Documente Academic

Documente Profesional

Documente Cultură

Fixed Plate Modeling and Modal Analysis by ANSYS

Încărcat de

Mohammad Ahmad GharaibehTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Fixed Plate Modeling and Modal Analysis by ANSYS

Încărcat de

Mohammad Ahmad GharaibehDrepturi de autor:

Formate disponibile

1

Constrained Plate Natural Frequencies and

Mode Shapes using ANSYS Modal analysis

Mohammad A Gharaibeh

11/19/2014

Goal

This Lecture aims to obtain natural frequencies and mode shapes

of a constrained isotropic plate using ANSYS Software

Problem Description

Problem:

Obtain natural frequencies and mode shapes of

squared isotropic plate with fixed boundary

conditions using ANSYS Modal analysis

Material: Aluminum

Material Parameter

SI units

English units

Youngs modulus

73.1 GPa

10.6 MSI

Density

2780 Kg/m3

2.6*10-4 lb.sec2/in4

Poissons ratio

0.3

0.3

Geometry Parameter

SI units (m)

English units (inch)

Length (a)

0.3

12

Width (b)

0.3

12

Thickness (h)

6.35*10-3

0.25

Be careful of this!!

Plate Size:

We will use

English units

ANSYS Environment

Utility Menu: File controls, plotting, selecting parameters, etc.

Input line: Allows you to type in commands directly

Toolbar: Used to open and save ANSYS jobs.

Main Menu: The place you will use a lot. Preprocessing, Solution and Postprocessing

Graphics window:

Where the model,

Postprocessing and

results will appear.

Start modeling - Preprocessing

In this step we will learn how:

Define Element Type.

Specify Material Parameters

Build the Model

Mesh

Element type defines the way how do you want to mesh your model. In FEA, it depends

on the problem type and it is very necessary to be selected carefully.

Define Element Type

Main Menu:

Preprocessor >> Element Type >> Add/Edit/Delete

Define Element Type (contd)

Element type window: Add

Library of Element type: Solid >> Brick 8 Node 185

This is SOLID185 element suitable for various 3-D modeling of solid structures

3

2

Define Element Type - Keyoption

We need to specify little more details for this element to make match our desired problem

using element KEYOPTION

Element types window: Options

SOLID185 element type options: Element technology (K2) >> Simple enhanced Strain

2

3

You can test

other options

available and

compare with

theoretical

results

Specify Material Properties - 1

Now we need to input material properties

Main Menu: Preprocessor >> Material Props >> Material Models

10

Specify Material Properties - 2

From Window appears

Material Model Number 1 >> Structural >> Linear >> Elastic >> Isotropic

Then Type in your values for Youngs Modulus and Poissons ratio >> OK

Take care of

your units!

2,3,4,5

10.6e6

equals to

10.6 MSI

11

Specify Material Properties - 3

Specify density

Material Model Number 1 >> Structural >> Density

Then Type in your value for Density>> OK

Close window (X)

Take care of

your units!

2.6e-4 equals

to 2.6*10-4

2

4

12

Build Geometry - 1

Main Menu: Preprocessor >> Modeling >> Create >>Volumes >> Block >> By dimensions

Type in your plate dimensions in x,y and z coordinates and hit OK.

Other Modeling procedure ??

Try keypoints, lines, areas and end up with volume

13

Build Geometry - 2

14

Meshing

Meshing is the most essential step in FEA modeling. It means that use the element type you

specified to fill in (mesh) your solid model with nodes and elements.

Important You need nodes and elements for the finite element solution NOT just the

solid model weve just created. The solid model does NOT participate in the FEA solution.

It requires three steps:

Attribute element type and material properties to the solid model

Mesh Control specify number of divisions.

Meshing the solid model (create elements and nodes)

Meshing

Solid Model

FEA Model

15

Meshing: 1- Attribution

Main Menu: Preprocessor >> Meshing >> Mesh Attributes >>Picked volumes

Click on the Solid model

Click on the

solid model

16

Meshing: 1- Attribution

Main Menu: Preprocessor >> Meshing >> Mesh Attributes >>Picked volumes

When you click on the solid model its color will turn into Purple

Now, hit OK

17

Meshing: 1- Attribution

Main Menu: Preprocessor >> Meshing >> Mesh Attributes >>Picked volumes

Volume attributes window: OK

Here we specify which material and/or element type to use. In our case, it should look like:

18

Meshing: 2- Mesh Control

In order to specify number of divisions, we need first to observe the LINES

Utility Menu: Plot >> Lines

19

Meshing: 2- Mesh Control

In order to specify number of divisions, we need first to observe the LINES

Utility Menu: Plot >> Lines

20

Meshing: 2- Mesh Control

In order to specify number of divisions, we need first to observe the LINES and lines NUMBERS

Utility Menu: PlotCtrls >> Numbering

21

Meshing: 2- Mesh Control

In order to specify number of divisions, we need first to observe the LINES and lines NUMBERS

Plot Number Controls window: LINE >> ON

Hit OK

Turn this ON

22

Meshing: 2- Mesh Control

To changes the angle of view use Dynamic Model Mode

Or simple using keyboard and mouse

Press and hold Ctrl + Mouse right click

For zoom Mouse scroll

23

Meshing: 2- Mesh Control

After plotting lines and numbers we need now to divide them

Main Menu: Preprocessor >> Meshing >> Size Cntrls >> Picked Lines

Then, click on the desired lines. In our case just select the in-plane 8 lines (top and bottom) of plate.

Hit OK

24

Meshing: 2- Mesh Control

After plotting lines and numbers we need now to divide them

Element size on Picked Lines window: NDIV type in 50 (or any other number of divisions)

OK

25

Meshing: 3- Mesh Creation

To create mesh (elements and nodes)

Main Menu: Preprocessor >> Meshing >> Mesh >> Volumes >> Mapped >> 4 to 6 sided

Click on the model (as done previously) >> Hit OK

To plot volumes:

Utility Menu: Plot

>> Volumes

26

Meshing: 3- Mesh Creation

The FEA Model

27

Constraint application

Applying constraint involves two steps:

Select required nodes based on the problem specifications 0.25 at corners

Add constraints in our case all directions (all DOF).

4

28

Constraint application node selection

Utility Menu: Select >> Entities

29

Constraint application node selection

Utility Menu: Select >> Entities

30

Constraint application

corner 1 nodes selection

1 select nodes at

the bottom of the

plate

2 reselect nodes at

required location in

x-direction

3 reselect nodes at

required location in

y-direction

Top view

y

x

z

Side view

x

Bottom of the plate

z =0

31

Apply constraints

Main Menu: Solution >> Define Loads >> Apply >> Structural >> Displacement >>

On Nodes

Pick All

32

Apply constraints

In the Box appears

All DOF

Value = 0

33

Apply constraints

In the Box appears

All DOF

Value = 0

34

Constraint application corner 2 node selection

To select corner 2 nodes - similarly

Utility Menu: Select >> Entities

y

x

35

Constraint application

corner 1 nodes selection

1 select nodes at

the bottom of the

plate

2 reselect nodes at

required location in

x-direction

3 reselect nodes at

required location in

y-direction

Top view

x

z

Side view

x

Bottom of the plate

z =0

36

Apply constraints

Main Menu: Solution >> Define Loads >> Apply >> Structural >> Displacement >>

On Nodes

Pick All

37

Apply constraints

In the Box appears

All DOF

Value = 0

Apply constraints

38

39

Apply Constraints

Similar procedure can be followed to constrain corner 3 and

corner 4.

4

40

Four corners constraints

41

Solution of the FE model

After applying constraints (Boundary conditions) on the FE

model, it is ready for solution.

As we have done last week:

Define analysis type Modal analysis.

Solve

42

Solution: 1- Define analysis type

To define the analysis type (which is here model analysis)

Main Menu: Solution >> Analysis Type >> New Analysis

Select Modal and OK

43

Solution: 1- Define analysis type

More analysis options

Main Menu: Solution >> Analysis Type >> Analysis Options

Solver: Block Lanczos

Number of Modes: 20 (or else) Hit OK

Make sure to have

same number

44

Solution: 1- Define analysis type

More analysis options

Main Menu: Solution >> Analysis Type >> Analysis Options

Specify frequency range that youd like to look in (make sure to be large enough)

45

Solution: 2- Solve the FE model

Solution

Main Menu: Solution >> Solve >> Current LS (Load Step)

OK

46

Solution: 2- Solve the FE model

Solution is DONE!

Life is Good!

Hit OK and close /Status window.

47

Postprocessing step

As discussed previously ANSYS has three main analysis step:

Preprocessing

Solution

Postprocessing

DONE!

DONE!

We are here!

In PostProcessing step:

List Natural Frequencies

Select mode shape you want to see

Plot it!

48

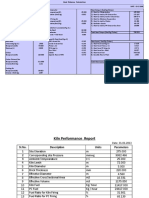

Postprocessing: 1- List Natural Frequencies

General Postprocessor: Results summary

A list of natural frequencies will appear

49

Postprocessing: 1- List Natural Frequencies

If you want to save natural frequencies as an ASCII file

File >> Save

Units here are in Hz!

50

Postprocessing: 2- Select mode shape needed

To select which mode shape to observe

Main Menu: General Postproc. >> Read results >> By load step

LSTEP = 1, SBSTEP = 1

>> OK

First Mode shape

51

Postprocessing: 3- Plot mode shape

To plot mode shape

Main Menu: General Postproc. >> Plot results >> Contour Plot >> Nodal Solution

From tree >> DOF Solution >> Displacement vector SUM

OK

First Mode shape

52

Postprocessing: 3- Plot mode shape

First Mode shape

53

Postprocessing: Animate a mode shape

Utility Menu: PlotCtrls >> Animate>> Mode Shape

54

Postprocessing: Animate a mode shape

Specify number of frames and delay time.

Display type >> DOF Solution >> Translation USUM

OK

55

Do you want your log file?

Main Menu: Session Editor

Everything youve

done is here

S-ar putea să vă placă și

- ANSYS Mechanical APDL for Finite Element AnalysisDe la EverandANSYS Mechanical APDL for Finite Element AnalysisEvaluare: 4.5 din 5 stele4.5/5 (8)

- Ansys Workshop 5Document34 paginiAnsys Workshop 5SudharsantÎncă nu există evaluări

- ANSYS Tutorial: Jake Blanchard January 2008Document24 paginiANSYS Tutorial: Jake Blanchard January 2008Joan HeviaÎncă nu există evaluări

- Airplane Wing AnalysisDocument21 paginiAirplane Wing AnalysisappunathanÎncă nu există evaluări

- Digital Simulation-Ii Lab (Type Text) Page 0Document43 paginiDigital Simulation-Ii Lab (Type Text) Page 0Rahul ChowdariÎncă nu există evaluări

- Paschal's Intensive Course ReportDocument176 paginiPaschal's Intensive Course ReportSamuel charlesÎncă nu există evaluări

- Modalna Analiza AnsysDocument5 paginiModalna Analiza AnsysludimataÎncă nu există evaluări

- Tutorial 1 Simple 3D TrussDocument11 paginiTutorial 1 Simple 3D TrussSalma FarooqÎncă nu există evaluări

- Tutorial #2: Linear-Static Analysis.: ME309: Finite Element Analysis in Mechanical DesignDocument22 paginiTutorial #2: Linear-Static Analysis.: ME309: Finite Element Analysis in Mechanical DesignimadÎncă nu există evaluări

- Ansys TutorialDocument24 paginiAnsys TutorialMuhammad BilalÎncă nu există evaluări

- Module 1.2: Moment of A 1D Cantilever BeamDocument16 paginiModule 1.2: Moment of A 1D Cantilever Beamnanduslns07Încă nu există evaluări

- Ans ExDocument19 paginiAns ExGanapathy VigneshÎncă nu există evaluări

- Thermal Analysis ExampleDocument9 paginiThermal Analysis ExampleTrung KiênÎncă nu există evaluări

- Tutorial 3 - Crack ProblemDocument8 paginiTutorial 3 - Crack ProblemImran2109Încă nu există evaluări

- SampleDocument5 paginiSampleKhusi1Încă nu există evaluări

- Module 1.5: Moment Loading of A 2D Cantilever BeamDocument17 paginiModule 1.5: Moment Loading of A 2D Cantilever Beamnanduslns07Încă nu există evaluări

- Ansys Tutorial For Lamb Waves PropagationDocument12 paginiAnsys Tutorial For Lamb Waves PropagationRamy100% (1)

- Module 4: Buckling of 2D Simply Supported BeamDocument18 paginiModule 4: Buckling of 2D Simply Supported Beamnanduslns07Încă nu există evaluări

- Module 1.2: Moment of A 1D Cantilever BeamDocument17 paginiModule 1.2: Moment of A 1D Cantilever Beamnanduslns07Încă nu există evaluări

- Ansys ExperimentsDocument10 paginiAnsys ExperimentsASIST MechÎncă nu există evaluări

- SFD and BMD in Ansys APDLDocument26 paginiSFD and BMD in Ansys APDLShadab Alam50% (2)

- ANSYS LAB Ex8Document3 paginiANSYS LAB Ex8baranirajÎncă nu există evaluări

- Problem: Analyze The 2D Truss As Shown Below. All The Members Have Cross-Sectional Area ofDocument5 paginiProblem: Analyze The 2D Truss As Shown Below. All The Members Have Cross-Sectional Area ofsmg26thmayÎncă nu există evaluări

- ANSYS ManualDocument62 paginiANSYS ManualPratheesh JpÎncă nu există evaluări

- Ansys TutorialDocument4 paginiAnsys TutorialborchecÎncă nu există evaluări

- Ball-Flange Impact Using Surface To Surface Contact ElementsDocument8 paginiBall-Flange Impact Using Surface To Surface Contact Elementsrishit_aÎncă nu există evaluări

- 9 Basic-Knuckle Joint PinDocument21 pagini9 Basic-Knuckle Joint Pinbartolo.garca2811Încă nu există evaluări

- Tutorial de Mecánica de La Fractura (Ansys APDL)Document14 paginiTutorial de Mecánica de La Fractura (Ansys APDL)omarihuanoÎncă nu există evaluări

- Cad Exp-7Document12 paginiCad Exp-7Harshal DodkeÎncă nu există evaluări

- Sub StructuringDocument16 paginiSub StructuringNafees ImitazÎncă nu există evaluări

- Problem Description:: Tutorial 1: Parallel PlatesDocument17 paginiProblem Description:: Tutorial 1: Parallel PlatesCharlton S.InaoÎncă nu există evaluări

- Ansys ManualDocument36 paginiAnsys ManualSaras ChandraÎncă nu există evaluări

- ANSYS TutorialDocument60 paginiANSYS TutorialDarmanto Suwarni MunirÎncă nu există evaluări

- Modeling Tools in ANSYS: /title, Meshing A Plate Using CutlinesDocument10 paginiModeling Tools in ANSYS: /title, Meshing A Plate Using CutlinesKushagra shivamÎncă nu există evaluări

- Module 3: Buckling of 1D Simply Supported BeamDocument18 paginiModule 3: Buckling of 1D Simply Supported Beamnanduslns07Încă nu există evaluări

- Result: Thus The Maximum Deflection, Tangential and Radial Stress Induced in Long Cylindrical PressureDocument25 paginiResult: Thus The Maximum Deflection, Tangential and Radial Stress Induced in Long Cylindrical Pressurepravi2010Încă nu există evaluări

- UiiuDocument20 paginiUiiupravi2010Încă nu există evaluări

- 2d TrussDocument19 pagini2d Trussbapu28Încă nu există evaluări

- Harmonic Response Tutorial v81 Rev PDFDocument15 paginiHarmonic Response Tutorial v81 Rev PDFAlex L. PuertoÎncă nu există evaluări

- Plane Stress BracketDocument18 paginiPlane Stress Bracketdeepak parariyaÎncă nu există evaluări

- Tutorial Gambit PDFDocument13 paginiTutorial Gambit PDFNacera BenslimaneÎncă nu există evaluări

- Ansys Tutorial Forthe Torque Analysis of The Shaft Attached With Two DisksDocument13 paginiAnsys Tutorial Forthe Torque Analysis of The Shaft Attached With Two DisksPugazhenthi ThananjayanÎncă nu există evaluări

- Cantilever BeamDocument7 paginiCantilever BeamjellowisÎncă nu există evaluări

- Solidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingDe la EverandSolidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingÎncă nu există evaluări

- AutoCAD 2015 and AutoCAD LT 2015: No Experience Required: Autodesk Official PressDe la EverandAutoCAD 2015 and AutoCAD LT 2015: No Experience Required: Autodesk Official PressÎncă nu există evaluări

- SolidWorks 2016 Learn by doing 2016 - Part 3De la EverandSolidWorks 2016 Learn by doing 2016 - Part 3Evaluare: 3.5 din 5 stele3.5/5 (3)

- AutoCAD 2016 and AutoCAD LT 2016 No Experience Required: Autodesk Official PressDe la EverandAutoCAD 2016 and AutoCAD LT 2016 No Experience Required: Autodesk Official PressEvaluare: 4 din 5 stele4/5 (1)

- Creality Ender 3 and Creality Slicer Tutorial for 3D printers and tips and tricks.De la EverandCreality Ender 3 and Creality Slicer Tutorial for 3D printers and tips and tricks.Evaluare: 3 din 5 stele3/5 (1)

- NX 9 for Beginners - Part 1 (Getting Started with NX and Sketch Techniques)De la EverandNX 9 for Beginners - Part 1 (Getting Started with NX and Sketch Techniques)Evaluare: 3.5 din 5 stele3.5/5 (8)

- SolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)De la EverandSolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Evaluare: 4.5 din 5 stele4.5/5 (5)

- Up and Running with AutoCAD 2012: 2D Drawing and ModelingDe la EverandUp and Running with AutoCAD 2012: 2D Drawing and ModelingEvaluare: 3.5 din 5 stele3.5/5 (3)

- Microelectronic Systems 1 Checkbook: The Checkbook SeriesDe la EverandMicroelectronic Systems 1 Checkbook: The Checkbook SeriesÎncă nu există evaluări

- A Student's Guide to Python for Physical Modeling: Second EditionDe la EverandA Student's Guide to Python for Physical Modeling: Second EditionÎncă nu există evaluări

- NX 9 for Beginners - Part 3 (Additional Features and Multibody Parts, Modifying Parts)De la EverandNX 9 for Beginners - Part 3 (Additional Features and Multibody Parts, Modifying Parts)Încă nu există evaluări

- 1141 - Modeling and Characterization For Vibration FinalDocument6 pagini1141 - Modeling and Characterization For Vibration FinalMohammad Ahmad GharaibehÎncă nu există evaluări

- Least Squares Finite Element Model UpdatingDocument8 paginiLeast Squares Finite Element Model UpdatingMohammad Ahmad GharaibehÎncă nu există evaluări

- Free Free Plate ModelingDocument48 paginiFree Free Plate ModelingMohammad Ahmad Gharaibeh100% (1)

- Stress Concentration Analysis For Countersunk Rivet Holes in Orthotropic PlatesDocument10 paginiStress Concentration Analysis For Countersunk Rivet Holes in Orthotropic PlatesMohammad Ahmad GharaibehÎncă nu există evaluări

- Random Vibration HistoryDocument9 paginiRandom Vibration HistoryMohammad Ahmad GharaibehÎncă nu există evaluări

- Some Answers From The WebDocument11 paginiSome Answers From The WebMohammad Ahmad GharaibehÎncă nu există evaluări

- Random Vibrations of Elastic PlatesDocument87 paginiRandom Vibrations of Elastic PlatesMohammad Ahmad GharaibehÎncă nu există evaluări

- ANSYS For Harmonic Transient and PSDDocument23 paginiANSYS For Harmonic Transient and PSDMohammad Ahmad GharaibehÎncă nu există evaluări

- Modalna Analiza AnsysDocument5 paginiModalna Analiza AnsysludimataÎncă nu există evaluări

- Plasticity For StructureDocument310 paginiPlasticity For StructureMohammad Ahmad GharaibehÎncă nu există evaluări

- Mechanical APDL Commands Quick ReferenceDocument20 paginiMechanical APDL Commands Quick ReferenceMohammad Ahmad GharaibehÎncă nu există evaluări

- Ma Hongtao 31Document214 paginiMa Hongtao 31Mohammad Ahmad GharaibehÎncă nu există evaluări

- University of Alberta - Ansys TutorialsDocument639 paginiUniversity of Alberta - Ansys TutorialsLaxmi Narayana100% (1)

- Plasticity For StructureDocument310 paginiPlasticity For StructureMohammad Ahmad GharaibehÎncă nu există evaluări

- Research Paper 1-TechDocument5 paginiResearch Paper 1-TechMohammad Ahmad GharaibehÎncă nu există evaluări

- UFF Universal File FormatDocument40 paginiUFF Universal File FormatMohammad Ahmad GharaibehÎncă nu există evaluări

- AnsysDocument5 paginiAnsysharel_868Încă nu există evaluări

- Multi Degree of FreedomDocument67 paginiMulti Degree of FreedomSrinath Gudur100% (1)

- Cantilever Beam TutorialDocument7 paginiCantilever Beam TutorialMohammad Ahmad GharaibehÎncă nu există evaluări

- ANSYS Solutions To Lead Free Package Design ChallengesDocument42 paginiANSYS Solutions To Lead Free Package Design ChallengesMohammad Ahmad GharaibehÎncă nu există evaluări

- P-Y Curves Methods - Laterally Loaded PilesDocument3 paginiP-Y Curves Methods - Laterally Loaded PilesRamanathan GnanasambandamÎncă nu există evaluări

- Beam Deflection 2bDocument2 paginiBeam Deflection 2bKrisia MartinezÎncă nu există evaluări

- DegeneracyDocument4 paginiDegeneracypradeep khannaÎncă nu există evaluări

- Sheet - 01-Pages-27-72Document46 paginiSheet - 01-Pages-27-72Hemant KumarÎncă nu există evaluări

- Differential Calculus ExamDocument6 paginiDifferential Calculus ExamCaro Kan LopezÎncă nu există evaluări

- Engineering Physics Lab ManualDocument47 paginiEngineering Physics Lab ManualBaiju George100% (2)

- PARATIE EN - Advanced-Modelling-2014 PDFDocument50 paginiPARATIE EN - Advanced-Modelling-2014 PDFJPachasÎncă nu există evaluări

- PhysicsDocument4 paginiPhysicsKhurshaid AhmadÎncă nu există evaluări

- Chapter - 21 Electromagnetic InductionDocument21 paginiChapter - 21 Electromagnetic InductionNafees FarheenÎncă nu există evaluări

- Solidification and Crystalline Imperfection Part 1Document25 paginiSolidification and Crystalline Imperfection Part 1Aiman MutallidÎncă nu există evaluări

- Physics ReviewerDocument18 paginiPhysics ReviewerTrisha ConcepcionÎncă nu există evaluări

- Thermodynamic Consideration Production of Ethyl BenzeneDocument3 paginiThermodynamic Consideration Production of Ethyl BenzeneCer No RusÎncă nu există evaluări

- Dubbel Handbook of Mechanical Engineering PDFDocument918 paginiDubbel Handbook of Mechanical Engineering PDFprajakt_pie50% (4)

- Heat Balance GCLDocument6 paginiHeat Balance GCLIrshad HussainÎncă nu există evaluări

- Design Method of Api High Pressure FRP PipeDocument2 paginiDesign Method of Api High Pressure FRP PipejaymuscatÎncă nu există evaluări

- Printing InkDocument23 paginiPrinting InkGema SukmaÎncă nu există evaluări

- Gyroscopic InstrumentsDocument23 paginiGyroscopic InstrumentsRobin ForbesÎncă nu există evaluări

- Donald Lee Smith: A Practical Guide To Free-Energy Devices Author: Patrick J. KellyDocument123 paginiDonald Lee Smith: A Practical Guide To Free-Energy Devices Author: Patrick J. KellySvajunas tesla100% (1)

- Unit-06 AC BridgesDocument8 paginiUnit-06 AC BridgesIqxca AzmYaniÎncă nu există evaluări

- Quiz 3 ReviewDocument26 paginiQuiz 3 ReviewameliawendelÎncă nu există evaluări

- (Chapter Iii) : Earthquake Records and Measuring InstrumentsDocument7 pagini(Chapter Iii) : Earthquake Records and Measuring InstrumentsDominic FloresÎncă nu există evaluări

- Properties of LightDocument8 paginiProperties of LightSha BtstaÎncă nu există evaluări

- GTE Micro Project 4th SemDocument6 paginiGTE Micro Project 4th SemNishikant Bhure100% (3)

- 1st Year ENTRY TEST PAPER MT-2Document3 pagini1st Year ENTRY TEST PAPER MT-2Shahzad AslamÎncă nu există evaluări

- Hygromax: VersionsDocument10 paginiHygromax: VersionsmendoncasegundoÎncă nu există evaluări

- 12-Direct Shear TestDocument10 pagini12-Direct Shear TestogulÎncă nu există evaluări

- Wpe ExercisesDocument11 paginiWpe ExercisesjoeÎncă nu există evaluări

- Mitchell 2014Document13 paginiMitchell 2014Kingshuk MukherjeeÎncă nu există evaluări

- Einstein, String Theory and The FutureDocument38 paginiEinstein, String Theory and The FutureAlexandra100% (1)