Documente Academic

Documente Profesional

Documente Cultură

Deep C Meter Operation Maintenance Manual

Încărcat de

Thaibinh NguyenDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Deep C Meter Operation Maintenance Manual

Încărcat de

Thaibinh NguyenDrepturi de autor:

Formate disponibile

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

TM

POLATRAK

DEEP-C-METER Mk.II

WITH GRADIENT PROBE

ROV MOUNTED SELF CONTAINED

CP MEASUREMENT SYSTEM

Operations & Maintenance Manual

Revision 1.1 April 1998

Phone: (713) 983-7117

Fax: (713) 983-8858

Deepwater Corrosion Services Inc.

www.stoprust.com

10851 Train Court

Houston, TX 77041

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

TABLE OF CONTENTS

1.0

Overview

2.0

Parts & Specifications

3.0

Calibration

4.0

Operation

5.0

Maintenance & Repair

6.0

Troubleshooting

Attachment 1.0 Drawings

2

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

1.0

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

OVERVIEW

1.1

The Deep-C-Meter Mk.II is a complete ROV interfaced Cathodic Protection

Monitoring System. The new model comprises of three basic parts; The

Readout Unit, twin voltmeters housed in a stainless steel pressure housing.

The Probe, a twin element, tip contact, CP probe (POLATRAK Model ROV

III). The Flying Lead, a 2 meter long umbilical that connects the probe to the

readout.

READOUT

PROBE UNIT

FLYING LEAD

ARTICULATED MOUNT

1.2

Figure 1.1

POLATRAKTM DEEP-C-METER Mk. II .

This new configuration offers a number of advantages over the Mk.1

instrument:

1.2.1

Easier to keep camera focused on readouts.

1.2.2

Easier to handle small probe in manipulator.

1.2.3

Probe can be wire into ROV umbilical if required for surface readout

and/or proximity measurement if required.

3

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

1.3

2.0

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

All the original innovative features of the Mk. 1 instrument are still included:

1.3.1

No interface required to ROV umbilical, unit operates independently of

ROV power or communications.

1.3.2

Light activated power up.

1.3.3

Twin electrodes and readouts for on-line calibration.

1.3.4

3000 Meter (10,000 Feet) Depth rating.

1.3.5

6 Month operations from 2 alkaline batteries (9V).

1.3.6

Can still be used with POLASTAB Tip to read POLASTAB permanent

monitors

1.3.7

All parts are replaceable.

PARTS

2.1

An assembled section of the instrument is shown in Attachment 1. Mounts

for the readout and the probe are omitted for clarity. The Readout Articulated

Mount is shown in Figure 2.2 and the Probe Compliant Tee-Handle Mount is

shown Figure 2.5. A parts list is shown in Table 2.1.

2.2

The major components along with specifications are described below:

2.3

Readout Unit

The readout unit has three major sub-assemblies: The Pressure Housing, the

Connector Housing and the Articulated Mount.

2.3.1

Pressure Housing

2.3.1.1 Housing Body

The pressure housing is made from a single solid piece of

316L Stainless Steel and is rated for 3000 M (10,000 Feet)

water depth.

2.3.1.2 Lens

One end of the housing contains an acrylic lens that seals with

o-rings into the pressure housing. A 316L SS retaining ring

and four SS screws keep the lens seated in the pressure

housing. Access to the inside of the pressure housing is

gained by pulling the lens. See maintenance and repair

section for details on lens removal/replacement.

4

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

2.3.1.3 Bulkhead Connector

The back end of the pressure housing is sealed with an

Impulse bulkhead connector. This connector threads into the

back of the pressure housing and also seals with an o-ring. It

should not be necessary to remove this connector during

normal maintenance. A blank (dummy) connector is provided

and should be in place whenever the mating connector is

removed.

2.3.1.4 Voltmeter Module

The voltmeter module is housed within the pressure housing

inside a shock absorbing / insulating holder (coozie). The

voltmeter module contains two independent plug-in four-digit

LCD readouts. Default factory range is +/- 2.000 VDC on both

readouts. A 9V alkaline battery powers each readout. On the

face of the module is a photocell that switches the unit on

when exposed to light and a small jumper that switches the

range of the either meter from +/- 2.000 VDC to +/- 200

mVDC. (This feature is used if reading monitors equipped with

POLASTAB interfaces or the ROV III Gradient Probe).

A desiccant pack is included to prevent interior fogging of the

lens.

Displays

Range

Selector

Photo Cells

Calibration

Pots

Figure 2.1 Voltmeter Module

2.3.2 Connector Housing

2.3.2.1 The Connector Housing is made from high impact natural

Delrin and is secured to the pressure housing with 4 stainless

steel cap screws. The housing protects the cable connector

and provides strain relief to the umbilical cable.

5

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

2.3.2.2 The strain relief fitting is secured to the connector housing with

two stainless steel cap screws, it is necessary to remove this

fitting before attempting to remove the housing from the

pressure housing.

2.3.3

Articulated Mount

The Articulated mount is designed to secure the Readout to the ROV frame,

and provides angled adjustment to optimize camera viewing of the displays.

The mount and all fixing hardware are 316 stainless steel.

Figure 2.2 Articulated Readout Mount

2.3.3.1 Ensure that all fasteners are secure and all lock nuts

and washers are in place before the ROV is deployed.

2.3

Probe Unit

The Deep-C-Meter Mk. II utilizes the popular POLATRAK ROV III Tip Contact

Gradient Probe. This probe can be used independently of the readout unit as a

standard topside wired CP probe. For reference the entire manual for this

equipment is included as Attachment 1.0 to this manual.

The Probe Unit comprises of the Nose Cone which houses the contact tip, the

Main Two Compartment Body section, the Tail Unit which houses the reference

electrode female plugs and the connection cable with strain relief, the Reference

Electrode Elements, the Compliant Tee Handle Mount for manipulator mounting

and the Flying Lead Connection back to the Readout Unit.

6

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

2.4.1

FORWARD

CONTACT US

PRINTABLE VERSION

Nose Cone

The nose cone assembly is inserted into the main body section and is held in

place with 2 set screws. The cone houses the replaceable contact tip, it also has

the female connector that attaches to the male pin on the extension cable from

the head unit. Tips are made from stainless steel; the nose cone is fabricated

from black Delrin. The tip also has four water entry ports.

Figure 2.3 Nose Cone / Tip Unit

Figure 2.4 Tail Unit

2.4.2

Main Body Section

The body section provides protection to the reference electrode elements. It is

made from black Delrin and is designed to fit the compliant tee handle mount for

convenient manipulator mounting.

2.4.3

Tail Unit

The tail unit attached to the main body section with 2 stainless steel cap screws.

The connection cable passes through this unit and is strain relieved with a PVC

strain relief fitting. One female electrode connector, one female connector for the

extension cable to the electrode element in the nose compartment and one male

tip connector are provided.

2.4.4

Reference Electrode Elements

Two plug-in sintered silver/silver chloride elements are included. Electrodes are

accurate to +/- 5 mV. See the operations and maintenance section for

instructions on electrode replacement.

CAUTION: NEVER HANDLE ELECTRODE ELEMENTS WITH BARE HANDS, or

EXPOSE ELEMENTS TO ANY LIQUID OTHER THAN WATER. PERMANENT

DAMAGE MAY RESULT.

7

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

2.4.5

FORWARD

CONTACT US

PRINTABLE VERSION

Compliant Tee Handle Mount

The Tee Handle Mount allows easy interface with most manipulator systems.

The entire mount is made from 316 stainless steel, the compliant elements are

neoprene rubber. For convenience the handle orientation can be altered by 90

degrees.

Figure 2.5 Compliant Tee Handle Mount

2.4.6

Flying Lead

The standard flying lead is 2 Meters long, a longer lead can be provided if it is

necessary to use a rear facing camera to look at the Readout. The lead has a

polyethylene abrasion resistant sheath and has connectors on either end that

mate with the bulkhead connector on the Readout and the whip cable on the

Probe unit.

2.5

Spare Parts & Accessories

2.5.1

The Deep-C-Meter is shipped in a waterproof case and should contain

the following spares and accessories (see pictures on following page).

2.5.1.1

2.5.1.2

2.5.1.3

2.5.1.4

2.5.1.5

2.5.1.6

2.5.1.7

2.5.1.8

2.5.1.9

2.5.1.10

2.5.1.11

2.5.1.12

Desiccant Pack

Zinc Calibration Block

Contact Tips

Connector Housing Screw

Cable Strain Relief Screw

Lens Retaining Ring Screw

O-Ring Lube

Silicone Connector Lube

Bulkhead Connector Dummy Plug

Ag/AgCl Electrode Element

Lens Back-Up Ring

Lens O-Ring

(2)

(1)

(3)

(4)

(4)

(4)

(1)

(1)

(1)

(1)

(2)

(4)

8

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

2.5.1.13 11Lens Puller

(1)

1

10

12

13

9

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

POLATRAK DEEP-C-METER KIT

ROV II PROBE UNASSEMBLED

(2) Ag/AgCl Refernce Electrodes

Nose Cone

Tail Unit

10

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

Part No.

DCM-010

Description

Readout Pressure Housing

DCM-011

PRINTABLE VERSION

No. Required

1

No. Spares

0

Readout Articulated Mount

DCM-020

Lens

DCM-011

Lens - O Ring

DCM-012

Lens - Backup Ring

DCM-021

Lens Retaining Ring

DCM-022

Lens Retaining Screw

DCM-023

Lens Cover

DCM-030

Bulkhead Male Connector

DCM-031

Bulkhead O Ring

DCM-032

Bulkhead Dummy Plug

DCM-110

Connector Housing Unit

DCM-111

ROV II Probe Nose Cone

DCM-112

Contact Tip

DCM-113

Connector Housing Retaining Screw

DCM-120

Main Connector

DCM-121

Replaceable Silver Chloride Element

DCM-210

Voltmeter Module

DCM-211

9V Alkaline Battery

DCM-212

LCD Display Module

DCM-214

Desiccant Pack

DCM-310

Compliant Probe Tee Handle Mount

DCM-410

Tube O-Ring Lubricant

DCM-411

Tube Silicone Grease

DCM-412

Zinc Calibration Block

DCM-413

Lens Puller

DCM-510

Instruction Manual

DCM-610

Transit Case

DCM-611

Transit Case O-Ring

DCM-612

Transit Case Foam Pack

Table 2.1

11

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

3.0

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

Calibration

With the system hooked up, the probe should be bucket calibrated prior to deploying

the ROV.

3.1 Bucket Calibration Procedure

1. Fill a non-metallic bucket or container with seawater, approximately

16 18 inches deep.

2. Place the probe in the bucket with the tip pointing up to fill body with

seawater. The entire probe, including tip must be immersed.

3. Stab the zinc coupon firmly onto the probe tip The upper displays on

the readout unit should read between (+) 1.000 & (+) 1.100 Volts.

The lower unit should read +/- 5 mV (+/- 50 on the display, the

decimal point is not displayed.)

4. Note: If the probe has not been used in a while it may take 15-30

minutes for the probe to reach equilibrium.

3.2 Online Calibration

While free flying the upper meter is reading the potential of the tip contact, this

number will vary. The lower meter displays the voltage gradient in the water.

When remote from any structure, the meter should display +/- 5 mV (+/- 50 on

the display)

If instrument will not calibrate go to Troubleshooting Section in this manual.

4.0

Operation

4.1 Mounting on ROV

Find a good location on the vehicle to mount the display unit, and attach the

articulated mount. The lens on the unit must be camera visible and have a light

source directed at it in order to activate the displays. Ensure that all fasteners are

good and tight and that all lock nuts and washers are in place. Leave the lens cover

in place while the unit is on deck (unless calibrating), the displays are light activated

and battery life will be reduced.

Insert the Probe unit into the compliant tee-handle probe mount and position in a

manipulator, or tool basket that is manipulator accessible. It is a good idea to tie a

safety lanyard to the probe mount u-bolts. Again, ensure that all fasteners are tight

and lock nuts are in place.

Route the flying lead in such a way that it will not be stressed, entangled or pinched

during manipulator operation.

Using the silicone grease provided, connect the flying lead to the probe and tighten

the connector lock ring.

12

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

Perform Bucket Calibration (see section 3.0)

Ensure that tip is tight in tip mount, and that tip is sharp.

Remove the lens cover from the instrument.

4.2 Taking CP Potential Readings

Simply stab the tip contact probe onto the point on the structure where the reading is

required, when a good contact is made the reading on upper meter will be steady.

The lower meter should display a positive number when contacting an anode, and a

negative number when contacting the structure remote from an anode.

CAUTIONS

Avoid stabbing painted or coated surfaces whenever possible,

try to take readings on bare steel or on spots specially

designated for CP measurement.

Avoid trying to stab through heavy hard marine growth if

possible.

If the readings are not steady or dont match the criteria in the

table below, its probably due to a high resistance contact, DO

NOT RECORD THESE NUMBERS continue to stab until

readings are in specification. See troubleshooting section if

problems persist.

Never operate the system with any of the connectors unmated unless the blanking plugs are installed.

4.3 Data Interpretation

Under normal conditions the readings obtained should be within the following ranges,

exceptions may occur under the following circumstances:

The probe is stabbed onto an isolated section of a corrosion

resistant alloy, stainless steel, copper nickel etc. In these

cases readings less negative than the indicated range may be

noted. If this is the case ensure that the readings are steady

and within the 5 mV allowable range.

The structure under investigation is fitted with impressed

current cathodic protection. In this case, the readings may be

more negative than those indicated below. Use the same

procedure as above.

13

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

Normal Cathodic Protection Ranges in Seawater

Range

Interpretation

<(-)0.500

Probable Error

(-)0.500 (-)0.650

Native state potential, no CP applied.

(-)0.650 (-)0.800

Under-Protected

(-)0.800 (-)0.850

Marginal Protection

(-)0.850 (-)1.050

Optimal Protection

(-)1.050 (-)1.150

Galvanic Anode Potential

>(-)1.150

Probable Error Check Contact

Note: Upper meter displays the potential with polarity reversed.

4.4 Removal from ROV

When equipment is removed from ROV hose down thoroughly with fresh water and

allow to dry. Replace lens cover and return to storage case provided.

5.0

Mainenance & Repair

This section covers general operational maintenance, do not attempt any tasks not

described in this section as it may damage the system.

5.1 Tip Replacement

From time to time it will be necessary to replace tips. Remove old tip with a wrench

(flats are provided). Ensure that new tip is tight.

5.2 Electrode Element Replacement

Remove the probe from the ROV and un-mate the connector. Install the

blank plug provided onto the exposed flying lead connector. Next determine

which element is bad.

Put the probe into a bucket and stab the zinc coupon as described in section

3.0.

Using a digital voltmeter set on 2.00 VDC range stab the large pin with the

positive voltmeter lead, and pin 1 (first clockwise of large pin) with the

negative lead (note reading). Then repeat stabbing pin 2 with the negative

lead, note the reading. The faulty electrode will be the one that gives the

lowest (least negative) reading.

Ensure that probe is drained of seawater.

Take probe unit to a clean area. Do not handle the small electrode pellets

with bare hands.

14

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

Remove the two screws securing the tail unit and gently pull out the tail unit

exposing the electrode elements. Try to avoid un-mating the tip connector.

Loosen the set screws and remove the nose cone.

Verify which electrode is bad using the Ohms setting on the multimeter.

Visually inspect to ensure that the wire is not damaged or the connector

improperly mated.

Remove the bad electrode and discard.

Take the new electrode and carefully place a small amount of silicone grease

on the pin and sealing section of the connector. Plug the new electrode into

the connector.

Check that all connectors are fully mated, then carefully put the electrodes

back into the housing and re-attach the tail unit and nose cone.

Repeat calibration as described above. (Note a new dry element may take

up to 30 minutes to reach equilibrium)

NEVER IMMERSE AN ELECTRODE

CONNECTOR PIN EXPOSED.

ELEMENT

IN

WATER

WITH

THE

5.3 Battery Replacement

Batteries will need replacing only after 4-6 months of operation. In order to replace

batteries, the readout must be removed from the vehicle and taken to a clean dry

location. This is best done in a workshop.

Follow these steps:

1. Remove the lens retaining ring.

2. Install the lens puller into the lowest exposed groove on

the lens as shown below:

15

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

3. Tighten down on the four screws one turn at a time until the

lens can be easily pulled from the housing. Remove the lens.

4. Carefully remove the voltmeter module from the housing, there

is enough slack cable to allow this. Then pull back the foam to

expose the two batteries.

5. Replace the batteries with new ones, also replace the desiccant

bag.

6. Carefully re-insert the voltmeter module. The displays should

illuminate.

7. Remove and discard the O-Rings and Back-up ring from the

lens, and replace with the spares provided. Ensure that the backup ring goes under the o-ring in the correct groove with the

concave side facing out. Use the lubricant provided and coat the

sealing surfaces with a thin layer.

8. Insert the lens into the housing so that the first o-ring is just

above the housing. Install the lens-retaining ring and engage

screws. Tighten screws one turn each on opposing screws until

both rings are fully inside pressure housing.

16

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

HOME

BACK

FORWARD

CONTACT US

PRINTABLE VERSION

6.0 Troubleshooting

Symptom

Instrument will not calibrate

Possible Problem

One electrode is bad

Zinc Coupon is passive

Both electrodes reading low

Tip wire damaged

Readings are not steady,

they continue to change.

Batteries are low

Poor structure contact

Action

See Section 5.3

Remove zinc and clean with

rasp

Allow to soak for 30 minutes

and retry

Remove probe tail unit,

unplug tip wire, remove nose

cone, inspect tip wire and

repair with ScotchKote as

temporary measure. Order

replacement nose cone.

Replace batteries

Re-stab to ensure contact.

One reading suddenly goes

less negative

Connector is flooded

Lead wire (Flying lead) is

nicked.

Not enough light to photocells

Batteries are dead

Check Connectors

Inspect and repair / replace

as necessary

Increase light intensity and

re-direct to center of lens.

Replace batteries

Electrodes are dry

Displays are blank

For any problem not described here call our Technical Hotline(s)

(713) 983 7117 x 225 or x 224

(281) 744-2342 (After Hours) Leave message if no answer.

17

DEEPWATER CORROSION SERVICES, INC.

DEEP C METER MANUAL

S-ar putea să vă placă și

- GPS Chapter 05. Binding TheoryDocument5 paginiGPS Chapter 05. Binding TheoryAhsan Raza100% (5)

- U10d2 CultureDocument4 paginiU10d2 Culturearhodes7770% (1)

- Activity 1: Making A Simple Rapid Curriculum EvaluationDocument9 paginiActivity 1: Making A Simple Rapid Curriculum EvaluationShainnah Cawa75% (4)

- DC4 DC8 DC10 (E2041700-02g)Document19 paginiDC4 DC8 DC10 (E2041700-02g)Mauricio Salazar100% (1)

- Matthew - Life For Today Bible Commentary - Andrew Wommack PDFDocument231 paginiMatthew - Life For Today Bible Commentary - Andrew Wommack PDFPascal Chhakchhuak100% (2)

- Deliverance QuestionnaireDocument13 paginiDeliverance QuestionnairemotmagicÎncă nu există evaluări

- Suggested Modifications To ASTM E477Document14 paginiSuggested Modifications To ASTM E477Jerry LillyÎncă nu există evaluări

- E560 Cmu04 CSDocument4 paginiE560 Cmu04 CSAlikÎncă nu există evaluări

- Experimental Testing and Fem Analysis of Corrugated TanksDocument2 paginiExperimental Testing and Fem Analysis of Corrugated TanksBash MatÎncă nu există evaluări

- Pe-1pbr-00238-H - Gerir Contratos de ServiçosDocument45 paginiPe-1pbr-00238-H - Gerir Contratos de ServiçosIsabella AntunesÎncă nu există evaluări

- FM-GUIDE Rubber StorageDocument20 paginiFM-GUIDE Rubber StorageTeodorescu Andrei0% (1)

- Ig 136 en 11Document84 paginiIg 136 en 11Islam DerazÎncă nu există evaluări

- Esl CVDocument1 paginăEsl CVSimon RattrayÎncă nu există evaluări

- DamageDocument7 paginiDamageNeeraj Singh GautamÎncă nu există evaluări

- 516 Vs 515Document2 pagini516 Vs 515Madan YadavÎncă nu există evaluări

- Catalogo de Conexoes para Tubos - GyrolokDocument59 paginiCatalogo de Conexoes para Tubos - GyrolokLuLi BoyÎncă nu există evaluări

- Procedure: Technical Requirement: A Provision Established As The Most Adequate andDocument8 paginiProcedure: Technical Requirement: A Provision Established As The Most Adequate andCaio JoppertÎncă nu există evaluări

- Instruction Manual 862 Interface-Thermo-ElementDocument16 paginiInstruction Manual 862 Interface-Thermo-ElementAlvaro Chang100% (1)

- Optical Fibers - Optical Attenuation Variation - Method of TestDocument8 paginiOptical Fibers - Optical Attenuation Variation - Method of Test张骏Încă nu există evaluări

- ASME I Part PMB Requirements For Miniature BoilersDocument2 paginiASME I Part PMB Requirements For Miniature BoilersAmanda Ariesta ApriliaÎncă nu există evaluări

- Catalogo Inyectores de QuimicoDocument6 paginiCatalogo Inyectores de QuimicoOscar Mauricio Santos MÎncă nu există evaluări

- Valkyrieas Instructionmanual en PDFDocument2 paginiValkyrieas Instructionmanual en PDFrss1311Încă nu există evaluări

- MS Samsung Cassette r22 Airconditioner 2 PDFDocument2 paginiMS Samsung Cassette r22 Airconditioner 2 PDFMacSparesÎncă nu există evaluări

- Catalogos de Motores Electricos Eberle - DelcrosaDocument1 paginăCatalogos de Motores Electricos Eberle - DelcrosaMiguel Guillermo Zelaya DamianÎncă nu există evaluări

- Washer Extractors: W4130S, W4180S, W4250SDocument2 paginiWasher Extractors: W4130S, W4180S, W4250SHanif Harun100% (1)

- API RP 651 - Section 1-ScopeDocument2 paginiAPI RP 651 - Section 1-ScopeAnonymous B7pghhÎncă nu există evaluări

- RiskWISE For Process Plant 2017Document2 paginiRiskWISE For Process Plant 2017Fabio TemporiniÎncă nu există evaluări

- Manual de Uso y Mantenimiento - 0006081349 - 3.0 PDFDocument88 paginiManual de Uso y Mantenimiento - 0006081349 - 3.0 PDFPaul OñaÎncă nu există evaluări

- LogicLevels PDFDocument4 paginiLogicLevels PDFsdeirÎncă nu există evaluări

- MAKO Piping Library Catalogue - Rev CDocument28 paginiMAKO Piping Library Catalogue - Rev Celmfp7774676Încă nu există evaluări

- 11E66919 A HAL2 User GuideDocument20 pagini11E66919 A HAL2 User GuideElias SantosÎncă nu există evaluări

- SENSOR J-BOX - 02ATEX3291Iss - 3 PDFDocument4 paginiSENSOR J-BOX - 02ATEX3291Iss - 3 PDFAdrian-Laurențiu RădulescuÎncă nu există evaluări

- 2/2-Way Valves DN 20 To DN 50Document4 pagini2/2-Way Valves DN 20 To DN 50Oscar CurimanyaÎncă nu există evaluări

- Advanced Heat Exchangers: Shell & Tube Marine CondensersDocument16 paginiAdvanced Heat Exchangers: Shell & Tube Marine CondensersMarco CambeiroaÎncă nu există evaluări

- DIN 3015 ClampsDocument17 paginiDIN 3015 ClampsKathirrasuÎncă nu există evaluări

- Analysis of Integral Snubber Circuit Design For Transformers in Urban High Rise Office BuildingDocument17 paginiAnalysis of Integral Snubber Circuit Design For Transformers in Urban High Rise Office BuildingLuis ÁtilaÎncă nu există evaluări

- Failure Analysis of An Electric Arc Furnace Off-Gas SystemDocument7 paginiFailure Analysis of An Electric Arc Furnace Off-Gas Systemgeraleao208Încă nu există evaluări

- MO-MM Sist Espuma Helipuerto WILHELMSENDocument54 paginiMO-MM Sist Espuma Helipuerto WILHELMSENArturo suzan arvizuÎncă nu există evaluări

- N 1693Document27 paginiN 1693Daniela Valdomiro PatrícioÎncă nu există evaluări

- Not For Production Use (For Reference Only) : ASTM A778-01Document1 paginăNot For Production Use (For Reference Only) : ASTM A778-01Abu Bakr AsharefÎncă nu există evaluări

- EVO Forza: Memory Product SpecificationsDocument5 paginiEVO Forza: Memory Product Specificationss_goulartÎncă nu există evaluări

- Leak Detection InspectorDocument41 paginiLeak Detection InspectortonÎncă nu există evaluări

- PRD - 3407 - Archivo - Preventive Om Checklist Inverter StationDocument7 paginiPRD - 3407 - Archivo - Preventive Om Checklist Inverter StationRichie RimbaniÎncă nu există evaluări

- Application Note Hardness Testing EnglishDocument12 paginiApplication Note Hardness Testing EnglishAnubhav LakhmaniÎncă nu există evaluări

- 200.061 MP Icm Modbus User Guide enDocument28 pagini200.061 MP Icm Modbus User Guide enVijaya Kumar100% (1)

- Medium Voltage Load Interrupter Switchgear: Descriptive BulletinDocument6 paginiMedium Voltage Load Interrupter Switchgear: Descriptive BulletinEslam SadekÎncă nu există evaluări

- DIO-562 Brief ManualDocument12 paginiDIO-562 Brief ManualDylkanWingsÎncă nu există evaluări

- NYLOFOR 2D Tech Installation PDFDocument2 paginiNYLOFOR 2D Tech Installation PDFMiralem Nevacinovic0% (1)

- API 651 Reading ChecklistDocument1 paginăAPI 651 Reading ChecklistbacabacabacaÎncă nu există evaluări

- Coastal F: Industry Standard Class 125/150 Slip-On FlangesDocument1 paginăCoastal F: Industry Standard Class 125/150 Slip-On Flangeskevin15vhÎncă nu există evaluări

- Seg Mri1 Relé de Proteção CatálogoDocument42 paginiSeg Mri1 Relé de Proteção CatálogoMarcelo Arriel100% (1)

- Bubble Cap FucntionDocument4 paginiBubble Cap FucntionPujo PurwantoÎncă nu există evaluări

- AirCooled Scroll Chiller Global CO R410A MFL67285211 0BHW0-02B (Jan.2020)Document110 paginiAirCooled Scroll Chiller Global CO R410A MFL67285211 0BHW0-02B (Jan.2020)alexÎncă nu există evaluări

- Arc Flash PPE-ATPV HRC 3 - 2020 PDFDocument9 paginiArc Flash PPE-ATPV HRC 3 - 2020 PDFRenán SuárezÎncă nu există evaluări

- Agrements TMD Recapitulatif Sept-2014Document30 paginiAgrements TMD Recapitulatif Sept-2014aldo2306Încă nu există evaluări

- 1.4462 EN-material Duplex PDFDocument3 pagini1.4462 EN-material Duplex PDFtien100% (1)

- Valvula Asca HC 74 IDocument4 paginiValvula Asca HC 74 IMAUROÎncă nu există evaluări

- Circuit Breaker - WikipediaDocument9 paginiCircuit Breaker - WikipediaManigandan212Încă nu există evaluări

- Válvula Esfera SBVF360 - DatasheetDocument4 paginiVálvula Esfera SBVF360 - DatasheetFabio GiehlÎncă nu există evaluări

- ASME B31.3 & Expansion Joints PDFDocument2 paginiASME B31.3 & Expansion Joints PDFsammar_10Încă nu există evaluări

- Manual Gaulin Homogenizers H P Pumps 899879 US Tcm11-7511Document114 paginiManual Gaulin Homogenizers H P Pumps 899879 US Tcm11-7511SirjuniAntoÎncă nu există evaluări

- ARC Welding PowARC Welding Power Sources - Pdfer SourcesDocument42 paginiARC Welding PowARC Welding Power Sources - Pdfer SourcesDanielÎncă nu există evaluări

- Indusoft - OracleDatabaseInx64OperationalSystemsDocument13 paginiIndusoft - OracleDatabaseInx64OperationalSystemslucasfernando22Încă nu există evaluări

- CP Gun Operation ManualDocument12 paginiCP Gun Operation ManualThaibinh NguyenÎncă nu există evaluări

- 77-0225A-E-PR018123096 TH1.X TFX Dehumidifier Unit (DHU) Installation ProcedureDocument23 pagini77-0225A-E-PR018123096 TH1.X TFX Dehumidifier Unit (DHU) Installation ProcedureJames AugustineÎncă nu există evaluări

- DeltaSol BS Plus V2.MonenDocument52 paginiDeltaSol BS Plus V2.MonenAlonso CoradoÎncă nu există evaluări

- Stray Curr Corr During Off WeldDocument5 paginiStray Curr Corr During Off WeldThaibinh NguyenÎncă nu există evaluări

- TankGard Operation ManualDocument18 paginiTankGard Operation ManualThaibinh NguyenÎncă nu există evaluări

- Snake Specs 2005 Rev3Document11 paginiSnake Specs 2005 Rev3Thaibinh NguyenÎncă nu există evaluări

- Polatrak OverviewDocument3 paginiPolatrak OverviewThaibinh NguyenÎncă nu există evaluări

- Deepwater Anode Data SheetsDocument18 paginiDeepwater Anode Data SheetsThaibinh NguyenÎncă nu există evaluări

- DC II Operation ManualDocument2 paginiDC II Operation ManualThaibinh NguyenÎncă nu există evaluări

- CP Gun Operation ManualDocument12 paginiCP Gun Operation ManualThaibinh NguyenÎncă nu există evaluări

- PIM Part3Document62 paginiPIM Part3Thaibinh NguyenÎncă nu există evaluări

- Cathodic Protection Strategies For FPSO's FinalDocument11 paginiCathodic Protection Strategies For FPSO's FinalThaibinh Nguyen100% (1)

- 49 CFR 195 Transportation of Hazardous Liquids by PipelineDocument18 pagini49 CFR 195 Transportation of Hazardous Liquids by PipelineThaibinh NguyenÎncă nu există evaluări

- 1169 - 40 CFR 122 Doc - 20140808Document16 pagini1169 - 40 CFR 122 Doc - 20140808Thaibinh NguyenÎncă nu există evaluări

- The Birth of The Bipolar Disorder: Historical ReviewDocument10 paginiThe Birth of The Bipolar Disorder: Historical ReviewFELIPE ABREOÎncă nu există evaluări

- Logistics ManagementDocument53 paginiLogistics Managementkarandeep89Încă nu există evaluări

- Transac SQLDocument1.663 paginiTransac SQLodlarhgÎncă nu există evaluări

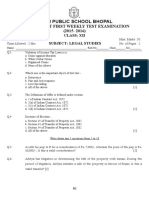

- Legal Studies XII - Improvement First Weekly Test - 2Document3 paginiLegal Studies XII - Improvement First Weekly Test - 2Surbhit ShrivastavaÎncă nu există evaluări

- Sharm o Hayaa-AshaarDocument127 paginiSharm o Hayaa-Ashaarbari bhattiÎncă nu există evaluări

- Steam Parameters Measurement - Steam Turbine PathDocument5 paginiSteam Parameters Measurement - Steam Turbine PathLTE002Încă nu există evaluări

- Covid FeversDocument7 paginiCovid FeversdbvidyaÎncă nu există evaluări

- Pubch 03Document111 paginiPubch 03Edwin Okoampa BoaduÎncă nu există evaluări

- Chapter 8 Accounts Receivable and Further Record-Keeping: Discussion QuestionsDocument3 paginiChapter 8 Accounts Receivable and Further Record-Keeping: Discussion Questionskiet100% (1)

- DigestDocument1 paginăDigestMich Donaire100% (1)

- Sets&StatisticsDocument6 paginiSets&StatisticsFarah AghaverdiyevaÎncă nu există evaluări

- 4B-Velocity Profiles (2021)Document18 pagini4B-Velocity Profiles (2021)ArinaAdilaÎncă nu există evaluări

- Interference Fields: in Healing Chronic IllnessDocument7 paginiInterference Fields: in Healing Chronic IllnessPoorni ShivaramÎncă nu există evaluări

- NCCS Statement On Homosexuality (Dec 2017)Document1 paginăNCCS Statement On Homosexuality (Dec 2017)NCCS AdminÎncă nu există evaluări

- Pure and Conditional ObligationDocument39 paginiPure and Conditional ObligationMajorie ArimadoÎncă nu există evaluări

- Survival - MCRP 3-02f FM 21-76Document571 paginiSurvival - MCRP 3-02f FM 21-76markdcoco690100% (4)

- Raghavendra Letter To Judge Hon. PitmanDocument10 paginiRaghavendra Letter To Judge Hon. PitmanIvyGateÎncă nu există evaluări

- Cawis vs. Cerilles - G.R. No. 170207 - April 19, 2010Document2 paginiCawis vs. Cerilles - G.R. No. 170207 - April 19, 2010Lordy Jessah AggabaoÎncă nu există evaluări

- FULLER Thesaurus of Epigrams 1943Document406 paginiFULLER Thesaurus of Epigrams 1943Studentul2000100% (1)

- Karnataka HC Adoption 1 448484Document19 paginiKarnataka HC Adoption 1 448484Winston MenezesÎncă nu există evaluări

- Unit23 SolutionsDocument7 paginiUnit23 SolutionsAbcÎncă nu există evaluări

- Project MaricoDocument23 paginiProject Maricoharishma29100% (1)

- News Feature and Essay (Ass.)Document4 paginiNews Feature and Essay (Ass.)Abegail TeodoroÎncă nu există evaluări

- The Basics of Systems Geology: British Geological Survey, 2012. HTTP://WWW - Bgs.ac - Uk/systemsgeology/basics PDFDocument0 paginiThe Basics of Systems Geology: British Geological Survey, 2012. HTTP://WWW - Bgs.ac - Uk/systemsgeology/basics PDFivica_918613161Încă nu există evaluări