Documente Academic

Documente Profesional

Documente Cultură

Dynamics of Machinery Lab COURSE PLAN

Încărcat de

M.ThirunavukkarasuDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Dynamics of Machinery Lab COURSE PLAN

Încărcat de

M.ThirunavukkarasuDrepturi de autor:

Formate disponibile

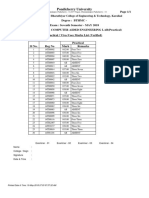

BHARATHIYAR COLLEGE OF ENGINEERING AND TECHNOLOGY

KARAIKAL

DEPARTMENT OF MECHANICAL ENGINEERING

COURSE PLAN 2010-2011

Subject: Dynamics of Machinery Lab (MEP 52)

Class / semester: B.Tech / V

Total number of students

: 70

No. of batches

: 02

No. of students / batch :

III Mech A sec

Period : 15 weeks

No.of cycle: 1

I Batch : 35

II Batch : 35

List of experiments:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

Demonstration of four bar inversion mechanism

Natural frequency of single mass, single helical spring system.

Natural frequency of combination of springs springs in parallel, springs in series

Natural frequency of undamped torsional single rotor, double rotor system. Effect

of inertia (I) and stiffness (kt).

Determination of radius of gyration of a given compound pendulum

Determination of radius of gyration, moment of inertia bifilar suspension

method trifilar suspension method

Damping coefficient of torsional single rotor system Effect of depth of immersion in oil and

damping ratio

Resonance frequency of equivalent spring mass system undamped and damped

condition. To plot amplitude Vs frequency graph for different damping.

Determination of characteristic curves of Watt, Porter, Proell and spring loaded governors.

Static and Dynamic balancing.

Whirling of shafts/ determination of critical speed with and with out Rotors.

Gyroscopic couple verification.

Journal bearing pressure distribution of different loads at different Speeds.

Cam motion analysis.

Generation of involute gear profile.

Tracing of coupler curves.

Determination of error in straight line drawn by watt chain mechanism.

BHARATHIYAR COLLEGE OF ENGINEERING AND TECHNOLOGY

KARAIKAL

DEPARTMENT OF MECHANICAL ENGINEERING

COURSE PLAN 2010-2011

Subject : Mechanical Measurment and Metrology Lab

Class / semester : B.Tech / VI

Total number of students

: 69

No. of batches

:2

No. of students / batch :

III Mech B sec

Period : 15 weeks

No. Of cycle: 1

I Batch : 35

II Batch : 34

List of experiments :

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

Demonstration of four bar inversion mechanism

Natural frequency of single mass, single helical spring system.

Natural frequency of combination of springs springs in parallel, springs in series

Natural frequency of undamped torsional single rotor, double rotor system. Effect

of inertia (I) and stiffness (kt).

Determination of radius of gyration of a given compound pendulum

Determination of radius of gyration, moment of inertia bifilar suspension

method trifilar suspension method

Damping coefficient of torsional single rotor system Effect of depth of immersion in oil and

damping ratio

Resonance frequency of equivalent spring mass system undamped and damped

condition. To plot amplitude Vs frequency graph for different damping.

Determination of characteristic curves of Watt, Porter, Proell and spring loaded governors.

Static and Dynamic balancing.

Whirling of shafts/ determination of critical speed with and with out Rotors.

Gyroscopic couple verification.

Journal bearing pressure distribution of different loads at different Speeds.

Cam motion analysis.

Generation of involute gear profile.

Tracing of coupler curves.

Determination of error in straight line drawn by watt chain mechanism.

BHARATHIYAR COLLEGE OF ENGINEERING AND TECHNOLOGY

KARAIKAL

DEPARTMENT OF MECHANICAL ENGINEERING

COURSE PLAN 2010-2011

Subject: Mechanical Measurements and Metrology Lab

III Mech B sec

Class / semester: B.Tech / VI

Total number of students

: 62

Period : 13 weeks

No. of batches

:2

No.of cycle: 1

No. of students / batch :

I Batch

: 31

II Batch : 31

List of experiments:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

Calibration of Micrometer

Measurement of taper using Sine Bar

Calibration of Plain Plug Gauge

Straightness and Flatness Measurement using Autocollimator

Surface Roughness Measurement

Inspection of Screw Threads (Effective Diameter)

Calibration of Inclined Tube Manometer

Measurement of Pressure using Strain Gauges

Determination of the constant of Thermocouples

Measurement of Force using Transducers

Measurement of Strain using Strain gauge

Study of Displacement using LVDT and RVDT

Vibration Measurement using Accelerometer

S-ar putea să vă placă și

- Applied Hydraulics & Pneumatics - JayakumarDocument287 paginiApplied Hydraulics & Pneumatics - Jayakumarjnnj2476% (21)

- New MET82 PDFDocument77 paginiNew MET82 PDFM.ThirunavukkarasuÎncă nu există evaluări

- Met82 Maintenanceandsafetyengineering (3 0 0 3) Unit-IDocument51 paginiMet82 Maintenanceandsafetyengineering (3 0 0 3) Unit-IM.ThirunavukkarasuÎncă nu există evaluări

- MSE 11 Mark Questions OnlyDocument4 paginiMSE 11 Mark Questions OnlyM.ThirunavukkarasuÎncă nu există evaluări

- FM BcetDocument17 paginiFM BcetM.ThirunavukkarasuÎncă nu există evaluări

- Bharathiyar College of Engineering and Technology Karaikal Department of Mechanical Engineering Subject: Maintenance and Safety Engineering Two Marks Questions With AnswerDocument14 paginiBharathiyar College of Engineering and Technology Karaikal Department of Mechanical Engineering Subject: Maintenance and Safety Engineering Two Marks Questions With AnswerM.ThirunavukkarasuÎncă nu există evaluări

- MSE LessonplanDocument4 paginiMSE LessonplanM.ThirunavukkarasuÎncă nu există evaluări

- First Cycle TestDocument2 paginiFirst Cycle TestM.ThirunavukkarasuÎncă nu există evaluări

- Pre FinalDocument2 paginiPre FinalM.ThirunavukkarasuÎncă nu există evaluări

- Second Cycle TestDocument2 paginiSecond Cycle TestM.ThirunavukkarasuÎncă nu există evaluări

- Course PlanDocument2 paginiCourse PlanM.ThirunavukkarasuÎncă nu există evaluări

- TE Lab Attendance 2018Document7 paginiTE Lab Attendance 2018M.ThirunavukkarasuÎncă nu există evaluări

- FM 2 Mark TestDocument1 paginăFM 2 Mark TestM.ThirunavukkarasuÎncă nu există evaluări

- FLUID MACHINERY - 2 MARKS FinalDocument22 paginiFLUID MACHINERY - 2 MARKS FinalM.ThirunavukkarasuÎncă nu există evaluări

- AE PrefinalDocument3 paginiAE PrefinalM.ThirunavukkarasuÎncă nu există evaluări

- FMDocument2 paginiFMM.ThirunavukkarasuÎncă nu există evaluări

- FM 4 5Document10 paginiFM 4 5M.ThirunavukkarasuÎncă nu există evaluări

- Answer Key For Kom 2 Cycle 2018Document6 paginiAnswer Key For Kom 2 Cycle 2018M.ThirunavukkarasuÎncă nu există evaluări

- Tentative Time Table M.tech Cad 2017Document1 paginăTentative Time Table M.tech Cad 2017M.ThirunavukkarasuÎncă nu există evaluări

- TE Lab Attendance 2018Document7 paginiTE Lab Attendance 2018M.ThirunavukkarasuÎncă nu există evaluări

- Fluid MachineryDocument9 paginiFluid MachineryM.ThirunavukkarasuÎncă nu există evaluări

- II Mech - Mach PaulDocument3 paginiII Mech - Mach PaulM.ThirunavukkarasuÎncă nu există evaluări

- Camd Lab 4 Sem May 2018 PDFDocument2 paginiCamd Lab 4 Sem May 2018 PDFM.ThirunavukkarasuÎncă nu există evaluări

- Final Year Name List 1Document4 paginiFinal Year Name List 1M.ThirunavukkarasuÎncă nu există evaluări

- CAD Cycle Test - II Questions 2018Document1 paginăCAD Cycle Test - II Questions 2018M.ThirunavukkarasuÎncă nu există evaluări

- CAD Cycle Test I Answer Key2018Document16 paginiCAD Cycle Test I Answer Key2018M.ThirunavukkarasuÎncă nu există evaluări

- Alumni Meet 13-08-2016Document1 paginăAlumni Meet 13-08-2016M.ThirunavukkarasuÎncă nu există evaluări

- Cae Lab 7 Sem May 2018 PDFDocument1 paginăCae Lab 7 Sem May 2018 PDFM.ThirunavukkarasuÎncă nu există evaluări

- Script Program - 3Document1 paginăScript Program - 3M.ThirunavukkarasuÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Our Fleet: Airbus A220 FamilyDocument2 paginiOur Fleet: Airbus A220 FamilyErim KaskaÎncă nu există evaluări

- Design and Fabrication of Ultra Light AircraftDocument111 paginiDesign and Fabrication of Ultra Light AircraftVarphi16100% (2)

- SaeslDocument26 paginiSaeslElla HermonioÎncă nu există evaluări

- SatracDocument18 paginiSatracvenkat_raj_38Încă nu există evaluări

- Box Shifting MechanismDocument21 paginiBox Shifting MechanismNishant Chauhan67% (9)

- NPTEL Aerospace Engineering Turbomachinery Lecture TopicsDocument2 paginiNPTEL Aerospace Engineering Turbomachinery Lecture TopicsBaskar SelvarajÎncă nu există evaluări

- Aircraft Maintenance Hangar Doc. No. UFC 4-211-101 Rev.3 2021Document308 paginiAircraft Maintenance Hangar Doc. No. UFC 4-211-101 Rev.3 2021Alphard DarmawanÎncă nu există evaluări

- Aer Lingus PDFDocument3 paginiAer Lingus PDFNg Wei JiangÎncă nu există evaluări

- Load Test On Scharge MotorDocument4 paginiLoad Test On Scharge MotorRamakrishna SagarÎncă nu există evaluări

- Aero Acoustics of Fixed Wing and Rotary Wing AircraftDocument15 paginiAero Acoustics of Fixed Wing and Rotary Wing AircraftgarridolopezÎncă nu există evaluări

- SB25 616 Taai2Document15 paginiSB25 616 Taai2aeprokofyevÎncă nu există evaluări

- SAFA Ramp ChecklistDocument3 paginiSAFA Ramp ChecklistVincent GrondinÎncă nu există evaluări

- B777 Circuit Breaker ListDocument32 paginiB777 Circuit Breaker Listsam sir33% (3)

- KMIADocument31 paginiKMIAjackpilot32Încă nu există evaluări

- David R. Emerso PDFDocument488 paginiDavid R. Emerso PDFsemabayÎncă nu există evaluări

- Apollo 13 Mission TranscriptDocument765 paginiApollo 13 Mission TranscriptSam Golledge100% (1)

- DATASHEEDocument2 paginiDATASHEERisto ZlatkovÎncă nu există evaluări

- The Path To Flight MH370 V2.0e Sergio Cavaiuolo 8mar2022wsDocument125 paginiThe Path To Flight MH370 V2.0e Sergio Cavaiuolo 8mar2022wsJugert MucoimajÎncă nu există evaluări

- MiniQAR MK IIDocument4 paginiMiniQAR MK IIChristina Gray0% (1)

- Examen Fluidos 2021-2 VirtualDocument5 paginiExamen Fluidos 2021-2 VirtualDiego MoyaÎncă nu există evaluări

- ICAO Aircraft Maintenance Training ManualDocument127 paginiICAO Aircraft Maintenance Training ManualAlphard DarmawanÎncă nu există evaluări

- Axial CompresserDocument48 paginiAxial Compresservishnu kadiyalaÎncă nu există evaluări

- Aluminium Honeycomb Walls Strength AnalysisDocument16 paginiAluminium Honeycomb Walls Strength AnalysisMangesh ThokalÎncă nu există evaluări

- Small Spacecraft Technology State of The Art 2014 PDFDocument211 paginiSmall Spacecraft Technology State of The Art 2014 PDFKarimTaha100% (1)

- 010-Air Law DISPATCHERS PART 1Document198 pagini010-Air Law DISPATCHERS PART 1Pedro SantosÎncă nu există evaluări

- R/C Soaring Digest - Apr 2007Document44 paginiR/C Soaring Digest - Apr 2007Aviation/Space History LibraryÎncă nu există evaluări

- Tolerance Limits and Fits ExplainedDocument35 paginiTolerance Limits and Fits Explainedmithunsingh90Încă nu există evaluări

- Order 8900.1Document5 paginiOrder 8900.1Peterson TelesÎncă nu există evaluări

- Wind Load For Superstructure: F PagcDocument2 paginiWind Load For Superstructure: F PagcAnirudh SabooÎncă nu există evaluări

- Revista ModelismoDocument8 paginiRevista ModelismoAlan Ferreira De Sousa100% (1)