63 paginiInformation Technology Audit A and C Control E E-15Munira SheraliÎncă nu există evaluări

- Strategy Automation and OrchestrationDocument16 paginiStrategy Automation and Orchestrationbgiangre8372Încă nu există evaluări

- M M MM: M M M MMMMMMMMMMMMMDocument5 paginiM M MM: M M M MMMMMMMMMMMMMAnnesasi ChowdaryÎncă nu există evaluări

- Rel APMDocument20 paginiRel APMoptisearch100% (1)

- Downtime AnalysisDocument7 paginiDowntime AnalysisRuchir100% (1)

- Preventive Maintenance Expanded DefinitionDocument5 paginiPreventive Maintenance Expanded DefinitionCadcamdestek CukurocaÎncă nu există evaluări

- APQP RevisitedDocument5 paginiAPQP RevisitedRita LepesiwthÎncă nu există evaluări

- Manpower Calculator Introduction V1.5Document18 paginiManpower Calculator Introduction V1.5lisahunÎncă nu există evaluări

- Kpi Question (1) ZXZXZXDocument14 paginiKpi Question (1) ZXZXZXTrash mailÎncă nu există evaluări

- Acl Data Analytics EbookDocument14 paginiAcl Data Analytics Ebookcassiemanok01Încă nu există evaluări

- STC-4 0Document30 paginiSTC-4 0sksnoopyÎncă nu există evaluări

- Achieving Excellence Optimizing IT Department KPIs for SuccessDe la EverandAchieving Excellence Optimizing IT Department KPIs for SuccessÎncă nu există evaluări

- Torque WrenchesDocument12 paginiTorque WrenchesjleonosÎncă nu există evaluări

- Rapallo Brochure1Document2 paginiRapallo Brochure1lacontrabarraÎncă nu există evaluări

- Baggage Policy United AirlinesDocument3 paginiBaggage Policy United AirlineslacontrabarraÎncă nu există evaluări

- Lindstrom CatalogueDocument60 paginiLindstrom CataloguelacontrabarraÎncă nu există evaluări

- B767 ApuDocument4 paginiB767 ApuGustavo Avila RodriguezÎncă nu există evaluări

- M05 Q&aDocument139 paginiM05 Q&aversineÎncă nu există evaluări

- Practice Exam m06Document80 paginiPractice Exam m06lacontrabarraÎncă nu există evaluări

- Servo TuningDocument3 paginiServo TuninglacontrabarraÎncă nu există evaluări

- Servo TuningDocument3 paginiServo TuninglacontrabarraÎncă nu există evaluări

- EASA Part66 - Module 15Document194 paginiEASA Part66 - Module 15kiki_d100% (8)

- Module 11B NewDocument473 paginiModule 11B NewlacontrabarraÎncă nu există evaluări

- DIY Solar InstallDocument3 paginiDIY Solar InstallThomas "Hirudinea" LeechÎncă nu există evaluări

- Balikpapan, Indonesia Wall/Bpn: 10-9 118.1 127.6 Sultan Aji Muhammad Sulaiman SepingganDocument1 paginăBalikpapan, Indonesia Wall/Bpn: 10-9 118.1 127.6 Sultan Aji Muhammad Sulaiman SepingganA YafiÎncă nu există evaluări

- Guidance Material SPO Pcar 3.2 PDFDocument357 paginiGuidance Material SPO Pcar 3.2 PDFken kenÎncă nu există evaluări

- 2005-01-18Document11 pagini2005-01-18Luz Analía Valdez CandiaÎncă nu există evaluări

- C-130 Three Engine TakeoffDocument22 paginiC-130 Three Engine TakeoffFSÎncă nu există evaluări

- Avionics Magazine - September 2016Document38 paginiAvionics Magazine - September 2016publi2030Încă nu există evaluări

- General Information General Information: (C) Jeppesen Sanderson, Inc., 2018, All Rights ReservedDocument14 paginiGeneral Information General Information: (C) Jeppesen Sanderson, Inc., 2018, All Rights ReservedOMAR EDUARDO HERRERA GALINDOÎncă nu există evaluări

- 01 Avionics January 2012 PDFDocument60 pagini01 Avionics January 2012 PDFSumit0789100% (1)

- Flutter and Directional Stability of AircraftDocument12 paginiFlutter and Directional Stability of AircraftdaliadavidkÎncă nu există evaluări

- Casestudy 181017115902Document23 paginiCasestudy 181017115902v121vÎncă nu există evaluări

- AMO List PDFDocument9 paginiAMO List PDFIrfanSidiÎncă nu există evaluări

- Extra 300 PDFDocument2 paginiExtra 300 PDFCharleneÎncă nu există evaluări

- Tcar 1 - Part 66 Regs - v04 - Ver FinalDocument139 paginiTcar 1 - Part 66 Regs - v04 - Ver Finaljakara tongchimÎncă nu există evaluări

- Horizon Q400 Memory Items Flashcards - Quizlet - 1Document7 paginiHorizon Q400 Memory Items Flashcards - Quizlet - 1Anish ShakyaÎncă nu există evaluări

- Piranha ManDocument18 paginiPiranha ManJuno Bass100% (1)

- ETOPS B777-300ER - Dedy Brian Ericson - FixDocument20 paginiETOPS B777-300ER - Dedy Brian Ericson - FixDedyBrianEricsonNainggolanÎncă nu există evaluări

- List of Mayday Episodes - WikipediaDocument67 paginiList of Mayday Episodes - WikipediaΑλέξιος ΚατσούγκρηςÎncă nu există evaluări

- Mikoyan MiG 29Document10 paginiMikoyan MiG 29edijhon5815Încă nu există evaluări

- Diamond Da42 MetodikaDocument16 paginiDiamond Da42 MetodikaTonyÎncă nu există evaluări

- F-4 Phantom II Variant by VariantDocument45 paginiF-4 Phantom II Variant by Variantdr059100% (7)

- Revised SOP For Handling of VVIP FlightsDocument17 paginiRevised SOP For Handling of VVIP FlightsPavan Gopalapuram50% (2)

- Forecasting CaseDocument2 paginiForecasting CaseAditya PrasadÎncă nu există evaluări

- Air Assembly Maintenance ManualDocument5 paginiAir Assembly Maintenance ManualAlex Slavoia0% (1)

- Aer Lingus Normal ChecklistDocument2 paginiAer Lingus Normal ChecklistChrisÎncă nu există evaluări

- LifeFlight of Maine Judge PDFDocument49 paginiLifeFlight of Maine Judge PDFMonica EninÎncă nu există evaluări

- SPP APC Minimum Flight Altitude PDFDocument8 paginiSPP APC Minimum Flight Altitude PDFMohammed Alsbeay0% (1)