Documente Academic

Documente Profesional

Documente Cultură

Us5274939 PDF

Încărcat de

Jin SongDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Us5274939 PDF

Încărcat de

Jin SongDrepturi de autor:

Formate disponibile

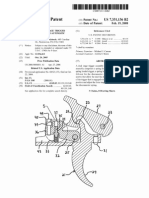

USO05274939A

United States Patent 1191

[11] Patent Number:

Scaramucci et al.

[45]

[54] FIRING MECHANISM FOR FIREARMS

2,139,202

Bellardi, Pesaro, both of Italy

[73] Assignee: Benelli Anni S.p.A., Urbino, Italy

[21] Appl. No.1 815,376

[30]

Italy .......................... .. MI91A 00046

161. c1; ................................. .. F41A 19/14

[52]

US. a. ................................... .. 42/69.03; 39/154;

89/27.1l

[58] Field 61 Search ............... ..42/69.03;89/139, 140,

89/141, 142, 146, 132, 154, 21.11

References Cited

[56]

U.S. PATENT DOCUMENTS

639,421 12/1989

Mauser .... ..

935,237

Savage .... ..

9/1909

42/6903

42/6903

939,882 11/1909 Whiting

1,202,017

10/1916

1,892,141 12/1932

Barnes . . . . . . .

42/6903

. . . ..

Campbell ................. .. 42/6903

Fontvieille ............... .. 42/6903

3,203,128

8/1965

Friend

4,011,996

4/1911

1.164116 .............................. .. 42/6903

. .. . . . .. . . .

. . . ..

42/6903

Italy .................................... .. 39/132

United Kingdom ............. .. 42/6903

Primary Examiner-Stephen M. Johnson

Attorney, Agent, or Firm-Amster, Rothstein &

Ebenstein

[51]

ABSTRACI

Firing mechanism for ?rearms, including a hammer

which is actuated by a spring and rotates about a pivot,

de?ning a cocked position and a percussion position; the

spring acts directly on the hammer on a surface point

which de?nes a lever arm with the pivot of the hammer,

so that the lever arm is variable as the hammer moves

between the cocked and percussion positions.

42/6903

Garand ............................. .. 42/6903

89/146

2,855,716 10/1958

2,901,853 9/1959

299313 3/1932

1410023 10/1915

Foreign Application Priority Data

[51]

Garland .............................. .. 89/139

FOREIGN PATENT DOCUMENTS

Dec. 31, 1991

Jan. 10, 1991 [IT]

2/1940

Jan. 4, 1994

2,675,638 4/1954 Crittendon

[75] Inventors: Sergio Scaramucci, Petriano; Paolo

[22] Filed:

Date of Patent:

5,274,939

6 Claims, 4 Drawing Sheets

US. Patent

Jan. 4, 1994

Sheet 1 of 4

'

5,274,939

US. Patent

Jan. 4, 1994

Sheet 2 of 4

'

5,274,939

US, Patent

Jan. 4, 1994

Sheet 3 of4 .

'

5,274,939

US. Patent

//4

w

Jan. 4, 1994

Sheet4 0:4

5,274,939

5,274,939

FIRING MECHANISM FOR FIREARMS

The present invention relates to a ?ring mechanism

for ?rearms.

BACKGROUND OF THE INVENTION

The ?ring mechanism of a ?rearm is generally consti

tuted by a hammer which rotates about a pivot and is

actuated by a spring.

One end of the hammer is provided with a hammer

dog which is adapted to engage an associated trigger

dog of the trigger, so that a rotation of the trigger leads

to the disengagement of the hammer, which, being 15

actuated by the spring, acts on the percussion pin.

In the ?ring action there are two critical moments in

BRIEF DESCRIPTION OF THE DRAWINGS

Further characteristics and advantages will become

apparent from the description of a preferred but not

exclusive embodiment of the invention, illustrated only

by way of non-limitative example in the accompanying

drawings, wherein:

FIG. 1 is a sectional side view of a ?ring mechanism

according to the invention in the disengagement step;

FIG. 2 is a sectional side view of the mechanism of

FIG. 1 during the percussion step;

FIG. 3 is a sectional side view of the mechanism of

FIG. 1 during the opening step; and

FIG. 4 is a sectional side view of the mechanism of

FIG. 1 during the engagement step.

DETAILED DESCRIPTION OF THE

INVENTION

With reference to the above ?gures, the ?ring mecha

the action of the spring on the hamme: the ?rst critical

moment is the percussion step, during which the spring

should preferably act with the maximum possible force 20 nism according to the invention, generally indicated by

on the hammer; the second critical moment is the ham

the reference numeral 1, comprises a hammer 3, which

mer cocking step, which naturally must encounter the

least possible resistance, especially in the case of auto

is pivoted to a pivot 5, and has a hammer dog 7. Ham

mer dog 7 is adapted to engage a trigger dog 9 of a

trigger 11.

matic or semiautomatic ?rearms.

In known ?ring mechanisms, the spring is generally

in the maximum compression position in the cocking

25

Trigger 11 is pivoted to a pivot 13 and has a second

trigger dog 15 which is adapted to engage a second

hammer dog 17 of the hammer. Second trigger dog 15

step, whereas in the percussion step it is in its maximum

is pivoted to trigger 11 and can perform a slight back

extension position; in this manner it is apparent that the

ward movement in contrast with a resilient member 19.

spring exerts excessive resistance during the cocking

step, while not all the possible force is exerted on the 30 The ?ring mechanism is also provided with a safety

catch device 21, which is per se known and therefore

will not be described herein for the sake of brevity.

According to the invention, a resilient member, con

stituted by a spring 23, is arranged in a conical seat 25 in

hammer during the percussion step.

A few attempts to solve this problem have been

made, at the cost of an excessively complex construc

tion, however. It would be in fact easy to design a

mechanism, with the desired characteristics, comprising

several levers; such mechanism, however, would be too

expensive and unreliable, as well as heavy and cumber

35 the body of the ?rearm. The upper end of spring 23 is

inserted in a cup 27.

some.

A simpler design has been proposed in US. Pat. No.

4,693,027 which discloses a ?at gun spring, for hand

guns. The spring has a progressively decreasing depth

that permits more energy to be stored in the spring

Under the action of spring 23, cup 27 acts on a ?rst

action surface 29 and on a second action surface 31 of

the hammer 3. Action surfaces 29 and 31 are connected

by a corner surface 33 and are arranged at a certain

angle with one another.

The operation of the ?ring mechanism according to

the invention is as follows.

during the early stages of the hammer rotation and less

In FIG. 1, the mechanism is illustrated in the disen

energy in the later stages of the hammer rotation. This 45 gagement step, i.e. when the trigger is pulled in order to

design substantially aims at eliminating "stack up im

mediately prior to hammer release.

SUMMARY OF THE INVENTION

The aim of the present invention is to provide a ?ring 50

mechanism in which the force exerted by the spring

during the percussion step is increased, while the resis

tance opposed during the cocking step is decreased.

?re; in this step, spring 23 is subjected to maximum

compression and is arranged with such an inclination

that cup 27 acts on the hammer substantially at the

surface 31 of the hammer.

FIG. 2 illustrates the percussion step, and in particu

lar the broken line 35 indicates the percussion plane; in

this step, spring 23 is at its maximum extension position

and the cup 27 acts on the hammer substantially on the

action surface 29. This is due to the conical con?gura

Within the scope of this aim, an object of the inven

tion is to provide a constructively simple mechanism 55 tion of the seat 25, which allows the spring 23 to rotate

backward through a set angle.

without the addition of further levers or other elements

FIG. 3 illustrates the subsequent step of the opening

of

the bolt 37 which, by sliding backward, acts on the

This aim, this object and others which will become

hammer 3 and cocks it. It is in fact apparent from FIG.

apparent hereinafter are achieved by a ?ring mechanism 60 3 that the point of action of the cup 27 shifts from the

to the mechanism.

for ?rearms, comprising a hammer and a resilient mem

ber, said hammer rotating about a pivot and having a

cocking position and a percussion position, wherein said

surface 29 to the corner surface 33 and then to the sur

face 31 in the subsequent engagement step, which is

illustrated in FIG. 4.

resilient member acts directly on a point of a surface of

In the engagement step, the hammer slides against the

said hammer, said point de?ning a lever arm with said 65 lower part of bolt 37, which transmits the minimum

hammer pivot, said lever arm being variable as said

amount of energy to the hammer. In this step, the com

hammer moves between said cocking position and said

pression of the spring is maximum. FIG. 4 furthermore

percussion position.

clearly shows that the second stop tooth 15 of the trig

5,274,939

ger engages the second tooth 17 of the hammer to pre

vent the subsequent actuation of the ?ring mechanism

by keeping the trigger pulled. It is therefore necessary

to release the trigger and pull it again in order to actuate

the mechanism a second time.

being arranged at an angle with respect to one another,

said resilient member acting directly on a point of one of

said surfaces of said hammer, said resilient member

having an axis, said axis being adapted to tilt from a

5 forward position to a rear position as said hammer

It has been observed in practice that the invention

achieves the intended aim and objects, a ?ring mecha~

moves between said cocking position and said percus

sion position; said resilient member comprising a cylin

nism having been provided in which the lever arm,

de?ned between the direction of the thrust of the ham

drical helical spring, said spring having at least one end

arranged in a conical seat de?ned in said ?rearm, said

mer spring and the hammers rotation pivot, is varied.

spring also having a second end acting on said point of

said hammer and said second end of said spring being

This variation is obtained by changing the direction

of the springs thrust and therefore the distance of its

inserted in a cup, said cup being adapted to slide on said

surface of said hammer during the movement of said

vector from the hammer pivot, so as to obtain a desired

variation of the hammer cocking effort and of the ham

hammer between said percussion and cocking positions.

mers pressure on the lower part of the bolt during its 15 2. Mechanism according to claim 1, wherein said

sliding, without compromising the thrust on the ham

angle between said action surfaces is approximately

mer during the percussion step.

equal to 90.

The variation in the vectorial direction of the ham

3. Firing mechanism for ?rearms, comprising a ham

mer springs thrust is obtained without levers or the

mer and a resilient member, said hammer rotating about

addition of parts, but simply by allowing the guiding 20 a pivot and having a cocking position and a percussion

cup of the spring to move within the conical seat under

position, said hammer comprising a ?rst action surface

the action of the thrust of the hammer and of the move

and a second action surface, said ?rst action surface

ment of the point of contact between the cup and said

being connected to said second action surface through a

hammer, which is obtained by means of the peculiar

corner surface, said ?rst and second action surfaces

shape given to the surface of contact between the ham 25 being arranged at an angle with respect to one another,

mer and the cup.

said resilient member comprising a cylindrical helical

Another advantage of the ?ring mechanism accord

spring, said spring being at least partially inserted into a

ing to the invention is constituted by the limited load on

cup, said cup being adapted to slide on said surfaces of

the trigger during disengagement.

said hammer, said spring being inserted in a seat, said

The ?ring mechanism according to the invention is 30 seat being substantially conical allowing for a tilting

susceptible to numerous modi?cations and variations,

motion of said spring as said hammer moves between

all of which are within the scope of the inventive con

said cocking position and said percussion position.

cept; all the details may furthermore be replaced with

4. Mechanism according to claim 3, wherein said said

technically equivalent elements.

hammer de?nes a point and said spring has at least one

The materials employed, as well as the dimensions, 35 end arranged in said seat and has a second end acting on

may naturally be any according to the requirements and

said point of said hammer.

the state of the art.

5. Mechanism according to claim 4, wherein said

second end of said spring is inserted in said cup, said cup

1. Firing mechanism for ?rearms, comprising a ham

being adapted to slide on said surface of said hammer

mer and a resilient member, said hammer rotating about 4-0 during the movement of said hammer between said

a pivot and having a cocking position and a percussion

percussion and cocking positions.

position, said hammer comprising a ?rst action surface

6. Mechanism according to claim 3, wherein said

and a second action surface, said ?rst action surface

angle between said action surfaces is approximately

being connected to said second action surface through a

equal to 90.

*

I

i

t

i

comer surface, said ?rst and second action surfaces 45

We claim:

55

65

S-ar putea să vă placă și

- (GUNSMITHING) Sten Submachine Gun WWIIDocument7 pagini(GUNSMITHING) Sten Submachine Gun WWIIMago Invisivel100% (10)

- 撞针选择的枪 PDFDocument9 pagini撞针选择的枪 PDFJin SongÎncă nu există evaluări

- 枪炮声抑制器 PDFDocument11 pagini枪炮声抑制器 PDFJin SongÎncă nu există evaluări

- 级触发自动武器 PDFDocument15 pagini级触发自动武器 PDFJin SongÎncă nu există evaluări

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDocument7 pagini1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongÎncă nu există evaluări

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDocument6 pagini偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongÎncă nu există evaluări

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 paginiUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongÎncă nu există evaluări

- 可调式双级触发机制半自动武器 PDFDocument12 pagini可调式双级触发机制半自动武器 PDFJin SongÎncă nu există evaluări

- 螺栓枪口装步枪 PDFDocument7 pagini螺栓枪口装步枪 PDFJin SongÎncă nu există evaluări

- 块化插入触发器的方法和装置5 PDFDocument23 pagini块化插入触发器的方法和装置5 PDFJin SongÎncă nu există evaluări

- 锤执行器的枪支 PDFDocument7 pagini锤执行器的枪支 PDFJin SongÎncă nu există evaluări

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Document13 paginiUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- Us6418655 PDFDocument17 paginiUs6418655 PDFJin SongÎncă nu există evaluări

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Document15 paginiUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- The DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFDocument15 paginiThe DIY Sheet Metal Self-Loading Pistol (Practical Scrap Metal Small Arms) PDFgunpdfs93% (121)

- Limited States Patent: LngramDocument7 paginiLimited States Patent: LngramJin SongÎncă nu există evaluări

- 安装装置,枪支消声器 PDFDocument28 pagini安装装置,枪支消声器 PDFJin Song100% (1)

- Us7946069 PDFDocument15 paginiUs7946069 PDFJin SongÎncă nu există evaluări

- Us4467698 PDFDocument11 paginiUs4467698 PDFJin Song100% (1)

- Us6772548 PDFDocument8 paginiUs6772548 PDFJin SongÎncă nu există evaluări

- Us6308609 PDFDocument18 paginiUs6308609 PDFJin SongÎncă nu există evaluări

- Us7676976 PDFDocument35 paginiUs7676976 PDFJin SongÎncă nu există evaluări

- Us4854065 PDFDocument7 paginiUs4854065 PDFJin SongÎncă nu există evaluări

- Us4358986 PDFDocument9 paginiUs4358986 PDFJin SongÎncă nu există evaluări

- Us4522106 PDFDocument13 paginiUs4522106 PDFJin Song100% (1)

- Us3276323 PDFDocument7 paginiUs3276323 PDFJin SongÎncă nu există evaluări

- Us4522105 PDFDocument10 paginiUs4522105 PDFJin SongÎncă nu există evaluări

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Document16 paginiSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongÎncă nu există evaluări

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Document6 paginiNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- TM 9-1340-222-34 - 2.75 - Inch - Low - Spin - Folding - Fin - Aircraft - Rockets - 1994 PDFDocument56 paginiTM 9-1340-222-34 - 2.75 - Inch - Low - Spin - Folding - Fin - Aircraft - Rockets - 1994 PDFWurzel1946Încă nu există evaluări

- Detailed Analysis of Plane Table SurveyingDocument11 paginiDetailed Analysis of Plane Table SurveyingNirbhay SinghÎncă nu există evaluări

- FESCO Consumer Service Manual OverviewDocument60 paginiFESCO Consumer Service Manual OverviewMus'ab FarouqÎncă nu există evaluări

- Plate Girder DesignDocument109 paginiPlate Girder Designhasib100% (3)

- Ups Installation and Maintenance ManualDocument141 paginiUps Installation and Maintenance ManualMuntasir100% (1)

- Marking Fixture PresentationDocument31 paginiMarking Fixture PresentationAvinash JejurkarÎncă nu există evaluări

- SHL Learning Resource Center List of Acquired Books for Engineering S.Y. 2012-2016Document27 paginiSHL Learning Resource Center List of Acquired Books for Engineering S.Y. 2012-2016jscansinoÎncă nu există evaluări

- THS Structural Plans (Combine)Document12 paginiTHS Structural Plans (Combine)genciÎncă nu există evaluări

- Eee MCQDocument39 paginiEee MCQRoshnal BluestacksÎncă nu există evaluări

- Masterful WiiFlow v4.2.3 Pack with Numerous UpdatesDocument4 paginiMasterful WiiFlow v4.2.3 Pack with Numerous UpdatesYulianÎncă nu există evaluări

- JNTU Previous Paper Questions ThermodynamicsDocument61 paginiJNTU Previous Paper Questions ThermodynamicsVishnu MudireddyÎncă nu există evaluări

- Industrial Sliding DoorsDocument40 paginiIndustrial Sliding DoorsAnonymous CPEha1db7UÎncă nu există evaluări

- 363-5 Machine Ride Control Actuator - Current Below NormalDocument3 pagini363-5 Machine Ride Control Actuator - Current Below NormalArtin HykoÎncă nu există evaluări

- Digital VLSI System Design Prof. Dr. S. Ramachandran Department of Electrical Engineering Indian Institute of Technology, MadrasDocument30 paginiDigital VLSI System Design Prof. Dr. S. Ramachandran Department of Electrical Engineering Indian Institute of Technology, MadrasPronadeep BoraÎncă nu există evaluări

- MVC Project Jarvis DatabaseDocument30 paginiMVC Project Jarvis DatabaseSravan SaiÎncă nu există evaluări

- Challenges Faced by PET ConvertorDocument35 paginiChallenges Faced by PET ConvertorRakeshjha75Încă nu există evaluări

- Dynamic Architecture Journal ArticleDocument11 paginiDynamic Architecture Journal Articlesakshi soniÎncă nu există evaluări

- Condition Report SIS 16M Daily Inspection GD16M-0053 (3 May 2016)Document4 paginiCondition Report SIS 16M Daily Inspection GD16M-0053 (3 May 2016)ahmat ramadani100% (1)

- What is an electrostatic shieldDocument3 paginiWhat is an electrostatic shieldsujaraghupsÎncă nu există evaluări

- Clements High School Celebrating 30 Years of Academic ExcellenceDocument22 paginiClements High School Celebrating 30 Years of Academic ExcellenceclementsrangersÎncă nu există evaluări

- Sa2009-001608 en Rel670 CT Calculation ExampleDocument7 paginiSa2009-001608 en Rel670 CT Calculation ExampleinsanazizÎncă nu există evaluări

- IWA SG Global TrendsDocument113 paginiIWA SG Global Trendsandik_yÎncă nu există evaluări

- If Steam Drum Under Vacuum Then What Will HappenDocument2 paginiIf Steam Drum Under Vacuum Then What Will HappenyogacruiseÎncă nu există evaluări

- Hex Head AVD 780 Installation Manual WEB PDFDocument77 paginiHex Head AVD 780 Installation Manual WEB PDFdasdsaÎncă nu există evaluări

- Weather and Aviation PDFDocument10 paginiWeather and Aviation PDFSergio GasparriÎncă nu există evaluări

- PSC Unit 4 PPT - Part 3Document35 paginiPSC Unit 4 PPT - Part 3Rino VidÎncă nu există evaluări

- AutoCAD CommandsDocument59 paginiAutoCAD Commandsamalendu_biswas_1Încă nu există evaluări

- Line Follower NXTDocument21 paginiLine Follower NXTKen LeÎncă nu există evaluări

- Volvo FMX: Product Guide - Euro 3-5Document24 paginiVolvo FMX: Product Guide - Euro 3-5HiT Dayat100% (2)

- Loop Back DSP Audio AppDocument12 paginiLoop Back DSP Audio AppGytis BernotasÎncă nu există evaluări